2x600MW锅炉主要施工组织设计方案

2x600MW锅炉主要施工组织设计方案

《2x600MW锅炉主要施工组织设计方案》由会员分享,可在线阅读,更多相关《2x600MW锅炉主要施工组织设计方案(6页珍藏版)》请在装配图网上搜索。

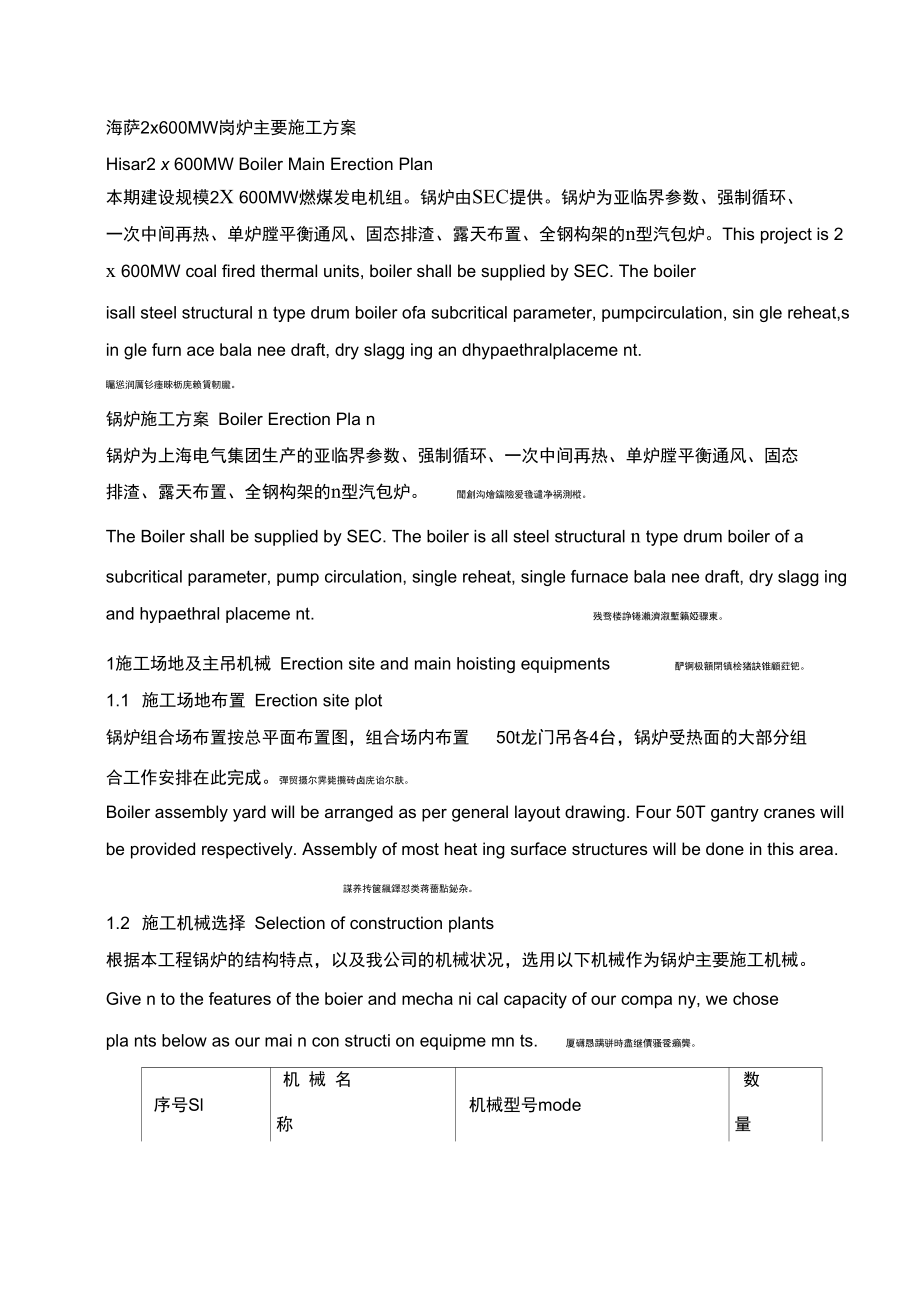

1、海萨2x600MW岗炉主要施工方案Hisar2 x 600MW Boiler Main Erection Plan本期建设规模2X 600MW燃煤发电机组。锅炉由SEC提供。锅炉为亚临界参数、强制循环、 一次中间再热、单炉膛平衡通风、固态排渣、露天布置、全钢构架的n型汽包炉。This project is 2 x 600MW coal fired thermal units, boiler shall be supplied by SEC. The boilerisall steel structural n type drum boiler ofa subcritical parameter

2、, pumpcirculation, sin gle reheat,s in gle furn ace bala nee draft, dry slagg ing an dhypaethralplaceme nt.矚慫润厲钐瘗睞枥庑赖賃軔朧。锅炉施工方案 Boiler Erection Pla n锅炉为上海电气集团生产的亚临界参数、强制循环、一次中间再热、单炉膛平衡通风、固态 排渣、露天布置、全钢构架的n型汽包炉。聞創沟燴鐺險爱氇谴净祸測樅。The Boiler shall be supplied by SEC. The boiler is all steel structural n typ

3、e drum boiler of a subcritical parameter, pump circulation, single reheat, single furnace bala nee draft, dry slagg ing and hypaethral placeme nt.残骛楼諍锩瀨濟溆塹籟婭骤東。1施工场地及主吊机械 Erection site and main hoisting equipments酽锕极額閉镇桧猪訣锥顧荭钯。1.1 施工场地布置 Erection site plot锅炉组合场布置按总平面布置图,组合场内布置50t龙门吊各4台,锅炉受热面的大部分组合工作

4、安排在此完成。彈贸摄尔霁毙攬砖卤庑诒尔肤。Boiler assembly yard will be arranged as per general layout drawing. Four 50T gantry cranes will be provided respectively. Assembly of most heat ing surface structures will be done in this area.謀养抟箧飆鐸怼类蒋薔點鉍杂。1.2 施工机械选择 Selection of construction plants根据本工程锅炉的结构特点,以及我公司的机械状况,选用以下

5、机械作为锅炉主要施工机械。Give n to the features of the boier and mecha ni cal capacity of our compa ny, we chosepla nts below as our mai n con structi on equipme mn ts.厦礴恳蹒骈時盡继價骚卺癩龔。序号Sl机 械 名称descripti on机械型号mode数量qua ntity1圆筒吊 cylindrical craneFZQ2000/80t22履带吊 crawlercraneCC140013龙门吊 frame crane50t44履带吊 crawle

6、rcraneCC250015劳辛格 Stand-jack system200t26塔吊 tower craneC7050/20t3 FZQ2000/ 80T 圆筒吊 FZQ2000/ 80Tcylindrical craneFZQ200C圆筒吊做为附吊机械,筒身高度102m采用60m臂长工况,主要负责锅炉本体部件的吊装工作。FZQ2008ylindricalcrane is arranged as auxiliaryhoisting plants, whichis designed to hoist boiler & components (crane body height 102m, le

7、ngth of jib 60m). 茕桢广鳓鯡选块网羈泪镀齐鈞。 250t 履带吊 250t Crawler craneCC1400/250t履带吊为锅炉主吊机械,采用 SWS塔式工况,后配重40t,主臂角度85度:主 副臂:72m加36m最大作业半径42n,负荷27t;最小作业半径24m时,负荷为39t。CC1400/250Crawler cranes are desig ned as main boiler hoist ing euqipme nt, adopti ng SWSL tower working conditions,with a banlance weight of 40t

8、and main jib angle of 85 ; lengthof mai n & auxiliary jib,72+36m, max worki ng radius 42m,load27t;m in worki ng radius24m,load 39t.鹅娅尽損鹤惨歷茏鴛賴縈诘聾。吊装主要内容为: Main hoisti ng scope:a. 锅炉钢架吊装。Boiler steel structure lifting.b. 锅炉受热面吊装、空气预热器吊装。Boiler heating surface ,airpreheater lifting.籟丛妈羥为贍债蛏练淨槠挞曉。c. 烟、风

9、、煤管道安装 Flue gas,air,coal pipi ng erecti on.d. 根据现场实际换工况用于大件设备的安装和卸车工作。Employed in erection of other6 / 6heavy equipme nts and uni oad ing works.預頌圣鉉儐歲龈讶骅籴買闥龅。CC1400/250t履带吊性能表(SWSL塔式、后配重40t工况)主附臂(主臂角度85o): 72m+36m幅度24m26m28m30m34m38m42m负荷load39t38t38t37t34t31t27tCC1400/250t crawler crane performanee

10、 list(SWSL TOWEtype,banlance weight 40t),main & auxiliary jib,72+36m(main jib angle of 85 ).渗釤呛俨匀谔鱉调硯錦鋇絨钞。 前期采用C7050/20t作为钢结构的主要吊装机械,后期作为电除尘的主吊机械。Inprophase,C7050/20t shall be employed as main hoisting plants for structure;inan aphase shall be employed in hoist ing ESP comp onents.铙誅卧泻噦圣骋贶頂廡缝勵罴。(4)其

11、它吊装机械 Other lifting plantsA四台50t龙门吊布置于锅炉组合场,负责设备装卸车、受热面膜式壁及蛇行管排的组合工作及烟风道的制作组合工作。4 frame cranes of 50t shall be arranged inBoiler structureassembly yard, employed in equipments loading and unioading, heatingsurface and pipecoil assembly works and flue/air duct ing fabricat ing asembly works.擁締凤袜备訊顎轮烂

12、蔷報赢无。b. 50t汽车吊负责现场设备卸车倒运等工作。b.Truck crane of 50t shall be employed in equipme nts uni oadi ng in site.贓熱俣阃歲匱阊邺镓騷鯛汉鼉。c.卷扬机布置在锅炉0m,辅助进行炉膛内管排及小件的吊装。c . winchshall be arra ngedin 0m, assisting furnace internals lifting and the lifting of some samll units.搏乡囂忏蒌鍥铃氈淚跻馱釣。d.劳辛格负责汽包吊装工作。 Stand-jack system wil

13、l be used in steam drum listingworks.蜡變黲癟報伥铉锚鈰赘籜葦繯。(5) 施工电梯布置 service lift arrangment为方便锅炉施工,在炉一侧布置一施工电梯。Sservice lifts shall be arranged in each side of the boiler.買鯛鴯譖昙膚遙闫撷凄届嬌擻。2 锅炉本体钢架安装 Boiler steel structure erection锅炉钢结构由顶板、柱和梁、垂直支撑、水平支撑等部件组成,顶板由主梁、次梁和小梁组成一个坚固的梁格,其四周有水平支撑,主梁端有垂直支撑。 Boiler stee

14、l structure consists of roof, column,girder, vertical and lateral supporting,while roofcomprising of girder, secondary beam, trabecula and forming a firm box. 綾镝鯛駕櫬鹕 踪韦辚糴飙钪麦。钢架内侧柱为主要承重钢柱,外侧副柱则通过梁、水平支撑与内侧柱相连,以增加钢架的整 体稳定性。钢结构从前至后共有 6排。锅炉钢架的连接, 采用高强螺栓和焊接相结合的方式, 顶板和主梁与次梁之间,柱和梁之间,垂直支撑、水平支撑之间采用扭剪型高强螺栓连接,

15、其余构件间采用焊接连接。 Internal pillars of the structure are designed for bearing, while the external pillars are designed to reinforce the entire stability of structure by connecting with girders, lateral supporting and internal pillars.There are 6 rows. Bolt and welding are employed in the connection of str

16、ucture. 驅踬髏彦浃绥譎饴憂锦諑琼针。 2.1 吊装方案 Hoisting plans主吊机械选用一台FZQ2OO0圆桶吊,一台CC140C履带吊为附吊机械,圆筒吊布置于锅炉炉左 K、L间距锅炉本体外侧柱中心线 5米处,CC140C履带吊布置于炉的另一侧。钢架各段本着由 炉前至炉后、先主柱后辅柱原则分段吊装,即安装一段找正一段,验收本段钢架后对高强螺 栓进行终紧。钢架安装过程中相应段平台、楼梯、栏杆随之安装。Main hoisting plantscomprise of anFZQ2000cylindrical craneand CC1400 crawler crane (as auxi

17、liary hoisting plants), the cylindrical crane shall be arranged at left side of boiller between boiler central line and it is 5 meters away from the boiler central line , CC14OO crawler shall be arranged on the other side of boiler. Each section of the structure follows the rule of from furnace fron

18、t to back, from main pillars to complement pillars. Duiring the process of structure erection, platform,stairecase and handrails should be finishsed. 猫虿驢绘燈鮒诛髅貺庑献鵬缩。 在钢架吊装过程中,视来货及制件完成情况,根据相应设备的安装位置和标高,把一次风热 风道、二次风热风道、回转式空预器、预热器入口烟道、省煤器出口灰斗以及燃烧器连接风 道等相关设备随之预存;各段吊装过程中,相应主降水管和刚性梁要临时吊挂在相应各层钢 架梁上;视图纸具体情况缓

19、装炉左侧及炉后 7m标高下的部分拉条,做为炉内吊装设备的进入 通道,炉膛内影响汽包 (吊装中的初偏斜和炉顶调水平处 )、板梁(炉膛内抬吊时 )吊装的杆件 缓装。 During the erection of structure, according to the progress of goods supplyand parts fabrication, and erection position and height , we can save someequipments in their required position and ercet later such equipments

20、including,primary hot air duct, secondary hot air duct, rotaty air preheator, preheator inlet flue gas ducting, economizer outlet ash bucket and burner connecting air duct. During each stage of erection, maindowncomers and stiffening bars should be temporarily hanged in their girders of structure. A

21、s per the drawings , some braces on the left side of boiler or back of boiler below the height of 7m should be erected later, so that access for the hoisting works of boiler internals are made, in addition, any parts of boiler internal shafts that affect steam drum and plate girder lifting should be

22、 erected later. 锹籁饗迳琐筆襖鸥娅薔嗚訝摈。2.2 施工顺序 Construction procedure锅炉基础划线f标高复验和基础凿毛f柱底板安装f立柱1m标高线复检f结构第一段吊装整体找正柱脚二次浇灌其它几层结构吊装顶板梁吊装钢结构完善。構氽頑黉碩饨荠龈话骛門戲鷯。 Column Plate StructureBoiler Foudation Lining Level Call Back And Surface PreparationErection Column 1m Level CallbackStructure Erection Stage 1Alignment C

23、olumn Foot Secondary Grouting Other Floors LiftingRoof PlateGirder Lifting Stucture Maintenance 輒峄陽檉簖疖網儂號泶蛴镧釃。3 顶板梁吊装方案 Roof girder hoisting plans 锅炉钢结构第八段立柱、横梁、拉条安装完毕后,根据大板梁吊装需要,部分杆件预留,经 检验合格,才能进行板梁吊装。 尧侧閆繭絳闕绚勵蜆贅瀝纰縭。After the erection of pillars of structure, beams, braces , to meet the requirement

24、 of girder hoisting, some shafts should be saved to their position and erected after passing test ,then plate beams hoisting could commence.识饒鎂錕缢灩筧嚌俨淒侬减攙。锅炉顶板梁的吊装机械为 FZQ2000/80t圆筒吊和CC1400/CC250C履带吊。FZQ2000/80t圆筒 吊布置在#1、#2炉的两侧,每台炉有一台磨机缓装,CC2500/CC1400B带吊在2台炉中间机动 布置,看情况缓装一台磨煤机,使CC2500/CC1400满足顶板梁吊装工况。 FZQ2000/80t cylindrical crane and CC1400/CC2500crawler crane are employed to hoist boiler roof plate girder.FZQ2000/80t cylindrical crane should be arranged in both sides of boiler

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。