qo人三工挖孔桩超深专项施工方案 2

qo人三工挖孔桩超深专项施工方案 2

《qo人三工挖孔桩超深专项施工方案 2》由会员分享,可在线阅读,更多相关《qo人三工挖孔桩超深专项施工方案 2(39页珍藏版)》请在装配图网上搜索。

1、step shape, control of step size, set aside a decoration project, to run up and down the stairs the same faade stepping angle. 4.4 reverse triangular plate is in the Middle bench, reinforcement time side boards. Reverse triangular plates consist of a number of triangular pieces of wood nailed to the

2、 wood, and two triangular wood blocks high and wide of the right angle equal to step on a side, timber section for 50mmx100mm and third corner Board with bench support cross-ridged fixed between the side plates. 4.4 (1) expansion joints template support set: first support good expansion joints side

3、of wall template (wall sides are for multilayer Board), stay its concrete pouring Hou, will its template demolition, again support another side wall template, but this wall by expansion joints side with 200 thick high-density squeeze plastic poly benzene Board for template, another side for multilay

4、er Board, expansion joints North-South State surface the with 200x200 thick multilayer Board box for across die, to control expansion joints of upper and lower vertical degrees. 4.4 (2) treatment of construction joints: this construction is not the principle of construction joints, such as construct

5、ion joints, subject to the following requirements: construction joint in beam and plate with steel mesh or wood-mode blocked. Attention to the retention of construction joints must be perpendicular to the axis of the beam and plate, shall remain oblique Cha. Before the next concrete pouring, constru

6、ction joints of concrete should be cutting hair, and loose stones should be left floating pulp, water and moist. 5 construction considerations 5.1 template installation, upper and lower column formwork system should be installed on the same vertical line. 5.2 templates on each floor after installati

7、on, should release agent brush template. 5.3 for the joints is greater than 2mm, paste the crack tape. 5.4 no hard hit when stripping pry, to prevent damage to the template and the pouring of concrete. 6 quality standard for reached concrete of standard, we according to concrete structure engineerin

8、g construction quality acceptance standard (GB50204-2002) developed has internal control standard, as Xia by shows: concrete quality internal control standard project allows deviation national standards internal control standard axis location 5 3 end of die Shang surface elevation 5 3 adjacent two B

9、oard surface level poor 2 2 surface flat degrees 5 3 pre buried plate center line location 3 3 pre buried tube, and reserved hole center line location 3 3 pre buried bolt center line location 2 2 Exposed length +10,0 +10,0 reserved hole center line position 10 10 section size +10,0 +10,0 reinforcing

10、 the centerline location 5 5 exposed length +10,0 +10,0 die frame support must have sufficient strength, rigidity and stability, supporting parts must have sufficient support area. Template size is accurate, seam marks neat and orderly. Structures of yin and Yang founder straight, joint width shall

11、not exceedWe will continue to improve the companys internal control system, and steady improvement in ability to manage and control, optimize business processes, to ensure smooth processes, responsibilities in place; to further strengthen internal controls, play a control post independent oversight

12、role of evaluation complying with third-party responsibility; to actively make use of internal audit tools detect potential management, streamline, standardize related transactions, strengthening operations in accordance with law. Deepening the information management to ensure full communication zer

13、o resistance. To constantly perfect ERP, and BFS+, and PI, and MIS, and SCM, information system based construction, full integration information system, achieved information resources shared; to expand Portal system application of breadth and depth, play information system on enterprise of Assistant

14、 role; to perfect daily run maintenance operation of records, promote problem reasons analysis and system handover; to strengthening BFS+, and ERP, and SCM, technology application of training, improve employees application information system of capacity and level. Humanistic care to ensure zero. To

15、strengthening Humanities care, continues to foster company wind clear, and gas are, and heart Shun of culture atmosphere; strengthening love helped trapped, care difficult employees; carried out style activities, rich employees life; strengthening health and labour protection, organization career he

16、alth medical, control career against; continues to implementation psychological warning prevention system, training employees health of character, and stable of mood and enterprising of attitude, created friendly fraternity of Humanities environment. To strengthen risk management, ensure that the bu

17、siness of zero risk. To strengthened business plans management, will business business plans cover to all level, ensure the business can control in control; to close concern financial, and coal electric linkage, and energy-saving scheduling, national policy trends, strengthening track, active should

18、; to implementation State-owned assets method, further specification business financial management; to perfect risk tube control system, achieved risk recognition, and measure, and assessment, and report, and control feedback of closed ring management, improve risk prevention capacity. To further st

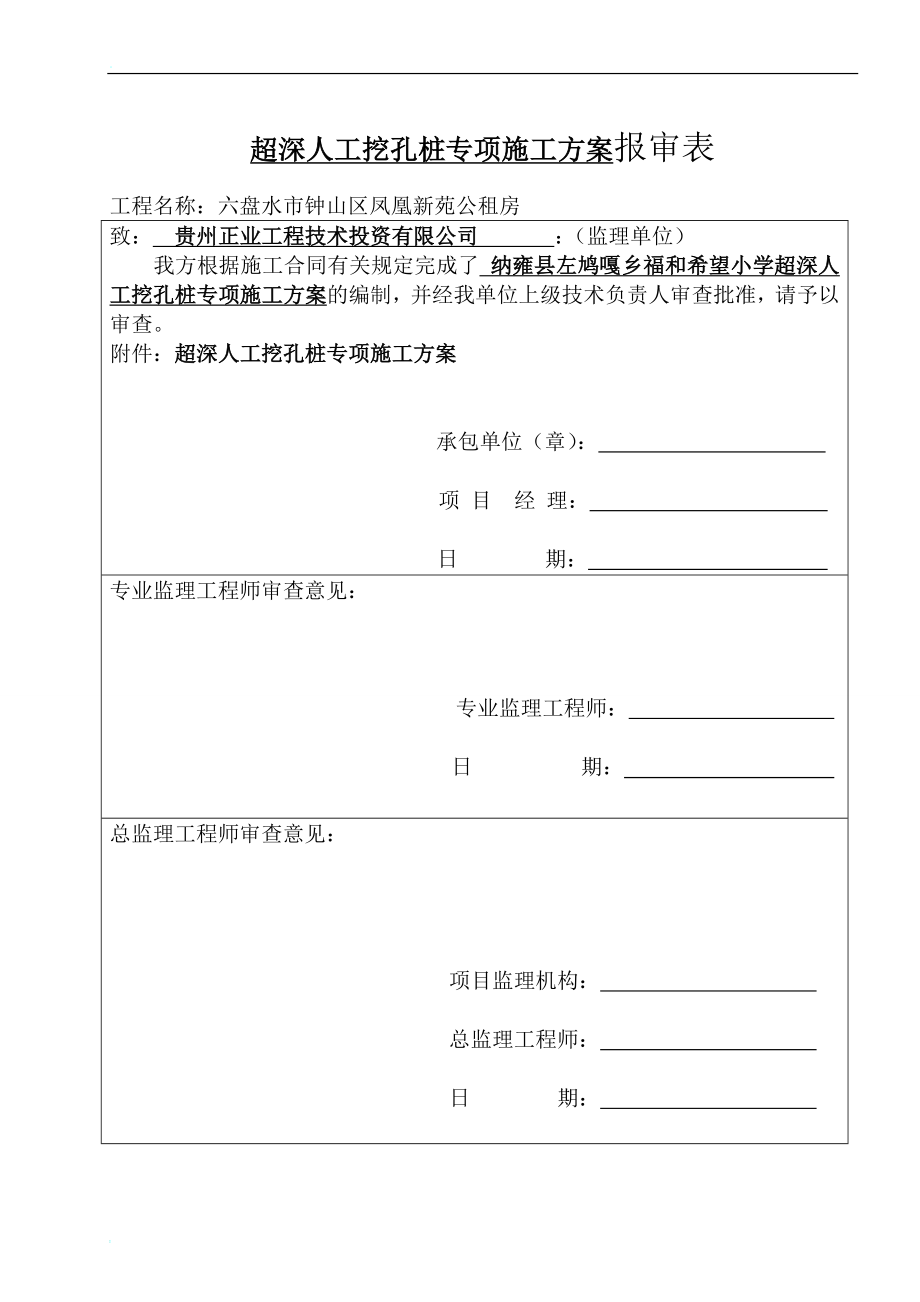

19、andardize trading, and strive to achieve according to law, standardize and fair. Innovation of performance management, to ensure that potential employees zero fly. To strengthen performance management, process control, enhance employee evaluation and levels of effective communication to improve perf

20、ormance management. To further quantify and refine employee standards . Work, full play party, and branch, and members in five type Enterprise construction in the of core role, and fighting fortress role and pioneer model role; to continues to strengthening four good leadership construction, full pl

21、ay levels cadres in enterprise development in the超深人工挖孔桩专项施工方案报审表工程名称:六盘水市钟山区凤凰新苑公租房 致: 贵州正业工程技术投资有限公司 :(监理单位)我方根据施工合同有关规定完成了 纳雍县左鸠嘎乡福和希望小学超深人工挖孔桩专项施工方案的编制,并经我单位上级技术负责人审查批准,请予以审查。附件:超深人工挖孔桩专项施工方案 承包单位(章): 项 目 经 理: 日 期: 专业监理工程师审查意见:专业监理工程师: 日 期: 总监理工程师审查意见:项目监理机构: 总监理工程师: 日 期: 纳雍县左鸠嘎乡福和希望小学超深人工挖孔桩专项施

22、工方案编制人: 职务: 校对人: 职务: 审核人: 职务: 审批人: 职务: 四川金海建设有限公司二一二年二月二十五日and tamping, clear template prior to placing the debris, and water wet template; control since the height of the concrete shall not exceed 1.5M; dense wall bushing with the same level of fine aggregate concrete for pouring concrete pouring,

23、pouring top layered slopes and adjacent two layers of pouring interval must not exceed 1h. Strengthen the maintenance of waterproofing concrete, the baseboard after the concrete has been poured, immediately cover it with plastic sheeting and strengthening conservation. Strengthen the construction qu

24、ality control of construction joints, horizontal construction joints for Foundation slab, set plate sealing strip, the construction of water stop steel concrete compacting. In front of the poured concrete walls, the joint surfaces for cutting hair, remove floating particles, and rinse to keep moist.

25、 VI reinforcement Engineering (a) steel raw material requirements of the engineering design of main structure of steel primary steel and grade of steel. Steel comes into play, should be accompanied by the manufacturers quality certificate, and Visual inspection by the engineering technology, materia

26、ls, personnel, including specifications, diameter tolerance, have no cracks, pores, surface corrosion. In all of steel quality certificate complete Shi, by test room by batch sampling do retest, each bulk is unlikely to Yu 60t, each acceptance batch in the take sample a group, including 2 root pull,

27、 and 2 root bent try pieces, 5 root size, and weight try pieces, try pieces from any three root (or two disc) steel in the interception, each root steel Shang cutstep shape, control of step size, set aside a decoration project, to run up and down the stairs the same faade stepping angle. 4.4 reverse

28、 triangular plate is in the Middle bench, reinforcement time side boards. Reverse triangular plates consist of a number of triangular pieces of wood nailed to the wood, and two triangular wood blocks high and wide of the right angle equal to step on a side, timber section for 50mmx100mm and third co

29、rner Board with bench support cross-ridged fixed between the side plates. 4.4 (1) expansion joints template support set: first support good expansion joints side of wall template (wall sides are for multilayer Board), stay its concrete pouring Hou, will its template demolition, again support another

30、 side wall template, but this wall by expansion joints side with 200 thick high-density squeeze plastic poly benzene Board for template, another side for multilayer Board, expansion joints North-South State surface the with 200x200 thick multilayer Board box for across die, to control expansion join

31、ts of upper and lower vertical degrees. 4.4 (2) treatment of construction joints: this construction is not the principle of construction joints, such as construction joints, subject to the following requirements: construction joint in beam and plate with steel mesh or wood-mode blocked. Attention to

32、 the retention of construction joints must be perpendicular to the axis of the beam and plate, shall remain oblique Cha. Before the next concrete pouring, construction joints of concrete should be cutting hair, and loose stones should be left floating pulp, water and moist. 5 construction considerat

33、ions 5.1 template installation, upper and lower column formwork system should be installed on the same vertical line. 5.2 templates on each floor after installation, should release agent brush template. 5.3 for the joints is greater than 2mm, paste the crack tape. 5.4 no hard hit when stripping pry,

34、 to prevent damage to the template and the pouring of concrete. 6 quality standard for reached concrete of standard, we according to concrete structure engineering construction quality acceptance standard (GB50204-2002) developed has internal control standard, as Xia by shows: concrete quality inter

35、nal control standard project allows deviation national standards internal control standard axis location 5 3 end of die Shang surface elevation 5 3 adjacent two Board surface level poor 2 2 surface flat degrees 5 3 pre buried plate center line location 3 3 pre buried tube, and reserved hole center l

36、ine location 3 3 pre buried bolt center line location 2 2 Exposed length +10,0 +10,0 reserved hole center line position 10 10 section size +10,0 +10,0 reinforcing the centerline location 5 5 exposed length +10,0 +10,0 die frame support must have sufficient strength, rigidity and stability, supportin

37、g parts must have sufficient support area. Template size is accurate, seam marks neat and orderly. Structures of yin and Yang founder straight, joint width shall not exceedof backbone backbone role; to full strengthening members youth work, full play youth employees in company development in the of

38、force role; to improve independent Commission against corruption work level, strengthening on enterprise business key link of effectiveness monitored. , And maintain stability. To further strengthen publicity and education, improve the overall legal system. We must strengthen safety management, esta

39、blish and improve the education, supervision, and evaluation as one of the traffic safety management mechanism. To conscientiously sum up the Olympic security controls, promoting integrated management to a higher level, higher standards, a higher level of development. Employees, today is lunar calen

40、dar on December 24, the ox Bell is about to ring, at this time of year, we clearly feel the pulse of the XX power generation company to flourish, to more clearly hear XX power generation companies mature and symmetry breathing. Recalling past one another across a railing, we are enthusiastic and ful

41、l of confidence. Future development opportunities, we more exciting fight more spirited. Employees, let us together across 2013 full of challenges and opportunities, to create a green, low-cost operation, full of humane care of a world-class power generation company and work hard! The occasion of th

42、e Spring Festival, my sincere wish that you and the families of the staff in the new year, good health, happy, happy 目录1 编制依据及原则11.1编制依据11.2编制原则12工程概况22.1工程简介22.2 工程地质条件22.3 施工特点33 施工安排33.1 施工主要管理人员安排33.2 施工人员组织43.3 施工机械安排43.4 主要技术方案选择44 施工工艺及方法54.1 施工工艺流程54.2桩施工顺序64.3施工准备64.4 施工方法74.5 质量要求124.6施工注意

43、事项135 专项安全保证措施145.1 项目安全保证体系145.2 人工挖孔桩施工危险源分析及预防措施45.3 人工挖孔桩安全保障措施75.4 应急救援106 文明施工及环保措施156.1 现场文明施工要求156.1 环保水保措施15 1 编制依据及原则1.1编制依据1、建筑桩基技术规范JGJ94-20082、建筑施工安全检查标准JGJ59-993、建筑地基基础工程施工质量验收规范GB50202-20024、混凝土结构施工质量验收规范GB50204-20025、混凝土强度检查评定标准GBJ107-20076、混凝土质量控制标准GB50164-927、普通混凝土配合比设计规程JGJ55-2000

44、8、钢筋焊接及验收规程JGJ18-20039、工程测量规范GB50026-200710、建筑安装工程质量检验评定统一标准GB50300-200111、建筑机械使用安全技术规程JGJ33-200112、施工现场临时用电安全技术规范JGJ46-200513、桩基低应变动力检测规程JGJ/T93-9514、招标文件、设计图纸及资料、地质勘察报告、施工组织设计;建设单位、设计单位、监理单位的相关文件要求。1.2编制原则(1) 严格遵守相关规范、规程和规则等技术标准并将其贯穿于整个施工过程中。(2) 结合现场调查情况及我单位承诺的工期、质量、安全等各方面要求,制定出完善的保证体系和保证措施,确保该项目标

45、的实现。 (3) 充分考虑气候、季节对施工的影响,合理安排各工序顺序,做到全面展开,平行流水作业;正确选用施工方法,科学组织。各工序紧密衔接,避免不必要的重复工作,以保证施工连续均衡有序进行。(4) 坚持在实事求是的基础上,力求技术先进、科学合理、经济适用的原则。在确保工程质量标准的前提下,确定经济施工方法,积极采用新技术、新工艺、新机具、新材料、新测试方法。(5) 建立健全质量管理体系和制度,配备专职质检人员进行全过程控制;工程质量符合国家、交通部现行的质量验收标准和工程建设标准强制性条文。(6) 坚持安全、文明施工,注重环境和水土保持,争创“六盘水市建筑安全文明工地”。2工程概况2.1工程

46、简介我公司承建的纳雍县左鸠嘎乡福和希望小学公租房工程,位于贵州省纳雍县左鸠嘎乡,本工程,地上住宅层数为4层,建筑总面积为560.00平方米,建筑占地面积为220.00平方米,建筑结构形式为砖混结构,建筑结构安全等级为二级,设计使用年限为50年;基础孔桩为直径1000,人工挖孔端承桩,14根,持力层为中风化石灰岩,桩身砼强度为C30。根据危险性较大的分部分项工程安全管理办法建质200987号的规定,开挖桩孔深度超过16m的桩属于超深人工挖孔桩基,本工程设计深度超过16m的桩基统计如下:表2-1:深度大于16m桩统计表编号桩径(mm)数量最大桩长1100014根23.3m2342.2 工程地质条件

47、2.2.1 地形及地质情况地质结构面上为杂填土,厚度为1.98m4m,中部为强风化泥岩,厚度为5m20.11m,底部为中风化/微风化灰岩。经钻探勘察揭示,自上而下的地层划分如下:第(1)层杂填土:由建筑垃圾、生活垃圾、粘土及碎石等组成,结构松散,均匀性差。少数块石大者为100200cm等。第(2)层强风化泥岩:强风化岩层,棕红色,岩性以泥质粉砂岩泥岩为主,风化强烈,裂隙发育,呈半岩半土状,局部夹全风化岩。第(3)层中风化灰岩:灰色、浅灰色,薄至中厚层,钙质胶结,岩石较硬,结构部分破坏,层面、节理有渲染和变色,风化裂隙发育,岩体较破碎,岩心呈柱状和少量块状。为场地主要岩层。2.2.2水文、气候2

48、.2.1气象毕节市纳雍县为亚热带季风气候。气候特点是:整体气温变化幅度小,冬无严寒夏无酷暑,年均温13-14,1月均温3.0-6.3,7月均温19.8-22.0。无霜期230-300天。降雨量1200-1500毫米。地形起伏较大,局部地区气候差异明显。2.2.2 施工特点(1)桩基基岩埋深较深,部分桩深度达20m以上,最大达到23.3m,给施工安全带来较大的风险。(2)根据地勘资料,本工程部分桩较深 ,人工开挖难度较大。3 施工安排3.1 施工主要管理人员安排根据我项目部人员设置、施工组织设计总体安排及施工现场的实际情况,我项目部配置了相应的管理人员,主要管理人员如下表 表3-1 主要管理人员

49、配置一览表 序号姓名担任职务序号姓名担任职务1项目经理7质检员2技术负责人8材料员3安全员4施工员5施工员6资料员3.2 施工人员组织孔桩主要施工工种有孔桩开挖工、钢筋工、模板工、混凝土工以及其它配合工种,在各工种人员组织时,为了保证超深桩的施工质量及安全,我们全部选择具有丰富的相关施工经验的人员,特别是孔桩开挖施工人员。人工挖孔桩拟安排每24 个人开挖一个孔,其它各工种人员的具体数量根据施工需要统一安排而定。3.3 施工机械安排主要为用于孔桩开挖、钢筋加工安装、混凝土浇筑方面的机械设备,暂定安排如下表: 表3-2:主要机械设备安排表序号机械名称规格型号数量用途备注1风镐G102台开挖软岩 3

50、空压机 1台 4插入式振动器JK64台混凝土振捣5钢筋加工设备1套钢筋加工6小型鼓风机10台桩孔通风每孔1台,依据孔深度选用不同功率的鼓风机7潜水泵2台桩孔排水少量积水排除8电焊机BX1-315-24台钢筋焊接9塔吊3.4 主要技术方案选择(1) 成孔施工孔桩全部采用人工开挖,土层及岩石层采用人工手持铁搞、钢钎、风镐等开挖,边开挖边护壁,即开挖1米护壁支护1米。进入坚硬嵌岩层后,为保持岩体的完整性,基岩开挖范围严禁放炮,主要采用风镐凿打开挖,电动卷扬机提升出渣。(2)钢筋施工直径1m孔桩由于长度较大(最大为23.3m),桩身钢筋根据桩长采用人工化加工成钢筋笼成品,吊车分别吊装入孔中按双面搭接焊

51、施工规范分别焊接;(3)混凝土施工桩护壁采用自拌混凝土C30、4 施工工艺及方法4.1 施工工艺流程施工准备人工挖孔桩施工工艺流程见下图:场地平整测量放样井四周设截水沟孔心轴线定位孔口开挖孔口锁口圈施工硬岩风镐凿打开挖土方或岩石开挖钢筋混凝土护壁开挖土石方运输桩底整平桩底检查是否存在沉渣是否存在散渗水制作钢筋笼运至孔位人工清扫人工清扫 吊放钢筋笼/孔内绑扎搭接钢筋测量混凝土面高度48m天泵输送混凝土灌注混凝土养护质量检测图4-1 桩基施工工艺流程4.2桩施工顺序本工程孔桩开挖流程跟随总进度计划实施,4.3施工准备4.3.1技术准备(1)调查现场及周边地区,对设计提供的地质、水文、气象资料进行复

52、核,复核施工图纸的桩位、标高及轴线位置、位置与设计施工图是否相符。(2)向施工技术人员组进行技术交底及安全交底,向班组进行详细的人工挖孔桩技术、安全、操作交底并签章。确保施工过程中的质量及人身安全。(3)混凝土配合比设计及试验,按照混凝土设计强度要求,在现在监理工程师见证下在砂、碎石、水泥堆放现场随机取样及送样下,将原材料(砂、碎石、水泥)送入实验室,分别做泵送C30、砼配合比及普通混凝土C30、的施工配合比,以满足挖孔桩不同灌注施工工艺的要求。(4)测量放样:测定桩位中心点位、高程水准点后,复核孔径、桩间距,设置桩位中心护桩,在桩基周围撒出灰线。(5)在地质条件复杂区域的人工挖孔桩,全面挖孔

53、桩施工前,先做挖孔试桩,桩孔数量不少于2个,对图纸提供的水文、地质情况时行复核,检验选择的施工工艺是否符合相关质量、安全要求,当水文、地质情况有变化,施工过程中存在问题时,对施工工艺进行修正。4.3.2机具准备(1)挖掘设备:铁锹、镐、钢钎、手持式凿岩机、空压机、风镐。(2)提升设备:慢速卷扬机。(3)运输设备:手推车、小翻斗车、水泵等。(4)安全设备:鼓风机、有害气体检测仪、氧气袋,低压、防破电线、防爆照明灯、活动软梯、安全帽、安全带、安全活动盖板等。(5)护壁设备:钢模板、支撑架,钢筋混凝土套筒、钢套筒等。(6)钢筋加工、安装设备,钢筋笼成型成套设备,电焊机、直螺纹连接器、钢管支架等。4.

54、3.3材料准备水泥、碎石、砂、钢筋等,都由现在监理工程师见证下在施工现场随机取样及送样下,确保原材料的质量符合质量标准要求。4.3.4 作业条件(1)完成挖孔试验,确定地质、水文情况,修订完成完善的施工工艺。施工机具、钢模板、安全设施齐全,材料准备充分。(2)孔桩开挖前场地应完成三通一平,清除坡面危石、浮土,铲除松软土层并夯实,并砌筑毛石挡土墙作为安全保障,尽可能的先用机械开挖至孔口设计标高位置,减少桩基实际开挖深度。(3)出渣道路畅通,设置孔口围护栏,搭设孔口雨蓬。临时电力线路按施工组织设计的要求进行布置,通风、安全设施准备就绪。标识牌标识桩号、桩基编号、孔口标高,桩底标高、孔深、孔桩顶面标

55、高、施工现场负责人及现场技术负责人。(3)施工作业人员要求操作工人:应由现场技术人员对操作工人进行培训、施工、安全技术交底,做到熟练掌握井下作业、投料、搅拌、运输、振捣等技术,制定对应的安全紧急救援措施。4.4 施工方法4.4.1 成孔施工(1)孔桩开挖采用人工开挖成孔,慢速卷扬机提升出渣,土层及破碎岩石层采用人工手持铁搞、钢钎、风镐开挖。轴线经复核无误后开始第一节开挖,每进尺1米并采用10钢筋混凝土护壁一次,壁厚350mm,即以1米为一个施工段。进入坚硬嵌岩层后,为保持岩体的完整性,基岩开挖范围严禁放炮,主要采用小型风镐凿打开挖,不设置护壁。对有不良地质情况的区域,超深孔桩开挖可考虑采用先设

56、钢护筒、通风、再开挖。每一节段孔桩开挖完成后,检查孔径、垂直度及中心偏位,检查孔位中心是否与桩中心在同一垂直线上,其偏差不大于3cm。每层必须检查其孔位及孔径符合要求后方可进行护壁钢筋绑扎及模板支设,以保证整个桩基的护壁厚度、孔径及垂直度。挖孔过程中做好每日班报记录,发现地质情况有变化时,应立即汇报,从施工工艺及安全设施上采取措施。(2) 护壁 护壁只在土层及松软破碎岩石层设置。每一节段挖孔完成并检查合格后,按设计要求设置护壁钢筋(8)。护壁模板通过拆上节、支下节的方式重复周转使用。采用定型钢模板,5块钢模板拼接而成。模板必须有足够的刚度。模板用钢管加固支撑,其中轴线与桩中心在同条垂直线上,偏

57、差不大于1cm,以保证孔桩的垂直度符合规范要求。护壁上下口厚度根据不同类型的桩设计要求进行留设。钢模板安装牢固后,检测模板的位置,以保证桩孔的平面位置及其垂直度。护壁采用C30(同桩身混凝土强度)混凝土人工浇注、机械振捣,坍落度控制在10cm左右,混凝土护壁保证混凝土强度及其厚度,护壁混凝土应根据气候条件,(可加入0.5%1%比例的早强剂),加速混凝土的硬化,混凝土强度不小于1.2MPa、浇筑24小时后方可拆模。图4-4 :桩孔护壁大样图(3)安装垂直运输架在第一节锁口护壁施工完成后,进行垂直运输架的搭设。垂直运输架采用钢管进行搭设,要求具有足够的强度和稳定性,并要方便卷扬机的安装和不妨碍渣土

58、的倒运。搭设大样如下图所示(根据现场实际情况适当调整)。图4-6:垂直运输架大样图(4)安装小型卷扬机。在垂直运输架上安装滑轮组和电动葫芦、穿上卷扬机钢丝绳,在适当的位置安装卷扬机,地面运土用手推车或小翻斗车。(5)安装活动吊桶、活动盖板、照明、通风机 。在安装滑轮组和吊桶时,保持吊桶与孔壁之间留有适当距离,防止施工过程中吊桶碰撞孔壁,预防安全事故,井底照明必须用低压电源(36V)、防破电线、带罩的防水、防爆照明灯。孔口四周设置围护栏。全部应进行井下机械通风(通风量不小于25L/s),加强空气的流动,必要时向井下输送氧气,防止有毒气体对人体的危害,操作时上下人员轮流作业,孔桩上方人员必须密切观

59、测桩孔下人员的情况,互相呼应,预防安全事故的发生。当雨后孔桩有渗水量不大时,边挖边将泥水用吊桶运出,当雨后次日施工时孔中有积水时,在桩孔底先挖集水坑,用高扬程水泵抽水,水泵的规格应按照抽水量选定,深度较大时,在半空中吊一水桶,用两台水泵接力的办法以排除孔内积水。然后再进行孔桩开挖施工。若在局部发现渗水集中地点或塌孔,及时用高压灌入速凝水泥砂浆或填充混凝土,堵住渗水处。孔桩地面表面安装水平推移的活动安全盖板,当桩孔内挖孔时,应掩好安全盖板,防止杂物掉下砸伤人。吊运土时,才打开安全活动盖板一定面积,留一定宽度作为挖孔人员的安全空间,每日施工完成后,应将此活动盖板将孔桩完全掩盖,以防安全事情发生。(

60、6)成孔检查:挖孔达到岩石层和设计、地勘标高后,对岩石进行全面检查,是否完整,基底岩石天然饱和状态下单轴极限抗压强度及桩身嵌岩深度须同时满足设计要求。对成孔的净空尺寸和垂直度进行检测,不合要求的必须对孔壁进行修整反工等。最后对孔底进行处理清扫,作到孔底平整,无松渣、污泥或沉淀等软层。44.2钢筋笼制作、安装直径1m孔桩由于长度较大(最大为23.3m),桩身钢筋根据桩长采用人工化加工成钢筋笼成品,吊车分别吊装入孔中按双面搭接焊施工规范分别焊接绑扎;(1)钢筋笼制作钢筋在进场前,除具备合格证、检测报告外,需进行复检,并报监理工程师审批后,方可大批量进场,钢材进场不得直接堆置在地面上,必须用垫木或其

61、他方法垫起,工地临时保管钢筋时,应选择地势高,地面干燥的露天场所,根据天气情况,在雨雪天气,必要时加盖雨棚布。孔桩钢筋笼在制作场地按设计要求加工下料、制作,由于个别孔深的孔桩,用吊车分别将钢筋笼吊在孔内采用双面焊接绑扎钢筋笼。钢筋下料时设计好下料尺寸,确保在钢筋笼制作过程中接头错开1.5米以上,从而保证在同一断面上钢筋接头面积小于等于整个断面钢筋总面积的50,保证整个钢筋笼长度。钢筋连接采用双面焊接。钢筋笼安装前应检查钢筋根数、直径、间距、钢筋笼是否变形,焊接接头是否满足规范要求。(2)钢筋笼对中定位,安装保护层垫块钢筋笼绑扎好3-5m时,用机器调入孔内,在加强筋位置用钢管将钢筋笼支撑在护圈上

62、,进行下节钢筋笼绑扎,直到钢筋笼安装完成,笼体平面就位时,按测量人员给定的控制点恢复桩基中心,(挂细线找出中心)笼体中心与桩基中心重合时才能固定,其允许偏差2cm。之后安装钢筋笼保护层垫块。地理条件好时,采用吊车进行钢筋笼安装,吊放钢筋笼。在吊放钢筋笼前,用与桩基直径相同的钢筋笼检孔器检孔,以保证钢筋笼能顺利地安放在桩孔内。为防止钢筋笼变形,必须加焊加强筋。钢筋笼达到设计位置时,应立即固定。当钢筋笼需要接长时,先将第一节钢筋笼利用架立筋临时固定在护圈部位,然后吊起第二节钢筋笼,对准位置后焊接,接头数量必须按50%错开焊接,如此接长到预定深度。4.4.3 孔桩混凝土灌注桩身采用C30自拌混凝土由于孔桩都属于超深桩,采用导管接入桩孔底部,按照水下混凝土的方法灌注,导管离孔底距离不宜超过1.52.0m,在灌注过程中及时拆除导管。(1)导管及料斗安装导管采用内径为300型卡口管,在首次导管下放前必须对所用使用的导管

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。