锅炉中部钢架安装记录最终版

锅炉中部钢架安装记录最终版

《锅炉中部钢架安装记录最终版》由会员分享,可在线阅读,更多相关《锅炉中部钢架安装记录最终版(6页珍藏版)》请在装配图网上搜索。

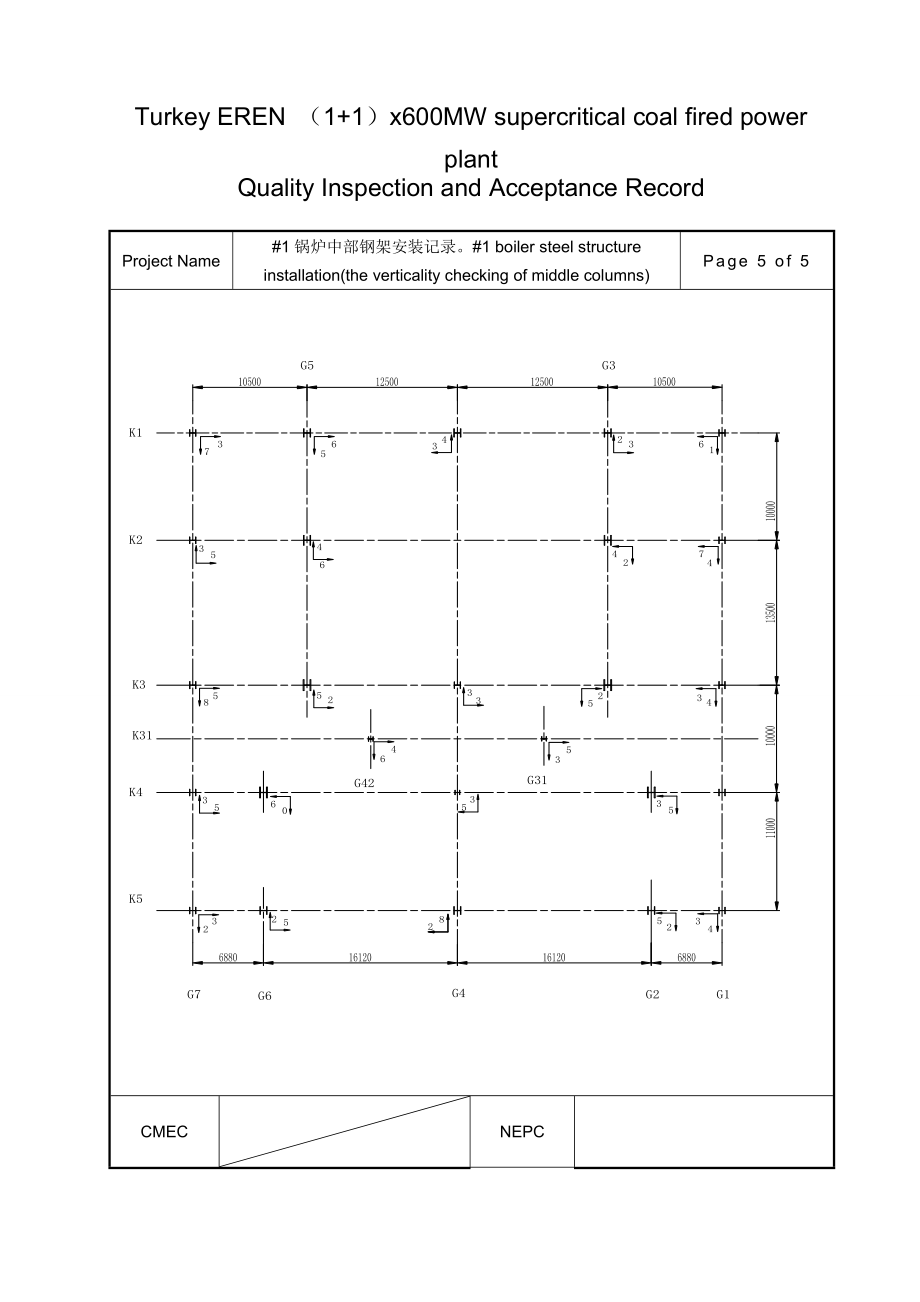

1、Turkey EREN (1+1)x600MW supercritical coal fired power plantQuality Inspection and Acceptance Record Project Name#1锅炉中部钢架安装记录。#1 boiler steel structure installation(the verticality checking of middle columns)Page 5 of 5CMECNEPCNEPCNEPCTurkey EREN (1+1)x600MW supercritical coal fired power plantQuali

2、ty Inspection and Acceptance Record Project Name#1锅炉中部钢架安装记录。#1 boiler steel structure installation( diagonal checking of middle column elevation 41m) Page 4 of 5CMECNEPCNEPCNEPCTurkey EREN (1+1)x600MW supercritical coal fired power plantQuality Inspection and Acceptance Record Project Name#1锅炉中部钢架安

3、装记录。#1 boiler steel structure installation(space checking of middle columns elevation 41m axis G ) Page 3 of 5CMECNEPCNEPCNEPCTurkey EREN (1+1)x600MW supercritical coal fired power plantQuality Inspection and Acceptance Record Project Name#1锅炉中部钢架安装记录。#1 boiler steel structure installation(space che

4、cking of middle columns elevation 41m axis K ) Page 2 of 5CMECNEPCNEPCNEPCTurkey EREN (1+1)x600MW supercritical coal fired power plantQuality Inspection and Acceptance Record Project Name#1锅炉中部钢架安装记录。#1 boiler steel structure installation(steel structure checking and installation) Page 1 of 51.appea

5、rance of the equipment: no crack, severe corrosion, damage.2.factory welding: no slag, porosity and other defects.ponent material: no misuse.4.the deviation of column, beam length comply with manufacturers technical documentation requirements, maximum 8 mm.5.column curvature 1 / 1000 (column length)

6、, the maximum is 7 mm6.column deviation turn value 1 / 1000 (column length), the maximum 8 mm, in line with requirements.7.beam deflection, and lateral bending of values: 17mm ,deviation is less than 1.5 mm.9. bolt hole ellipticity deviation is less than 1.5mm10.The bolts and nuts has no cracks and

7、bumps, threads are complete without grease, rust and other attachments.11.The bolts, nuts and washers are the line with equipment, technical documentation requirements.12.The node friction joints surface comply with equipment technical documentation requirements.Clean rust ,grease and dust without d

8、istortion, bending, burrs and other defects.13.Engagement plates are installed flatly, position is correctly, and structures is close.14.The maximum relative displacement of beam and column centers is 2 mm .15.The maximum parallel deviation between beams is 3 mm.16.The maximum elevation deviation of

9、 beam is 3 mm .17.The maximum horizontal deviation of beam is 2 mm.18.The maximum space deviation of beam is 3 mm.19.The steel bolt tightening torque of each node all comply with manufacturers technical documentation requirements: M16 initial screw torque is 130N.m; final screw torque end with the c

10、inquefoil shape nut off, final pre-tension is 100KN. M22 initial screw torque is 340N.m; final screw torque end with the cinquefoil shape nut off, final pre-tension is 190KN. M24 initial screw torque is 440N.m; final screw torque end with the cinquefoil shape nut off, final pre-tension is 225KN. M27 initial screw torque is 670N.m; final screw torque is 1200 N.m, final pre-tension is 290KN.CMECNEPCNEPCNEPC

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。