安全风险评估电气焊

安全风险评估电气焊

《安全风险评估电气焊》由会员分享,可在线阅读,更多相关《安全风险评估电气焊(18页珍藏版)》请在装配图网上搜索。

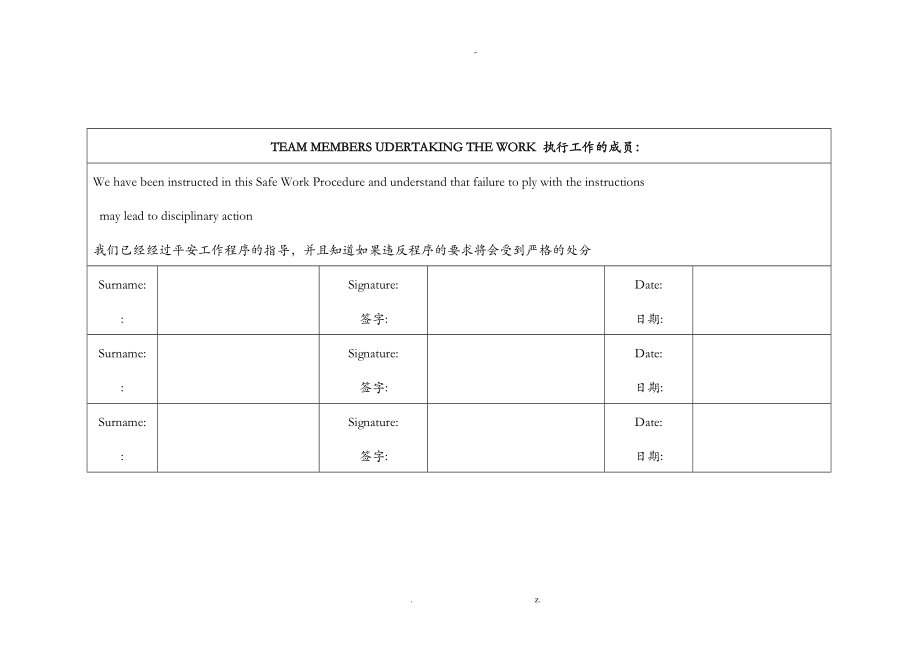

1、-TEAM MEMBERS UDERTAKING THE WORK 执行工作的成员:We have been instructed in this Safe Work Procedure and understand that failure to ply with the instructions may lead to disciplinary action我们已经经过平安工作程序的指导,并且知道如果违反程序的要求将会受到严格的处分Surname:Signature:签字:Date:日期:Surname:Signature:签字:Date:日期:Surname:Signature:签字:D

2、ate:日期:SEQENCE OF BASIC JOB STEPS根本的工作步骤HAZARDS隐患CONTROLS/REMENDEDSAFE WORK PROCEDURE控制方法工作方案准备Plan preparation1 施工方案不详细、不周全造成施工混乱,易造成伤人,如穿插作业。Injuryeasily caused by inpletes plan such as inters electing work.2、施工许可PTW未办理,JHA、STA会议交底不清,警告、标志不明,工人不知道、不熟悉平安要求,违章作业造成伤害。Injury caused without JHA or blur

3、red STA Meeting or ine*plicit warning sing or workers not familiar with safety requirement.1施工员每日工作前,必须有当日的详细工作方案与安排,并与平安部门沟通。The technician must municate with safety department for the daily work piano before day working 2施工前JHA、PTW、警告标志必须贴在明显处,施工员要招开STA会议,对工人详细讲解当天的工作程序和平安要求。JHA, PTW, Warning sing

4、s should be put up obviously. The technician should tell the workers the day work procedure and safety requirement by holding STA meeting.3工人不熟悉IIP现场规章制度平安要求。The workers are not familiar with IIP field safety rules4PPE佩戴不正确。Not wearing PPEproperly3 有员工进入IIP现场必须经过IIP HSE 部门培训,方可上岗作业。All the workers e

5、ntering the IIP site should be trained by IIP HSE.4 人根据岗位特点及JHA、 PTW、 STA要求正确佩戴PPE。Workers wear right PPE according to the kind of work and JHA,PTW,STArequirement.材料运输Material Transportation1 交通事故Traffic accident2输中材料捆绑不牢伤人The material not tied tightly during transportation3 搬运方法不当伤腰、伤手伤脚。Incorrect

6、methods cause injury when unloading4 吊车吊运伤人。Injury caused by the crane lifting5 滑轮固定不牢伤人The pulley not fi*ing tightly1、 运输材料采用人力车、汽车运输,材料必须捆绑结实。Material can be delivered by the map powered car can the material should be tied tightly.2、 用正确的搬运方法,超过100公斤以上重物用吊车吊运卸车。Using the right carrying methods. He

7、avy loads above 100kg can be unloaded by crane.3、 采用人工传运时,工人必须相互照应招呼,待另外一人把握结实时方可松手。The workers must municate with each other when delivering with hand .One couldnt rela* until the other one is ready.4、 滑轮必须与构筑物捆绑结实方可使用。Pulley must be tied tightly with the constructions before being used.5、 超过10M以上高

8、度,材料采用吊车吊运,绳子、滑轮辅助吊运。The material shall be delivered with crane and assist antedby ropes6、 车辆行使按IIP现场行使路线行使,限速1公里/小时。Vehicles should be driven according to IIP requirement the ma*im speed within 10KM per hour.7、 施工人员必须从梯子上下。The workers must go up and down from ladders.施工用电Construction Electricity吊装作

9、业Lifting work电焊、气焊作业welding work 1、 无证操作造成触电Electrical injury by operating without license.2、 电工接电时与他人合闸造成触电。Electrical injury by switching on with others when electrical work.3、 选择劳保用品不适宜造成失火触电。Electrical injury by unsuitable PPE and tools 4、 选择的用电材料不合格不适宜造成失火触电。Electrical injury by unqualified ele

10、ctrical material5、工用电安装不规造成失火触电。Construction electricity fi*ing not fit for the requirement cause fire and electrical injury 6、 电缆与建筑物钢性物质接触造成触电失火。Cable touching with the steel material of constructure cause7、 电缆接头不规造成触电失火。Joint of cable done unqualified cause 8、 用电量过载造成失火。Over loading of the quanti

11、ty of electricity using cause fire 1、 不合格的吊车吊具造成人员受伤、机械损坏unqualified crane rigging cause injury and machinery getting bad2、 不合格的司机、指挥人员造成人员受伤、机械损坏unqualified driver and conductor cause injury and machinery getting bad 3、 对无关人员的伤害injury to others 4、 吊车倾倒造成人员受伤、机械损坏the crane raved over cause injury an

12、d machinery getting bad5、 吊物伤人,破坏机械设备lifting injury, mechanic equipment turning wrong6、 沟通不够伤人not enough munication lead to injury7、 交通事故traffic accident8、 吊物捆绑不牢伤人injury by uptight lifting object9、 索具损坏断裂伤人injury by bad rigging1、 适宜的劳保用品造成人员伤害injury by unfit PPE 2、 焊光容易灼伤人的眼、脸eye and face injury ea

13、sily caused3、 氧气、乙炔泄露引起失火、爆炸fire and e*plosion caused by leakage of o*ygen ethane.4、 焊条及焊条头未回收造成对土壤污染soil pollution by not recycling the welding rod.5、 焊机漏电造成触电electricity machinery6、 电弧焊造成灼伤,应设置挡板arc injury, set arc screen1、 电工必须持证上岗,非电工严禁从事电工作业。设警告标识electrical operator should work with license, no

14、n-electrical operator couldnt do electrical work. Setting warning signs.2、 操作时设警告标识,戴绝缘手套,一人看护一人操作。Setting warning signs, wearing insulated gloves, one operates the other one standing by during operating.3、 电工必须正确佩戴PPE,选择电工专用工具。Electrical operator must wear proper PPE , choose the special tools.4、 配

15、电箱、电缆必须有合格证,必须符合国家用电规。Distribution bo* and cable and cable must be qualified and fit for the rules of temporary electricity in our country 5、施工用电,配电箱、电缆必须经过IIP、HSE检查合格方能使用。配电箱必须设接地,离地不得低于50CM。严格按照三级配电二级漏电保护。电缆离地大于2.5M。construction electricity ,distribution bo* and cable should be used after acceptan

16、ce by IIP HSE. Distribution bo* must join to the ground with the distance no less than 50CM, strictly according to 3rd distribution no less than 2nd leakage protection .cable is 2.5CM high from the ground.6、 缆用绝缘瓷瓶或木方,与钢性物质隔离。The cable should be insulated with steel material by insulated stoneware o

17、r wood.7、 电缆接头必须用防水插头或用绝缘防水胶布包裹严密。The cable joint must be tied tightly with waterproof switch or insulated adhesive plaster.8、符合临时用电设计要求,用电量大于50KW或5台以上用电设备,必须有施工用电组织设计。Fit for the requirement of temporary electricity . if the quantity of electricity use is more than 50KM,or the quantity of electrici

18、ty equip. is more than 5, there will be design for construction electricity.1、 所有的吊车、砼泵车吊装索具、钢丝绳必须经IIP HSE检查合格前方可使用all the riggings, ropes of the vehicles must be accepted by IIP HSE.2、 吊车司机、起重工必须持证上岗,并经过IIP HSE部门培训方可上岗。All the operator with licenses starts to work after being trained by IIP HSE .3、

19、 吊装作业区域设戒备线、警告表示,派专人监护,无关人员严禁入。吊车旋转半径、吊臂下严禁站人setting cordon and warning signs in the lifting area. No permit no entering. No standing person under the crane vehicles.4、 吊装前首先检查地基结实、吊装支腿下设垫木、垫板,吊装设备要每日检查,每日填写检查表,吊车的重量符合吊车的起重重量。Check the ground foundation firmly , the slab under the crane leg .crane e

20、quipment must checked everyday . and writing check table everyday. The weight of crane must fit for the vehicles lifting weight.5、 吊装时吊物要设溜绳setting tag line when doing lifting work.6、 起重工必须指挥信号清楚,司机的视线清晰the operator should give clear signals and the driver should see forward clearly.7、 吊车按照施工现场行使路线行

21、使,车辆限速10公里/小时vehicles should be driven according to IIP requirement, the ma*im speed within 10KM per hour.8、 吊运前要检查吊物捆绑是否结实check the material whether it is tide tightly before lifting.9、 吊运前要检查索具、吊绳是否符合IIP标准,check the riggings and slings whether they are fit for the standard of IIP ,using after havi

22、ng tag. Change them if turning bad.1、 作业人员必须经IIP HSE 培训持证上岗,超过1.8米配戴平安带,平安带要捆绑在结实物体构件上,平安带高挂低用。All the operators with license should be trained by IIP HSE , safety belt shall be hung on the firm member at high place if the work height is more than 1.8m2、 作业时必须申请办理PTW 热工作许可证,设置灭火器,派专人看火,看火人员严禁脱岗。配戴正确

23、的 PPE 面罩,设弧光挡板。Obtain PTW hot work permit prior to mence to work, e*tinguisher should be set at work area, full-time watchman should be at site during working . wearing right PPE , face shield ,setting arc shield.3、 氧气、乙炔运输时必须捆绑结实分别运输,吊运时用吊笼,氧气、乙炔应分类放置,放置必须结实,放置距离必须大于8米。O*ygen ethane cylinder should

24、 be transferred separately and tied, lifting cage shall be used when lifting , the distance between two kind of gas should be more than 8m and should be put on the firm pad.4、 氧气、乙炔设回火装置,每天使用前检查乙炔、氧气瓶胶带、阀门、压力表是否有泄露现象,平安阀、压力表平安指数是否正常,焊枪是否堵塞,都必须经检查合格正常前方可使用。Retro-fire system shall set at o*ygen Ethane

25、, check leakage of adhesive ribbon, valve pression meter and safety inde* of safety valve pression meter and block barrier in the welding gun before used. 5、 焊接前检查配电箱漏电开关是否正常,电焊机试运转,待运转正常前方可投入使用。Check all the leakage switch in the distribution bo*, welding machine shall run prior to mence to weld.6、 焊接作业前,要检查作业现场是否有易燃易爆品,如有应处理完毕前方可使作业。Deal with all e*plosive flammables at word yard prior to weld.7、 作业完毕后要把焊条、电焊头及时清理干净。焊条必须专门回收。Cleaning all the welding rod immediately after work pleting. And the welding rod should be recycled. z.

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。