设备表中英文

设备表中英文

《设备表中英文》由会员分享,可在线阅读,更多相关《设备表中英文(5页珍藏版)》请在装配图网上搜索。

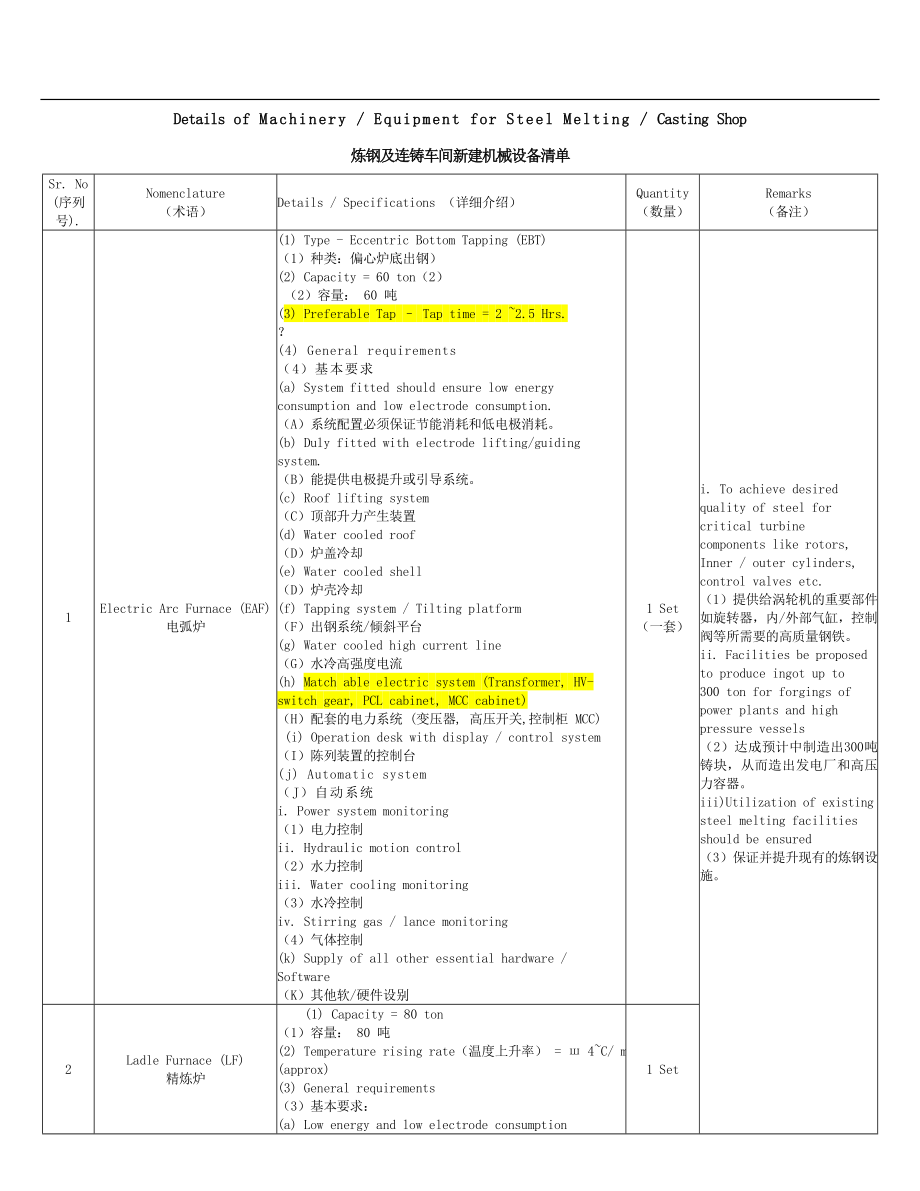

1、Details of Machinery / Equipment for Steel Melting / Casting Shop炼钢及连铸车间新建机械设备清单Sr. No(序列号).Nomenclature(术语)Details / Specifications (详细介绍)Quantity(数量)Remarks(备注)1Electric Arc Furnace (EAF)电弧炉(1) Type - Eccentric Bottom Tapping (EBT)(1)种类:偏心炉底出钢)(2) Capacity = 60 ton(2) (2)容量: 60 吨(3) Preferable Tap

2、 Tap time = 2 2.5 Hrs.?(4) General requirements (4)基本要求(a) System fitted should ensure low energyconsumption and low electrode consumption.(A)系统配置必须保证节能消耗和低电极消耗。(b) Duly fitted with electrode lifting/guidingsystem.(B)能提供电极提升或引导系统。(c) Roof lifting system(C)顶部升力产生装置(d) Water cooled roof(D)炉盖冷却(e) Wate

3、r cooled shell(D)炉壳冷却(f) Tapping system / Tilting platform(F)出钢系统/倾斜平台(g) Water cooled high current line(G)水冷高强度电流(h) Match able electric system (Transformer, HVswitch gear, PCL cabinet, MCC cabinet)(H)配套的电力系统 (变压器, 高压开关,控制柜 MCC) (i) Operation desk with display / control system(I)陈列装置的控制台(j) Automat

4、ic system(J)自动系统i. Power system monitoring(1)电力控制ii. Hydraulic motion control(2)水力控制iii. Water cooling monitoring(3)水冷控制iv. Stirring gas / lance monitoring(4)气体控制(k) Supply of all other essential hardware /Software(K)其他软/硬件设别1 Set(一套)i. To achieve desiredquality of steel forcritical turbinecomponent

5、s like rotors,Inner / outer cylinders,control valves etc.(1)提供给涡轮机的重要部件如旋转器,内/外部气缸,控制阀等所需要的高质量钢铁。ii. Facilities be proposedto produce ingot up to300 ton for forgings ofpower plants and highpressure vessels(2)达成预计中制造出300吨铸块,从而造出发电厂和高压力容器。iii)Utilization of existingsteel melting facilitiesshould be en

6、sured(3)保证并提升现有的炼钢设施。2Ladle Furnace (LF)精炼炉(1) Capacity = 80 ton(1)容量: 80 吨(2) Temperature rising rate(温度上升率) = 4C/ min (approx)(3) General requirements(3)基本要求:(a) Low energy and low electrode consumption(A)低能低电极消耗(b) Easy access and maintenance(B)简易操作及维护(c) Water cooled current lines(C)水冷高强度电流(d) L

7、adle transfer trolley (As required to achieve300ton metal)(D)钢包运转小车 (根据需要能达到300吨)(e) Automatic gas coupling system(E)气流自动连接系统(f) Cooling water system(F)冷却水系统(g) Water cooled roof(G)水冷炉顶(h) Match able electric system (Transformer, HVswitch gear, PCL cabinet, MCC cabinet)(H)配对的电子设备 (变压器, 高压开关,控制柜 MCC)

8、(i) Operation desk with display/ system control(I)陈列装置的控制台(j) Automatic system(J)自动系统i. Power system monitoring(1)电力控制ii. Hydraulic motion control(2)水力控制iii. Water cooling monitoring(3)水冷控制iv. Stirring gas / lance monitoring(4)气体控制v. Temperature and sampling lancemonitoring(5)温度和取样监视(k) Supply of al

9、l other essential hardware /Software(K)其他软/硬件设备1 Set3VD / VOD with pumpingequipment(1) Capacity = 80100 ton(1)容量:80100吨(2) Vacuum pump = 400+ kg/hr(2)真空泵(3) Final vacuum = 60 70 Pa(3)真空度=6070Pa(4) Easy access and maintenance(4)简易操作及维护(5) Supply of all essential hardware / software(5)其他软/硬件设备(6) Boil

10、er = 16ton/hr (approx), gas fired.(6)锅炉= 16吨/小时(大约),天然气1 Set4Holding stations(1) Capacity = 80 100 ton molten metal each容积:80100吨(2) with all essential allied equipment.包含所有必需设备Preferabely 3Sets5Mobile continuous sand mixer移动连续混砂机(1) Capacity= 50 60 t/hr容积= 50 60 吨/小时(2) Type - Sodium silicate self-

11、hardening sand / Resinbased sand(3)With all essential allied accessories包含所有必需设备1 Set6Fixed continuous sand mixer固定连续混砂机(1) Capacity = 10 ton/hr容积= 10 吨/小时(2) Type - Sodium silicate self-hardening sand /Resinbased sand(3)With all essential allied accessories包含所有必需设备1 Set7Shakeout Machine落砂机Capacity

12、= 30 ton容积:30吨1 Set8Used sand reclamation system填砂系统Capacity = 15 ton / hr容积:15吨With all essentil accessories包含所有必需设备1 Set9Electric hot air blower for moulddrying模具烘烤电机Capacity = 200kW (Approximately)容量= 大约200kW3 Sets10Vacuum ingot casting chamber真空铸锭室Capacity = 300 ton容积300吨1 Set11Vacuum ingot cast

13、ing chamber真空铸锭室Capacity = 200 ton容积200吨1 Set12Vacuum ingot casting chamber真空铸锭室Capacity = 100 ton容积100吨1 Set13De-dusting / Filteration System除尘过滤系统(1) As essentially required.满足本质需要(2) To fulfill national environmental code满足国家环保法规1 Set14Ladle dryer钢包烘烤器(1) Type of fuel - Gas fired(1)燃料类型 天然气(2) Ge

14、neral Requirements一般要求(a) Automatic temperature control system温度自动控制系统(b) Low energy consumption低能耗3 Sets15Car Bottom Gas Heat treatmentFurnace燃气热处理炉(1) Size = 12m x 7.5m x 5m(L x W x H) 尺寸 = 12m x 7.5m x 5m(2) Maximum temperature = 1200C最高温度 = 1200C(3) Temp. uniformity = 5C温度误差 = 5C(4) Design be ba

15、sed on low energy consumtion andautomatic control设计基于低能耗和自动控制 1 Set16Shot Blasting Machine(1) Loading capacity = upto 100t承载能力= 100吨(2) Chamber body = 8m x 8m (approx) 尺寸 = 8m x 8m(3) With rotary table有回转台1 Set17Weigh bridge轨道(1) Capacity= up to 60 Ton容量=60吨(2) Preferably fitted with load cell 最好有传感

16、器1 Set18Scrap Bucket废料桶(1) Capacity = up to 45 ton容量=45吨4 sets19Ladles钢包炉(1) Capacity = 80100 ton(2) Will be used in LF and VD/VOD(1)容量 = 80100 ton(2)用于精炼炉和脱气炉620Cut - Off Saw for wood work切割开关(1) Working size = 1110 x 665mm(2) Cutting width = 10 x 530 mm(3) Cutting thickness = 10 x 150 mm(4) Saw bl

17、ade = 610 mm(5) Spindle dia = 30 mm(6) Spindle speed = 2000 rpm approx.(1) 尺寸 = 1110 x 665mm(2)切割最大宽度 = 10 x 530 mm(3) 切割最窄宽度 = 10 x 150 mm(4)锯片 = 610 mm(5) 主轴直径 = 30 mm(6) 转速 = 2000转/分1 Set21Pressure Planner for wood work切割参数(1) Cutting width = 1250 mm切割宽度=1250mm(2) Main Saw blade = 300 mm主锯片 = 300

18、 mm(3) Main Spindle dia = 30mm主轴直径= 30mm(4) Max Hight of Cut = 85mm最大切割高度= 85mm(5) Tillting = 45 /90 tillting(6) Speed of main spindle = 4500 / 6000 rpm主轴转速 = 4500 / 6000 转/分(7) Scoring saw blade = 120 mm划线锯片= 120 mm(8) Scoring spindle dia = 20mm主轴直径= 20mm(9) Speed of scoring saw blade = 8000 rpm划线锯

19、片转速 = 8000转/分1 Set22切割铣床(1) Processing area = 1300 x 2500 mm加工区域 = 1300 x 2500 mm(2) Engraving speed = 0 4000 mm/min速度 = 0 4000 mm/min(3) X,Y,Z movement location precision = 0.03/ 100mm坐标精度 = 0.03/ 100mm(4) X,Y,Z repeate lcoation precision = 0.01 mmX,Y,Z重复定位精度= 0.01 mm(5) Main spindle rotating speed

20、 = 8,000 24,000 rpm主轴转速 = 8,000 24,000转/分(6) Z movement distance = 120mmZ轴移动距离=120mm(7) Feed height = 60 150 mm高度 = 60 150 mm(8) Processing precision = 0.01mm加工精度= 0.01mm1 Set23切割电机(1) Maximum planning width = 500mm最大切割宽度 = 500mm(2) maximum cutting depth = 150mm最大切割深度 = 150mm(3) Spindle speed = 5,00

21、0 rpm主轴转速= 5,000转/分1 Set24Spindle Sander machine主电机(1) Spindle Speed (RPM) = 1725速 (转/分) = 1725(2) Oscillations Per Minute = 75每分钟振动次数 = 75(3) Length of Oscillations (mm) = 40振幅 (mm) = 40(4) Table Size (L x W) = 610 x 610 mm表尺寸 (L x W) = 610 x 610 mm(5) Table Tilt (deg.) = 0 45 down表倾角(度) = 0 45度1 S

22、etNOTE(1) Tools and accessories for each equipment be included.(1)包含每个设备所必需的工具及配套设施(2) Addition/Subsitutuion/Alteration may be suggested/incorporated against any equipment to producedifferent grades of steel castings for power plant equipments (upto 300MW). Detailed justification beindicated for the

23、 additional / alternate suggested equipment.(2)根据发电厂所需的不同等级的钢铸件,可进行适当的加/减或者调整。额外的替换或备用设备有其具体的调节说明。(3) All documents / manuals for technical support (repair / maintenance, softwares and processes for callibration ofthe equipment) be provided.(3)提供所有相关文件/说明手册(维修/维护,软件和维护程序)。请做总体工艺方案,另外附:1、业绩2、技术方案3、计划价格及交货期4、七月九号前返回

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。