Risk Assess Report

Risk Assess Report

《Risk Assess Report》由会员分享,可在线阅读,更多相关《Risk Assess Report(3页珍藏版)》请在装配图网上搜索。

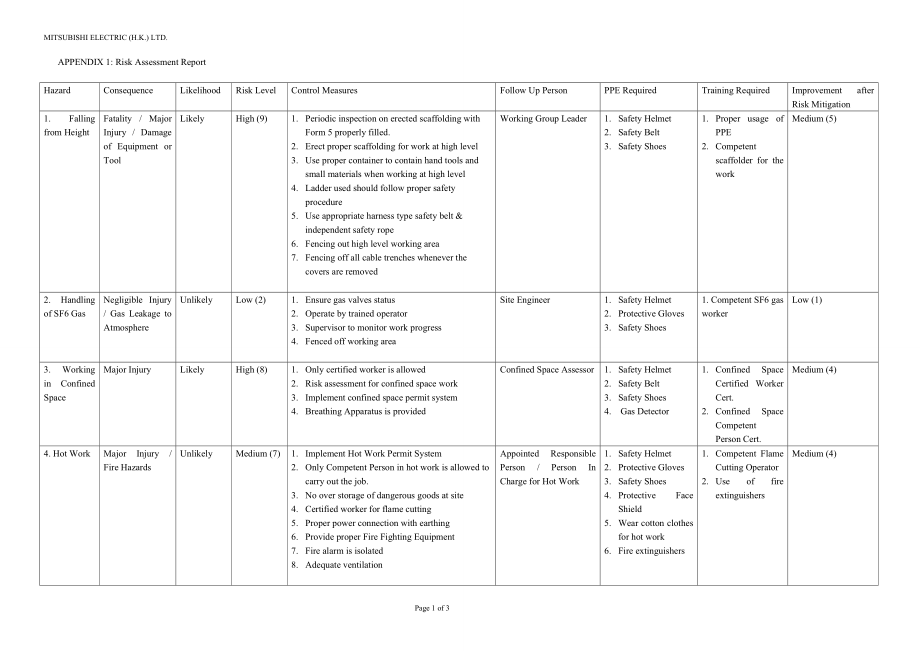

1、MITSUBISHI ELECTRIC (H.K.) LTD.APPENDIX 1: Risk Assessment Report HazardConsequenceLikelihoodRisk LevelControl MeasuresFollow Up PersonPPE RequiredTraining RequiredImprovement after Risk Mitigation1. Falling from HeightFatality / Major Injury / Damage of Equipment or Tool LikelyHigh (9)1. Periodic i

2、nspection on erected scaffolding with Form 5 properly filled.2. Erect proper scaffolding for work at high level3. Use proper container to contain hand tools and small materials when working at high level4. Ladder used should follow proper safety procedure5. Use appropriate harness type safety belt &

3、 independent safety rope6. Fencing out high level working area7. Fencing off all cable trenches whenever the covers are removedWorking Group Leader1. Safety Helmet2. Safety Belt3. Safety Shoes1. Proper usage of PPE2. Competent scaffolder for the workMedium (5)2. Handling of SF6 GasNegligible Injury

4、/ Gas Leakage to AtmosphereUnlikelyLow (2)1. Ensure gas valves status2. Operate by trained operator3. Supervisor to monitor work progress4. Fenced off working areaSite Engineer1. Safety Helmet2. Protective Gloves3. Safety Shoes 1. Competent SF6 gas workerLow (1)3. Working in Confined SpaceMajor Inju

5、ryLikelyHigh (8)1. Only certified worker is allowed2. Risk assessment for confined space work3. Implement confined space permit system4. Breathing Apparatus is providedConfined Space Assessor1. Safety Helmet2. Safety Belt3. Safety Shoes4. Gas Detector1. Confined Space Certified Worker Cert.2. Confin

6、ed Space Competent Person Cert. Medium (4)4. Hot WorkMajor Injury / Fire Hazards UnlikelyMedium (7)1. Implement Hot Work Permit System2. Only Competent Person in hot work is allowed to carry out the job.3. No over storage of dangerous goods at site4. Certified worker for flame cutting5. Proper power

7、 connection with earthing6. Provide proper Fire Fighting Equipment 7. Fire alarm is isolated8. Adequate ventilationAppointed Responsible Person / Person In Charge for Hot Work1. Safety Helmet2. Protective Gloves3. Safety Shoes4. Protective Face Shield5. Wear cotton clothes for hot work6. Fire exting

8、uishers1. Competent Flame Cutting Operator2. Use of fire extinguishersMedium (4)HazardConsequenceLikelihoodRisk LevelControl MeasuresFollow Up PersonPPE RequiredTraining RequiredImprovement after Mitigation5. Lifting Major Injury / Damage of Equipment UnlikelyMedium (7)1. All L.A. & L.G. shall be in

9、spected & tested by Competent Person periodically2. All L.A. & L.G. shall be checked before use3. All L.A. & L.G. shall be inspected weekly (Form 1)4. All load shall be estimated before lifting to ensure no overload of L.A. & L.G.5. Assigned person in charge & experienced riggerLifting Group Leadera

10、. Safety Helmetb. Protective Glovesc. Safety Shoes1. Certification of Crane OperatorMedium (4)6. HandlingChemical SubstancesMinor Injury / Unexpected Chemical Reactions UnlikelyMedium (6) 1. Provide MSDS2. No over storage at site3. Proper PPE shall be used4. Isolate chemical substances from other ma

11、terials Working Group Leader1. Safety Helmet2. Safety Belt3. Safety Shoes4. Protective Gloves5. Protective GogglesLow (3)7. Electrical AppliancesMajor Injury / Fire HazardsUnlikelyMedium (7)1. Lock & Tag System2. Provide RCB for portable electrical appliance3. Periodic maintenance of electrical equi

12、pment4. No overloading of supply pointsSite Engineer1. Safety Helmet2. Protective Gloves3. Safety Shoes 1. Appointed responsible REW for the main switchboard Medium (4)8. Connection to existing equipment Major Injury /Damage to Equipment Highly UnlikelyMedium (6)1. Permit to Work System2. Protection

13、 of existing equipment in the vicinity of work area3. Fenced off working zoneSite Engineer1. Safety Helmet2. Safety Belt3. Safety ShoesLow (3)9. Multi-core Cable Laying WorkMinor Injury UnlikelyMedium (6)1. Define cable route2. Assigned experienced work group leader3. Assigned adequate man powerWork

14、ing Group Leader1. Safety Helmet2. Protective Gloves3. Safety ShoesLow (3)10. Multi-core Cable Termination WorkMinor Injury UnlikelyMedium (6)1. Define destination panel for termination2. Isolate power supply 3. Isolate other live part that cannot be made deadWorking Group Leader1. Safety Helmet2. P

15、rotective Gloves3. Safety Shoes4. Protective GogglesLow (3)HazardConsequenceLikelihoodRisk LevelControl MeasuresFollow Up PersonPPE RequiredTraining RequiredImprovement after Mitigation11. Manual Handling OperationMinor InjuryLikelyMedium (7)1. Carry out manual handling operation assessmentWorking G

16、roup Leader1. Safety Helmet2. Protective Gloves3. Safety Shoes4. Protective Goggles Low (3)12. Live WorkMajor InjuryUnlikelyMedium (7)1. Isolation of live parts with warning notice posted at operating device to prevent interferenceSite Engineer1. Safety Helmet2. Protective Gloves3. Safety Shoes4. Pr

17、otective Goggles1. Appointed responsible REW to lead the working team.Low (3)13. Lifting in the proximity of Live circuitsMajor Injury / Damage Due to Existing of High Voltage Equipment UnlikelyMedium (7)1. Location of mobile crane and extend of crane movement should be agreed with HEC in advance to

18、 maintain a safe clearance with the Live equipment2. Demarcation of work area of the mobile crane to maintain the required safe clearance 3. Watchman is assigned to monitor the movement of the crane within the designated work area Site Engineer1. Safety Helmet2. Protective Gloves3. Safety Shoes4. Pr

19、otective Goggles5. Reflective Vest1. Certification of Crane OperatorLow (2)Risk MatrixLikelihoodConsequenceVery LikelyLikelyUnlikelyHighly UnlikelyFatalityHigh Risk (10)High Risk (9)High Risk (8)Medium Risk (7)Major InjuryHigh Risk (9)High Risk (8)Medium Risk (7)Medium Risk (6)Minor InjuryHigh Risk (8)Medium Risk (7)Medium Risk (6)Low Risk (3)NegligibleMedium Risk (5)Medium Risk (4)Low Risk (2)Low Risk (1)Legend:Acceptable Risk LevelPage 3 of 3

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。