X射线萤光光谱仪XRF检验规范

X射线萤光光谱仪XRF检验规范

《X射线萤光光谱仪XRF检验规范》由会员分享,可在线阅读,更多相关《X射线萤光光谱仪XRF检验规范(10页珍藏版)》请在装配图网上搜索。

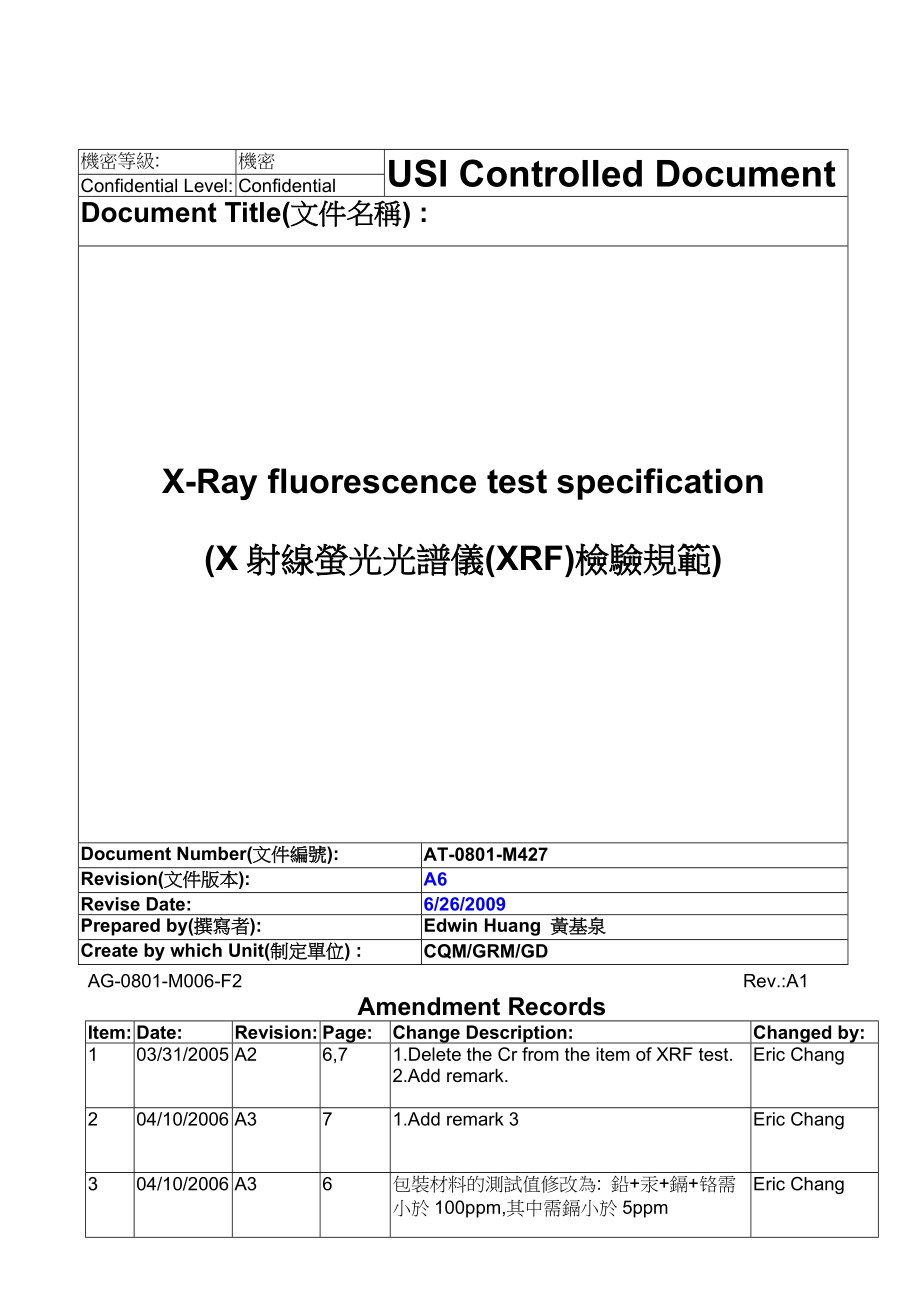

1、機密等級:機密USI Controlled DocumentConfidential Level: ConfidentialDocument Title(文件名稱) :X-Ray fluorescence test specification(X射線螢光光譜儀(XRF)檢驗規範)Document Number(文件編號):AT-0801-M427Revision(文件版本):A6Revise Date:6/26/2009Prepared by(撰寫者):Edwin Huang 黃基泉Create by which Unit(制定單位) :CQM/GRM/GDAG-0801-M006-F2 Re

2、v.:A1Amendment RecordsItem:Date:Revision:Page:Change Description:Changed by:103/31/2005A26,71.Delete the Cr from the item of XRF test.2.Add remark.Eric Chang204/10/2006A371.Add remark 3Eric Chang304/10/2006A36包裝材料的測試值修改為: 鉛+汞+鎘+铬需小於100ppm,其中需鎘小於5ppmEric Chang405/05/2006A1AllCoding change from TT-080

3、1-Q095 to TT-0801-M401Eric Chang505/05/2006A16,71. 修改附件一XRF測試零件及產品類別之有害物質限值表規格之 Pb, Cr, Hg: 700ppm,增加Cd:60ppm之管制2. 刪除Remark對Cr暫不設定管制上限之規定Eric Chang607/05/2006A1All1. Document coding change from TT-0801-M401-A1 to AT-0801-M427-A1.2. Add the purpose and scope.Ken Ke柯炤榕711/30/2006A22,4,111. Omit that t

4、his program is practicable in Taiwan and China sites.2. Modify Method 3: test point of PCB.3. Remove Package item on attachment 1: the Cd must under 5 ppm.Edwin Huang804/29/2008A310,121. Add halogen free and Spot test items.2. Delete Br controlling item.Edwin Huang908/20/2008A41,10,12141. Add attent

5、ion items for the tool management process of mechanical preparation.2. Add the flow chart and form for the management process to attachment.Edwin Huang1009/04/2008A51012Updated Attachment 1: EHS threshold value of component type for XRF testEdwin Huang1106/26/2009A6101112141. Add test method if cust

6、omer request2. Delete” IQC wont control the threshold value of Cl.3. Add “If the material composed of metal, glass and ceramic. The component wont be carried out halogen free.4. Updated AT-0801-M427-F1 to A2 version.Edwin HuangAG-0801-M006-F3 Rev.:A1目錄Content一、 目的Purpose二、 適用範圍Scope三、 樣品檢測條件及方法Test

7、condition & method for sample四、 零件及產品測試原則Testing Rule五、 測試方法Test Method六、 注意事項Attention item七、 附件Attachment1.XRF測試零件及產品類別之有害物質限值表限值表EHS threshold value of component type for XRF test2.拆解治工具管理流程The management process for disassembly tools of the component.3. XRF治工具季驗證紀錄表(AT-0801-M427-F1) The record o

8、f disassembly tools in quarter inspection by XRF (AT-0801-M427-F1).目的:Purpose本規範在建立進料之XRF檢驗標準,以確保品質合乎既定之標準。The purpose of this program is to establish the specification ofthe XRFinspection for incoming materials to assure the quality of materials and comply with specified criteria.一、 適用範圍:Scope適用於各大

9、類零件之檢驗。Apply to all types of materials.二、 樣品檢測條件及方法:Test condition & method1.分析方法分為檢量線法及FP法,說明如下:Test methodscan be separated to the method of calibration curve and FP method.1.1. 檢量線法:對應於XRF之分析條件為”Cd,Pb, Hg,Br,Cr.bcc”,適用之材質為塑料、紙張、木材及Mg,Al,Si較輕元素)為主材質之樣品。Method of calibration curve: The method is us

10、ed for plastic, paper, wood and somematerials mainly composing of Mg, Al, and Si. The analysis condition is ”Cd, Pb, Hg, Br, Cr.bcc”.1.2. FP法:對應於XRF之分析條件為”metal 2.bfb”,適用之材質為金屬(較重元素)為主材質之樣品。FP method: The method is used for some materials mainly composing of heavy metal. The analysis condition is ”m

11、etal 2.bfb” .四、零件及產品測試原則:Testing Rule1.金屬及塑料共存者: 平鋪於測試台並裁切至適當尺寸測試之。The sample composed of metallic and plastic materials: Cut the sample to be suitable size in the test platform.2.形狀凹凸不平者:測試點過高(超過0.5cm)時須拆解樣品,再取平整面測試(約1cm1cm)。The surface not bumpy: Separate the sample while the test point is higher

12、than test platform (0.5 cm).3.條狀金屬線者: 依其縱方向排列於測試台測試之。The metallic sample shaped into bar type : Arrange it vertically in test platform.4.鮮豔紅、黃、橙色者: 應優先量測(如油墨、塑膠類、PVC等)。The sample painted by brightly red, yellow and orange color: Measure the point first(such as ink,plastic and PVC).五、測試方法:Test Method

13、:Method 1:1.DIP類測試方法:以檢量線法測試。DIP: test by the method of calibration curve.1.1.本體大於1cm時:以本體為主並包括部分接腳進行測試(請參閱圖1) 。Sample size 1 cm: Focus on body and includes partial terminal (Refer to figure 1).1.2.本體小於1cm時:包含本體及接腳測試(請參閱圖2)。Sample size 1cm)量測流程Figure 1 The test procedure for DIP type(sample size 1 c

14、m)本體含接腳之影像視窗圖The test image including body and partial terminal.縱方向平鋪於測試台Put the sample in test platform verticallyDIP類DIP type縱方向平鋪於測試台Put the sample in test platform vertically本體包含接腳之影像視窗圖The test image including body and partial terminal.DIP類DIP type圖2 DIP類(本體 1 cm)Method 2:以檢量線法測試。Test by the me

15、thod of calibration curve.2.SMD類:分為長(L),寬(W),高(H)2mm類及其他尺寸類。SMD : Divide sample into two types, one isLength (L), width (W), or height (H)2mm, and another is other dimension。2.1.長(L),寬(W),高(H)2mm:裝滿1/2樣品杯測試(請參閱圖3)。Length (L), width (W), or height (H) 2mm:Fill up the 1/2 test cup with samples. (Refer

16、 to figure 3)2.1.其他尺寸類:以pad或接腳為優先量測面(請參閱圖4)。Other dimension: Focus on pad or terminal. (Refer to figure 3)L,W,H2mm類L,W,H2mm type填裝1/2樣品杯Fill up 1/2 cup with samples空樣品杯=2.7cmTest Cup圖3 SMD類填裝於1/2樣品杯之流程Figure 3 Procedure for fill up 1/2 cup with SMD type其他尺寸類Other Dimension含pad之影像視窗圖Test image includ

17、ing pad圖4 測試含pad面之SMD類Figure4 Procedure for SMD type including padMethod 3:以檢量線法測試。Test by the method of calibration curve.3.PCB類:測試點以涵蓋pad、文字、印刷線路為優先選擇,否則應依序分開測試(請參閱圖5)。PCB: Test the pad、word、printed line bythe method of calibration curve. (Refer to figure 5)PCB板PCB偵測點之影像視窗圖 Test imageTest point圖5

18、含pad、文字、印刷線路點之PCB板測試部位Figure 5 Test point including pad、word、printed line for PCBMethod 4:4.電感,變壓器類:Inductor and Transformer:類:分為漆包線外露(純金屬材質)所組成及外覆塑料之零件之兩種。DIP: Divide into two types, one is Enamel-insulated wire that is obvious to display; and another is covered with plastic.4.1.1.漆包線外露之零件:FP法測試(請參

19、閱圖6)。Enamel-insulated wire is obvious to display: test by FP method (Refer to figure 6)4.1.2.外覆塑料之零件:本體以檢量線法測試,接腳以FP法測試(請參閱圖7)。The inductor with the plastic jacket: Test the body by the method of calibration curve, and the terminal by FP test method separately(Refer to figure 7)接腳之影像視窗圖Terminal imag

20、e本體之影像視窗圖Body image拆解為本體及接腳To separate the sample into body and terminal外覆塑料之電感The inductor withthe plastic jacket圖7 外覆塑料之電感之測試流程Figure 7 Procedure for inductor with the plastic jacket偵測點之影像視窗圖Test image平鋪於測試台Put the inductoron test platform電感Inductor圖6 漆包線外露之電感測試流程Figure 6 Procedure for enamel-insu

21、lated wire being obvious to display類:SMD type:4.2.1.長(L),寬(W),高(H)5mm:裝滿1/2樣品杯測試,並使用檢量線法。Length (L), width (W), or height (H) 5mm,則量測方式分為:Any side on length(L), width (W), orheight (H) 5mm:The test methods as the followings,4.2.2.1.漆包線外露之零件:FP法測試(請參閱圖8)。The component of enamel-insulated wire isobvio

22、us to display: test by FP method (Referto figure 8)。4.2.2.2.包覆漆包線之零件:含pad面為優先量測面(請參閱圖9)。若pad面之主材質為塑料時,應以檢量線法測試。The component of enamel-insulated wire being covered: Test the pad side first (Refer to figure 9). If the materials on pad side is composed of plastic, choose the method of calibrationcurve

23、 for test.測試底部 Test the bottom測試側邊 Test the side漆包線外露之SMD元件(頂面含鮮豔之油墨)SMD component with enamel-insulated wire being obvious to display (Contain colorful ink)測試頂部 Test the top side圖8 漆包線外露之零件測試流程Figure 8 Procedure for the SMD component of enamel-insulated wire being obvious to display測試pad面Test the p

24、ad side包覆漆包線之SMD元件Component with enamel-insulated wire being covered圖9 包覆漆包線之零件測試流程Figure 9 Procedure for the component of enamel-insulated wire being coveredMethod 5: 5.金屬、塑膠材料類:樣品必須平貼測試,必要時將個別拆開(約1cm1cm) (請參閱圖10)。Metallic and Plastic materials: The test side of sample shall be flat on the test pla

25、tform, and it couldbe testedspecifically ifnecessary.(about 1cmx1cm) (Refer to figure 9)5.1.塑膠件:以檢量線法測試。Plastic materials: test bythe method of calibration curve.5.2.複合材料:金屬類以FP法測試,塑料類以檢量線法測試。Complexmaterials: Metallic materialsare tested by FP method and plastic materials by the method ofcalibratio

26、n curve.測試塑料 Test plasticTest plastic測試金屬 Test metal拆解成金屬及塑料Separate the sample無法平鋪於測試平台If the sample couldnt be flat on the test platform含塑料及金屬之機構件Test sample including metal and plastic圖10 機構件之測試流程Figure 10 Procedure for mechanical component5.3.金屬件:分鋁(鎂)合金及其他非鋁(鎂)合金系列材質(如銅,鐵,鋅等)。Metallicmaterials:

27、separate to two portions, one is for Al or Mg alloy, another is for non-Al or Mg alloy (e.g. Cu,Fe, and Zn).5.3.1鋁(鎂)合金(如heat sink,housing):檢量線法測試(請參閱圖11)。Aluminum (Al) or magnesium (Mg) alloy (e.g. heat sink and housing): test by the method of calibration curve (Refer to figure 11)5.3.2其他非鋁(鎂)合金系列材

28、質:FP法測試。Non- aluminum (Al) or magnesium (Mg) alloy materials: test by FP method.平鋪於測試台Put the sample on test platformHousing(Al)圖11 金屬件之測試流程Figure 11 Procedure for Metal componentMethod 6:6.包裝材:檢量線法測試(必要時再裁切)。Packaging materials: Test by the method of calibration curve (To cut the sample as the suit

29、able size ifnecessary)6.1.蓬鬆之包裝材:重疊高度至少3cm (請參閱圖12)。Fluffy package materials: The thickness shall be taken a height of3 cm at least (Refer to figure 12).、說明書、tray盤類:重疊高度至少0.5cm。Label, User manual and Tray: The thickness shall be taken a height of0.5 cm at least.瓦楞紙板Corrugated 氣泡袋Bubble bag發泡棉Sponge圖

30、12 包裝材之測試流程Figure 12.Procedure for packagingMethod 7:檢量線法測試(針對外觀測試即可)Test by the method of calibration curve (Only test the surface of sample)7.周邊材料類:以鮮豔紅、黃、橙顏色之部位優先測試, 其次為外殼,導線等。Periphery materials: Prefer to test the location painted by brightly red, yellow andorange, and then test outer covering

31、inturn.Method 8:檢量線法測試Test by the method of calibration curve8.PCBA板:插件之焊點處優先量測, 其次為SMD之焊點(請參閱圖12)。PCBA: Prefer to test the solder joint of DIP components, andthe second is the same area of SMD(Refer to figure 12).8.1.Sample size 小於L:12cm W:15cm時,則任選2點焊點。Sample size L (12cm)and W (15cm) : Choose fou

32、r solder joint randomly.SMD焊點放大圖SMD view插件之焊點放大圖DIP view選擇SMD及插件之焊點測試To choose the solder area of DIP or SMD測點距測試台過高The gap is too big between sample and XRFPCBA板PCBA圖13 PCBA板之測試流程Figure 13 Procedure for PCBAMethod 9:9.若為上述未涵蓋之零件類別,請取其平整面進行測試,並以鮮豔顏色如紅、黃、橙色之油墨,以及pad為優先量測點。If there are the other mater

33、ial type that didnt be covered above, they are preferred to test the flat side of thepad and the location painted by brightly red, yellow or orange.9.1.塑料材質以檢量線法進行測試。Plastic materialshave to test by the method of calibration curve.9.2.金屬部分以FP法進行測試。Metallic materials have totest by FP method.六、注意事項:A

34、ttention item:1.零件及產品經XRF試驗後之測定值應依XRF測試零件及產品類別之有害物質限值表(參照附件1)進行確認程序。After the testing by XRF, the result should be verifiedby attachment 1.2.當總鉻含量超過附件一的限值時,且零件含有金屬外層時,得依照AT-0801-M428金屬樣品塗覆鉻酸鹽之六價鉻存在之斑塊測試方法之化學檢測方法確認。If the XRF test result over threshold value in Cr with metallic coating, then follow u

35、p AT-0801-M428Spot Test for the Presence of Hexavalent Chromium (Cr VI) in Chromate Coating on Metallic Samplesto make sure whether contain (Cr VI). 3. 拆解治工具管理注意要項(管理流程如附件二):The management process for disassembly tools of the component. (See attachment 2)3.1拆解治工具須經XRF驗證符合規範後始得使用,否則須另購新治工具並經檢測合格為止。Th

36、e disassembly tools should pass through XRF inspection and qualification. Or else, IQC should purchase the new toolsthenqualifythemby XRF inspection.3.2符合要求之治工具需張貼XRF專用標示始得使用,並收納於XRF治工具專用櫃中,以避免與其他工具混用,且嚴禁使用未標示之治工具。Thetool thathad passed through XRF qualified. It should be labeled and separated.3.3治工

37、具於使用前或於拆解樣品A與樣品B之間,治工具需先要以酒精及棉布進行擦拭,並於檢驗完畢後須將工作台清潔乾淨,以避免測試樣品受污染。It is necessary that cleaning by alcohol for the disassembly tools before to use or between the different samples, and that cleaning the worktable after inspection.3.4治工具定期驗證:每季以XRF驗證治工具後之數據記錄於AT-0801-M427-F1,以供備查Quarter inspection by X

38、RF for tools and recording the result into AT-0801-M427-F13.5拆解樣品超標時:若樣品超標時,須以XRF檢驗拆解工具,以排除工具造成之污染Ifthe samples XRF test result is fail. The disassembly tools should be inspected by XRF to clarify the factor of contamination.4. 上述測試方法為主要拆解原則,若客戶另有要求則依照其規範實施測試。Above test methods are general rules for

39、 disassembly. If customers have further request for the test method, then we will follow their requirements.七、附件Attachment附件一:XRF測試零件及產品類別之有害物質限值表Attachment 1:EHS threshold value ofcomponent type for XRF test電子零件類 Component Type測試限值 Threshold Value測試零件Main Category零件類別DetailXRF測試方法 Test Method鉛(Pb)鎘

40、(Cd)汞(Hg)鉻(Cr) *溴(Br) *氯(Cl) * 溴(Br)+氯(Cl)主動零件類Active二極體(Diode)1.DIP:Method 12.SMD:Method 2700607007006306301050電晶体(Transistor)700607007006306301050閘流体(Thyratron)700607007006306301050積体電路(Integrated circuit)700607007006306301050FET700607007006306301050被動零件類Passive電容器(Capacitor)1.DIP:Method 12.SMD:Me

41、thod 2700607007006306301050電阻器(Resistor)700607007006306301050電感器(Inductance)Method 4700607007006306301050變壓器(Transformer)700607007006306301050記憶體零件類MemoryCPU, CHIP SETS, EPROM, DRAM, SRAM, PAL, RAMDAC, ASIC CHIP.Method 2700607007006306301050電機材料類Electrical有披覆之導線;裸導線; CABLE. cover of cable; nude of c

42、able; cableMethod5700607007006306301050Bonding wire, CONNECTOR, SOCKET, SWITCH, PIN HEADER, RELAY, SHORT PLUG, WIRE (SILVER), COPPER WIRE, FUSE, FACK, BATTERY.700607007006306301050水晶振盪子、振盪器Crystal, Oscillator700607007006306301050陶磁基片類(Ceramic)700607007006306301050MIRROR 類700607007006306301050化學材料類 C

43、hemicalEPOXY RESIN,COATING POSDER,RTV,SOLVENT等。ICP, IC測試 Test by ICP/IC限值參閱綠色環保產品規格(AT-0801-R300) Threshold value refer to AT-0801-R300五金材料類 Metallic五金類材料,包括所有沖壓、壓鑄及其電鍍、皮膜、表面塗裝及組立等之五金件。All of the incoming metal part, include all stamping, die-casting and electroplate, wiper and assembly etc.Method 5

44、700607007006306301050塑膠材料類Plastic所有一般進料之塑膠類材料,包括所有塑膠、橡膠及其組合件等。All of the incoming plastic part, include plastic, rubber and others assembly parts.Method 5700607007006306301050包裝材料類 Package包裝類材料,包括所有彩盒、紙箱、棧板、保麗龍、EPE、塑膠袋、文件手冊及各種防靜電材料等。All of the incoming packaging includes color box, carton, pallet, E

45、PS foam, EPE form, plastic bag, document manual and ESD material.Method 6鉛+汞+鎘+鉻之總量小於100ppm Pb+Hg+Cd+Cr 100ppmCd 5ppm6306301050印刷電路板類 PCB單面板、雙面板及多層板印刷電路板。Single sided、double sided and multilayer boardMethod 3700607007006306301050週邊材料類Periphery各種電源供應器、記憶體模組、輸出入設備、各式介面卡、PC卡等。 Power supply、memory modul

46、e、in-out put instrument、interface cards、PC cards etc.Method 7700607007006306301050產品類-PCBA Product type-PCBAMethod 8700607007006306301050Remark: (*)無鹵材料,於進料驗收報告單上會加註”HF”標示,以通知IQC執行XRF無鹵素檢驗。For Halogen Free components, There is a wording “HF” in incoming inspection sheet. IQC should to carry out halo

47、gen free inspection for the component.1.上述零件及產品類別如測試方法不適用時,請採行method 9。If the above-mentioned test method cannot be used on thematerials and products, please follow method9.2.上表中之晶片電阻本體含有玻璃纖維而含鉛量甚高,故此零件之鉛含量將暫不設定管制上限,但該材料仍須檢測。Due to lead in glass of Chip Resistor, lead (Pb) can be exempted from the r

48、equirement of above table, but the test results have to be kept.3.上表中之晶片電容及鐵蕊電感因本體含有陶瓷而含鉛量甚高,故此類零件之鉛含量,將暫不設定管制上限,但該材料仍須檢測。Due to lead in electronic ceramic parts (e.g. Chip Capacitor & Ferrite bead), lead (Pb) can be exempted from the requirement of above table, but the test results have to be kept.

49、4.上表中週邊材料若含有聚氯乙烯(PVC)電源線外被,其鉛含量不得大於300ppm。 If the above periphery type included the power cord made of PVC material. The threshold value of Lead substanceis not over 300 ppm by XRF.5.上表中材料若為金屬、玻璃及陶瓷材質(如USI 06大類),則不需實施無鹵素檢驗,但材質若為添加塑料、油墨等組成之複合材料,該材料仍需實施無鹵素檢驗。 If the material composeof metal, glass and

50、 ceramic. The componentwont be carried out halogen free inspection. Otherwise, Shall carry out halogen free inspectiondepend on“HF”indication.附件二:拆解治工具管理流程Attachment 2: The management process for disassembly tools of the component.附件三:XRF治工具季驗證紀錄表XRF治工具季驗證紀錄表(AT-0801-M427-F1),此表格僅供TW/SH/SZ sites 使用.Attachment 3: The record of disassembly tools in quarter inspection by XRF. (For TW/SH/SZ sites usage only)

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。