NISSAN 6.实验方法及判定条件

NISSAN 6.实验方法及判定条件

《NISSAN 6.实验方法及判定条件》由会员分享,可在线阅读,更多相关《NISSAN 6.实验方法及判定条件(8页珍藏版)》请在装配图网上搜索。

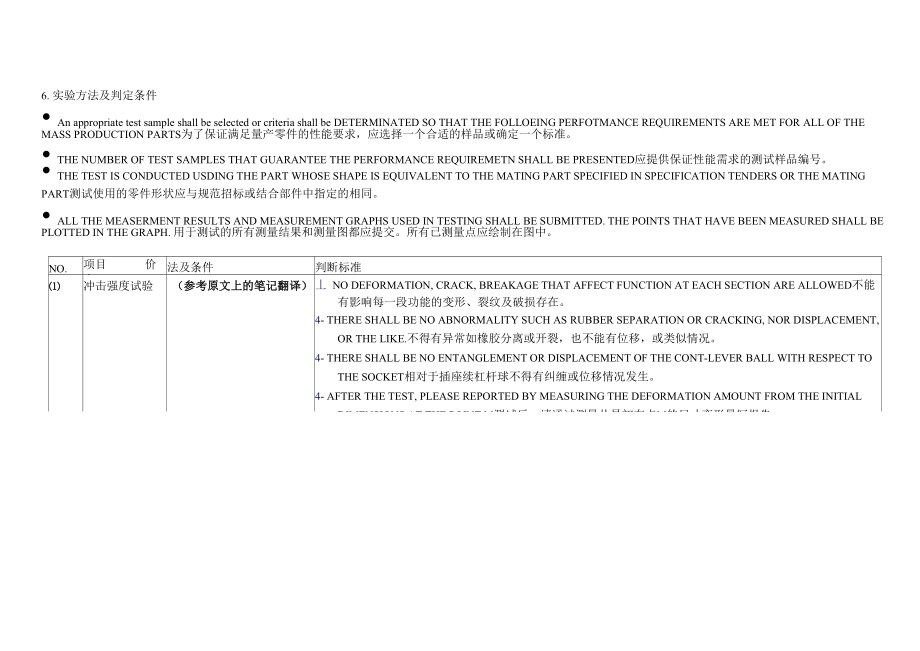

1、6. 实验方法及判定条件 An appropriate test sample shall be selected or criteria shall be DETERMINATED SO THAT THE FOLLOEING PERFOTMANCE REQUIREMENTS ARE MET FOR ALL OF THE MASS PRODUCTION PARTS为了保证满足量产零件的性能要求,应选择一个合适的样品或确定一个标准。 THE NUMBER OF TEST SAMPLES THAT GUARANTEE THE PERFORMANCE REQUIREMETN SHALL BE PRE

2、SENTED应提供保证性能需求的测试样品编号。 THE TEST IS CONDUCTED USDING THE PART WHOSE SHAPE IS EQUIVALENT TO THE MATING PART SPECIFIED IN SPECIFICATION TENDERS OR THE MATING PART测试使用的零件形状应与规范招标或结合部件中指定的相同。 ALL THE MEASERMENT RESULTS AND MEASUREMENT GRAPHS USED IN TESTING SHALL BE SUBMITTED. THE POINTS THAT HAVE BEEN

3、MEASURED SHALL BE PLOTTED IN THE GRAPH. 用于测试的所有测量结果和测量图都应提交。所有已测量点应绘制在图中。NO.项目价方法及条件判断标准冲击强度试验(参考原文上的笔记翻译)丄 NO DEFORMATION, CRACK, BREAKAGE THAT AFFECT FUNCTION AT EACH SECTION ARE ALLOWED不能有影响每一段功能的变形、裂纹及破损存在。4- THERE SHALL BE NO ABNORMALITY SUCH AS RUBBER SEPARATION OR CRACKING, NOR DISPLACEMENT,

4、OR THE LIKE.不得有异常如橡胶分离或开裂,也不能有位移,或类似情况。4- THERE SHALL BE NO ENTANGLEMENT OR DISPLACEMENT OF THE CONT-LEVER BALL WITH RESPECT TO THE SOCKET相对于插座续杠杆球不得有纠缠或位移情况发生。4- AFTER THE TEST, PLEASE REPORTED BY MEASURING THE DEFORMATION AMOUNT FROM THE INITIAL DIMENSIONS AT THE POINT M测试后,请通过测量从最初在点M的尺寸变形量写报告。静态

5、强度试验(参考原文上的笔记翻译)丄 NO DEFORMATION, CRACK, BREAKAGE THAT AFFECT FUNCTION AT EACH SECTION ARE ALLOWED不能有影响每一段功能的变形、裂纹及破损存在。丄 THERE SHALL BE NO ABNORMALITY SUCH AS RUBBER SEPARATION OR CRACKING, NOR DISPLACEMENT, OR THE LIKE.不得有异常如橡胶分离或开裂,也不能有位移,或类似情况。丄 THERE SHALL BE NO ENTANGLEMENT OR DISPLACEMENT OF

6、THE CONT-LEVER BALL WITH RESPECT TO THE SOCKET相对于插座续杠杆球不得有纠缠或位移情况发生。丄 AFTER THE TEST, PLEASE REPORTED BY MEASURING THE DEFORMATION AMOUNT FROM THE INITIAL DIMENSIONS AT THE POINT M测试后,请通过测量从最初在点M的尺寸变形量写报告。(3)疲劳强度及耐热 性能试验(参考原文上的笔记翻译)亠 NO DEFORMATION, CRACK, BREAKAGE THAT AFFECT FUNCTION AT EACH SECTI

7、ON ARE ALLOWED不能有影响每一段功能的变形、裂纹及破损存在。丄 THERE SHALL BE NO ABNORMALITY SUCH AS RUBBER SEPARATION OR CRACKING, NOR DISPLACEMENT, OR THE LIKE.不得有异常如橡胶分离或开裂,也不能有位移,或类似情况。丄 THE BOOT SHALL NOT BE DISPLACED FROM THE HSG. ALSO, THE MOUNTING LOCA TION OF THE BOOT SHALL NOT BE DISPLACED REMARKABLY.防护罩不应从HSG开始移动

8、,同时,防护罩安装位置 的位移应不明显。丄 AFTER THE TEST, PLEASE REPORTED BY MEASURING THE DEFORMATION AMOUNT FROM THE INITIAL DIMENSIONS AT THE POINT M测试后,请通过测量从最初在点M的尺寸变形量写报告。丄 SHALL BE REPORTED BY MEASURING THE NO-LOAD SLIDING RESISTANCE(BOTH FOR SHIFTING AND FOR SELECTING) BEFORE AND AFTER THE TEST AT THE MEASUREME

9、NT POINT M POINTS应通 过测量测定点M在试验前后的空载滑行阻力出具报告(换挡和选档测试均如此)。丄 RATE OF CHANGE BEFORE AND AFTER THE TEST THE STIFFNESS V ALUE AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.测定点 M 在试 验前后的刚性值变化率应不咼于15% (换挡和选档测试均如此)。丄 RATE OF CHANGE BEFORE AND AFTER THE AMOUNT OF

10、PLAY AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.测定点 M 在试验前后的 活动量变化率应不咼于15% (换挡和选档测试均如此)。丄 OPERATION SHALL BE SMOOTH AND WITHOUT TWISTING, SQUEAKING, INTERFERENCE OR THE LIKE THROUGHOUT THE MAXIMUM STROKE OF THE CONTROL LEVER (BOTH FOR SHIFTING AND FOR

11、 SELECTING).控制杆的最大行程中,操作应平整无扭曲,无异响,无干扰或类似情况(换挡和选档测 试均如此)。丄 THERE SHALL BE NO NOISE BY CONTROL LEVER OPERATION(BOTH FOR SHIFTING AND FOR SELECTING). ALSO IT MUST BE REPORTED BY MEASURING THE VIBRA TION LEVEL BEFORE AND AFTER THE TEST.控制杆操作时不得有噪声(换挡和选档测试均如此)。还必须对测量前后的振动水平出具 报告。亠 AFTER THE TEST, THERE

12、SHALL BE NO PENETRATION BY WAER INTO THE BOOTS.试验后,不得有 水渗透进防护罩。(4)耐臭氧试验 适用于控制杆防 护罩采用JIS K6259执行丄无裂纹(5)加振耐久性试验 适用于操纵杆组 件,W防护罩(参考原文上的笔记翻译)丄 THERE SHALL BE NO CRACKING, BREAKAGE, LOOSENESS, PLAY OR THE LIKE.不能有变形、裂纹、 松动、活动等类似情况。4- SHALL BE REPORTED BY MEASURING THE NO-LOAD SLIDING RESISTANCE(BOTH FOR S

13、HIFTING AND FOR SELECTING) BEFORE AND AFTER THE TEST AT THE MEASUREMENT POINT M POINTS应通 过测量测定点M在试验前后的空载滑行阻力出具报告(换挡和选档测试均如此)。4- RATE OF CHANGE BEFORE AND AFTER THE TEST THE STIFFNESS VALUE AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.测定点 M 在试 验前后的刚性值变化率

14、应不咼于15% (换挡和选档测试均如此)。4- RATE OF CHANGE BEFORE AND AFTER THE AMOUNT OF PLAY AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.测定点 M 在试验前后的 活动量变化率应不咼于15% (换挡和选档测试均如此)。4- OPERATION SHALL BE SMOOTH AND WITHOUT TWISTING, SQUEAKING, INTERFERENCE OR THE LIKE THROUG

15、HOUT THE MAXIMUM STROKE OF THE CONTROL LEVER (BOTH FOR SHIFTING AND FOR SELECTING).控制杆的最大行程中,操作应平整无扭曲,无异响,无干扰或类似情况(换挡和选档测 试均如此)。4- THERE SHALL BE NO NOISE BY CONTROL LEVER OPERATION(BOTH FOR SHIFTING AND FOR SELECTING). ALSO IT MUST BE REPORTED BY MEASURING THE VIBRA TION LEVEL BEFORE AND AFTER THE

16、TEST.控制杆操作时不得有噪声(换挡和选档测试均如此)。还必须对测量前后的振动水平出具 报告。4- AFTER THE TEST, THERE SHALL BE NO PENETRATION BY WJTER INTO THE BOOTS.试验后,不得有 水渗透进防护罩。(6)耐热老化性试验 适用于橡胶件ALLOW THE RUBBER PORTION TO STAND AT A TEMPERATURE OF 100 C FOR30DAYS.THENCONDUCT THE STRENGTH TEST 使橡胶部分在温度 100C环境中矗立30天,然后 进行强度试验。亠 NO DEFORMATI

17、ON, CRACK, BREAKAGE THAT AFFECT FUNCTION AT EACH SECTION ARE ALLOWED不能有影响每一段功能的变形、裂纹及破损存在。4- THERE SHALL BE NO ABNORMALITY SUCH AS RUBBER SEPARATION OR CRACKING, NOR DISPLACEMENT, OR THE LIKE.不得有异常如橡胶分离或开裂,也不能有位移,或类似情况。4- SHALL BE REPORTED BY MEASURING THE NO-LOAD SLIDING RESISTANCE(BOTH FOR SHIFTIN

18、G AND FOR SELECTING) BEFORE AND AFTER THE TEST AT THE MEASUREMENT POINT M POINTS应通 过测量测定点M在试验前后的空载滑行阻力出具报告(换挡和选档测试均如此)。4- RATE OF CHANGE BEFORE AND AFTER THE TEST THE STIFFNESS VALUE AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.测定点 M 在试 验前后的刚性值变化率应不咼于15

19、% (换挡和选档测试均如此)。4- RATE OF CHANGE BEFORE AND AFTER THE AMOUNT OF PLAY AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.测定点 M 在试验前后的 活动量变化率应不咼于15% (换挡和选档测试均如此)。4- OPERATION SHALL BE SMOOTH AND WITHOUT TWISTING, SQUEAKING, INTERFERENCE OR THE LIKE THROUGHOUT T

20、HE MAXIMUM STROKE OF THE CONTROL LEVER (BOTH FOR SHIFTING AND FOR SELECTING).控制杆的最大行程中,操作应平整无扭曲,无异响,无干扰或类似情况(换挡和选档测 试均如此)。4- THERE SHALL BE NO NOISE BY CONTROL LEVER OPERATION(BOTH FOR SHIFTING AND FOR SELECTING). ALSO IT MUST BE REPORTED BY MEASURING THE VIBRA TION LEVEL BEFORE AND AFTER THE TEST.控

21、制杆操作时不得有噪声(换挡和选档测试均如此)。还必须对测量前后的振动水平出具 报告。4- AFTER THE TEST, THERE SHALL BE NO PENETRATION BY WJTER INTO THE BOOTS.试验后,不得有 水渗透进防护罩。抗湿性试验 适用于塑料部件CONDUCTINACCORDANCE WITH NESM 0132 N0. 3 METHOD丄 NO DEFORMATION, CRACK, BREAKAGE THAT AFFECT FUNCTION AT EACH SECTION ARE ALLOWED不能有影响每一段功能的变形、裂纹及破损存在。4- SH

22、ALL BE REPORTED BY MEASURING THE NO-LOAD SLIDING RESISTANCE(BOTH FOR SHIFTINGTYPE 2. THEN CONDUCT THE STRENGTH TEST.米用NES M 0132方法3类型 2进行。然后进行强度试验。AND FOR SELECTING) BEFORE AND AFTER THE TEST AT THE MEASUREMENT POINT M POINTS应通 过测量测定点M在试验前后的空载滑行阻力出具报告(换挡和选档测试均如此)。4- RATE OF CHANGE BEFORE AND AFTER T

23、HE AMOUNT OF PLAY AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.测定点 M 在试验前后的 活动量变化率应不高于15% (换挡和选档测试均如此)。4- OPERATION SHALL BE SMOOTH AND WITHOUT TWISTING, SQUEAKING, INTERFERENCE OR THE LIKE THROUGHOUT THE MAXIMUM STROKE OF THE CONTROL LEVER (BOTH FOR SH

24、IFTING AND FOR SELECTING).控制杆的最大行程中,操作应平整无扭曲,无异响,无干扰或类似情况(换挡和选档测 试均如此)。(8)寒冷接触性试验 适用于粘合部位ALLOW THE RUBBER PORTION TO STAND AT A TEMPERATURE OF -40 C FOR30DAYS.THENCONDUCT THE STRENGTH TEST 使橡胶部分在温度 -40C环境中矗立30天,然后 进行强度试验。丄 NO DEFORMATION, CRACK, BREAKAGE THAT AFFECT FUNCTION AT EACH SECTION ARE ALLO

25、WED不能有影响每一段功能的变形、裂纹及破损存在。4- THERE SHALL BE NO ABNORMALITY SUCH AS RUBBER SEPARATION OR CRACKING, NOR DISPLACEMENT, OR THE LIKE.不得有异常如橡胶分离或开裂,也不能有位移,或类似情况。4- RATE OF CHANGE BEFORE AND AFTER THE AMOUNT OF PLAY AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.

26、测定点 M 在试验前后的 活动量变化率应不高于15% (换挡和选档测试均如此)。4- OPERATION SHALL BE SMOOTH AND WITHOUT TWISTING, SQUEAKING, INTERFERENCE OR THE LIKE THROUGHOUT THE MAXIMUM STROKE OF THE CONTROL LEVER (BOTH FOR SHIFTING AND FOR SELECTING).控制杆的最大行程中,操作应平整无扭曲,无异响,无干扰或类似情况(换挡和选档测 试均如此)。4- THERE SHALL BE NO NOISE BY CONTROL L

27、EVER OPERATION(BOTH FOR SHIFTING AND FOR SELECTING). ALSO IT MUST BE REPORTED BY MEASURING THE VIBRA TION LEVEL BEFORE AND AFTER THE TEST.控制杆操作时不得有噪声(换挡和选档测试均如此)。还必须对测量前后的振动水平出具 报告。(9)热循环试验 适用于橡胶及树CONDUCTINACCORDANCE WITH NES亠 NO DEFORMATION, CRACK, BREAKAGE THAT AFFECT FUNCTION AT EACH SECTION ARE

28、ALLOWED不能有影响每一段功能的变形、裂纹及破损存在。脂部件M 0132 N0. 3 METHOD TYPE 2. THEN CONDUCT THE STRENGTH TEST.米用NES M 0132方法3类型 2进行。然后进行强度试验。亠 THERE SHALL BE NO ABNORMALITY SUCH AS RUBBER SEPARATION OR CRACKING, NOR DISPLACEMENT, OR THE LIKE.不得有异常如橡胶分离或开裂,也不能有位移,或类似情况。4- SHALL BE REPORTED BY MEASURING THE NO-LOAD SLID

29、ING RESISTANCE(BOTH FOR SHIFTING AND FOR SELECTING) BEFORE AND AFTER THE TEST AT THE MEASUREMENT POINT M POINTS应通 过测量测定点M在试验前后的空载滑行阻力出具报告(换挡和选档测试均如此)。4- RATE OF CHANGE BEFORE AND AFTER THE TEST THE STIFFNESS VALUE AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR

30、 LESS.测定点 M 在试 验前后的刚性值变化率应不咼于15% (换挡和选档测试均如此)。4- RATE OF CHANGE BEFORE AND AFTER THE AMOUNT OF PLAY AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.测定点 M 在试验前后的 活动量变化率应不咼于15% (换挡和选档测试均如此)。4- OPERATION SHALL BE SMOOTH AND WITHOUT TWISTING, SQUEAKING, INTERF

31、ERENCE OR THE LIKE THROUGHOUT THE MAXIMUM STROKE OF THE CONTROL LEVER (BOTH FOR SHIFTING AND FOR SELECTING).控制杆的最大行程中,操作应平整无扭曲,无异响,无干扰或类似情况(换挡和选档测 试均如此)。4- THERE SHALL BE NO NOISE BY CONTROL LEVER OPERATION(BOTH FOR SHIFTING AND FOR SELECTING). ALSO IT MUST BE REPORTED BY MEASURING THE VIBRA TION LE

32、VEL BEFORE AND AFTER THE TEST.控制杆操作时不得有噪声(换挡和选档测试均如此)。还必须对测量前后的振动水平出具 报告。4- AFTER THE TEST, THERE SHALL BE NO PENETRATION BY WJTER INTO THE BOOTS.试验后,不得有 水渗透进防护罩。(10)抗化学性试验 适用于橡胶及塑 料部件CONDUCTINACCORDANCE WITH NES M 0133 N0. 4 METHOD。采用NES M 0133方法4进 行。丄 THERE SHALL BE NO CRACKING, BREAKAGE, LOOSENES

33、S, PLAY OR THE LIKE.不能有变形、裂纹、 松动、活动等类似情况。4- THERE SHALL BE NO ABNORMALITY SUCH AS RUBBER SEPARATION OR CRACKING, NOR DISPLACEMENT, OR THE LIKE.不得有异常如橡胶分离或开裂,也不能有位移,或类似情况。4- SHALL BE REPORTED BY MEASURING THE NO-LOAD SLIDING RESISTANCE(BOTH FOR SHIFTINGAND FOR SELECTING) BEFORE AND AFTER THE TEST AT

34、THE MEASUREMENT POINT M POINTS应通 过测量测定点M在试验前后的空载滑行阻力出具报告(换挡和选档测试均如此)。4- RATE OF CHANGE BEFORE AND AFTER THE AMOUNT OF PLAY AT THE MEASUREMENT POINT M POINTS (BOTH FOR SHIFTING AND FOR SELECTING) MUST BE 15% OR LESS.测定点 M 在试验前后的 活动量变化率应不高于15% (换挡和选档测试均如此)。4- OPERATION SHALL BE SMOOTH AND WITHOUT TWIS

35、TING, SQUEAKING, INTERFERENCE OR THE LIKE THROUGHOUT THE MAXIMUM STROKE OF THE CONTROL LEVER (BOTH FOR SHIFTING AND FOR SELECTING).控制杆的最大行程中,操作应平整无扭曲,无异响,无干扰或类似情况(换挡和选档测 试均如此)。4- AFTER THE TEST, THERE SHALL BE NO PENETRATION BY WJTER INTO THE BOOTS.试验后,不得有 水渗透进防护罩。(11)耐磨损试验 适用于黑色粉末 涂层CONDUCT 75000 TIMES BY THELONGSTROKEFORMULAABRASIONTESTER WITH NES M 136 NO. 3 METHOD.采用长冲程 式磨损试验NES M 136方法 3号进行75000次。丄 THERE SHALL BE NO EXPOSURE OF THE SUBSTRATE SURFACE.不得有暴露的衬底表面。(12)耐光性试验 适用于黑色粉末 涂层丄 TO SATISFY THE CRITERIA CLASS B PRESCRIBED BY THE NES M0135.为了满足 NES m0135 中规定的 标准等级B的判定标准。

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。