钢材和连接的强度设计值

钢材和连接的强度设计值

《钢材和连接的强度设计值》由会员分享,可在线阅读,更多相关《钢材和连接的强度设计值(66页珍藏版)》请在装配图网上搜索。

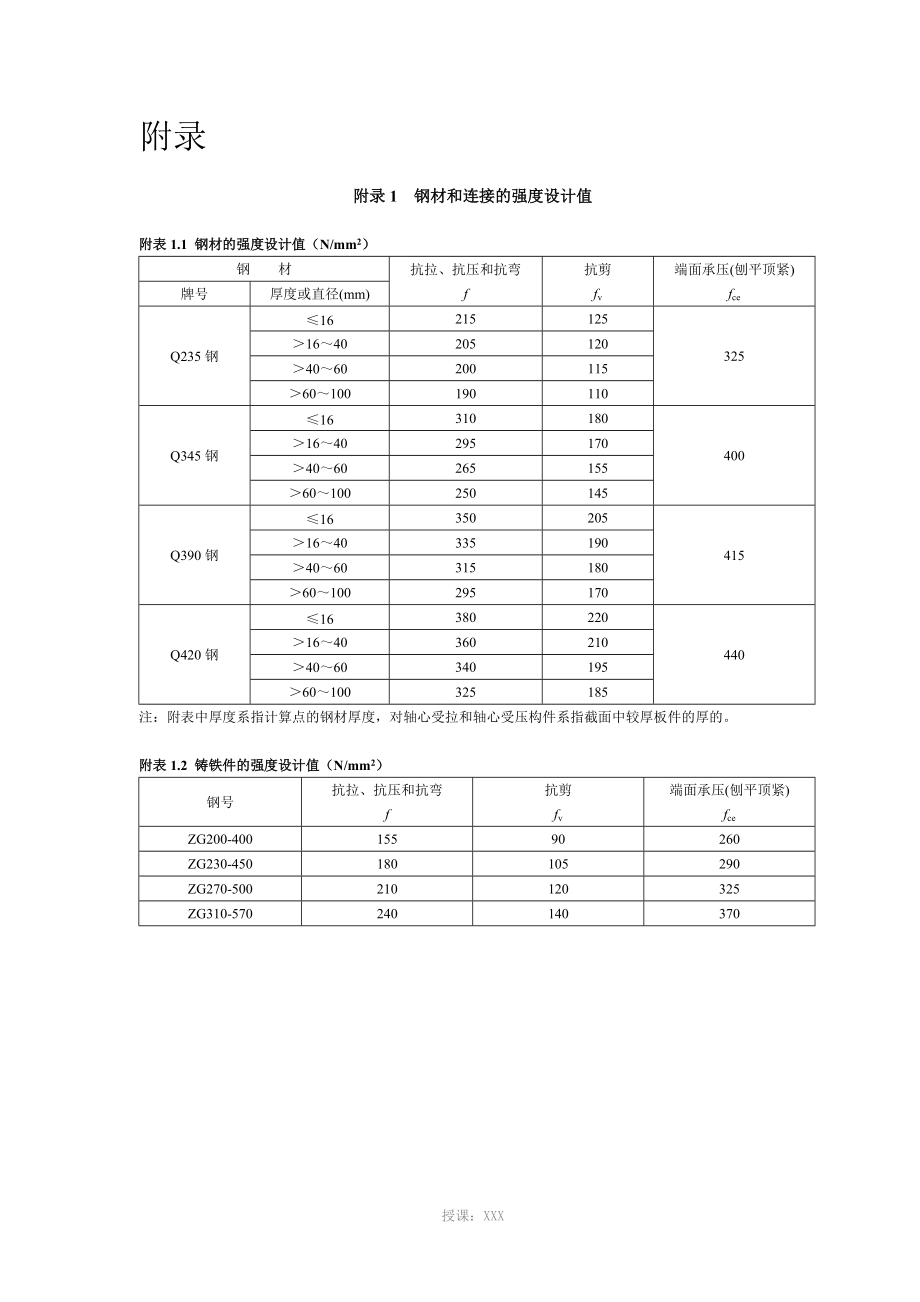

1、附录附录1 钢材和连接的强度设计值附表1.1 钢材的强度设计值(N/mm2)钢 材抗拉、抗压和抗弯f抗剪fv端面承压(刨平顶紧)fce牌号厚度或直径(mm)Q235钢162151253251640205120406020011560100190110Q345钢163101804001640295170406026515560100250145Q390钢163502054151640335190406031518060100295170Q420钢163802204401640360210406034019560100325185注:附表中厚度系指计算点的钢材厚度,对轴心受拉和轴心受压构件系指截面

2、中较厚板件的厚的。附表1.2 铸铁件的强度设计值(N/mm2)钢号抗拉、抗压和抗弯f抗剪fv端面承压(刨平顶紧)fceZG200-40015590260ZG230-450180105290ZG270-500210120325ZG310-570240140370授课:XXX附表1.3 焊缝的强度设计值(N/mm2)焊接方法和焊条型号构件钢材对接焊缝角焊缝牌号厚度或直径(mm)抗压fcw焊接质量为下列等级时,抗拉ftw抗剪fvw抗拉、抗压和抗剪ftw一级、二级三级自动焊、半自动焊和E43型焊条的手工焊Q235钢16215215185125160164020520517512040602002001

3、7011560100190190160110自动焊、半自动焊和E50型焊条的手工焊Q345钢163103102651802001635295295250170355026526522515550100250250210145自动焊、半自动焊和E55型焊条的手工焊Q390钢163503503002052201635335335285190355031531527018050100295295250170Q420钢163803803202202201635360360305210355034034029019550100325325275185注:1 自动焊和半自动焊所采用的焊丝和焊剂,应保证其熔

4、敷金属的力学性能不低于现行国家标准埋弧焊用碳钢焊丝和焊剂GB/T 5293和低合金钢埋弧焊用焊剂GB/T 12470中相关的规定。 2 焊缝质量等级应符合现行国家标准钢结构工程施工质量验收规范GB 50205的规定。其中厚度小于8mm钢材的对接焊缝,不应采用超声波探伤确定焊缝质量等级。 3 对接焊缝在受压区的抗弯强度设计值取fcw,在受拉区的抗弯强度设计值取ftw。 4 附表中厚度系指计算点的钢材厚度,对轴心受拉和轴心受压构件系指截面中较厚板件的厚度。授课:XXX附表1.4 螺栓连接的强度设计值(N/mm2)螺栓的性能等级、锚栓和构件钢材的牌号普 通 螺 栓锚栓承压型连接高强度螺栓C级螺栓A级

5、、B级螺栓抗拉ftb抗剪fvb承压fcb抗拉ftb抗剪fvb承压fcb抗拉ftb抗拉ftb抗剪fvb承压fcb普通螺栓4.6级、4.8级1701405.6级2101908.8级400320锚栓Q235钢140Q345钢180承压型连接高强度螺栓8.8级40025010.9级500310构件Q235钢305405470Q345钢385510590Q390钢400530615Q420钢425560655注:1 A级螺栓用于d24mm和l10d或l150mm(按较小值)的螺栓;B级螺栓用于d24mm和l10d或l150mm(按较小值)的螺栓。d为公称直径,l为螺杆公称长度。 2 A、B级螺栓孔的精度

6、和孔壁表面粗糙度,C级螺栓孔的允许偏差和孔壁表面粗糙度,均应符合现行国家标准钢结构工程施工质量验收规范GB 50205的要求。附表1.5 铆钉连接的强度设计值(N/mm2)铆钉钢号和构件钢材牌号抗拉(钉头脱落)ftr抗剪fvr承压fcr类孔类孔类孔类孔铆钉BL2或BL3120185155构件Q235钢450365Q345钢565460Q390钢590480注:1 属于下列情况者为类孔:1) 在装配好的构件上按设计孔径钻成的孔;2) 在单个零件和构件上按设计孔径分别用钻模钻成的孔;3) 在单个零件上先钻成或冲成较小的孔径,然后在装配好的构件上再扩钻至设计孔径的孔。 2 在单个零件上一次冲成或不用

7、钻模钻成设计孔径的孔属于类孔。附录2 结构或构件的变形容许值2.1 受弯构件的挠度容许值授课:XXX2.1.1 吊车梁、楼盖梁、屋盖梁、工作平台梁以及墙架构件的挠度不宜超过附表2.1.1所列的容许值。附表2.1.1 受弯构件挠度容许值项次构 件 类 别挠度容许值vTvQ1吊车梁和吊车桁架(按自重和起重量最大的一台吊车计算挠度)(1) 手动吊车和单梁吊车(含悬挂吊车)(2) 轻级工作制桥式吊车(3) 中级工作制桥式吊车(4) 重级工作制桥式吊车l/500l/800l/1000l/12002手动或电动葫芦的轨道梁l/4003有重轨(重量等于或大于38kg/m)轨道的工作平台梁有轻轨(重量等于或小于

8、24kg/m)轨道的工作平台梁l/600l/4004楼(屋)盖梁或桁架、工作平台梁(第3项除外)和平台板(1) 主梁或桁架(包括设有悬挂起重设备的梁和桁架)(2) 抹灰顶棚的次梁(3) 除(1)、(2)款外的其他梁(包括楼梯梁)(4) 屋盖檩条支承无积灰的瓦楞铁和石棉瓦屋面者支承压型金属板、有积灰的瓦楞铁和石棉瓦等屋面者支承其他屋面材料者(5) 平台板l/400l/250l/250l/150l/200l/200l/150l/500l/350l/3005墙架构件(风荷载不考虑阵风系数)(1) 支柱(2) 抗风桁架(作为连续支柱的支承时)(3) 砌体墙的横梁(水平方向)(4) 支承压型金属板、瓦楞

9、铁和石棉瓦墙面的横梁(水平方向)(5) 带有玻璃窗的横梁(竖直和水平方向)l/200l/400l/1000l/300l/200l/200注:1 l为受弯构件的跨度(对悬臂梁和伸臂梁为悬伸长度的2倍)。 2 vT为永久和可变荷载标准值产生的挠度(如有起拱应减去拱度)的容许值;vQ为可变荷载标准值产生的挠度的容许值。2.1.2 冶金工厂或类似车间中设有工作级别为A7、A8级吊车的车间,其跨间每侧吊车梁或吊车桁架的制动结构,由一台最大吊车横向水平荷载(按荷载规范取值)所产生的挠度不宜超过制动结构跨度的1/2200。2.2 框架结构的水平位移容许值2.2.1 在风荷载标准值作用下,框架柱顶水平位移和层

10、加相对位移不宜超过下列数值:1 无桥式吊车的单层框架的柱顶位移 H/1502 有桥式吊车的单层框架的柱顶位移 H/4003 多层框架的柱顶位移 H/5004 多层框架的层加相对位移 h/400H为自基础顶面至柱顶的总高度;h为层高。注:1 对室内装修要求较高的民用建筑多层框架结构,层间相对位移宜适当减小。无墙壁的多层框架结构,层间相对位移可适当放宽。授课:XXX 2 对轻型框架结构的柱顶水平位移和层间位移均可适当放宽。2.2.2 在冶金工厂或类似车间中设有A7、A8级吊车的厂房柱和设有中级和重级工作制吊车的露天栈桥柱,在吊车梁或吊车桁架的顶面标高处,由一台最大吊车水平荷载(按荷载规范取值)所产

11、生的计算变形值,不宜超过附表A.2.2所列的容许值。附表2.2.2 柱顶水平位移(计算值)的容许值项次位移的种类按平面结构图形计算按空间结构图形计算1厂房柱的横向位移Hc/1250Hc/20002露天栈桥柱的横向位移Hc/25003厂房和露天栈桥柱的纵向位移Hc/4000注:1 Hc为基础顶面至吊车梁或吊车桁架顶面的高度。 2 计算厂房或露天栈桥柱的纵向位移时,可假设吊车的纵向水平制动力分配在温度区段内所有柱间支撑或纵向框架上。 3 在设有A8级吊车的厂房中,厂房柱的水平位移容许值宜减小10。 4 设有A6级吊车的厂房柱的纵向位移宜符合表中的要求。附录3 梁的整体稳定系数3.1 等截面焊接工字

12、形和轧制H型钢简支梁等截面焊接工字形和轧制H型钢(图3.1)简支梁的整体稳定系数应按下式计算: (3.1.1)yyb1b1ht1t1xxyyb1b2ht1t2xxyyyb1b2ht1t2xxyyb1b1ht1t1xx(a)双轴对称焊接工字形截面(b)加强受压翼缘的单轴对称焊接工字形截面(c) 加强受拉翼缘的单轴对称焊接工字形截面(d)轧制H型钢截面图3.1 焊接工字形和轧制H型钢截面授课:XXX式中 梁整体稳定的等效临界弯矩系数,按附表3.1采用;梁在侧向支撑点间对截面弱轴y-y的长细比,为侧向支承点间的距离,为梁毛截面对y轴的截面回转半径;A梁的毛截面面积;h、t1梁截面的全高和受压翼缘厚度

13、;截面不对称影响系数;对双轴对称截面(图3.1a、d):;对单轴对称工字形截面(图3.1b、c):加强受压翼缘:;加强受拉翼缘:;,式中I1和I2分别为受压翼缘和受拉翼缘对y轴的惯性矩。当按公式(3.1.1)算得的值大于0.6时,应用下式计算的代替值: (3.1.2) 注:公式(3.1.1)亦适用于等截面铆接(或高强度螺栓连接)简支梁,其受压翼缘厚度t1包括翼缘角钢厚度在内。附表3.1 H型钢和等截面工字形简支梁的系数b项次侧向支承荷 载2.02.0适用范围1跨中无侧向支承均布荷载作用在上翼缘0.690.130.95图3.1a、b和d的截面2下翼缘1.730.201.333集中荷载作用在上翼缘

14、0.730.181.094下翼缘2.230.281.675跨度中点有一个侧向支承点均布荷载作用在上翼缘1.15图3.1中的所有截面6下翼缘1.407集中荷载作用在截面高度上任意位置1.758跨中有不少于两个等距离侧向支承点任意荷载作用在上翼缘1.209下翼缘1.4010梁端有弯矩,但跨中无荷载作用,但2.3注:1 为参数,其中l1和b1分别为H型钢或等截面工字形简支梁受压翼缘的自由长度和宽度。 2 M1、M2为梁的端弯矩,使梁产生同向曲率时M1和M2取同号,产生反向曲率时取异号,|M1|M2|。授课:XXX 3 附表中项次3、4和7的集中荷载是指一个和少数几个集中荷载位于跨中央附近的情况,对其

15、他情况的集中荷载,应按附表中项次1、2、5、6内的数值采用。 4 附表中项次8、9的b,当集中荷载作用在侧向支承点处时,取b1.20。 5 荷载作用在上翼缘系指荷载作用点在翼缘表面,方向指向截面形心;荷载作用在下翼缘系指荷载作用点在翼缘表面,方向背向截面形心。 6 对0.8的加强受压翼缘工字形截面,下列情况的b值应乘以相应的系数: 项次1:当1.0时,乘以0.95; 项次3:当0.5时,乘以0.90;当0.51.0时,乘以0.95。3.2 轧制普通工字钢简支梁轧制普通工字钢简支梁的整体稳定系数应按附表3.2采用,当所得的值大于0.6时,应按公式3.1.2算得相应的代替值。附表3.2 轧制普通工

16、字钢简支梁的项次荷载情况工字钢型 号自由长度l1(m)23456789101跨中无侧向支承点的梁集中荷载作用于上翼缘1020223236632.002.402.801.301.481.600.991.091.070.800.860.830.680.720.680.580.620.560.530.540.500.480.490.450.430.450.402下翼缘1020224045633.105.507.301.952.803.601.341.842.301.011.371.620.821.071.200.690.860.960.630.730.800.570.640.690.520.560.

17、603均布荷载作用于上翼缘1020224045631.702.102.601.121.301.450.840.930.970.680.730.730.570.600.590.500.510.500.450.450.440.410.400.380.370.360.354下翼缘1020224045632.504.005.601.552.202.801.081.451.800.831.101.250.680.850.950.560.700.780.520.600.650.470.520.550.420.460.495跨中有侧向支承点的梁(不论荷载作用点在截面高度上的位置)1020224045632.

18、203.004.001.391.802.201.011.241.380.790.961.010.660.760.800.570.650.660.520.560.560.470.490.490.420.430.43注:1 同附表3.1的注3、5。 2 附表中的适用于Q235钢。对其他钢号,附表中数值应乘以235/fy。3.3 轧制槽钢简支梁轧制槽钢简支梁的整体稳定系数,不论荷载的形式和荷载作用点在截面高度上的位置,均可按下式计算: (3.3)式中h、b、t 分别为槽钢截面的高度、翼缘宽度和平均厚度。授课:XXX 按公式(3.3)算得的大于0.6时,应按公式(3.1.2)算得相应的代替值。3.4

19、双轴对称工字形等截面(含H型钢)悬臂梁双轴对称工字形等截面(含H型钢)悬臂梁的整体稳定系数,可按公式(3.1.1)计算,但式中系数b应按附表3.4查得,y=l1/iy(l1为悬臂梁的悬伸长度)。当求得的大于0.6时,应按公式(3.1.2)算得相应的代替值。附表3.4 双轴对称工字形等截面(含H型钢)悬臂梁的系数b项次荷载形式0.601.241.241.961.963.101自由端一个集中荷载作用在上翼缘0.210.670.720.261.170.032下翼缘2.940.652.640.402.150.153均布荷载作用在上翼缘0.620.821.250.311.660.10注:1 本附表是按支

20、承端为固定的情况确定的,当用于由邻跨延伸出来的伸臂梁时,应在构造上采取措施加强支承处的抗扭能力。 2 附表中见附表3.1注1。3.5 受弯构件整体稳定系数的近似计算均匀弯曲的受弯构件,当时,其整体稳定系数可按下列近似公式计算:1 工字形截面(含H型钢):双轴对称时: (3.5.1)单轴对称时: (3.5.2)2 T形截面(弯矩作用在对称轴平面,绕x轴)1) 弯矩使翼缘受压时:双角钢T形截面: (3.5.3)部分T型钢和两板组合T形截面: (3.5.4)2) 弯矩使翼缘受拉且腹板宽厚比不大于时: (3.5.5) 按公式(3.5.1)至公式(3.5.5)所得的值大于0.6时,不需按公式(3.1.2

21、)换算成值;当按公式(3.5.1)和公式(3.5.2)算得的授课:XXX值大于1.0时,取1.0。授课:XXX附录4 轴心受压构件的稳定系数附表4.1 a类截面轴心受压构件的稳定系数012345678901020304050607080901001101201301401501601701801902002102202302402501.0000.9950.9810.9630.9410.9160.8830.8390.7830.7140.6380.5630.4940.4340.3830.3390.3020.2700.2430.2200.1990.1820.1660.1530.1410.1301.

22、0000.9940.9790.9610.9390.9130.8790.8340.7760.7060.6300.5550.4880.4290.3780.3350.2980.2670.2410.2180.1980.1800.1650.1520.1401.0000.9930.9770.9590.9370.9100.8750.8290.7700.6990.6220.5480.4810.4230.3730.3310.2950.2640.2380.2150.1960.1790.1640.1500.1391.0000.9920.9760.9570.9340.9070.8710.8240.7630.6910.

23、6150.5410.4750.4180.3690.3270.2920.2620.2360.2130.1940.1770.1620.1490.1380.9990.9910.9740.9550.9320.9040.8670.8180.7570.6840.6070.5340.4690.4120.3640.3230.2890.2590.2330.2110.1920.1750.1610.1480.1360.9990.9890.9720.9520.9290.9000.8630.8130.7500.6760.6000.5270.4630.4070.3600.3200.2850.2560.2310.2090.

24、1900.1740.1590.1470.1350.9980.9880.9700.9500.9270.8970.8580.8070.7430.6680.5920.5200.4570.4020.3560.3160.2820.2530.2290.2070.1890.1720.1580.1460.1340.9980.9860.9680.9480.9240.8940.8540.8010.7360.6610.5850.5140.4510.3970.3510.3120.2790.2510.2260.2050.1870.1710.1570.1440.1330.9970.9850.9660.9460.9210.

25、8900.8490.7950.7280.6530.5770.5070.4450.3920.3470.3090.2760.2480.2240.2030.1850.1690.1550.1430.1320.9960.9830.9640.9440.9190.8860.8440.7890.7210.6450.5700.5000.4400.3870.3430.3050.2730.2460.2220.2010.1830.1680.1540.1420.131注:见附表4.4注。授课:XXX附表4.2 b类截面轴心受压构件的稳定系数0123456789010203040506070809010011012013

26、01401501601701801902002102202302402501.0000.9920.9700.9360.8990.8560.8070.7510.6880.6210.5550.4930.4370.3870.3450.3080.2760.2490.2250.2040.1860.1700.1560.1440.1330.1231.0000.9910.9670.9320.8950.8520.8020.7450.6810.6140.5490.4870.4320.3830.3410.3040.2730.2460.2230.2020.1840.1690.1550.1430.1321.0000.9

27、890.9630.9290.8910.8470.7970.7390.6750.6080.5420.4810.4260.3780.3370.3010.2700.2440.2200.2000.1830.1670.1540.1420.1310.9990.9870.9600.9250.8870.8420.7910.7320.6680.6010.5360.4750.4210.3740.3330.2980.2670.2410.2180.1980.1810.1660.1530.1410.1300.9990.9850.9570.9220.8820.8380.7860.7260.6610.5940.5290.4

28、700.4160.3700.3290.2950.2650.2390.2160.1970.1800.1650.1510.1400.1290.9980.9830.9530.9180.8780.8330.7800.7200.6550.5880.5230.4640.4110.3650.3260.2910.2620.2360.2140.1950.1780.1630.1500.1380.1280.9970.9810.9500.9140.8740.8280.7740.7140.6480.5810.5170.4580.4060.3610.3220.2880.2590.2340.2120.1930.1760.1

29、620.1490.1370.1270.9960.9780.9460.9100.8700.8230.7690.7070.6410.5750.5110.4530.4020.3570.3180.2850.2560.2320.2100.1910.1750.1600.1480.1360.1260.9950.9760.9430.9060.8650.8180.7630.7010.6350.5680.5050.4470.3970.3530.3150.2820.2540.2290.2080.1900.1730.1590.1460.1350.1250.9940.9730.9390.9030.8610.8130.7

30、570.6940.6280.5610.4990.4420.3920.3490.3110.2790.2510.2270.2060.1880.1720.1580.1450.1340.124注:见附表4.4注。授课:XXX附表4.3 c类截面轴心受压构件的稳定系数012345678901020304050607080901001101201301401501601701801902002102202302402501.0000.9920.9660.9020.8390.7750.7090.6430.5780.5170.4630.4190.3790.3420.3090.2800.2540.2300.21

31、00.1920.1760.1620.1500.1380.1280.1191.0000.9900.9590.8960.8330.7680.7020.6360.5720.5110.4580.4150.3750.3390.3060.2770.2510.2280.2080.1900.1750.1610.1480.1370.1271.0000.9880.9530.8900.8260.7620.6950.6290.5660.5050.4540.4110.3710.3350.3030.2740.2490.2260.2060.1890.1730.1590.1470.1360.1260.9990.9860.94

32、70.8840.8200.7550.6890.6230.5590.5000.4490.4070.3670.3320.3000.2710.2460.2240.2050.1870.1720.1580.1460.1350.1250.9990.9830.9400.8770.8140.7480.6820.6160.5530.4940.4450.4030.3640.3280.2970.2690.2440.2220.2030.1860.1700.1570.1450.1340.1240.9980.9810.9340.8710.8070.7420.6760.6100.5470.4880.4410.3990.36

33、00.3250.2490.2660.2420.2200.2010.1840.1690.1560.1440.1330.1240.9970.9780.9280.8650.8010.7350.6690.6040.5410.4830.4360.3950.3560.3220.2910.2640.2390.2180.1990.1820.1680.1540.1430.1320.1230.9960.9760.9210.8580.7940.7290.6620.5970.5350.4770.4320.3910.3530.3190.2880.2610.2370.2160.1970.1810.1660.1530.14

34、20.1310.1220.9950.9730.9150.8520.7880.7220.6560.5910.5290.4720.4280.3870.3490.3150.2850.2580.2350.2140.1960.1790.1650.1520.1400.1300.1210.9930.9700.9090.8460.7810.7150.6490.5840.5230.4670.4230.3830.3460.3120.2820.2560.2330.2120.1940.1780.1630.1510.1390.1290.120注:见附表4.4注。授课:XXX附表4.4 d类截面轴心受压构件的稳定系数01

35、2345678901020304050607080901001101201301401501601701801902001.0000.9840.9370.8480.7660.6900.6180.5520.4930.4390.3940.3590.3280.2990.2720.2480.2270.2080.1910.1760.1621.0000.9810.9270.8400.7590.6830.6120.5460.4870.4340.3900.3560.3250.2960.2700.2460.2250.2060.1890.1740.9990.9780.9180.8310.7510.6750.605

36、0.5400.4810.4290.3870.3530.3220.2930.2670.2440.2230.2040.1880.1730.9990.9740.9090.8230.7430.6680.5980.5340.4760.4240.3830.3500.3190.2900.2650.2420.2210.2030.1860.1710.9980.9690.9000.8150.7350.6610.5910.5280.4700.4190.3800.3460.3160.2880.2620.2400.2190.2010.1840.1700.9960.9650.8910.8070.7280.6540.585

37、0.5220.4650.4140.3760.3430.3130.2850.2600.2370.2170.1990.1830.1680.9940.9600.8830.7990.7200.6460.5780.5160.4600.4100.3730.3400.3100.2820.2580.2350.2150.1970.1810.1670.9920.9550.8740.7900.7120.6390.5720.5100.4540.4050.3700.3370.3070.2800.2550.2330.2130.1960.1800.1660.9900.9490.8650.7820.7050.6320.565

38、0.5040.4490.4010.3660.3340.3040.2770.2530.2310.2120.1940.1780.1640.9870.9440.8570.7740.6970.6250.5590.4980.4440.3970.3630.3310.3010.2750.2510.2290.2100.1920.1770.163注:1 附表4.1至附表4.4中的值系按下列公式算得:当时: 当时: 式中,、为系数,根据截面的分类,按附表4.5采用。2 当构件的值超出附表4.1至附表4.4的范围时,则值按注1所列的公式计算。附表4.5 系数、截面类型a类0.410.9860.152b类0.650.

39、9650.300c类0.730.9060.5951.2160.302d类1.350.8680.9151.3750.432授课:XXX附录5 各种截面回转半径的近似值ix=0.30hiy=0.90biz=0.195hix=0.32hiy=0.28biz=0.09(b+h)ix=0.30hiy=0.215bix=0.32hiy=0.20bix=0.28hiy=0.24bix=0.30hiy=0.17bix=0.28hiy=0.21bix=0.21hiy=0.21biz=0.185hix=0.21hiy=0.21bix=0.45hiy=0.24bix=0.40hiy=0.21bix=0.45hiy=

40、0.235bix=0.43hiy=0.43bix=0.39hiy=0.20bix=0.42hiy=0.22bix=0.43hiy=0.24bix=0.365hiy=0.275bix=0.35hiy=0.56bix=0.39hiy=0.29bix=0.38hiy=0.60bix=0.38hiy=0.44bix=0.32hiy=0.58bix=0.32hiy=0.40bix=0.38hiy=0.21bix=0.44hiy=0.32bix=0.44hiy=0.38bix=0.37hiy=0.54bix=0.37hiy=0.45bix=0.40hiy=0.24bix=0.41hiy=0.29bix=0

41、.32hiy=0.49bix=0.29hiy=0.50bix=0.29hiy=0.45bix=0.39hiy=0.53bix=0.28hiy=0.37bix=0.29hiy=0.29bix=0.25diy=0.25dix=iy=0.175(D+d)ix=0.40h平iy=0.40b平ix=0.47hiy=0.40b授课:XXX附录6 柱的计算长度系数附表6.1 无侧移框架柱的计算长度系数K1K200.050.10.20.30.40.5123451000.050.10.20.30.40.512345101.0000.9900.9810.9640.9490.9350.9220.8750.8200.

42、7910.7730.7600.7320.9900.9810.9710.9550.9400.9260.9140.8670.8140.7840.7660.7540.7260.9810.9710.9620.9460.9310.9180.9060.8600.8070.7780.7600.7480.7210.9640.9550.9460.9300.9160.9030.8910.8460.7950.7670.7490.7370.7110.9490.9400.9310.9160.9020.8890.8780.8340.7840.7560.7390.7280.7010.9350.9260.9180.9030.

43、8890.8770.8660.8230.7740.7470.7300.7190.6930.9220.9140.9060.8910.8780.8660.8550.8130.7650.7380.7210.7100.6850.8750.8670.8600.8460.8340.8230.8130.7740.7290.7040.6880.6770.6540.8200.8140.8070.7950.7840.7740.7650.7290.6860.6630.6480.6380.6150.7910.7840.7780.7670.7560.7470.7380.7040.6630.6400.6250.6160.

44、5930.7730.7660.7600.7490.7390.7300.7210.6880.6480.6250.6110.6010.5800.7600.7540.7480.7370.7280.7190.7100.6770.6380.6160.6010.5920.5700.7320.7260.7210.7110.7010.6930.6850.6540.6150.5930.5800.5700.549注:1 附表中的计算长度系数值系按下式所得: 式中,K1、K2分别为相交于柱上端、柱下端的横梁线刚度之和与柱线刚度之和的比值。当横梁远端为铰接时,应将横梁线刚度乘以1.5;当横梁远端为嵌固时,则将横梁线刚

45、度乘以2。2 当横梁与柱铰接时,取横梁线刚度为零。3 对底层框架柱:当柱与基础铰接时,取K20(对平板支座可取K20.1);当柱与基础刚接时,取K210。4 当与柱刚性连接的横梁所受轴心压力Nb较大时,横梁线刚度应乘以折减系数N; 横梁远端与柱刚接和横梁远端铰支时:N=1-Nb/NEb 横梁远端嵌固时:N=1-Nb/(2NEb) 式中,NEb=2EIb/l2,Ib为横梁截面惯性矩,l为横梁长度。附表6.2 有侧移框架柱的计算长度系数K1K200.050.10.20.30.40.5123451000.050.10.20.30.40.512345106.024.463.423.012.782.642.332.172.112.082.072.036.024.163.472.862.582.422.312.071.941.901.871.861.834.463.473.012.562.332.202.111.901.791.751.731.721.703.422.862.562.232.051.941.871.701.601.571.551.54

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。