2022年APQP经典文件

2022年APQP经典文件

《2022年APQP经典文件》由会员分享,可在线阅读,更多相关《2022年APQP经典文件(57页珍藏版)》请在装配图网上搜索。

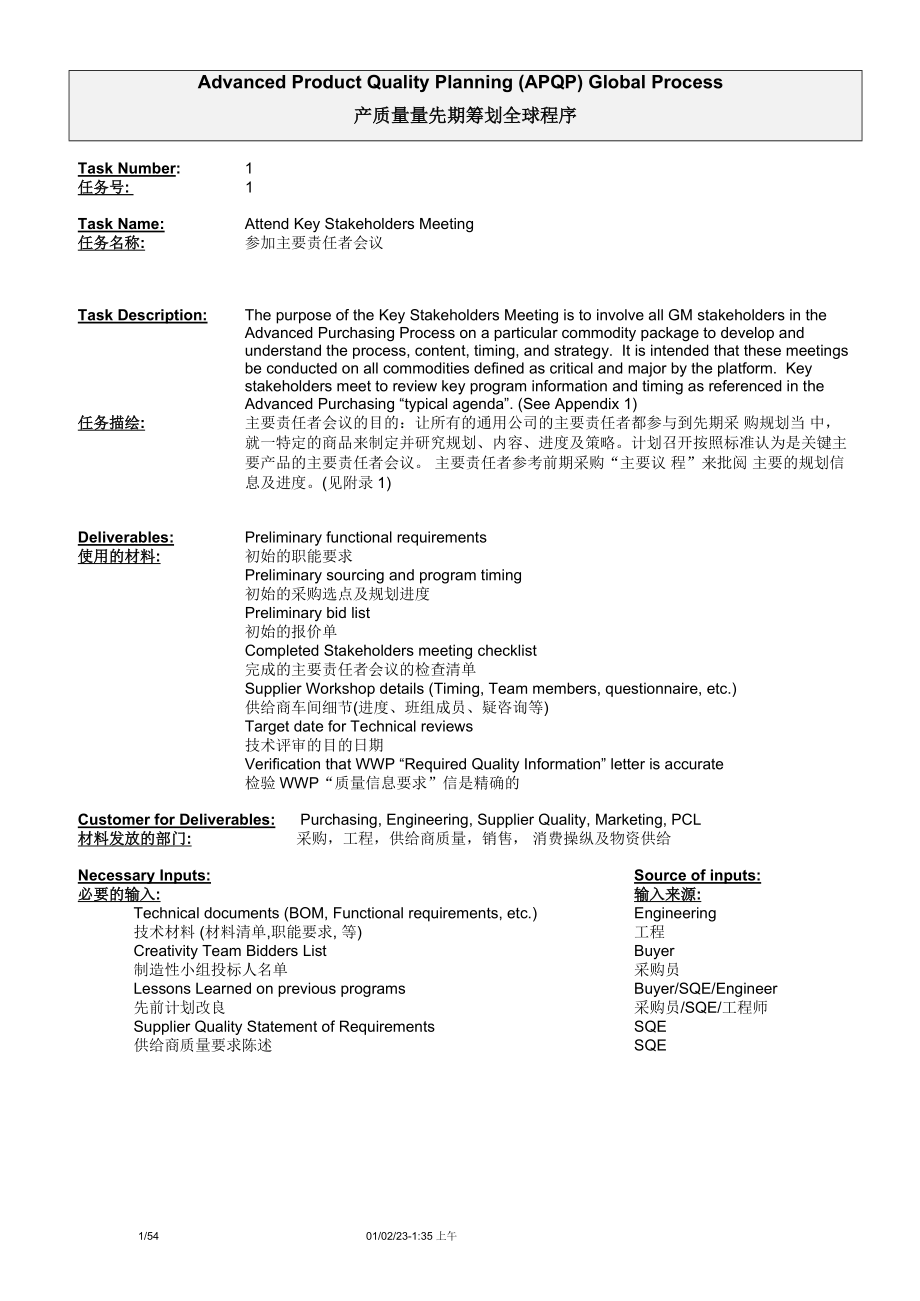

1、 Advanced Product Quality Planning (APQP) Global Process产质量量先期筹划全球程序Task Number:1任务号: 1Task Name:Attend Key Stakeholders Meeting任务名称:参加主要责任者会议Task Description:The purpose of the Key Stakeholders Meeting is to involve all GM stakeholders in the Advanced Purchasing Process on a particular commodity pa

2、ckage to develop and understand the process, content, timing, and strategy. It is intended that these meetings be conducted on all commodities defined as critical and major by the platform. Key stakeholders meet to review key program information and timing as referenced in the Advanced Purchasing “t

3、ypical agenda”. (See Appendix 1)任务描绘:主要责任者会议的目的:让所有的通用公司的主要责任者都参与到先期采 购规划当 中,就一特定的商品来制定并研究规划、内容、进度及策略。计划召开按照标准认为是关键主要产品的主要责任者会议。 主要责任者参考前期采购“主要议 程”来批阅 主要的规划信息及进度。(见附录1)Deliverables:Preliminary functional requirements使用的材料:初始的职能要求Preliminary sourcing and program timing初始的采购选点及规划进度Preliminary bid list

4、初始的报价单Completed Stakeholders meeting checklist 完成的主要责任者会议的检查清单Supplier Workshop details (Timing, Team members, questionnaire, etc.)供给商车间细节(进度、班组成员、疑咨询等)Target date for Technical reviews技术评审的目的日期Verification that WWP “Required Quality Information” letter is accurate检验WWP“质量信息要求”信是精确的Customer for Deli

5、verables:Purchasing, Engineering, Supplier Quality, Marketing, PCL材料发放的部门: 采购,工程,供给商质量,销售, 消费操纵及物资供给Necessary Inputs:Source of inputs:必要的输入:输入来源:Technical documents (BOM, Functional requirements, etc.)Engineering技术材料 (材料清单,职能要求, 等)工程Creativity Team Bidders ListBuyer制造性小组投标人名单采购员Lessons Learned on pr

6、evious programsBuyer/SQE/Engineer先前计划改良采购员/SQE/工程师Supplier Quality Statement of RequirementsSQE供给商质量要求陈述SQETask Number:1 continured任务号: 1 续Task Name:Attend Key Stakeholders Meeting任务名称:参加主要责任者会议Resources:Purchasing, Supplier Quality, Engineering 来源:采购,供给商质量,工程Methodology:方法: Buyer indicates estimate

7、 of timing for Key Stakeholder Meeting in the Advanced Purchasing Planning calendar. 采购员指出先期采购计划时间表上主要责任者会议的进度 Buyer sends invitation to SQE prior to meeting. 采购员在会议开场前将邀请送到SQE SQE participates in meeting. SQE 参加会议 Key stakeholders review program information and timing. 主要的责任者批阅规划信息及进度SQE Responsibi

8、lity:SQE 责任: Clarify the role of the SQE in the sourcing process. 说明SQE在选点过程中的作用. Obtain knowledge of what is being sourced (functional aspects of part) 获取正在选点的部件的知识 (零件的关键部分) Obtain knowledge of timing (sourcing and program) 获取进度知识 (选点及规划) Review Creativity Team Bidders List - Identify suppliers to

9、 remove based on SQE knowledge of their capability. 批阅 制造性小组投标人名单-依照SQE对供给商消费才能的理解来确定删除的供给商名单 Confirm “Make or Purchase” (MOP) coding has been done for modules/integrated packages (Should accompany SOR) 确认已完成的模具/集成包装有“制造或购置”(MOP)的符号(应附有SOR)。 Inquire about any sequencing plans 询咨询后续的任何计划 Provide SQ q

10、uestions to be included in the Pre-Workshop questionnaire. 提供包括在入厂前调查单的SQ咨询题 Provide overview of lessons learned. (Appendix 18) 提供改良的概览(附录 18) Complete checklist. (Appendix 2 ) 完好的检查单 (附录2 )Task Number:1 continured任务号: 1 续Task Name:Attend Key Stakeholders Meeting任务名称:参加主要责任者会议Additional Information:

11、补充信息:Appendix 1 - Typical Agenda Stakeholders Meeting附录 1 典型议程 主要责任者会议Appendix 2 - Stakeholders Meeting Checklist附录 2 主要责任者会议检查单Appendix 18 Lessons Learned Overview Presentation附录18 改良整体展示Task Number:2任务号:2Task Name:Attend the Technical review任务名称:技术评审Task Owner: Buyer facilitates the meeting. SQE p

12、articipates.任务负责人: 采购员主持会议。SQE参加。Task Timing:Pre-sourcing任务进度:采购决定前Task Description:任务描绘:The Technical Review is a meeting attended by the supplier, buyer, engineer, SQE, with representation from other pertinent organizations. The purpose of the meeting is to review any item related to the manufactu

13、rability of the part, including timing, design, manufacturing capability, packaging, etc. The “APQP Open Issues List” (Appendix 3 ) will be started at this meeting with items that are identified as concerns related to the suppliers ability to meet the quality expectations.技术评审是供给商、采购员、工程师、SQE 及其他相关部

14、门的代表参加的会议。会议的 目的是审核与零部件消费才能相关的任何工程,包括进度、设计、消费才能、包装等。“APQP 未处理咨询题单” (附录3)将从本次会议开场,议题为经确认与供给商满足质量要求的才能有关的工程。Deliverables:使用的材料:A. Identification of suppliers that should not continue in the sourcing process.A. 确认采购计划当中不应接着进展下去的供给商B. Initial Risk Assessment for appropriate suppliersB. 初始风险评估以确定适当的供给商C.

15、 Initial Concerns list C. 初始咨询题清单Customer for Deliverables:材料发放的部门:A - BuyerA - 采购员B SQE B - SQEC - SQE, PDTC - SQE, PDTTask Number:2 continued任务号:2 续Task Name:Attend the Technical review任务名称:参加技术评审Necessary Inputs:Source of inputs:必要的输入:输入来源:Technical documentsEngineering技术文件工程Quality History (Supp

16、lier Quad Report if available)SQE质量历史 (供给商 Quad 报告,假如适用) SQEPreliminary timing chartsSupplier初始进度表供给商Information on the manufacturing facility(Location, capacity, etc)Supplier消费设备的信息(地点,才能等)供给商Preliminary process flow diagramsSupplier初始工艺流程表 供给商Warranty Risk and Reward PlanSupplier保修风险及报答计划供给商Prelim

17、inary Control plans Supplier初始操纵计划 供给商Manufacturing site organizational chart Supplier消费厂家组织构造图供给商Tier 2 management Supplier2级供给商治理 供给商Capability studies on similar parts Supplier类似零件功能研究 供给商Major disruptions, PR/Rs and PPM Reduction PlansSupplier主要缺陷,PR/R 及百万分之废品率减少计划供给商Serial Tooling / Checking Eq

18、uipment SheetSupplier系列工装 /检查仪器单供给商Checking fixture planSupplier检查夹具计划供给商Prototype planSupplier样件计划供给商Continuous Compliance testing PlanSupplier持续一致测试计划供给商Preliminary PFMEA Supplier初始工艺失效方式及后果分析供给商Proof of QS9000 certification / Implementation planSupplier证明有获得QS9000证书及执行的计划供给商Description of operato

19、r-training programSupplier描绘操作人员培训计划供给商Plan for communication between technical support and manufacturing plantSupplier技术支持及消费厂家之间的的交流计划供给商Team Feasibility Commitment (Required by QS-9000 )Supplier团队可行性承诺(QS9000所要求)供给商Error Proofing/Poke-Yoke TechniquesSupplier错误预防/因果图技术供给商Lessons Learned Overview s

20、lidesSQE改良一览幻灯片SQETask Number:2 continued任务号:2 续Task Name:Attend the Technical review任务名称:参加技术评审Resources:Purchasing, Engineering, Supplier Quality, Supplier来源:采购,工程, 供给商质量, 供给商 Methodology:方法: Supplier addresses topics related to timing, design capability (if applicable), manufacturability of the p

21、art as designed, quality processes, packaging, and transportation. 供给商 讲述与如下内容有关的议题:进度,设计才能(如适用), 所设计的零部件消费才能,质量工艺, 包装及运输。 Supplier addresses the specific quality topics listed in the RFQ. (See Appendix 3 - WWP “Required Quality Information”.) 供给商 讲述RFQ所列的详细的质量议题。(见附录3-WWP“质量信息要求”) Supplier provides

22、 Team Feasibility Commitment (Appendix 5), Serial Tooling / Equipment Checklist (Appendix 6), and signed Supplier Quality SOR sheet (Appendix 4) 供给商 提供小组可行性承诺(附录5),系列工具/仪器检查清单(附录6),签署的供给商质量SOR单(附录4) SQE reviews expectations relative to Lessons Learned. SQE 批阅与改良相关的期望事务. At the conclusion of the Tech

23、nical Review, the Buyer, SQE and Engineer complete the Risk Assessment. 技术评审完毕时,采购员,SQE及工程师一起完成风险评估 。SQE Responsibility:SQE 责任: Ask questions relative to quality and any issues related to the manufacturability of the component. 询咨询与质量有关的咨询题,以及与零部件消费才能相关的任何议题。 Ask questions pertaining to the supplier

24、s responses to items requested in the quality portion of the RFQ package. 就与RFQ材料中质量部分要求供给商反应的工程来询咨询相关的咨询题 Provide a five minute overview of the Lessons Learned Process 提供五分钟的改良的过程概况 Participate in the Risk Assessment. 参加风险评估.Task Number:2 continued任务号:2 续Task Name:Attend the Technical review任务名称:技术

25、评审Supplier Responsibilities:供给商责任: Prior to the Technical Review, the supplier must provide responses to all quality related information that is requested in the WWP “Required Quality Information” letter that has been included in the RFQ package.If this information is not received prior to the Techn

26、ical Review, the supplier must submit this information prior to the sourcing decision. 在技术评审前,供给商必须提供与质量相关的信息的反应,这是WWP“质量信息要求”信中所要求的。这封信附在RFQ包裹中。如在技术评审前未收到该信息,则供给商应在采购决定前提交该信息。 If time permits at the technical review, the supplier must review the following information: 技术评审时假如时间同意,供给商必须批阅如下信息。1. Pre

27、liminary timing charts. Supplier will highlight any concerns relative to tooling / testing that may impact providing a quality process/part on time. 初始进度表。供给商应高度注重妨碍按时提供质量工艺/部件的工装/试验的相关咨询题。2. Review of the manufacturing facility. Where is it located? How long has it been in operation? What modificat

28、ions to the facility would be required to support the RFQ volumes?批阅消费设备。设备的位置在哪里?要做怎么样的改动才能满足RFQ产量?3. The time frame of the last review by a General Motors SQE.通用公司的SQE最后一次批阅的时间框架。4. Preliminary process flow diagrams. (Including any special assembly techniques, test methods, and containment procedu

29、res used)初始工艺流程图(包括特别的装配工艺,测试方法,及使用的遏制程序.)5. Warranty Risk and Reward Plan. (If indicated by the GM buyer as a risk reward commodity). Plans in place to meet the IPTV targets. Capability studies on similar parts, along with plans for error proofing, data analysis, and record keeping must be included

30、 in plan.保修风险及报答计划(假如通用公司的采购员指出这是风险与报答并存的商品)。已有计划来满足IPTV目的同时该计划应包括类似零件的功能研究,纠错计划,数据分析以及保存的记录。 The supplier will also receive in the RFQ package, a GM Supplier Quality SOR. This document is a reference and brief explanation of the automotive quality requirements plus GM specific quality requirements.

31、 The supplier is expected to be familiar with all processes and procedures listed in this document . The last page of the Supplier Quality SOR must be signed and submitted to the SQE at the Technical review. 供给商 将收到RFQ包裹中的通用公司供给商质量SOR。该文件是汽车质量要求及通用公司特别质量要求 的参考及简要介绍。希望供给商熟悉本文件中的所有工艺及计划。供给商质量SOR的最后一页必

32、须签字 并在技术评审时交给SQE。Additional Information:补充信息:Appendix 8 - Common APQP Open Issues List附录 8 通用性APQP 未处理咨询题单Appendix 3 - Common WWP “Required Quality Requirements”附录 3 通用性 WWP “强迫质量要求”Appendix 4 - Common Supplier Quality SOR附录 4 通用供给商质量 SORAppendix 5 - Team Feasibility Commitment and Feasibility attac

33、hment附录 5 小组习惯性承诺及习惯性附件Appendix 7 - Common WWP Early Warning Risk Assessment附录 7 通用性WWP早期警告风险评估Appendix 6 - Serial Tooling / Equipment Checklist附录 6 系列工装 /仪器检查单Task Number:3任务号:3Task Name:Conduct a Risk Assessment任务名称:进展风险评估Task Owner: Buyer initiates initial risk assessment with support from SQE an

34、d Engineer.任务负责人:在SQE及工程师的协助下,采购员着手做初始风险评估。Updates to the risk assessment are completed by the SQE.SQE完成风险评估的最新信息。Task Timing:Initial assessment prior to sourcing任务进度:采购决定前进展初步评估Second assessment in the prototype timeframe在消费样件期间进展第二次评估Task Description:任务描绘:Risk assessment is a tool to assess the po

35、tential for problems early in the vehicle development process, and to determine which parts and/or suppliers will require additional focus by General Motors. It is intended that the assessment be conducted on all new parts / suppliers. 风险评估是在汽车开发阶段前期用来评估可能出现咨询题的工具,并决定哪些零部件及/ 或供给商需要通用公司特别留意。所有的新部件/供给

36、商都将被评估。The Buyer, Engineer and the SQE complete the Risk Assessment Form prior to source selection. The SQE must update the risk assessment at least once. (Near the Prototype build event)采购员,工程师, SQE 在采购选择前填好风险评估表。SQE 至少将风险评估的信息更新 一次(接近样件消费时) The form is a one page document with clear instructions p

37、rinted on the back of the form or as a second page. The directions provide detail for the category rankings. 表格为一页文件,背面印有明确的指导说明或可作为第二页。说明提供了分类标准的详细信息。Deliverables:A completed Risk Assessment Form for each part.使用的材料:每一零部件都有一填好的风险评估表。 Information will be housed in the GQTS system under “Risk Assessm

38、ent” 信息存在GQTS系统下的“风险评估” Initial assessment will be available for review at sourcing meeting 初始评估可在采购决定会议上批阅。 A level of risk for each supplier. 每一供给商都有一风险等级。Task Number:3 Continued任务号:3 续Task Name:Participate in the Risk Assessment process.任务名称:参加风险评估程序Customer for Deliverables:Supplier Quality, Pur

39、chasing, PDT材料发放的部门: 供给商质量,采购, PDTNecessary Inputs:Source of inputs:必要的输入:输入来源:Technical documentsEngineering技术文件工程Design stabilityEngineering设计稳定性工程Supplier s technical capabilitySupplier/Engineering供给商 技术才能供给商/工程Suppliers manufacturing process capability on similar partsSupplier/SQE供给商类似件的消费工艺才能供给

40、商/SQESuppliers past quality history and performance reports SQE/supplier供给商过去的质量记录及表现报告 SQE/供给商Suppliers manufacturing site informationSupplier/Buyer供给商消费场地信息供给商/采购员Suppliers sub-tier supplier planSupplier/Buyer供给商的下层供给商计划供给商/采购员QS-9000 statusSupplier/Buyer/SQEQS-9000 状态供给商/采购员/SQEPreliminary DFMEA,

41、 PFMEA, and Flow DiagramSupplier/SQE初始 DFMEA, PFMEA, 及流程图供给商/SQEHistorical program management experience by supplierSQE(Launch history, lessons learned, etc.)供给商提供的计划治理经历SQE(投产历史,经历教训等)Complexity of management structureBuyer治理层构造的复杂性采购员Regional SQ support availabilitySQE是否可获得地区供给商质量的支持SQECapacity of

42、 systemSupplier /Buyer /SQE系统才能供给商/采购员/SQECustomer Impact of partEngineer/SQE顾客对零部件的妨碍工程师/SQEPotential Supplier Assessment (PSA)SQE/Team潜在供给商评估 (PSA)SQE/小组Task Number:3 Continued任务号:3 续Task Name:Participate in the Risk Assessment process.任务名称:参加风险评估程序Resources:Purchasing, Supplier Quality, Engineeri

43、ng and supplier.来源:采购, 供给商质量, 工程及供给商.Methodology:方法:The first risk assessment is conducted prior to the sourcing decision. 第一次风险评估在采购决定前完成 If a Technical Review is held, the risk assessment is conducted directly following this review. The Buyer, SQE and Engineer evaluate the information presented th

44、roughout the sourcing process by the supplier and evaluate that information as it applies to the questions on the risk assessment form.假如进展技术评审,则评审后立即完成风险评估。采购员、SQE及工程师评估由供给商在采购过程当 中提供的信息。并评估适用于风险评估表上咨询题的信息。 If the buyer does not conduct a Technical Review, the Buyer has the responsibility to contac

45、t the SQE and Engineer for their joint input in completing the risk assessment.假如采购员没完成技术评审,采购员有责任联络SQE及工程师来共同完成风险评估。The risk assessment must be updated at least once prior to the prototype build event.在样件消费前,至少将风险评估更新一次SQE Responsibility:SQE 责任: Participate in the initial risk assessment process at

46、 the time of the technical review.技术评审时,参加初始的风险评估。 Determine the appropriate level of APQP follow-up and Run Rate based on the risk level- High risk will have customer-monitored APQP and Run Rate- Medium and low risk can be either customer or supplier-monitored for APQP or Run Rate (discretion of SQ

47、E) 依照风险大小决定APQP跟进措施的适当水平及按节拍消费- 高风险将施行客户监视来进展APQP及按节拍消费- 中等风险或低风险将施行客户监视或者供给商监视来进展APQP获按节拍消费(按照SQE的意见) Update the risk assessment a second time prior to Program Review #2, which is targeted near the Prototype build event. 在计划批阅2之前将风险评估进展第二次更新,应在接近样件消费时完成。 Adjust APQP and Run Rate plan based on chang

48、es in the risk level. 依照风险程度的变化来调整APQP及按节拍消费。Supplier Responsibilities:供给商责任:Provide all necessary data required to evaluate risk prior to sourcing. (See necessary inputs)采购决定前评估风险,提供所有要求的必要数据 (见必要的输入)Additional Information:补充信息:Appendix 7 - Common WWP Risk Assessment Form附录 7 通用 WWP 风险评估表Task Numbe

49、r:4任务号:4Task Name:Supplier Program Reviews 任务名称:供给商 计划批阅Task Owner: Supplier 任务负责人: 供给商Task Timing:Four reviews as shown on APQP Project Plan任务进度:APQP 工程计划所示的四次批阅Task Description:The purpose of the Supplier Program Reviews is to review the APQP Project Plan and track the status and progress for item

50、s listed on the APQP timing chart. These reviews are conducted on all parts tracked as customer-monitored APQP and are intended to identify GM and supplier issues that require resolution. 任务描绘: 供给商计划批阅的目的是批阅APQP工程计划并跟踪APQP时间进度表所列工程的状态及进展。批阅的内容为顾客监视的APQP所跟踪的所有零部件,目的为确认需要GM与供给商处理的议题。Deliverables:Updat

51、ed APQP Timing Chart and APQP Open Issues List (See Appendix 8and 9) 使用的材料:更新过的 APQP 进度表及APQP未处理咨询题单 (见附录 8及 9)Customer for Deliverables:SQE, Buyer, Product Engineer, Readiness Coordinator材料发放的部门:SQE, 采购员, 产品工程师, 预备协调员Necessary Inputs:Source of inputs:必要的输入:输入来源:Program timing for key eventsEngineer

52、/Buyer主要事件的计划进度工程师/采购员rDetail timing for tools, facilities, etc.Supplier工具及设备等的详细进度供给商Lessons learned checklistSQE经历教训的检查清单SQEAPQP Open Issues ListSupplier/SQEAPQP 未处理咨询题单供给商/SQEAPQP Timing ChartSupplier/SQEAPQP 进度表供给商/SQEResources:Buyer, Engineer, SQE, Readiness Coordinator来源:采购员, 工程师, SQE, 预备协调员Ta

53、sk Number:4 continued任务号:4 续Task Name:Supplier Program Reviews任务名称:供给商计划批阅Methodology:方法: Supplier Program Review #1 (Kick-off Meeting) 供给商 计划批阅 #1 (起动会议)This meeting should occur within 30 days of the sourcing decision. The meeting contains both instruction to the supplier, and report out by the su

54、pplier. The SQE uses the instructional portion of the meeting to relay GMs expectations relative to APQP and the timing of the program (See Appendix 10.) The supplier is expected to give updates on the following: 此会议应在采购决定的30天之内召开。会议包括对供给商的指导及供给商所作的报告。SQE在该会议的指导部分来传达GM对APQP相关的内容及工程进度的期望(见附录10)。希望供给商

55、应对以下内容提供最新信息:- APQP Open Issues List- APQP 未处理咨询题单- APQP timing chart- APQP 进度表- Lessons Learned Review Criteria- 经历教训批阅标准- APQP 进度表- AIAG DFMEA checklist (A-1)- AIAG DFMEA 检查单 (A-1)The APQP Project Contact list is used to track all individuals involved in the APQP project (Appendix 21)APQP工程合同单用于跟踪

56、包括在APQP工程的所有个人(附录21)。 Supplier Program Review #2 供给商工程批阅 #2This meeting should occur approximately 60 days prior to the Gamma/Prototype build. The SQE provides feedback relative to program timing. The supplier is expected to give updates on the following:在Gamma/样件制造前大约60天左右召开本次会议。SQE提供与工程进度相关的反应。希望供

57、给商提供下述内容的最新信息:- APQP Open Issues List- APQP 未处理咨询题单- APQP Timing chart- APQP 进度表- Supplier Manufacturing Assessment of Design- 供给商消费设计评估- Lessons Learned - 经历教训- AIAG Design Information Checklist (A-2)- AIAG 设计信息检查单 (A-2)- AIAG New Equipment Checklist (A-3)- AIAG 新仪器检查单 (A-3)- AIAG Process Flow Chec

58、klist (A-6)- AIAG 工艺流程检查单 (A-6)- AIAG PFMEA Checklist (A-7)- AIAG PFMEA 检查单 (A-7)- AIAG Control Plan Checklist (A-8)- AIAG 操纵计划检查单 (A-8)- GP-11 Prototype Part Approval Status- GP-11 样件批准状态Task Number:4 continued任务号:4 续Task Name:Supplier Program Reviews任务名称:供给商计划批阅 Supplier Program Review #3 供给商计划批阅#

59、3This meeting should follow the prototype build event (Approximately 60 days after the start of Prototype.) The SQE provides feedback relative to program timing and provides a risk assessment update. The supplier is expected to give updates on the following:本次会议应按照样件消费时间表(大约在开场样件消费后的60天后进展)进展。SQE提供有关计划时间表的反应情况及最新的风险评估情况. 供给商应提供以下各项的最新情况:- APQP Open I

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。