船舶建造检验项目表

船舶建造检验项目表

《船舶建造检验项目表》由会员分享,可在线阅读,更多相关《船舶建造检验项目表(21页珍藏版)》请在装配图网上搜索。

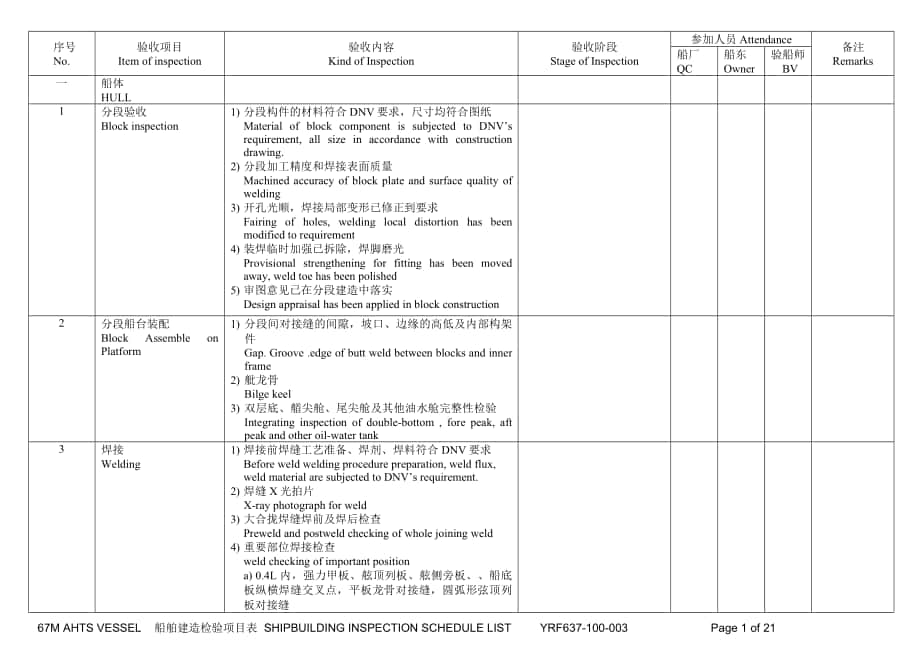

1、 序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师BV一船体HULL1分段验收Block inspection1) 分段构件的材料符合DNV要求,尺寸均符合图纸Material of block component is subjected to DNVs requirement, all size in accordance with construction drawing.2) 分段加工精度和焊接表面质量Machine

2、d accuracy of block plate and surface quality of welding3) 开孔光顺,焊接局部变形已修正到要求Fairing of holes, welding local distortion has been modified to requirement4) 装焊临时加强已拆除,焊脚磨光Provisional strengthening for fitting has been moved away, weld toe has been polished5) 审图意见已在分段建造中落实Design appraisal has been appli

3、ed in block construction2分段船台装配Block Assemble on Platform1) 分段间对接缝的间隙,坡口、边缘的高低及内部构架 件Gap. Groove .edge of butt weld between blocks and inner frame2) 舭龙骨Bilge keel 3) 双层底、艏尖舱、尾尖舱及其他油水舱完整性检验Integrating inspection of double-bottom , fore peak, aft peak and other oil-water tank3焊接Welding1) 焊接前焊缝工艺准备、焊剂、

4、焊料符合DNV要求Before weld welding procedure preparation, weld flux,weld material are subjected to DNVs requirement.2) 焊缝X光拍片X-ray photograph for weld3) 大合拢焊缝焊前及焊后检查Preweld and postweld checking of whole joining weld4) 重要部位焊接检查weld checking of important positiona) 0.4L 内,强力甲板、舷顶列板、舷侧旁板、船底板纵横焊缝交叉点,平板龙骨对接缝,

5、圆弧形弦顶列板对接缝序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师BVIn 0.4L ,strength deck, vertically and horizontally weld intersection of sheer strake, sheer side and strake; butt weld of plate keel; butt weld of arc sheer strakeb) 强力甲板角隅板 Cor

6、ner plate of strength deck c)船舯0.4L区域内纵向骨架和纵舱壁扶强材对接头 In 0.4L extent of midship, butt weld of longitudinal frame to longitudinal bulkheads stiffenersd) 起重柱、桅对接缝,包括焊接缝上的每个交叉点 Butt weld of crane pillar and mast, include each intersection of welde) 机舱内底板与机座面板的边界缝 boundary of innerbottom to machine found

7、ation f) 各层甲板、平台板、内底板和纵横舱壁的边接缝 boundary at each deck, flat floor, innerbottom and longitudinal and transverse bulkheads4船体焊接密性实验Weld sealed test of hull按规程要求,各部位的密性实验According to the rules, tightness test of each position.5油漆及涂料Paint1) 车间底漆Priming paint in workshop2) 水下Underwater paint3) 水上Above wat

8、er paint4) 舱内In the compartment paint二 舾装1锚泊及系泊实验Anchor equipment and mooring equipment test1) 完整性检查,外部检查Inspection of completeness and exterior2) 弃锚器牢固可靠,易于弃锚Releasing anchor is solid and dependable ,easy to release.3) 止链器工作的可靠性Reliability of stopper work4) 设备底座与甲板结构的加强Strength of equipment foundat

9、ion to deck construction5) 按实验大纲进行实验Test according to test schedule序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师BV2舱口盖Hatch cover1) 完整性Completeness2) 密性实验、效应实验Tightness test, effectiveness test3船体防腐Ship antisepsis1) 牺牲阳极antianode2) 阴极保

10、护Cathodic protection4救生设备Life saving equipment1) 救生艇Rescue boata) 检查证书Check certificateb) 外部检查External inspectionc) 起动效应实验Operate effectiveness testd) 备品完整性Storage completeness2) 起艇系统Operating systema) 查阅证书及合格标志Check certificate and qualitified mark b) 外观检查 External inspectionc) 位置走向Arrangement plan

11、 d) 按实验大纲进行实验 Test according to test schedule3) 救生筏、浮圈Life raft and ringa) 查阅证书及合格标志Check certificate and quality mark b) 外观检查 External inspection c) 全船完整性检查Check completeness of whole ship 序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师

12、BV d) 安装检查Installation inspection4) 抛绳设备Line-throwing appliancea) 合格证、出厂日期Qualified certificate , manufactured dateb) 数量Count5航行灯、信号灯、号笛、号型、音响信号、遇险信号Navigate light, signal light, siren, siren stytle, sounding signal, distress signal1) 查阅船用产品合格证Check qualified certificate of marine production2) 核对数量C

13、heck count3) 核对航行灯、信号灯、和号笛的钢印Check steel mark of navigate light, signal light and siren4) 检查音响信号Check sounding signal5) 检查遇险信号的出厂日期及标志Check produce date and mark of distress signal6) 检查航行灯、信号灯安装位置的正确性Check accuracy of install navigate light and signal light position 7) 航行灯、信号灯、号笛作用效用试验Effectiveness

14、test on navigate light ,signal light and siren 6倾斜试验Inclining test1) 检查试验准备工作check preparation work for test2) 倾斜试验Inclining test 3) 审查倾斜试验并计算结果Check inclining test and calculate the result7防火、探火和灭火Fire protection ,finding fire and extinguish fire1) 防火结构Fire-resisting constructiona) 查耐火材料、防火门、甲板敷料等的

15、船用产品合格证和耐火标准试验报告或型式认可Check marine product qualified certificate of refractory material ,fire-resisting door, deck dressing and so on ; refractory standard test report or typical approvalb) 检查外表结构的完整性Check completeness of external construction序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage

16、 of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师BVc) 检查外表结构的完整性 check completeness of external constructiond) 防火舱壁上通风管通的进风口关闭装置及开孔防火措施及防火门 vent and inlet shut equipment in fireproof bulkhea and fire protection measure and fire resisting door2) 探火及报警Finding fire and alarma) 查阅船用产品合格证check qualifi

17、ed certificate of marine productb) 安装检查Check installationc) 探火装置及报警系统效用试验Effectiveness test of finding fire equipment and alarm system3) 水灭火系统Water extinguish fire systema) 查阅船用产品合格证check qualified certificate of marine productb) 检查消防栓、水栓、水龙带的数量及布置Check quantity and arrangement of fire hydrant, wate

18、r bolt, fire hosec) 检查国际海岸接头的设置位置Check installation of the connection in international seashore d) 效用试验Effectiveness test4) 固定式压力水雾灭火系统Hydrophore system a) 查阅船用产品合格证check qualified certificate of marine productb) 检查喷嘴及系统布置情况Check muzzle and system arrangement c) 效用试验 Effectiveness test5) 泡沫灭火系统Foam

19、system序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师BVa) 查阅船用产品合格证check qualified certificate of marine productb)低膨胀泡沫进行喷射试验,高膨胀泡沫进行施行试验 Low expand foam do ejection test, high expandig foam do ejection test6) 二氧化碳及卤化烃系统Carbon dioxide an

20、d halogenate hyrocarbon systema) 查阅二氧化碳或卤化烃钢瓶的船用产品合格证Check shipuse product qualified certificate of carbon dioside or halogenate hyrocarbon steel bottleb) 核对钢印Check steel stampc) 检查卤化烃瓶超压释放安全装置Check superpress releasing safety equipment of halogenate hyrocarbond) 查阅灭火剂重量和称重记录Check fire extinguishing

21、 weight and recorde) 检查装置的安装情况Check equipment installatioinf) 二氧化碳管系在车间液压试验,装船后作密性试验Do hydraulic test on carbon dioxide pipe system in workshop, after install in ship do seal test.g) 用压缩空气吹通检查Do blowing test by compressed airh) 检查站室及操纵站Check station room and control roomi) 检查施放报警装置Check alarm equipm

22、ent j) 装置作效用试验Do effctiveness test on equipment7) 自动喷水系统a) 查阅船用产品合格证Check shipuse product qualified certificate b) 检查喷水器装置及系统安装情况 Check sprinkler equipment and system installation c)用开启试验阀的模拟方法进行效用试验 序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC

23、船东Owner验船师BVDo effectiveness test in simulated method opening trial valve8) 惰性气体系统a) 查阅船用产品合格证Check shipuse product qualified certificateb) 检查安装情况 Check installationc)检查各种安全装置的效能 Check every safety equipment effectivenessc) 效用试验Do effectiveness test9) 消防供应品fire protection supply a) 查阅船用产品合格证 Check m

24、arine product qualified certificate b) 检查供应品数量及手提灭火器的出厂日期 Check quality of supply product and product manufacture date of fire extinguisher r by hand c) 检查安放位置Check install position10) 防火控制图a) 检查防火控制图完整性Check completeness of fire protection control planb) 检查悬挂位置Check hanging position8水密门窗和其他类似开口及关闭设

25、施watertight door and window and similar opening and close appliance1) 外部检查External inspection2) 密性试验Seal test3) 效性试验Effectiveness test9钢质舱口盖、平台、首尾门、滚装船跳板steel hatch, headaft door, roll on ship gangway1) 查阅材质证件Check material certificate2) 检查装配精度、构件尺寸及焊缝质量Check assembly accuracy, accessory size and we

26、ld quality3) 查阅焊缝射线,透视底片Check weld rays, examine photofilm序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师BV4) 效应试验Effective test5) 密封试验Seal test6) 打钢印steel stamp10船体完整性hull completeness1) 参加主尺度的测量take part in the measurement of the main

27、size2) 检查船体、舵推进装置、安装完整性Check hull, rudder propeller equipment, installation completeness3) 检查船体防腐装置的安装情况Check antiseptic appliance installation11下水Launching1) 对水下开口关闭设施的关闭情况Check closing of close appliance underwater opening2) 检查舵杆、螺旋桨轴固定的可靠性Check rudder tiller, propeller axis 3) 下水后对船体各部件进行复查After

28、launch review each components of hull12载重线标志Load line mark1) 检查船首、船中、船尾吃水标尺和载重线标志勘划的正确性Check accuracy of drawing head, midship, aft draft scale and loadline13船舶及货运系统 Ship pipe and freight system1) 各种泵组及设备Pump group and equipmenta) 查阅船用产品合格证Check product qualified certificate for shipb) 核对钢印Check ste

29、el stampc) 检查安装情况 Check installation2) 船舶及货运管系Ship pipe and freight systema) 外观检查 External inspectionb) 车间液压试验,打钢印及安装上船后的完整性及密性检查序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师BVWorkshop hydraulic test, steel stamp and integrality after

30、installation and seal test3) 系统效用试验 System effectiveness test14舱室设备Compartment equipment按照审查批准的图纸对舱室设备进行检查 According to approved drawing, inspect compartment equipment15起货设备Lifting equipment1) 绞车及起重机Winch and cranec) 查阅船用产品合格证Check product qualified certificate for shipd) 核对钢印Check steel stamp2)起货设备

31、安装后试验After installation do test on lifting equipmenta) 检查安装情况Check installationb) 进行吊重试验Do lifting testc) 试验后部件拆验After test depart accessoriedd) 吊杆上打钢印Stamp on suspender三轮机部分1主机Main Engine1) 查阅船用产品合格证和制造厂质量证件Check product qualified certificate and manufacture quality certificate2) 核对钢印Check steel st

32、amp3) 主机安装固定Main engine installation and fixation4) 按照审查同意的试验大纲试验Test according to the approved test2螺旋桨、艏侧推、 1) 查阅船用合格证和制造厂质量证件.Check marine product certificate and the manufacture quality certificate.序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂

33、QC船东Owner验船师BV 2) 核对钢印.Check the steel stamp.3) 浆安装固定检查Propeller installation and fixation inspection4) 滑油及液压管系安装、串油、试压Lube oil and hydraulic oil pipe installation 、oil flushing、 pressure test 5) 按照审查的试验大纲进行试验. Test according to the approved test brief.3锅炉Boiler1) 查阅船用合格证书和制造厂质量证件.Check product qual

34、ified certificate and the manufacture quality certificate.2) 核对钢印.Check the steel stamp.3) 检查安装情况.Check the installation.4) 按照审查的试验大纲进行试验. Test according to the approved test brief.4动力系统Dynamic system1) 发电机Generatora) 查阅船用产品合格证和制造厂质量证件.Check product qualified certification and manufacture quality ce

35、rtification.b) 核对钢印Check steel stamp.c) 安装检查Installation inspection.d) 按照审查同意的试验大纲进行试验.Test according to the approved test brief.2) 停泊发电机Harbor Generatora) 查阅船用产品合格证书.Check product qualified certificate.b) 核对钢印.Check steel stamp.c) 安装检查Installation inspection.d) 按照审查同意的试验大纲进行试验.Test according to the

36、 approved test brief.序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师BV3) 应急发电机 Emergency Generatora) 查阅船用产品合格证书.Check product qualified certificate.b) 核对钢印.Check steel stamp.c) 安装检查Installation inspection.d) 按照审查同意的试验大纲进行试验. Test accordi

37、ng to the approved test brief.4) 空气压缩机Air compressor.a) 查阅船用产品合格证书.Check marine product qualified certificate.b) 核对钢印. Check steel stamp. c) 外部检验. External inspection.d) 效用试验(包括充气试验)Efficiency test (include air filling test).5) 空气瓶 Air bottle.a) 查阅船用安全产品合格证书.Check ship safety product qualified certi

38、ficate.b) 核对钢印Check steel stamp.c) 检查安装情况.Inspect the installation.d) 气密试验(连同管系进行)Air sealing test(include pipe system)e) 校验安全阀 Inspect the safe valve.6) 为主辅机,锅炉服务的各种泵以及消防泵,舱底泵,压载泵,货油泵,热交换器等. Fire pump, bilge pump, ballast pump, oil discharge pump, heat exchange etc. and some other pump service for

39、the main engine, assistant engine, boiler.序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师DNVa) 查阅船用产品合格证书.Check ship product qualified certificate.b) 核对钢印.Check steel stamp.c) 外部检查External inspection.d) 效用试验Efficiency test7) 动力管系.Dynamic

40、 pipe system.a) 外部检查External inspection.b) 燃油, 滑油,海水冷却、淡水冷却,排烟,压缩空气管系在车间的液压试验和打钢印及安装上船后的密性检查. Fuel oil pipe, Lube oil pipe ,sea water cooling pipe, fresh water cooling pipe, exhaust pipe, air compression pipe are tested in the workshop and are pressed steel stamp, and are tested the tightness after

41、installation.c) 效用试验Efficiency test.8) 机舱应急设施(油柜速闭阀, 通风管, 天窗关闭,安全阀,防风闸,燃油泵和风机切断,烟囱环形开口极其舱应 急排水).Emergency equipment in engine room (oil tank quick close valve, ventilation duct, skylight closing, safety valve, damper, fuel oil pump and shut off fans, funnel hatch, and cabin emergency drain.)a) 外部检查E

42、xternal inspection.b) 效用试验Efficiency test.9) 通海阀, 舷外阀 Suction sea valve, ship side valve.a) 查船用产品合格证书.Check marine product qualified certificate.b) 校对钢印Check steel stamp.序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师DNVc) 检查安装情况Check in

43、stallation.d) 起闭效用试验.Open-close efficiency test5备件Spare part按审查批准的备件清册核对备件数量 Check quantity according to the approved spare parts list.6机舱自动化engine room autom-atization1) 控制站Control station.a) 检查各控制站(室)的布置及安装情况.Inspect the arrangement and the installation of each control station.b) 检查主控制室2个进出口通道的布置.

44、Inspect the arrangement of 2 in-out passage in the main control station.c) 对照明,振动及噪音进行测量.Measure lighting, quiver and noise.2) 主机遥控,自动电站控制,锅炉自动控制,泵自动控制,报 警,通信系统. Main engine remote control, automatic generator station control, boiler automatic control, pump automatic control, alarm, communications s

45、ystem.a) 查阅船用产品合格证书.Check marine product qualified certificate.b) 外部检查External inspection.3) 机舱防火探头和灭火.Engine room fire detector and fire fight.a) 检查防火布置的安装情况。Inspect arrangement installation of the fireproofing setting.b) 查阅探头报警装置的船用产品合格证书. Check the detector alarm setting marine product qualified

46、certificate.c) 检查探头报警指示器,火警探测器的数量和安装位置的正确性。Inspect the quantity and position of the alarm indictor, the fire detector.序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师DNV4) 遥控测深系统.Remote control sounding system.a) 检查液位探测器的数量和安装位置的正确性.Inspe

47、ct the quantity and position of the level detector.5) 机舱舱底水位检测系统.The bilge level detector system in engine rooma) 检查液位探测器的数量和安装位置的正确性.Inspect the quantity and position of the level detector.6) 自动打印记录仪和故障记录仪. Auto-print scorer and failure scorer.a) 效用试验Efficiency test.7) 机舱自动化装置试验.Engine room automat

48、ization test.a) 按照审查同意的试验大纲进行整个系统的试验. Test the whole system according to the approved test brief.7防油污装置oil pollution preventing equipment1) 残油舱及排放装置.The rest oil cabin and discharge equipment.a) 外部检查 External inspection.b) 焚烧炉等排放装置的效用试验.Efficiency test for the discharge equipment as incinerator.c) 通

49、过排放管路通岸的效用试验.The efficiency test for the deck connection in dischage pipe system.2) 标准排放接头.Standard discharge connection.a) 外部检查External inspectionb) 通过标准排放接头通岸的效用试验.The efficiency test for the deck connection with standard connections.3) 油水分离器 Oily-water separata) 查阅型式认可证书及船用产品合格证.Check typical app

50、roved certificate and product quality certificate.序号No.验收项目Item of inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks船厂QC船东Owner验船师DNVb) 外部检查External inspection.c) 效用试验Efficiency test.8其他防油污装置The other oil pollution preventing equipment.d) 查阅型式认可证书及船用产品合格证.Check typical

51、approved certificate and product quality certificate.e) 外部检查External inspection.f) 效用试验Efficiency test.9冷藏装置cooling storage equip-ment.1) 压缩机 Compressor a) 查船用产品合格证 Check ship product quality certificate.b) 核对钢印 Check steel stampc) 外部检查 External inspection.d) 与制冷管系一起进行密性试验.Air sealing test with refr

52、igeration pipe system.e) 效用试验. Efficiency test.2) 冷凝器,中间冷却器,储存器,蒸发器.Condenser, middle cooler, packet, evaporator.a) 查阅船用产品合格证.Check product quality certification.b) 核对钢印Check steel stamp.c) 外部检查External inspection.d) 校验安全阀 Checkout safety valvee) 效用试验Efficiency test.3) 循环水泵, 海水泵, 冷风机.序号No.验收项目Item o

53、f inspection验收内容Kind of Inspection验收阶段Stage of Inspection参加人员 Attendance备注Remarks检查科QC船东Owner船检DNVCircle pump, seawater pump, cold wind fan.a) 查阅船用产品合格证.Check product quality certificate.b) 核对钢印 Check steel stamp.c) 外部检查 External inspection.d) 效用试验 External test.4) 制冷管系. refrigeration pipe systema) 外部检查 External inspection.b) 气密试验. Air sealing test.c) 抽真空试验Vacuuming test. d) 效用试验 Efficiency test.5) 冷却水及海水管系Cooler water and seawater pipe system.a) 外部检查External insp

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。