电气预埋规范

电气预埋规范

《电气预埋规范》由会员分享,可在线阅读,更多相关《电气预埋规范(3页珍藏版)》请在装配图网上搜索。

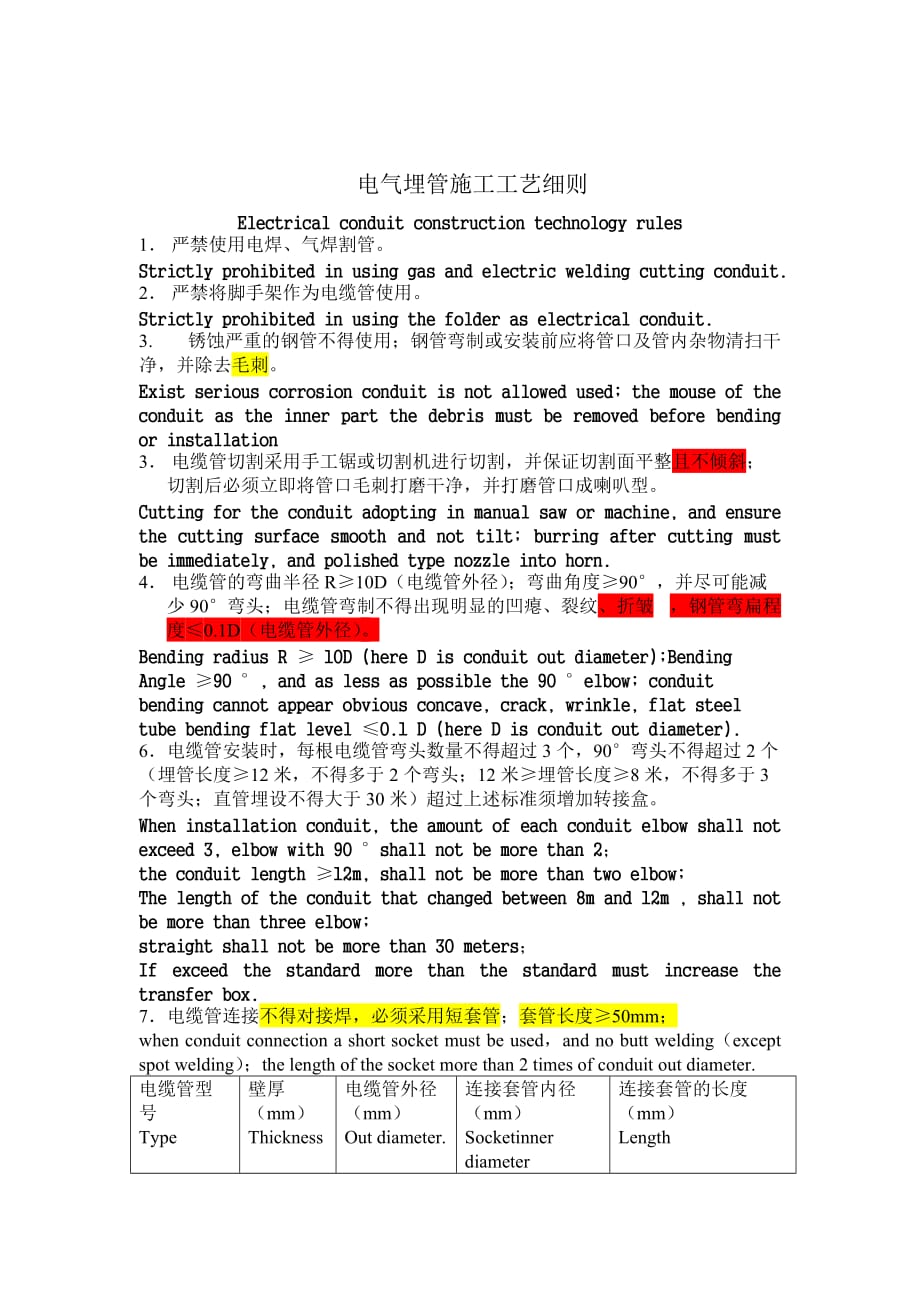

1、 电气埋管施工工艺细则Electrical conduit construction technology rules1 严禁使用电焊、气焊割管。Strictly prohibited in using gas and electric welding cutting conduit.2 严禁将脚手架作为电缆管使用。Strictly prohibited in using the folder as electrical conduit.3. 锈蚀严重的钢管不得使用;钢管弯制或安装前应将管口及管内杂物清扫干净,并除去毛刺。 Exist serious corrosion conduit is

2、not allowed used; the mouse of the conduit as the inner part the debris must be removed before bending or installation3 电缆管切割采用手工锯或切割机进行切割,并保证切割面平整且不倾斜;切割后必须立即将管口毛刺打磨干净,并打磨管口成喇叭型。Cutting for the conduit adopting in manual saw or machine, and ensure the cutting surface smooth and not tilt; burring af

3、ter cutting must be immediately, and polished type nozzle into horn.4 电缆管的弯曲半径R10D(电缆管外径);弯曲角度90,并尽可能减少90弯头;电缆管弯制不得出现明显的凹瘪、裂纹、折皱 ,钢管弯扁程度0.1D(电缆管外径)。Bending radius R 10D (here D is conduit out diameter);Bending Angle 90 , and as less as possible the 90 elbow; conduit bending cannot appear obvious con

4、cave, crack, wrinkle, flat steel tube bending flat level 0.1 D (here D is conduit out diameter).6电缆管安装时,每根电缆管弯头数量不得超过3个,90弯头不得超过2个(埋管长度12米,不得多于2个弯头;12米埋管长度8米,不得多于3个弯头;直管埋设不得大于30米)超过上述标准须增加转接盒。When installation conduit, the amount of each conduit elbow shall not exceed 3, elbow with 90 shall not be m

5、ore than 2;the conduit length 12m, shall not be more than two elbow; The length of the conduit that changed between 8m and 12m , shall not be more than three elbow; straight shall not be more than 30 meters;If exceed the standard more than the standard must increase the transfer box.7电缆管连接不得对接焊,必须采用

6、短套管;套管长度50mm;when conduit connection a short socket must be used,and no butt welding(except spot welding);the length of the socket more than 2 times of conduit out diameter.电缆管型号Type壁厚(mm)Thickness电缆管外径(mm)Out diameter.连接套管内径(mm)Socketinner diameter连接套管的长度(mm)LengthDN253.2533.53550mmDN323.2542.34350

7、mmDN503.5606150mmDN804888950mm8电缆管连接时,先将套管中间凸台毛刺打磨干净,然后将电缆管插入套管中,电缆管与凸台之间不得留有间隙;连接套管与电缆管两侧均匀电焊4点,并用黑胶布缠绕封实; When coupling, there shouldnt gap between the two conduit and the counterpart malocclusion is less than 2 mm, counterpart seam should be in the middle of the socket, and the both sides along t

8、he circumferential welding sealing, partial cannot welding must use black tape winding sealing with fastened iron wire; 9 电缆管不得在外壁直接点焊加固,加固采用铁丝绑扎或煨制钢筋成环钩加固、切割2030mm套管套至固定点进行,固定间距:1520为1.01.5米,2532为1.52.0米,4050为2.02.5米,65以上不大于3米。 Pot welding reinforce cant be allowed outside the wall of conduit direc

9、tly, a available steel bar will be made into a ring hook, and then cutting 20 30 mm one end fasten to conduit another one stable point or iron wire colligation fixed spacing: 15mm 20mm is 1.0 1.0 m, from 25mm to 32mm is 1.5 1.5 meters, 40mm 50mm is 2.0 2.5 meters, exceed 65mm not more than 3 meters

10、10电缆管与接线盒的连接可采用焊接和丝扣连接,:电缆管伸入接线盒36mm管口用黑胶布包扎结实,接线盒内用湿棉纱、破布填实;外部用黑胶布缠绕,以防止水泥沙浆进入。Welding and threaded can be used for the connection between electrical conduit and sockets, electrical conduit are putted into the sockets 3 6 mmThe mouse of the conduit with black adhesive bandage, internal parts of the

11、 socket filled with a wet cotton yarn ,cloth; External with black tape winding, in order to prevent cement mortar having a access into.11接线盒安装时必须与模板紧贴,并用钢筋在接线盒四周加固;电缆管直径DN25的指明及消防报警预埋管放置于模板与钢筋网之间,预埋管绑扎在钢筋网上,与模板之间预留间隙15mm;电缆管在接线盒处的固定点与接线盒间距不得大于200mm。Socket must be clingy to the template and reinforce

12、d around, between the electrical conduit and template reserved clearance 15 mm or more. into the sockets of the cable must be welding with a cross bar (from 6 or 8mm round steel; 12. 所有外露预留的电缆管及伸入分电箱、木制接线盒等管口应伸出砼面200mm以上,电缆管口必须封堵。续接管路用胶布封口后加套帽。All the reserved outside electrical conduit and those in

13、to the distribution box, and wooden box should stretch out the concrete over 200mm, adding iron plate welding seal, steel plate with cutting machine and smooth. The continued jacketed pipe set a cover after sealing with tape.13电缆管过缝制作:采用在电缆管外套比电缆管外径大两级套管,套管与电缆管口部密实封堵,电缆管套管制作规格,长度如下:Manufacture for e

14、xpansion joint, adopting the two levels of casing pipe coat than electrical conduit diameter, first winding linen between casing and electrical conduit then filling with asphalt close-grained, Specifications, the length is as follows:电缆管型号Type壁厚(mm)thickness电缆管外径(mm)out diameter过缝套管规格specification过缝

15、套管内径(mm)Inner diameter过缝套管的长度(mm)length253.253354041600323.254235053800503.5608080.51200804885125131180014 同一处电缆管超过3根,出砼必须排列整齐、美观(横平竖直 );图纸没有明确要求时,按下述原则排列:(1):电缆管由大到小顺序排列;(2):39根可排列成一排或两排;(3):10根及以上必须排列成两排或两排以上,且每排宽度大致相当,宽度相差宜小于两根埋管的直径;(4)成排电缆管预留高度(或长度)一致。There are more than three conduit at a same

16、place, the outing concrete must be neat, beautiful (horizontal and vertical);Drawings without clear requirements, sorted by the following principles: (1) : from big to small order;(2) : 3 9 pieces can be arranged in a row or two rows;(3) : 10 and above must be arranged in two rows or more and each row width is the same, the width of the difference should be less than the diameter of two embedded pipes;(4) rows electrical conduit reserved height (or length) are the same;

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。