ICHQ7中英文对照

ICHQ7中英文对照

《ICHQ7中英文对照》由会员分享,可在线阅读,更多相关《ICHQ7中英文对照(53页珍藏版)》请在装配图网上搜索。

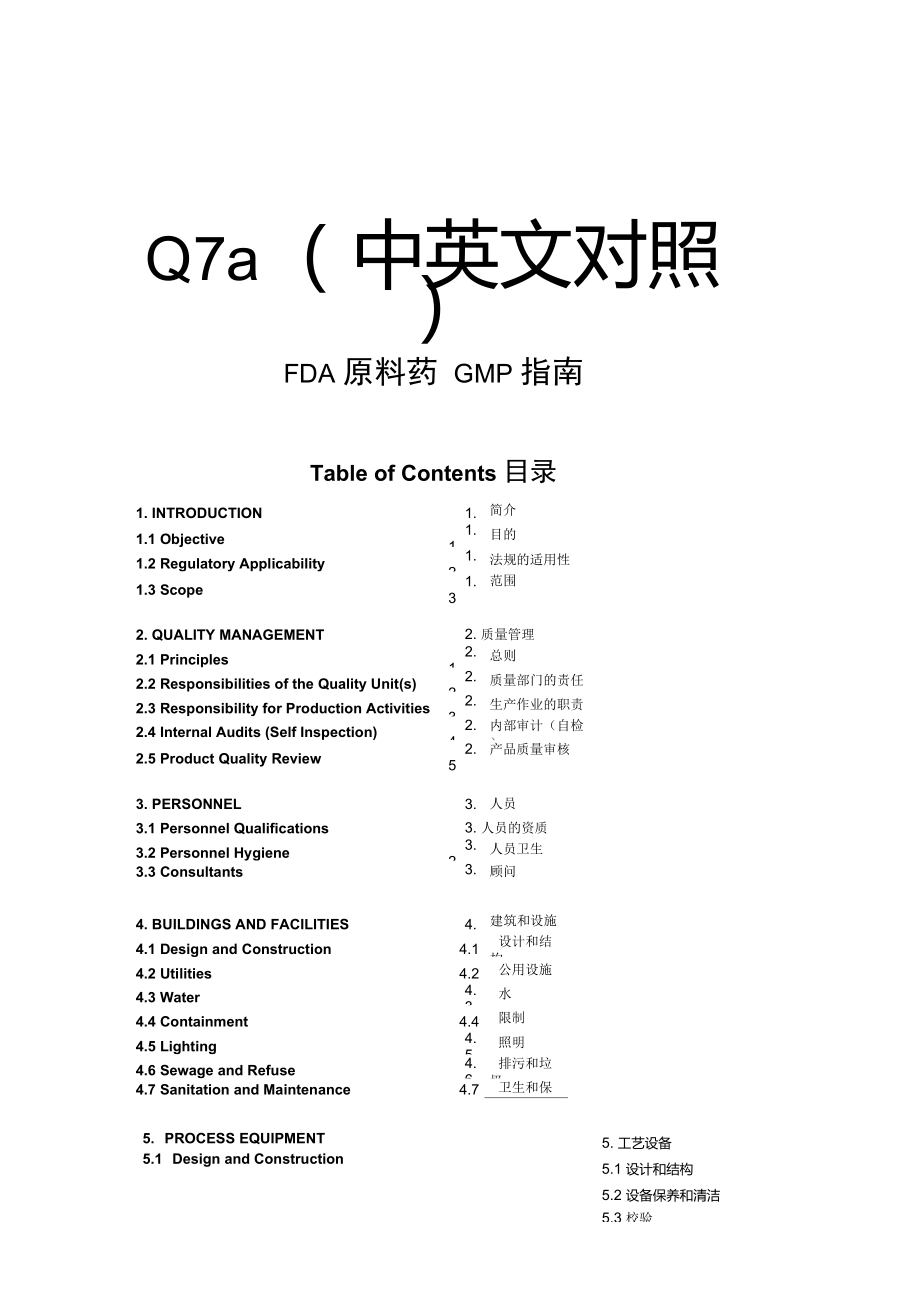

1、Q7a (中英文对照 )FDA 原料药 GMP 指南Table of Contents 目录1. INTRODUCTION1.简介1.1 Objective1.1目的1.2 Regulatory Applicability1.2法规的适用性1.3 Scope1.3范围2. QUALITY MANAGEMENT2. 质量管理2.1 Principles2.1总则2.2 Responsibilities of the Quality Unit(s)2.2质量部门的责任2.3 Responsibility for Production Activities2.3生产作业的职责2.4 Internal

2、 Audits (Self Inspection)2.4内部审计(自检)2.5 Product Quality Review2.5产品质量审核3. PERSONNEL3.人员3.1 Personnel Qualifications3. 人员的资质3.2 Personnel Hygiene3.2人员卫生3.3 Consultants3.3顾问4. BUILDINGS AND FACILITIES4.建筑和设施4.1 Design and Construction4.1设计和结构4.2 Utilities4.2公用设施4.3 Water4.3水4.4 Containment4.4限制4.5 Lig

3、hting4.5照明4.6 Sewage and Refuse4.6排污和垃圾4.7 Sanitation and Maintenance4.7卫生和保养5. 工艺设备5.1 设计和结构5.2 设备保养和清洁5.3 校验5. PROCESS EQUIPMENT5.1 Design and Construction5.2 Equipment Maintenance and CleaningCalibrationEC Q7a3EC Q7a5.4 Computerized Systems5.4计算机控制系统#EC Q7a#EC Q7a6. DOCUMENTATION AND RECORDS6.1 D

4、ocumentation System and Specifications6.2 Equipment cleaning and Use Record6.3 Records of Raw Materials, Intermediates, API Labeling and Packaging Materials6.4 Master Production Instructions (Master Production and Control Records)6.5 Batch Production Records (Batch Production and Control Records)6.6

5、 Laboratory Control Records6.7 Batch Production Record Review7. MATERIALS MANAGEMENT7.1 General Controls7.2 Receipt and Quarantine7.3 Sampling and Testing of Incoming Production Materials7.4 Storage7.5 Re-evaluation6. 文件和记录 6.1文件系统和质量标准 6.2设备的清洁和使用记录6.3原料、中间体、原料药的标签和包装材 料的记录6.4生产工艺规程(主生产和控制记录)6.5批生产

6、记录(批生产和控制记录)6.6实验室控制记录6.7批生产记录审核7. 物料管理7.1控制通则7.2接收和待验7.3进厂物料的取样与测试7.4储存7.5复验#EC Q7a#EC Q7a8. PRODUCTION CONTROLSAND IN-PROCESS8.1 Production Operations8.1生产操作8.2 Time Limits8.2时限8.3 In-process Sampling and Controls8.3工序取样和控制8.4 Blending Batches of Intermediates or8.4中间体或原料药的混批8.生产和过程控制APIs8.5污染控制8.

7、5 Contamination Control#EC Q7a#EC Q7a9.原料药和中间体的包装和贴签PACKAGING AND IDENTIFICATION#EC Q7aLABELINGOF APIs ANDINTERMEDIATES9.1 General9.1总则9.2 Packaging Materials9.3 Label Issuance and Control9.4 Packaging and Labeling Operations9.2包装材料9.3标签发放与控制9.4包装和贴签操作10. STORAGE AND DISTRIBUTION10.1 Warehousing Pro

8、cedures10.2 Distribution Procedures10.储存和分发10.1入库程序10.2分发程序#EC Q7a4EC Q7a11. LABORATORY CONTROLS11.1 General Controls11.2 Testing of Intermediates and APIs11.3 Validation of Analytical Procedures11.4 Certificates of Analysis11.5 Stability Monitoring of APIs11.6 Expiry and Retest Dating11.7 Reserve/R

9、etention Samples11.实验室控制11.1控制通则11.2中间体和原料药的测试11.3分析方法的验证11.4分析报告单11.5原料药的稳定性监测11.6有效期和复验期11.7留样12.1 Validation Policy12.1验证方针12.2 Validation Documentation12.2验证文件12.3 Qualification12.3确认12.4 Approaches to Process Validation12.4工艺验证的方法12.5 Process Validation Program12.5工艺验证的程序12.6 Periodic Review of

10、 Validated Systems12.6验证系统的定期审核12.7 Cleaning Validation12.7清洗验证12.8 Validation of Analytical Methods12.8分析方法的验证12. VALIDATION12.验证13.变更的控制13. CHANGE CONTROL14. REJECTION AND RE-USEMATERIALS14.1 Rejection14.2 Reprocessing14.3 Reworking14.4 Recovery of Materials and Solvents14.5 ReturnsOF 14.拒收和物料的再利用

11、14.1拒收14.2返工14.3重新加工14.4物料与溶剂的回收14.5退货15. COMPLAINTS AND RECALLS15.投诉与召回#EC Q7a#EC Q7a16. CONTRACT MANUFACTURERS(INCLUDING LABORATORIES)协议生产商(包括实验室)#EC Q7a#EC Q7a16. AGENTS, BROKERS, TRADERS, DISTRIBUTORS, REPACKERS, AND RELABELLERS16.1 Applicability16.2 Traceability of Distributed APIs and Intermed

12、iates16.3 Quality Management16.4 Repackaging, Relabeling, and Holding of APIs and Intermediates17. 代理商、经纪人、贸易商、经销商、重新 包装者和重新贴签者17.1适用性17.2已分发的原料药和中间体的可追溯性 17.3质量管理17.4原料药和中间体的重新包装、重新贴签 和待检#EC Q7a#EC Q7a17.5 Stability17.5稳定性17.6 Transfer of Information17.6信息的传达17.7 Handling of Complaints and Recalls1

13、7.7投诉和召回的处理17.8 Handling of Returns17.8退货的处理18.SpecificGuidanceforAPIs18.用细胞繁殖/发酵生产的原料药的特殊Manufactured by Cell Culture/Fermentation指南18.1 General18.1总则18.2 Cell Bank Maintenance and Record18.2细胞库的维护和记录的保存Keeping18.3 Cell Culture/Fermentation18.3细胞繁殖/发酵18.4 Harvesting, Isolation and Purification18.4收

14、取、分离和精制18.5 Viral Removal/Inactivation steps18.5病毒的去除/灭活步骤19. APIs for Use in Clinical Trials19.用于临床研究的原料药19.1 General19.1总则佃.2 Quality19.2质量19.3 Equipment and Facilities19.3设备和设施佃.4 Control of Raw Materials19.4原料的控制佃.5 Production19.5生产19.6 Validation19.6验证佃.7 Changes19.7变更佃.8 Laboratory Controls19.

15、8实验室控制19.9 Documentation19.9文件20. Glossary20.术语5EC Q7aQ7a GMP Guida nee for APIsQ7a原料药的GMP指南6EC Q7a#EC Q7a1. INTRODUCTION1.1 ObjectiveThis docume nt is inten ded to provide guida nee regarding good manufaeturing practice (GMP) for the manu faeturi ng of active pharmaceutical in gredie nts (APIs) un

16、der an appropriate system for managing quality. It is also inten ded to help ensure that APIs meet the quality and purity characteristics that they purport, or are represe nted, to possess.In this guidanee, the term manufacturing is defi ned to in elude all operati ons of receipt of materials, produ

17、ct ion, packagi ng, repackagi ng, labeling, relabeling, quality control, release, storage and distribution of APIs and the related controls. In this guidanee, the term should iden tifiesrecomme ndati onsthat, whe nfollowed, will ensure complianee with CGMPs.An alter native approach may be used if su

18、ch approach satisfies the requirements of the applicable statues. For the purposes of this guida nee,the terms curre nt goodmanu facturi ngpractices and goodmanu facturi ng practices are equivale nt.1. 简介1.1目的本文件旨在为在合适的质量管理体系下制造 活性药用成分(以下称原料药)提供有关优 良药品生产管理规范(GMP )提供指南。它 也着眼于帮助确保原料药符合其旨在达到或 表明拥有的质量与纯

19、度要求。本指南中所指的“制造”包括物料接收、生 产、包装、重新包装、贴签、重新贴签、质 量控制、放行、原料药的储存和分发及其相 关控制的所有操作。本指南中,“应当”一词表示希望采用的建议,除非证明其不适用或 者可用一种已证明有同等或更高质量保证水 平的供选物来替代。本指南中的“现行优良 生产管理规范(eGMP)”和“优良生产管理 规范(GMP )”是等同的。The guida nee as a whole does not cover safety aspects for the pers onnel en gaged in manu facturi ng, nor aspects relat

20、ed to protect ing the en vir onment. These con trols are in here nt responsibilities of the manufacturer and are gover ned by n ati onal laws.本指南在总体上未涉及生产人员的安全冋 题,亦不包括环保方面的内容。这方面的管 理是生产者固有的责任,也是国家法律规定 的。7EC Q7a#EC Q7aThis guidanee is not intended to define registratio nan d/or fili ngrequireme nts o

21、rmodify pharmacopoeial requireme nts. This guidanee does not affect the ability of the responsible regulatory agency to establish specificregistrati on /fili ngrequireme ntsregard ingAPIs within the con text ofmarketi ng/ma nu facturi ng authorizati ons or drug applicati ons.All commitme nts inregis

22、tratio n/fili ng docume nts should be met.1.2 Regulatory ApplicabilityWithin the world community, materials may vary as to their legal classification as an API. When a material is classified as an API in the regi on or country in which it is manu factured or used in a drug product, it should be manu

23、 factured accord ing to this guida nee.本指南未规定注册/归档的要求、或修改药典 的要求。本指南不影响负责药政审理部门在 原料药上市/制造授权或药品申请方面建立 特定注册/归档要求的能力。注册/归档的所有 承诺必须做到。1.2法规的适用性在世界范围内对原料药的法定定义是各不相 同的。当某种物料在其制造或用于药品的地 区或国家被称为原料药,就应该按照本指南 进行生产。#EC Q7a#EC Q7a1.3 ScopeThis guidanee applies to the manufacture of APIs for use in huma n drug (m

24、edic in al) products. It applies to the manufacture of sterile APIs only up to the point immediately prior to the APIs being ren dered sterile. The sterilization and aseptic processing of sterile APIs are not covered by this guidanee, but should be performed in accordanee with GMP guidances for drug

25、 (medicinal) products as defined by local authorities.1.3范围本文件适用于人用药品(医疗用品)所含原 料药的生产。它适用于无菌原料药在灭菌前 的步骤。本指南不包括无菌原料药的消毒和 灭菌工艺,但是,应当符合地方当局所规定 的药品(医疗用品)生产的 GMP指南。#EC Q7aThis guida nee covers APIs that are manu facturedby chemicalsyn thesis,extract ion, cell culture/ferme ntati on, recovery from n atural

26、 sources, or any comb in ati on of these processes. Specific guidanee for APIs manufactured by cell culture/fermentation is本文件适用于通过化学合成、提取、细胞培 养/发酵,通过从自然资源回收,或通过这些 工艺的结合而得到的原料药。通过细胞培养/发酵生产的原料药的特殊指南则在第18章论述。#EC Q7adescribed in Section 18.8EC Q7a#EC Q7aThis guidanee excludes all vaccines, whole cells,

27、 whole blood and plasma, blood and plasma derivatives (plasma fractionation), and gene therapy APIs. However, it does include APIs that are produced using blood or plasma as raw materials. Note that cell substrates (mammalia n, pla nt, in sect or microbial cells, tissue or animal sources including t

28、ransgenic ani mals) and early process steps may be subject to GMP but are not covered by this guida nee. In addition, the guidanee does not apply to medical gases, bulk-packaged drug (medici nal) products (e.g., tablets or capsules in bulk contain ers), or radiopharmaceuticals.Secti on 19 contains g

29、uida nee that only applies to the manufacture of APIs used in the product ionof drug (medici nal) productsspecifically for clinical trials (investigational medic inal products).An API starting material is a raw material, an in termediate, or an API that is used in the product ion of an API and that

30、is in corporated as a significantstructural fragment into thestructure of the API. An API starting material can be an article of commerce, a material purchased from one or more suppliers under con tract or commercial agreeme nt, or produced in-house. API starting materials normally have defi ned che

31、mical properties and structure.The compa ny should desig nate and docume nt the rati on ale for the point at which product ion of the API begi ns. For syn thetic processes, this is known as the point at which API starting materials are en tered into the process. For other processes (e.g., ferme ntat

32、i on,extracti on,purificati on), thisrati on aleshould beestablished on a case-by-case basis. Table 1 gives guidanee on the point at which the API starting material is normally introduced into the本指南不包括所有疫苗、完整细胞、全 血和血浆、全血和血浆的衍生物(血浆成分) 和基因治疗的原料药。但是却包括以血或血 浆为原材料生产的原料药。值得注意的是细 胞培养基(哺乳动物、植物、昆虫或微生物 的细胞、组

33、织或动物源包括转基因动物)和 前期生产可能应遵循 GMP规范,但不包括在 本指南之内。另外,本指南不适用于医用气 体、散装的制剂药(例如,散装的片剂和胶 囊)和放射性药物的生产。第19章的指南只适用于用在药品 (医疗用品) 生产中的原料药制造,特别是临床实验用药(研究用医疗产品)的原料药制造。“原料药的起始物料”是指一种原料、中间 体或原料药,用来生产一种原料药,或者以 主要结构单元的形式被结合进原料药结构 中。原料药的起始物料可能是在市场上有售、 能够通过合同或商业协议从一个或多个供应 商处购得,或由生产厂家自制。原料药的起 始物料一般来说有特定的化学特性和结构。生产厂商要指定并用书面文件说

34、明原料药的 生产从何处开始的理论依据。对于合成工艺 而言,就是“原料药的起始物料”进入工艺 的那一点。对其他工艺(如:发酵,提取, 纯化等)可能需要具体问题具体对待。表1给出了原料药的起始物料从哪一点引入工艺 过程的指导原则。process.From this point on, appropriate GMP as defined in this guidanee should be applied to these in termediate an d/or API manu faeturi ng steps. This would in elude the validati on of

35、critical process steps determ ined to impact the quality of the API. However, it should be no ted that the fact that a company chooses to validate a process step does not necessarily define that steps as critical.The guida nee in this docume nt would no rmally be applied to the steps show n in gray

36、in Table1. However, all steps shown may not be completed. The stringency of GMP in API manu facturi ng should in crease as the process proceeds from early API steps to final steps, purificati on,and packagi ng. Physicalprocess ing of APIs, such as granu lati on, coati ng or physical manipulation of

37、particle size (e.g., milli ng,micronizing) should be con ductedaccord ing to this guida nee.This GMP guidanee does not apply to steps prior to the introduction of the defined API starting material.从这步开始,本指南中的有关 GMP规范应当 应用在这些中间体和/或原料药的制造中。这 包括对原料药质量有影响的关键工艺步骤的 验证。但是,值得注意的是厂商选择某一步 骤进行验证,并不一定将该步骤定为关键步

38、骤。本文件的指南通常适用于表 1中的灰色步骤。 但在表中体现的所有步骤并不是将应用 GMP管理的所有步骤全部体现出来了。 原料 药生产中的GMP要求应当随着工艺的进行, 从原料药的前几步到最后几步,精制和包装,越来越严格。原料药的物理加工,如制粒、 包衣或颗粒度的物理处理(例如制粉、微粉 化)应当按本指南的标准进行。本GMP指南不适用于引入定义了的 “原料药 的起始物料”以前的步骤。9EC Q7a#EC Q7aTable 1: Application of this Guidance to API ManufacturingType ofManufacturingApplication of

39、this guidance to steps (shown in gray) used in this type of manufacturingChemical manufacturingProduction of the APIStarting materialIntroduction of the API starting material into processProduction ofIntermediate(s)Isolation and purificationPhysical processing, and packagingAPI derived fromCollectio

40、n of organ,Cutting, mixing, and/orIntroduction of the APIIsolation andPhysical processing, andanimal sourcesfluid, or tissueinitial processingstarting material intopurificationpackagingprocessAPI extracted fromCollection of plantCutting and initialIntroduction of the APIIsolation andPhysical process

41、ing, andplant sourcesextraction(s)starting material intopurificationpackagingprocessHerbal extracts usedCollection of plantsCutting and initialFurtherPhysical processing, andas APIextractionextractionpackagingAPI consisting ofCollection of plantsCutting/comminutingPhysical processing, andcomminuted

42、orand/or cultivationpackagingpowdered herbsand harvestingBiotechnology: fermentation/cell cultureEstablishment of master cell bank and working cell bankMaintenance of working cell bankCell culture and/or fermentationIsolation and purificationPhysical processing, and packaging“ Classical ”Establishme

43、nt of cellMaintenance of the cellIntroduction of the cellsIsolation andPhysical processing, andfermentation tobankbankinto fermentationpurificationpackagingproduce an APIIn creas ing GMP requireme nts表1:本指南在原料药生产中的应用生产类型本指南在用于各类生产的工艺步骤(灰色背景)中的应用化学品的生产原料药起始物料的生产原料药起始物料引入工艺过程中间体的生产分离和纯化物理加工和包装动物源原料药器官

44、、分泌物或组织的收集切割、混合和/或初步加工原料药起始物料引入工艺过程分离和纯化物理加工和包装从植物源提取的原料药植物的收集切割和初步提取原料药起始物料引入工艺过程分离和纯化物理加工和包装草药提取物用作原料药植物的收集切割和初步提取进一步提取物理加工和包装由粉碎的或粉末状草药组成的原料药植物的收集和/或培养和收获切割/粉碎物理加工和包装生物技术:发酵/细胞培养主细胞库和工作细胞库的建立工作细胞库的维护细胞培养和/或发酵分离和纯化物理加工和包装经典”发酵生产原料药细胞库的建立细胞库的维护细胞引入发酵分离和纯化物理加工和包装10EC Q7a#EC Q7a#EC Q7a#EC Q7a2. QUALI

45、TY MANAGEMENT2.1 Principles2.10 Quality should be the responsibilities of all pers ons in volved in manu facturi ng.2.11 Each manu facturer should establish, document, and implement an effective system for managing quality that involves the active participation of management and appropriate manu fac

46、turi ng pers onn el.2. 质量管理2.1总则2.10参与原料药生产的每一个人都应当对质 量负责。2.11每一个生产商都应当建立并执行一套有 管理人员和有关员工积极参与的有效的质量 管理体系,并使其文件化。2.12 The system for managing quality shoulden compass theorga ni zatio nalstructure,procedures, process and resources, as well as activities to en sure con fide nee that the API will meet

47、its inten ded specificati ons for quality and purity. All quality-related activities should be defi ned and docume nted.2.13 There should be a quality unit(s) that is in depe ndent of product ion and that fulfills both quality assuranee (QA) and quality control (QC) resp on sibilities. The quality u

48、nit can be in the form of separate QA and QC units or a sin gle in dividual or group, depe nding upon the size and structure of the orga ni zati on.2.14 The pers ons authorized to release in termediates and APIs should be specified.2.15 All quality-related activities should be recorded at the time t

49、hey are performed.2.16 Any deviati on from established procedures should be documented and explained. Critical deviations should be investigated, and the investigation and its conclusions should be docume nted.2.17 No materials should be released or usedbefore the satisfactory completi on of evaluat

50、i on by the quality un it(s) uni ess there are appropriate systems in place to allow for such use (e.g., release un der quara ntine as described in Section 10 or the use of raw materials or in termediatespending completi on ofevaluati on).2.18 Procedures should exist for notifying resp on sible man

51、ageme nt in a timely manner of regulatory in spect ions, serious GMP deficie ncies, product defects and related actions (e.g., quality-related complaints, recalls, and regulatory action s).2.12质量管理体系应当包括组织机构、规程、 工艺和资源,以及确保原料药会符合其预期 的质量与纯度要求所必需的活动。所有涉及 质量管理的活动都应当明确规定,并使其文 件化。2.13应当设立一个独立于生产部门的质量部 门,同

52、时履行质量保证(QA)和质量控制(QC) 的职责。依照组织机构的大小,可以是分开 的QA和QC部门,或者只是一个人或小组。2.14应当指定授权发放中间体和原料药的人 员。2.15所有有关质量的活动应当在其执行时就 记录。2.16任何偏离既定规程的情况都应当有文字 记录并加以解释。对于关键性偏差应当进行 调查,并记录调查经过及其结果。2.17在质量部门对物料完成满意的评价之 前,任何物料都不应当发放或使用,除非有 合适的系统允许此类使用(如10.20条款所述的待检情况下的使用,或是原料或中间体在 等待评价结束时的使用)。2.18应当有规程能确保公司的责任管理部门 能及时得到有关药政检查、严重的G

53、MP缺陷、产品缺陷及其相关活动(如质量投诉, 召回,药政活动等)的通知。2.2 Responsibilities of the Quality Unit(s)2.20 The quality unit(s) should be involved in all quality-related matters.2.21 The quality unit(s) should review and approve all appropriate quality-related docume nts.2.22 The main resp on sibilities of the independent

54、quality unit(s) should not be delegated. These responsibilities should be described in writing and should include, but notn ecessarily be limited to:1. Releasing or rejecting all APIs. Releasing or reject ing in termediates for use outside the con trol of the manu facturi ng compa ny2. Establishing

55、a system to release or reject raw materials, in termediates, packag ing, and labeling materials3. Review ing completed batch product ion and laboratory con trol records of critical process steps before release of the API for distributi on4. Making sure that critical deviations are in vestigated and

56、resolved5. Approving all specifications and master product ion in struct ions6. Approving all procedures affecting the quality of in termediates or APIs7. Making sure that internal audits (self- in spect ions) are performed8. Approvi ng in termediate and API con tract manu facturers9. Approving chan

57、ges that potentially affect in termediate or API quality10. Reviewing and approving validation protocols and reports11. Making sure that quality-related complaints are in vestigated and resolved12. Making sure that effective systems are used for maintaining and calibrating critical equipme nt13. Mak

58、ing sure that materials are appropriately tested and the results are2.2质量部门的责任2.20质量部门应当参与所有与质量有关的事 物。2.21所有与质量有关的文件应当由质量部门 审核批准。2.22独立的质量部门的主要职责不应当委派 给他人。这些责任应当以文字形式加以说明, 而且应当包括,但不限于:1. 所有原料药的放行与否。用于生产商控制 范围以外的中间体的放行与否;2. 建立一个放行与拒收原材料、中间体、包 装材料和标签的系统;3. 在供销售的原料药放行前,审核已完成的 关键步骤的批生产记录和实验室检验记录;4. 确保已对

59、重大偏差进行了调查并已解决;5. 批准所有的规格标准和主生产指令;6. 批准所有可能影响原料药和中间体质量的规程;7. 确保进行内部审计(自检);8. 批准中间体或原料药的委托生产商;9. 批准可能影响到中间体或原料药质量的 变更;10. 审核并批准验证方案和报告;11. 确保调查并解决质量问题的投诉;12. 确保用有效的体系来维护和校验关键设 备;13. 确保物料都经过了适当的检验并报告结 果;reported14. Maki ng sure that there is stability data to support retest or expiry dates and storage

60、con diti ons on APIs an d/or in termediates, where appropriate15. Performing product quality reviews (as defined in Section 2.5)14. 确保有稳定性数据支持中间体或原料药 的复验期或有效期和储存条件;15. 开展产品质量审核(详见 2.5节)。2.3 Responsibility for Production ActivitiesThe responsibility for production activities should be described in wr

61、iting and should in clude, but not n ecessarily be limited to:1. Prepari ng, review ing,approvi ng,anddistribut ing thein struct ionsfor theproduct ionof in termediates or APIsaccord ing to writte n procedures2. Producing APIs and, when appropriate, in termediates accord ing to pre-approved in struct ions

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。