精品资料(2021-2022年收藏的)汽车倒车防撞自动测距报警系统设计

精品资料(2021-2022年收藏的)汽车倒车防撞自动测距报警系统设计

《精品资料(2021-2022年收藏的)汽车倒车防撞自动测距报警系统设计》由会员分享,可在线阅读,更多相关《精品资料(2021-2022年收藏的)汽车倒车防撞自动测距报警系统设计(16页珍藏版)》请在装配图网上搜索。

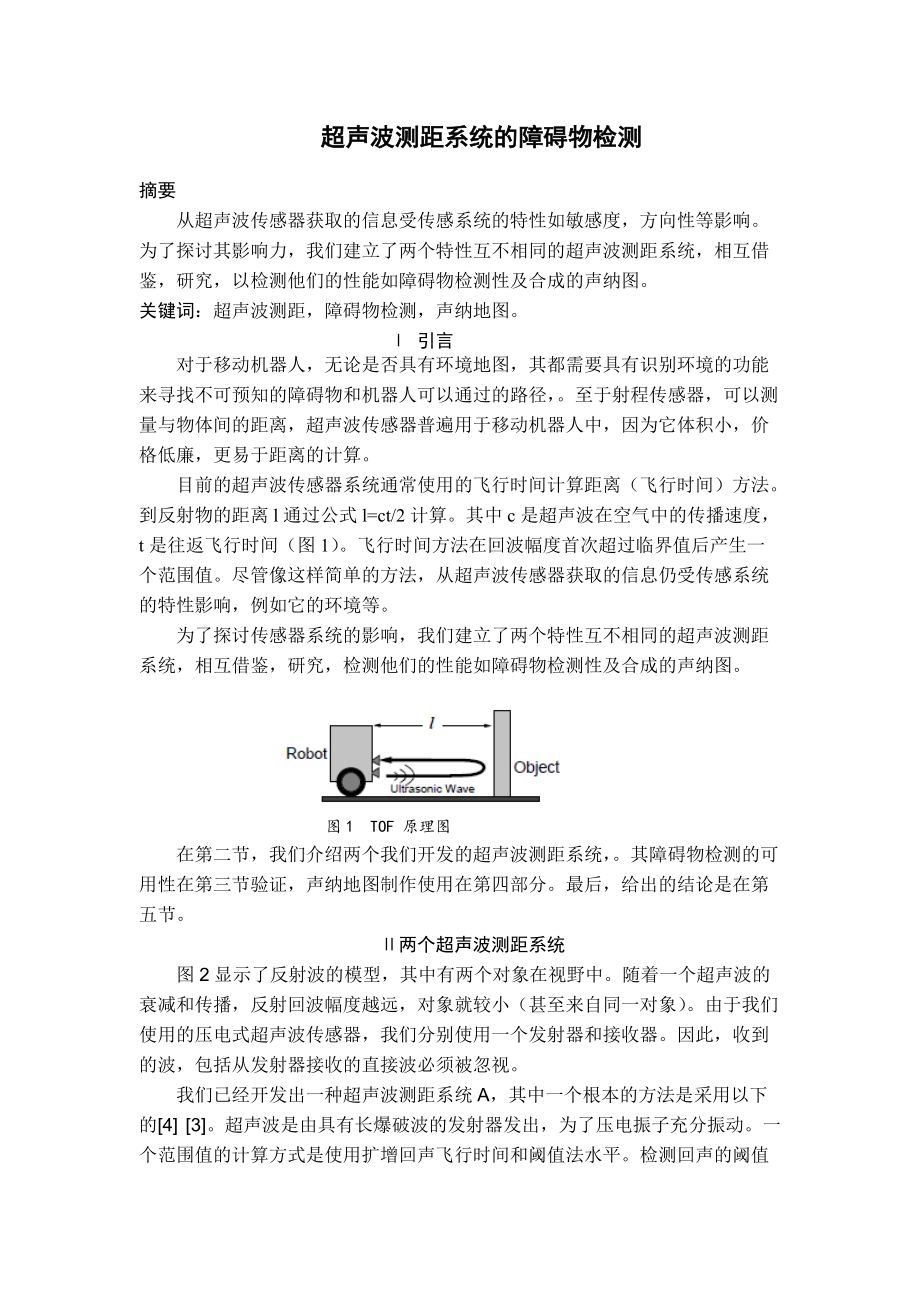

1、超声波测距系统的障碍物检测摘要从超声波传感器获取的信息受传感系统的特性如敏感度,方向性等影响。为了探讨其影响力,我们建立了两个特性互不相同的超声波测距系统,相互借鉴,研究,以检测他们的性能如障碍物检测性及合成的声纳图。关键词:超声波测距,障碍物检测,声纳地图。 引言对于移动机器人,无论是否具有环境地图,其都需要具有识别环境的功能来寻找不可预知的障碍物和机器人可以通过的路径,。至于射程传感器,可以测量与物体间的距离,超声波传感器普遍用于移动机器人中,因为它体积小,价格低廉,更易于距离的计算。目前的超声波传感器系统通常使用的飞行时间计算距离(飞行时间)方法。到反射物的距离l通过公式l=ct/2计算

2、。其中c是超声波在空气中的传播速度,t是往返飞行时间(图1)。飞行时间方法在回波幅度首次超过临界值后产生一个范围值。尽管像这样简单的方法,从超声波传感器获取的信息仍受传感系统的特性影响,例如它的环境等。为了探讨传感器系统的影响,我们建立了两个特性互不相同的超声波测距系统,相互借鉴,研究,检测他们的性能如障碍物检测性及合成的声纳图。图1 TOF 原理图在第二节,我们介绍两个我们开发的超声波测距系统,。其障碍物检测的可用性在第三节验证,声纳地图制作使用在第四部分。最后,给出的结论是在第五节。 两个超声波测距系统图2显示了反射波的模型,其中有两个对象在视野中。随着一个超声波的衰减和传播,反射回波幅度

3、越远,对象就较小(甚至来自同一对象)。由于我们使用的压电式超声波传感器,我们分别使用一个发射器和接收器。因此,收到的波,包括从发射器接收的直接波必须被忽视。我们已经开发出一种超声波测距系统A,其中一个根本的方法是采用以下的4 3。超声波是由具有长爆破波的发射器发出,为了压电振子充分振动。一个范围值的计算方式是使用扩增回声飞行时间和阈值法水平。检测回声的阈值恒定不变,以简化电路。A系统每个信号的概念如图3所示。但是,这种系统存在一些问题。首先,回波信号是缓慢上升,然而回波信号强度没有那么大。因此,易造成测量误差。为了减少这种测量误差,超声波必须加速增加。其次,测量范围是有限的,它由固定阈值水平决

4、定。当级别设置较高时,不可能检测远距离物体。或者它当级别设置为低时可能检测出近距离的噪声。此外,喇叭连接到A体系中增加波强度。然而,它使方向性狭窄。图2反射波的模型图3 A系统信号的概念为了解决A系统的问题,我们改进了发送和接收电路,开发了一种新型超声波传感器系统B。B系统每个信号的概念如图4所示。为了扩大回波信号的强度,加快了它的增加,一个单脉冲高电压用于发射器。峰值电压约为720V,尽管它在系统A中是 12V的。这种方法有以下好处。首先,掩蔽时间随着传送时间的缩短可缩短。因此,它可以测量近距离物体。其次,通过利用高电压超声波脉冲发射,发射波上升时间缩短了。因此,测量误差可减少。对于接收,阈

5、值水平随时间递减,并逐步适应回波振幅减少随距离增加。我们把这种方法称为时间阈值控制。此方法对于近处物体具有很强的噪声,而且可以测量较远距离的对象。宝丽来超声波测距定位传感器解决了随时间变化的放大系数这个问题。这就是所谓的时间增益控制。但电路复杂。为了以一个简单的电路解决这个问题,而不是放大因素,阈值水平应随时间变化。系统B增加衡量的范围,减少测量误差,并以一个简单的电路提高测量性能。图4 B系统信号的概念图5 A系统获取的信号举例图5显示了由A系统获得的回声信号的例子。左边是一个直接波,右边是一个回音。在这种情况下,如果忽视了直接波,这时附近返回回声的物体则无法测量。此外,由于超声波缓慢上升造

6、成测量误差。图6显示了由B系统获得的回声信号的例子。其表明直接波缩短,以及超声波上升时间也缩短。图7显示了B系统中的放大接收信号和阈值水平。接收波在4V左右达到饱和。直接波通过起初设置高的阈值水平被忽略。在此之后,阈值水平随时间递减。 图6 B系统获取的信号举例图7 B系统中放大的接收信号及极限值举例 障碍物检测为了检测前面提到的两个超声波测距系统障碍物检测的实用性,我们测量了一个反射物体宽度的最大量测距离。传统的系统连接到角,以增加回波强度。我们测量的最大范围,而这些数据可以检测对象与实际距离误差。实验设置如图8,实验结果如图9所示。在图9,系统A的结果在图形下方,系统B在图形上方。实线表示

7、测量值,虚线表示的到物体的实际距离。如图所示在A和B两个系统中,如果反射物体的宽度小于10厘米其可测量的距离锐减。不过,这个数字表明,系统B在不使用喇叭时可以比系统A测量得更远,而且系统B与实际物体的误差比A小。我们得出结论可靠性和测量性能的改善B系统实现。在许多情况下,超声波传感器连接到一个喇叭,以增加换能器视线内波的强度,所以方向性变窄。窄指向性是为了更好地知道确切存在障碍的方向。然而,只有障碍物垂直于换能器的视线内,其才可以被检测到。了解障碍物存在与否及有多远对于移动机器人的障碍物检测很重要。因此,如图10所示宽指向性对于障碍物检测也很需要。带有喇叭的系统B较系统A可以获得较多的敏感性,

8、因此,在下一节验证系统B的指向性可以较宽,并提供更适合的障碍检测。 图8 反射物体宽度的最大量测距离实验设置 图9 反射物体宽度的最大量测距离实验结果图10 障碍物检测的超声波测距方向性 声纳地图理解我们调查了使用两个超声波测距系统制作的环境地图。该地图的制作方法是为将一定范围的数据沿传感器放置在一个方向测量范围内。其有围墙和直角弯道(凸,凹)。A系统使用了一个喇叭,以增加其强度。每个系统都安装在我们的移动机器人“YAMABICO”上5(图11),以及该系统的旋转方向是由机器人改变。实验环境如图12,系统A和B的实验结果分别显示在图13和14中。这些传感器被放在原点(0,0)。图11系统B安装

9、在移动机器人“YAMABICO”上。右侧是一个方向的发送和接收电路(70毫米*60毫米),左边是为4个发送和接收电路供电的高电压电路(70毫米*72毫米)。传感器直接连接到电路板,没有喇叭。图12实验环境。传感器被置于0点 图13表明系统A只可以检测到传感器视线内到墙的垂直回声。因为此系统中回声信号的强度很低,而且当回声从传感器反射回来时,其信号幅度无法超过其极限值。作为一个结果,看来这个系统有一个狭窄的方向性。另外,当传感器的线路和围墙的法线方向角变大时,回波强度变小。然后,后来的回声振幅超过一个阈值水平。因此,该区域的数据显示在圆与墙的接触弧上,其中心在墙外。与上述相比,图14表明,系统B

10、可以检测在每一个方向的回声,由于在这个系统中的回波信号的强度足够大。从这个图形可以看到,该系统B指向性宽,由于距离数据躺在一个传感器与圆的弧线上且其中心在传感器上。因此,当一个机器人移动,障碍是可以检测到的,即使他们没有垂直面对到换能器的视线。因此,系统B可以改善检测障碍物的能力。 结论从上述结果可以得到以下结论:障碍物检测的性能随着不同传感器系统变化。传感器的指向性不仅取决于换能器得方向性,而且取决于传感器的敏感性。由此得到的声纳地图形状急剧变化,根据传感器的特点,如灵敏度,方向性等。声纳地图的认识应当做到细心,因为声纳地图形状可能在很大程度上与真实的环境不符合。如果机器人感知能力与人类几乎

11、无异,我们可以信任机器人。不幸的是,几乎大多数的电流传感器并没有那么聪明,而且能力是有限的。因此,我们必须小心处理机器人的存在。图13 系统A 的合成声纳地图 图14 系统B 的合成声纳地图Obstacle Detectability of Ultrasonic Ranging Systemand Sonar Map UnderstandingAbstractInformation obtained by the ultrasonic sensor is influenced by the characteristics of the sensing system such as sensit

12、ivity, directivity and so on. In order to investigate its influence, we constructed two ultrasonic ranging systems of which characteristics differs from each other and examined their performance such as obstacle detectability and resultant sonar map.Keywords: Ultrasonic Sensing, Obstacle Detection,

13、Sonar MapI. IntroductionFor mobile robots, functions which recognize environments are required to find unpredictable obstacles and paths through which the robot can pass, whether having an environmental map or not. As for range sensors, which can measure a distance to objects, ultrasonic sensor is m

14、ore commonly used with mobile robots because it is small, inexpensive and easy to calculate distances.Present ultrasonic sensor systems generally calculate distance using the time-of-flight (TOF) method. The distance l to a reflected object is calculated by l =c t/2; (1) where c is the speed of soun

15、d, and t is the round-trip time-of-flight (Fig. 1). The TOF method produces a range value when the echo amplitude first exceeds the threshold level after transmitting. In spite of the simple method like this, information obtained by the ultrasonic sensor is influenced by the characteristics of the s

16、ensing system, it of environment and so on.In this paper, in order to investigate the influence of the sensor system, we constructed two ultrasonic ranging systems of which characteristics differs from each other and examined their performance such as obstacle detectability and resultant sonar map.I

17、n section II, we introduce two ultrasonic ranging systems which we developed. Their availability for obstacle detection is examined in section III, sonar map making using them in section IV. Finally, the conclusions are presented in section V. Fig. 1. The principles of the time-of-flight (TOF) metho

18、dII. Two Ultrasonic Ranging SystemsFig. 2 shows a model of reflected waves, where there are two objects in a field of view. As an ultrasonic wave attenuates and spreads, the echo amplitude reflected off farther object is smaller (even from the same object2). Because we use piezoelectric ultrasonic s

19、ensors, we use a transmitter and a receiver separately. So, the received waves include the direct wave from the transmitter which must be neglected.We have developed a ultrasonic range finding system A in which the following fundamental method is employed43. Ultrasonic waves are discharged from a tr

20、ansmitter given comparatively long burst waves in order to vibrate its piezoelectric vibrator fully. A range value is calculated by TOF method using the amplified echo and a threshold level. The threshold level to detect echoes is constant in order to simplify the circuit. The concept of each signal

21、 for System A is shown in Fig. 3. However, this system has some problems. First, the rise of echo signal is slow, since the intensity of the echo signal is not so large. So measuring errors result. To reduce such measuring errors, the rise of ultrasonic waves must be quickened. Next, the measuring r

22、ange is limited by a fixed threshold level. It is impossible to detect far distance objects when the level is set higher, or it is likely to detect noise from near distance objects when the level is set lower. Also, horns are attached to System A to increase the intensity of waves. However, it makes

23、 the directivity narrow. Fig. 2. A model of reflected waves.To solve the problems of System A, we improved the transmit and receive circuit, and developed a new ultrasonic sensor system B. The concept of each signal for System B is shown in Fig. 4. In order to enlarge the intensity of echo signal an

24、d quicken the rise of it, a high voltage single pulse is employed for transmitting. The peak voltage is about 720V, while it is about 12V in System A. This method has the following benefits. First, themasking time can be shortened by shortening the transmitting time. Thus it is possible to measure n

25、ear distances. Second, the rise time of transmitting waves is shortened byusing a high voltage for discharging ultrasonic pulses. Therefore the measuring errors can be reduced. For receiving, the threshold level is decreased with time, and is gradually adjusted to the echo amplitude decreasing with

26、the distance. We call this method timethreshold-control. This method is robust to noises from close objects, and makes it possible to measure far distance object. The Polaroid ultrasonic range sensor1 solves this problem by changing the amplification factor with time. This is called time-gain-contro

27、l. But the circuit is complicated. To solve this problem with a simple circuit, not the amplification factor but the threshold level should be varied with time. System B realizes increases in the measurable range, decreases measuring errors, and increases measuring performance with a simple circuit.

28、Fig. 5 shows an example of echo signal obtained by System A. The left one is a direct wave, and the right is an echo. In this case, if ignoring the direct wave, it was impossible to measure near objects whose echo returns in this time. Also, measuring errors resulted because of slow rise of ultrason

29、ic wave. Fig. 6 shows an example of echo signal obtained by System B. It shows that the direct wave is shortened, and the rise time of ultrasonic waves is also shortened. Fig. 7 shows the amplified received signal and the threshold level in System B. The received waves are saturated around 4V. The d

30、irect wave is ignored by making threshold level high at first. After that, the threshold level is decreased with time.Fig. 3. The concept of each signal for System A.Fig. 4. The concept of each signal for System B.Fig. 5. An example of echo signal obtained by System A.Fig. 6. An example of echo sign

31、al obtained by System B.Fig. 7. An example of the amplified received signal and the threshold level in System BIII. Obstacle DetectabilityTo examine the availability for obstacle detection of two ultrasonic ranging systems mentioned in previous section, we measured the relation of the maximum measur

32、able distance to the width of a reflected object. The conventional system is attached to a horn to increase the intensity of echoes. We measured the maximum range data to the object which can be detected, and errors to the real distance. The experimental set-up is shown in Fig. 8, and the experiment

33、al results are shown in Fig. 9. In Fig. 9, the result of System A is below the graph, and System B is above. Solid lines mean the measured value, and dotted lines mean the real distance to the object. As shown in this figure, in both System A and B, the maximum measurable distances decrease steeply

34、if the width of the reflected object is smaller than 10cm. However, this figure indicates that System B can measure farther distances than System A, without using horn in System B. Also the errors of System B to the real distance are smaller than that of System A, we conclude the reliability and the

35、 measuring performance are improved with System B.Fig. 8. Experimental set-up for the measurement of the relation of the maximum measurabledistance to the width of a reflected object.Fig. 9. The change of the maximum measurable distance to the width of a reflected object.Fig. 10. The directivity of

36、ultrasonic sensor for the obstacle detection. The obstacles cannot bedetected by the narrow directivity. In many cases, ultrasonic sensors are attached to a horn to increase the intensity of waves on the transducer line-of-sight, so the directivity becomes narrow. A narrow directivity is better in o

37、rder to know the exact direction which obstacles exist. However, only obstacles which face perpendicularly the transducers line-of-sight can be detected with a narrow directivity. It is important for mobile robots obstacle detection to know whether obstacles exist or not, and how far there are. So,

38、a wide directivity is also required for obstacle detection as shown in Fig. 10. With System B, more sensitivity can be obtained without a horn than with System A. Therefore the directivity of System B can be wide as is verified in next section, and it is more available for obstacle detection.IV. Son

39、ar Map UnderstandingWe investigate environment map making using two ultrasonic ranging systems. The method of making maps was for the range data to be placed along the transducer orientation at a measured range. There were flat walls and right-angle corners (convex and concave). System A used a horn

40、 to increase its intensity. Each system is mounted on our mobile robot “YAMABICO”5 (Fig. 11), and the orientation of the system was changed by rotating the robot. The experimental environment is shown in Fig. 12, the experimental results of System A and B are shown in Fig. 13 and 14, respectively. T

41、he sensors were put on the origin (0, 0).Fig. 11. System B mounted on our mobile robot “YAMABICO”. The right side is a transmit and receive circuit for one direction (70mm 60mm), the left side is a high voltage power supplyfor 4 transmit and receive circuits (70mm 72mm). Transducers are attached to

42、the board directly, without horns.As shown in Fig. 13, System A detected only echoes from which the transducer line-ofsight is perpendicular to the wall, because the intensity of echo signal is low in this system and the echo amplitude cannot exceed a threshold level when the echo is reflected out o

43、f transducer line-of-sight. As a result, it seems this system has a narrow directivity. Also, the intensity of echoes becomes smaller as the angle between the transducer line-of-sight and the normal direction of the wall becomes larger. Then, the echo amplitude exceeds later a threshold level. Conse

44、quently, the range data lay on the arc of a circle which was contact with the wall, and its center was out of walls.Fig. 12. Experimental environment. Sensors were put at the point 0.Compared with above, Fig. 14 indicates that System B could detect echoes in every direction, because the intensity of

45、 echo signal is large enough in this system. It can be seen from this figure that the directivity of System B is wide, since the range data lay on the arc of a circle with center at the sensor. Therefore, when a robot moves, obstacles can be detected even if they have no perpendicular faces to trans

46、ducer line-ofsight. Consequently, the ability to detect obstacles is improved in System B.V. ConclusionIt is concluded from the above-mentioned results that: Obstacle detectability varys with the individual sensor system. The directivity of the sensor depends on not only directivity of the transduce

47、r butsensitivity of sensor. The shape of the resultant sonar map changes drastically according to the characteristics of the sensor such as sensitivity, directivity and so on. Understanding of the sonar map should be done with carefulness, because the shape of sonar map may be largely different form

48、 the real shape of the environment. If the sensing ability of robot is nearly equal to it of human, we can trust the robot. Unfortunately, almost current sensors are not so intelligent and the ability is limited. So, we must be careful in the presence of the robot.References1 Polaroid Corp., Cambrid

49、ge, Massachusetts 02139, Ultrasonic Ranging System.2 P.J. McKerrow and J.C.T. Hallam: “An Introduction to the Physics of Echolocation,”Proceedings of the Third National Conference on Robotics of the Australian Robot Association, pp.198209, Melbourne, June 1990.3 Yoshiaki Nagashima and Shinich Yuta:

50、“Ultrasonic Sensing for a Mobile Robot to Recognize an Environment Measuring the Normal Direction of Walls,” Proceedings of the 1992 IEEE/RSJ International Conference on Intelligent Robots and Systems, pp.805812, Raleigh, NC, July 1992.4 Minho Song and Shinichi Yuta: “Autonomous Mobile Robot Yamabic

51、o and Its Ultrasonic Range Finding Module,” 89 Korean Automatic Control Conference, Vol.2, pp.711714, Seoul, October 1989.5 Shinichi Yuta, Shoji Suzuki and Shigeki Iida: “Implementation of a Small Size Experimental Self-contained Autonomous Robot Sensors, Vehicle Control and Description of Sensor Based Behavior,” R. Chatila et al. Eds, Experimental Robotics II (The 2nd International Symposium on Experimental Robotics, Toulouse, June 1991), Springar-Verlag, pp.344359, 1993.Fig. 13. Resultant sonar map for System A.Fig. 14. Resultant sonar map for System B.

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。