控制计划(模板)

控制计划(模板)

《控制计划(模板)》由会员分享,可在线阅读,更多相关《控制计划(模板)(1页珍藏版)》请在装配图网上搜索。

1、.wdPart Description/产品描述: SUPPLY SEAT 撰写人 / 联系方式: XXXX 123456789112Team Leader/Phone/:XXXXXX 123456478585Orig. Date/编制日期:2015-7-2文 件 版 本: ACurrent Rev: ADate/日期:2010.7.2Part Number/零件编号:123456-770团队成员:XXXX、XXX、XXX、XXX、XXX、Team Members:XXXX、XXXX 、XXXX、XXXXX、XXXXXRemark/备注: Critical/重要 Safety/安全 Syste

2、m/系统图 纸 版 本: CDrawing Revision: C审核 / 日期:XXX 2010.7.2Checkd/Date:Fei Zhang 2010.7.2供 应 商: XXXXX金属Supplier/Location: XXXXXX客 户 批 准 / 日 期:Customer Approval / Date:批 准 / 日期:IvanXXX Approval/Date:Ivan XXX Process Descriptions/过程描述产品/过程特性Product / process characteristicsRisk: Major Average Minor/不安全等级:重要

3、、普通、较小Methods/方法预防行动Reaction Plan工序Step工序名称、作业描述DescriptionMachine and Tool Number/生产设备及机台编号客户图尺寸/Customer sizeSerial number / key/序号/重点测量方法仪器Evaluation/Measurement Method检测数量Sample Size检测频率Sample Frequency控制方法Control Method/00来料检验Incoming Inspectionmolding machine /型材机Incomingcertificate来料证书major/重

4、要material/材质: 303 S.ST(1)Certification./证明Ounce/盎司IQC incoming inspection IQC 来料检查If non-conformance is found: 1)inform supplier;2)return parts to supplier;3)SCAR issue per Incoming QP-PR-009 /如果不符合要求,行动如下:1通知供给商;2返回给供给商;3按照QP-PR-009来料检验程序填写ROHS/环保SGS报告SGS ReportHRC15-26Sclerometer/硬度仪AQL0.65 Level

5、II C=0Per LOT/每批Dimensionalinspection尺寸检查160.1(MM)Caliper/卡尺500xN(MM)Tape/卷尺01Cut down/下料Cutting/锯床Dimensional inspection尺寸检查major/重要CMM/三次元1PCSOn 11Hourly Basis/11小时IPQC Check/IPQC检查If non-conformance is found:1)Stop line;2)Identify and separate part to MRB;3)Adjust machines per QP-PR-010/如果不符合要求,行

6、动如下:1)通知停机;2)分货和隔离到MRB仓;3)调整机台,按照 QP-PR-010检测程序处理。4971(MM)Tape/卷尺Visual/外观major/重要The workpiece surface can not have any scratches, crush, bumps and other bad appearance./工件外表不可有任何刮伤、压伤、碰伤等外观不良。naked eyes/目测5PCSOn 2 Hourly Basis/2小时IPQC Check/IPQC检查Process Descriptions/过程描述产品/过程特性Product or Process

7、CharacteristicRisk: Major Average Minor/不安全等级:重要、普通、较小Methods/方法预防行动Reaction Plan工序Step工序名称、作业描述DescriptionMachine and Tool Number/生产设备及机台编号客户图尺寸/Customer sizeINCHSerial number / key/序号/重点测量方法仪器Evaluation/Measurement Method检测数量Sample Size检测频率Sample Frequency控制方法Control Method/02Lathe 1 /车加工1CNC lath

8、e/数控车床Dimensional inspection尺寸检查major/重要33CMM/三次元1PCSOn 2 Hourly Basis/2小时IPQC Check /IPQC检查If non-conformance is found:1)Stop line;2)Identify and separate part to MRB;3)Adjust machines per QP-PR-010/如果不符合要求,行动如下:1)通知停机;2)分货和隔离到MRB仓;3)调整机台,,按照 QP-PR-010检测程序处理。40CMM/三次元44CMM/三次元7.170.1345Height meter

9、/高度表On 5 Hourly Basis/5小时2.750.1336Pin gauge/塞规11.100.1332Outside micrometer /外径千分尺坑卡2XR0.250.25(10)Projection/投影仪 15.000.1337Outside micrometer /外径千分尺Visual/外观major/重要The workpiece surface can not have bumps, scratches and other bad appearance /工件外表不可有碰伤、划伤等外观不良naked eyes/目测5PCSOn 2 Hourly Basis/2小

10、时IPQC Check/IPQC检查03CNC1CNC milling machine /数控铣床Dimensionalinspection尺寸检查major/重要4X 6.000.15(38)Pin gauge/塞规1PCSOn 5 Hourly Basis/5小时IPQC Check/IPQC检查(37)CMM/三次元On 2 Hourly Basis/2小时43Height gauge/高度仪Visual/外观major/重要The workpiece surface can not have bumps, scratches and other bad appearance /工件外表

11、不可有碰伤、划伤等外观不良naked eyes/目测5PCSOn 2 Hourly Basis/2小时IPQC Check/IPQC检查Process Descriptions/过程描述产品/过程特性Product or Process CharacteristicRisk: Major Average Minor/不安全等级:重要、普通、较小Methods/方法预防行动Reaction Plan工序Step工序名称、作业描述DescriptionMachine and Tool Number/生产设备及机台编号客户图尺寸/Customer sizeINCHSerial number / ke

12、y/序号/重点测量方法仪器Evaluation/Measurement Method检测数量Sample Size检测频率Sample Frequency控制方法Control Method/04Lathe 2/车加工2CNC lathe/数控车床Dimensional inspection尺寸检查major/重要 13.720.1341Outside micrometer /外径千分尺1PCSOn 5 Hourly Basis/5小时IPQC Check /IPQC检查If non-conformance is found:1)Stop line;2)Identify and separat

13、e part to MRB;3)Adjust machines per QP-PR-010/如果不符合要求,行动如下:1)通知停机;2)分货和隔离到MRB仓;3)调整机台,,按照 QP-PR-010检测程序处理。8.000.1323Projection/投影仪65.000.2519CMM/三次元R0.4+0/-0.420Projection/投影仪 9.000.1329Pin gauge/塞规0.750.13(15)Projection/投影仪452.5(16)Projection/投影仪0.250.13(17)Projection/投影仪452.5(18)Projection/投影仪Ra0.

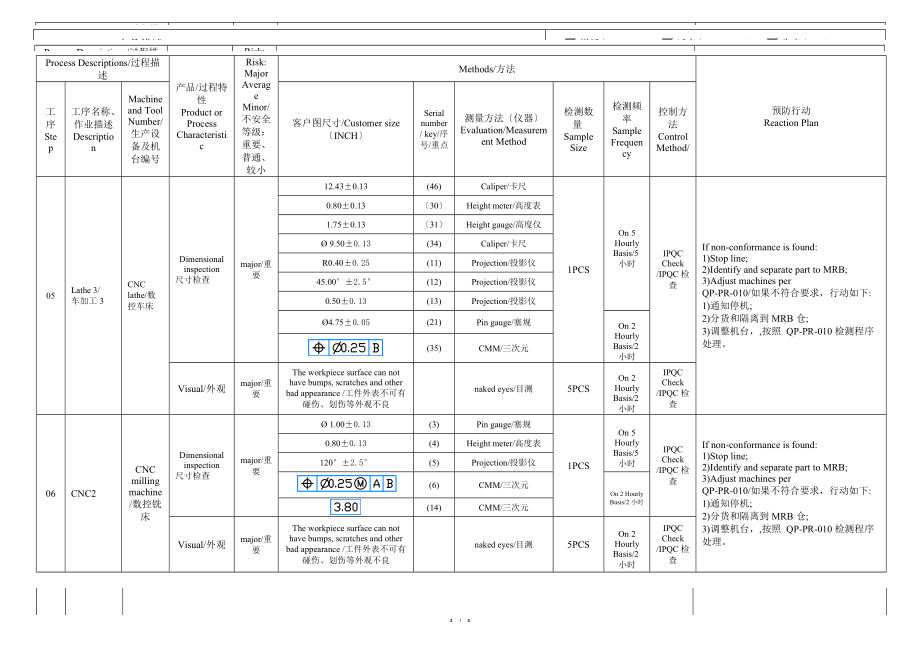

14、8(9)CPK keyRoughness instrument/粗糙度仪0.300.0222Projection/投影仪1PCSOn 2 Hourly Basis/2小时42CMM/三次元 9.5000.00527Pin gauge/塞规(26)CMM/三次元28CMM/三次元10.950.0524Height meter/高度表25CMM/三次元Visual/外观major/重要The workpiece surface can not have bumps, scratches and other bad appearance /工件外表不可有碰伤、划伤等外观不良naked eyes/目测

15、5PCSOn 2 Hourly Basis/2小时IPQC Check/IPQC检查Process Descriptions/过程描述产品/过程特性Product or Process CharacteristicRisk: Major Average Minor/不安全等级:重要、普通、较小Methods/方法预防行动Reaction Plan工序Step工序名称、作业描述DescriptionMachine and Tool Number/生产设备及机台编号客户图尺寸/Customer sizeINCHSerial number / key/序号/重点测量方法仪器Evaluation/Me

16、asurement Method检测数量Sample Size检测频率Sample Frequency控制方法Control Method/05Lathe 3/车加工3CNC lathe/数控车床Dimensional inspection尺寸检查major/重要12.430.13(46)Caliper/卡尺1PCSOn 5 Hourly Basis/5小时IPQC Check /IPQC检查If non-conformance is found:1)Stop line;2)Identify and separate part to MRB;3)Adjust machines per QP-P

17、R-010/如果不符合要求,行动如下:1)通知停机;2)分货和隔离到MRB仓;3)调整机台,,按照 QP-PR-010检测程序处理。0.800.1330Height meter/高度表1.750.1331Height gauge/高度仪 9.500.13(34)Caliper/卡尺R0.400.25(11)Projection/投影仪45.002.5(12)Projection/投影仪0.500.13(13)Projection/投影仪4.750.05(21)Pin gauge/塞规On 2 Hourly Basis/2小时(35)CMM/三次元Visual/外观major/重要The wor

18、kpiece surface can not have bumps, scratches and other bad appearance /工件外表不可有碰伤、划伤等外观不良naked eyes/目测5PCSOn 2 Hourly Basis/2小时IPQC Check/IPQC检查06CNC2CNC milling machine /数控铣床Dimensional inspection尺寸检查major/重要 1.000.13(3)Pin gauge/塞规1PCSOn 5 Hourly Basis/5小时IPQC Check/IPQC检查If non-conformance is foun

19、d:1)Stop line;2)Identify and separate part to MRB;3)Adjust machines per QP-PR-010/如果不符合要求,行动如下:1)通知停机;2)分货和隔离到MRB仓;3)调整机台,,按照 QP-PR-010检测程序处理。0.800.13(4)Height meter/高度表1202.5(5)Projection/投影仪(6)CMM/三次元On 2 Hourly Basis/2小时(14)CMM/三次元Visual/外观major/重要The workpiece surface can not have bumps, scratch

20、es and other bad appearance /工件外表不可有碰伤、划伤等外观不良naked eyes/目测5PCSOn 2 Hourly Basis/2小时IPQC Check/IPQC检查Process Descriptions/过程描述产品/过程特性Product or Process CharacteristicRisk: Major Average Minor/不安全等级:重要、普通、较小Methods/方法预防行动Reaction Plan工序Step工序名称、作业描述DescriptionMachine and Tool Number/生产设备及机台编号客户图尺寸/Cu

21、stomer sizeSerial number / key/序号/重点测量方法仪器Evaluation/Measurement Method检测数量Sample Size检测频率Sample Frequency控制方法Control Method/07Deburr /去披锋Tool deburr /披锋刀Visual/外观major/重要The workpiece surface can not have bumps, scratches and other bad appearance /工件外表不可有碰伤、划伤等外观不良(1)naked eyes/目测全检ALLPer LOT/每批FQC

22、 inspection/FQC检查If non-conformance is found:1) Stop machines;2)Identify and separate part to MRB;3)Adjust machines per QP-PR-010/如果不符合要求,行动如下:1)通知停机;2)分货和隔离到MRB仓;3)调整机台,,按照 QP-PR-010检测程序处理08 QA抽检/QA InspectionVisual/外观major/重要The workpiece surface can not have bumps, scratches and other bad appeara

23、nce /工件外表不可有碰伤、划伤等外观不良naked eyes/目测AQL0.65 Level II C=0Per LOT/每批FQC inspection/FQC检查09镭射/Laser镭射机/Laser machineVisual/外观major/重要0.3850.027Pin gauge/塞规AQL0.65 Level II C=0Per LOT/每批IQC incoming inspection IQC 来料检查If non-conformance is found: 1)inform supplier;2)return parts to supplier;3)SCAR issue

24、per Incoming QP-PR-009 / 如果不符合要求,行动如下:1通知供给商;2返回给供给商;3按照QP-PR-009来料检验程序填写(6)CMM/三次元The workpiece surface can not have bumps, scratches and other bad appearance , NO BURRS EITHER END/工件外表不可有碰伤、划伤等外观不良,孔两端不可有任何毛刺47目测naked eyesProcess Descriptions/过程描述产品/过程特性Product or Process CharacteristicRisk: Major

25、 Average Minor/不安全等级:重要、普通、较小Methods/方法预防行动Reaction Plan工序Step工序名称、作业描述DescriptionMachine and Tool Number/生产设备及机台编号客户图尺寸/Customer sizeSerial number / key/序号/重点测量方法仪器Evaluation/Measurement Method检测数量Sample Size检测频率Sample Frequency控制方法Control Method/10来料检查/Incoming InspectionVisual/外观major/重要The workp

26、iece surface can not have bumps, scratches and other bad appearance /工件外表不可有碰伤、划伤等外观不良目测naked eyesAQL0.65 Level II C=0Per LOT/每批IQC incoming inspection IQC 来料检查If non-conformance is found: 1)inform supplier;2)return parts to supplier;3)SCAR issue per Incoming QP-PR-009 / 如果不符合要求,行动如下:1通知供给商;2返回给供给商;

27、3按照QP-PR-009来料检验程序填写11钝化/PassivationVisual/外观major/重要The workpiece surface can not have bumps, scratches and other bad appearance /工件外表不可有碰伤、划伤等外观不良2目测naked eyesAQL0.65 Level II C=0Per LOT/每批IQC incoming inspection IQC 来料检查If non-conformance is found: 1)inform supplier;2)return parts to supplier;3)S

28、CAR issue per Incoming QP-PR-009 / 如果不符合要求,行动如下:1通知供给商;2返回给供给商;3按照QP-PR-009来料检验程序填写12Inspection /检查Visual/外观major/重要4.750.05(21)Pin gauge/塞规全检ALLPer LOT/每批FQC inspection/FQC检查If non-conformance is found:1) Stop machines;2)Identify and separate part to MRB;3)Adjust machines per QP-PR-010/如果不符合要求,行动如下

29、:1)通知停机;2)分货和隔离到MRB仓;3)调整机台,,按照 QP-PR-010检测程序处理。 9.5000.00527Pin gauge/塞规0.3850.027Pin gauge/塞规The workpiece surface can not have bumps, scratches and other bad appearance /工件外表不可有碰伤、划伤等外观不良目测naked eyesProcess Descriptions/过程描述产品/过程特性Product or Process CharacteristicRisk: Major Average Minor/不安全等级:重

30、要、普通、较小Methods/方法预防行动Reaction Plan工序Step工序名称、作业描述DescriptionMachine and Tool Number/生产设备及机台编号客户图尺寸/Customer sizeSerial number / key/序号/重点测量方法仪器Evaluation/Measurement Method检测数量Sample Size检测频率Sample Frequency控制方法Control Method/13OQC抽检/OQC InspectionOQC 抽样检测方法OQC Sampling plan参照客户图纸Refer to customer d

31、rawingREF.TML- QI 055200-740AQL0.65 Level II C=0Per LOT/每批OQC inspection/OQC检查 If non-conformance is found:1)Stop line;2)Identify and separate part to MRB;3)Adjust machines per QP-PR-010/如果不符合要求,行动如下:1)通知停机;2)分货和隔离到MRB仓;3)调整机台,,按照 QP-PR-010检测程序处理。14包装Packaging纸板箱Carton手工/Handworkmajor/重要参照/REF.WI-055200-740 BZ参照/REF.WI-055200-740 BZQA 报告及包装SGS合格证书QA REPORT and SGSGeneral sampling plan/一般的抽样水准If non-conformance is found:1)Stop line;2)Identify and separate part to MRB;3)Adjust machines per QP-PR-010/如果不符合要求,行动如下:1)通知停机;2)分货和隔离到MRB仓;3)调整机台,,按照 QP-PR-010检测程序处理。15海运Shipping1 / 1

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。