第二节-冷冲压模具常用零件标准(共10页)

第二节-冷冲压模具常用零件标准(共10页)

《第二节-冷冲压模具常用零件标准(共10页)》由会员分享,可在线阅读,更多相关《第二节-冷冲压模具常用零件标准(共10页)(10页珍藏版)》请在装配图网上搜索。

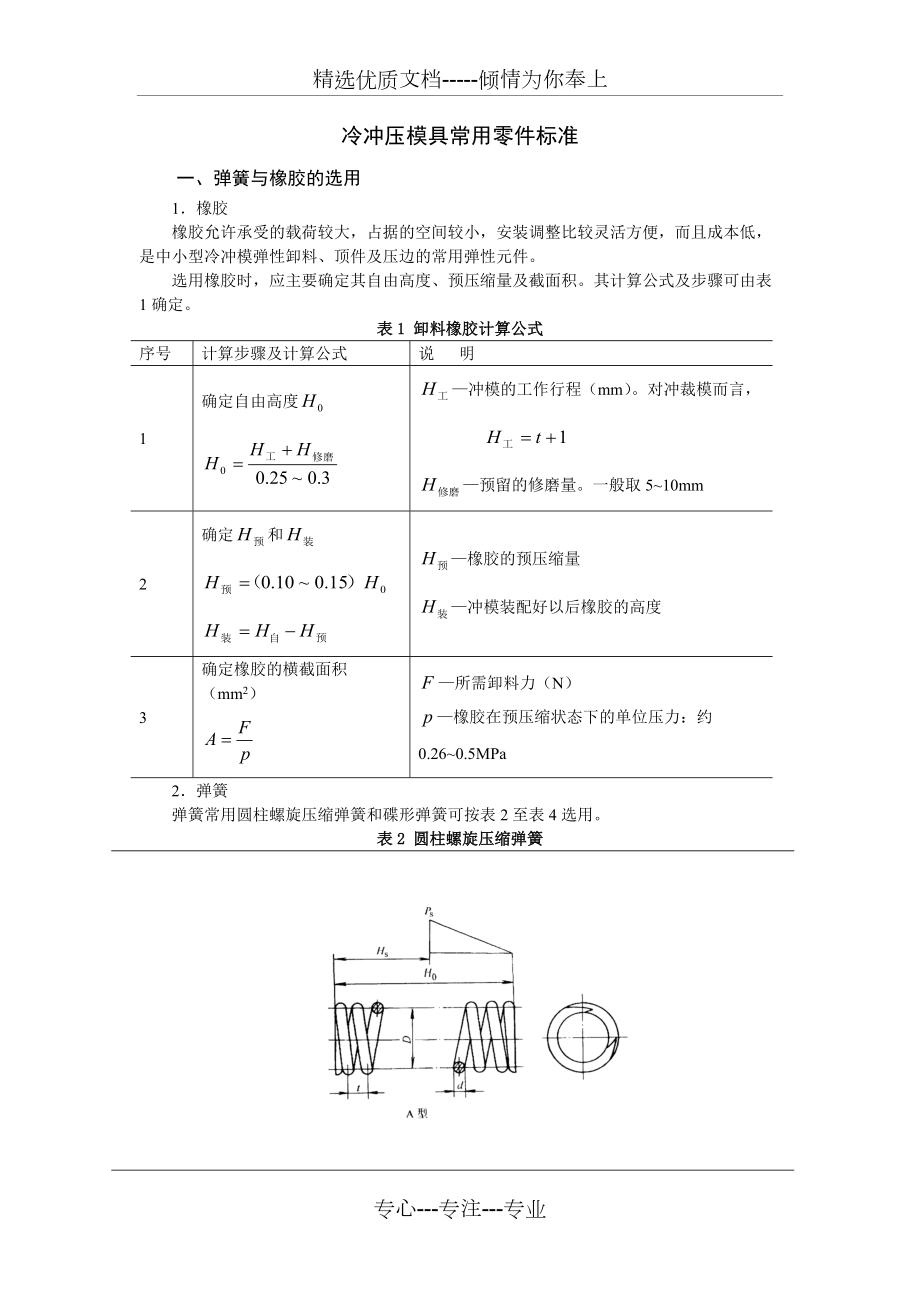

1、精选优质文档-倾情为你奉上冷冲压模具常用零件标准一、弹簧与橡胶的选用1橡胶橡胶允许承受的载荷较大,占据的空间较小,安装调整比较灵活方便,而且成本低,是中小型冷冲模弹性卸料、顶件及压边的常用弹性元件。选用橡胶时,应主要确定其自由高度、预压缩量及截面积。其计算公式及步骤可由表1确定。表1 卸料橡胶计算公式序号计算步骤及计算公式说 明1确定自由高度冲模的工作行程(mm)。对冲裁模而言,预留的修磨量。一般取510mm2确定和橡胶的预压缩量冲模装配好以后橡胶的高度3确定橡胶的横截面积(mm2)所需卸料力(N)橡胶在预压缩状态下的单位压力:约0.260.5MPa2弹簧弹簧常用圆柱螺旋压缩弹簧和碟形弹簧可按

2、表2至表4选用。表2 圆柱螺旋压缩弹簧dDtPsDxmaxDTminH0nPFSF1F2L0.541.7511.42.95.1126.51.487.701.546.161072212.50.77214.82.9611.81822614.50.66517.23.4413.820763.167.624.57.51440.71410.72.148.56113226.50.44017.33.4613.81600.862.3428.74.27.8134.54.166.911.385.53123207.52.5011.52.309.2117932*12.51.5019.23.8415.427338*14.

3、51.2922.34.4617.831183.5321.66.29.8184.51.7612.32.469.841631.030*7.51.0620.54.1016.42393.1240.9610205.53.5111.72.349.3618930*8.52.2718.03.6014.1264104.3132.78122042.4713.32.6610.6189306.51.5221.54.3017.226712243.51.6316.73.3413.4207357.51.3224.84.9619.82981.6103551267.412.6245.511.810.72.148.5623635

4、8.57.6116.63.3213.3330124.411058.415.62249.3611.22.248.96226326.55.7618.33.6614.6320166.5978.812.419.63043.9520.04.0016.0302405.52.8727.55.5022.0376486.52.4332.46.4825.942760*8.51.8642.48.4833.952870*10.51.5052.410.541.96282.0124.11192816244.520.39.481.907.58245357.512.215.83.1612.6358165.7414412202

5、849.4615.03.0012.0302385.57.0120.64.1216.5377487.55.1428.15.6222.5478558.54.5431.86.3625.452865*10.53.6739.37.8631.472975*12.53.0946.89.3637.4729186.741281422557.53.6135.57.1028.4537658.53.1940.38.0632.254975*10.52.5849.89.9639.8707207.851151525404.54.3926.35.26210408485.53.5932.264425.8471657.52.63

6、43.98.7835.159775*8.52.3249.79.9439.866090*10.51.8861.412.349.1785dDtPsDxmaxDTminH0nPFSF1F2L2.0207.851151525120*14.51.3684.817.067.810372.5165.4027311.520.5304.520.913.02.6010.4327406.514.518.83.7615.0427487.512.621.54.3417.447865*10.58.9730.46.0824.362875*12.57.5336.27.2429.0729227.981.9816.527.538

7、49.0621.94.3817.5415505.56.5930.16.0224.1518586.55.5735.77.1228.5587657.54.8341.18.2232.9657758.54.2646.59.3037.272690*10.53.4557.511.546.08643.0165.334541121457.526.017.43.4813.9478528.523.019.83.9615.8528185.94403132365*10.518.624.44.8819.562875*12.515.629.15.8223.3729354.530.513.22.6410.6368456.5

8、21.119.13.8215.3481588.516.125.05.0020.059470*10.513.130.96.1824.77073.5185.9461912.523.532463.59.751.957.80340405.546.213.42.6810.7424527.533.918.33.6614.6537206.5155713.526.5384.541.213.52.7010.8408506.528.519.63.9215.7534587.524.722.64.5218.159775*10.517.631.66.3225.3785227.1450615.528.538434.814

9、.62.9211.7415485.525.320.24.0016.0518627.518.627.35.4621.8657708.516.430.96.1824.77264.0206.638311327455.557.514.52.9011.6471587.542.519.73.9415.8597658.537.222.44.4817.966080*10.530.127.65.5222.1785227.187561529485.557.517.53.5014.0518556.548.620.74.1416.6587708.537.227.15.4221.772685*10.530.133.46

10、.6826.7864258.116651832454.536.018.53.7014.8511555.529.422.64.5218.1589707.521.630.96.1824.7746dDtPsDxmaxDTminH0nPFSF1F2L4.0258.116651832808.519.035.07.0028.0825309.925542337857.512.544.48.8835.589595*8.511.050.310.140.2990115*10.58.9262.212.449.81178140*12.57.4974.014.859.213674.5258.1694717.532.54

11、2464.814.62.9211.7471555.547.120.14.0216.1589606.539.923.84.7519.0668707.534.627.45.4821.9746309.7678922.537.5453.542.918.43.6814.7518524.533.323.74.7418.9613655.527.328.95.7923.2707807.520.239.57.8931.68955.0258.2912991733555.571.818.13.6214.5589656.560.821.44.2817.1668707.552.724.74.9319.7746808.5

12、46.528.05.5922.4825309.741083223850457.118.93.7915.2565655.541.626.15.2120.8707756.535.230.86.1624.6801857.530.535.57.1028.48953511.59282644604.532.029.05.8023.2715755.526.235.57.0928.4825856.522.141.98.3833.5935957.519.248.49.6738.71045注:1. 材料:65Mn、60Si2Mn,热处理硬度4048HRC,表面磷化处理。2. 带“*”的系细长比大于3.7,应考虑设

13、置心轴或套筒。3. 标准:GB/T2089-1994。表3 碟形弹簧类别Ddt(t)h0H0PfH0fOM、QKg/1000件f0.75H0NN/mm2N/mm2系列A 1189.210.41.412500.31.1-117013001.48022512.21.50.552.0529100.410.64-121014104.40031.516.31.750.72.4539000.531.92-119013107.8435.518.320.82.851900.62.2-1210133011.404020.42.250.93.1565400.682.47-1210134016.404522.42.

14、513.577200.752.75-1150130023.505025.431.14.1120000.833.27-1250143034.30系列B 1189.20.70.51.25720.380.82-104011301.0302512.20.90.71.68680.531.07-93810302.640231.516.31.250.92.1519200.681.47-109011905.60035.518.31.2512.2517000.751.5-99410707.1304020.41.51.152.6526200.861.79-1020113010.954522.41.751.33.0

15、536600.982.07-1050115016.405025.421.43.447601.052.35-1060114022.90系列C 1189.20.450.61.052140.450.6-78911100.6612512.20.70.91.66010.680.92-93612702.06031.516.30.81.051.856870.791.06-81011303.58035.518.30.91.152.058310.861.19-77910805.1404020.411.32.310200.981.32-77210707.3024522.41.251.62.8518901.21.6

16、5-920125011.705022.41.251.62.8515501.21.65-754104014.30注:1. 材料:60Si2MnA或50CrVA,硬度4252HRC。 2. 摘自GB/T1972-1992。表4 碟形弹簧的主要计算公式计算项目对合式安装(图a)复合式安装(图b)整个弹簧的允许负荷(N)一个弹簧的最大允许变形量(mm)整个弹簧的最大允许压缩量(mm)整个弹簧的预压缩量(mm)弹簧的工作行程(mm)保证规定行程的弹簧个数(个)弹簧自由长度注:表中一个弹簧在压缩量等于0.75h0时的最大允许负荷; 弹簧的极限行程(mm); 装置中一组弹簧的总数; 组合弹簧中每叠的弹簧数(

17、图b中); 一个弹簧的高度(mm); 弹簧板厚度(mm),。二、模具常用螺钉与销钉冷冲模零件的连接与紧固常用圆柱头内六角螺钉和沉头螺钉(表5和表6),零件的定位常用圆柱销(表7)。表5 圆柱头内六角螺钉 螺纹M4M5M6M8M10M12M16M20螺距0.70.811.251.51.7522.52022242832364452max3)7.008.5010.0013.0016.0018.0024.0030.004)7.228.7210.2213.2716.2718.2724.3330.33min6.788.289.7812.7315.7317.7323.6729.67max4.75.76.89

18、.211.213.717.722.4Max4.005.006.008.0010.0012.0016.0020.00min3.824.825.827.789.7811.7315.7319.67min3.444.585.726.869.1511.431619.44max0.60.60.681.021.021.451.452.04螺纹M4M5M6M8M10M12M16M20max4.005.006.08.0010.0012.0016.0020.00min3.824.825.77.649.6411.5715.5719.48rmin0.20.20.250.40.40.60.60.8S公称45681012

19、1620max6)3.0714.0845.0846.0958.11510.11514.14217.237)3.0804.0955.1406.1408.17510.17514.212min3.0204.0205.0206.0208.02510.02514.03217.05min22.53456810max0.40.50.60.811.21.62min6.538.039.3812.3315.3317.2323.1728.87min1.41.92.33.344.86.88.6L(长度系列)6,8,10,12,16,20,25,30,35,408, 10,12,16,20,25,30,35,40,45

20、5010,12,16,20,25,30,35,40,45,5055,6012,16,20,25,30,35,40,4550,55,60,6570,8016,20,25,30,35,40,45,5055,6065,70,80,90,10020,25,30,35,40,4550,55,60,6570,8090,100,110,12025,30,35,40,45,5055,6065,70,80,90,100,110,120,130,140,150,16025,30,35,40,45,5055,6065,70,80,90,100,110,120,130,140,150,160,180,200注:1.

21、标准:GB/T70.1-2000 2. 材料:35钢。表6开槽沉头螺钉螺纹规格dM4M5M6M8M10螺距0.70.811.251.5aMax1.41.622.53bmin38理论值max9.410.412.617.320实际值公称=max8.409.3011.3015.8018.30min8.048.9410.8715.3717.78公称=max2.72.73.34.655公称1.21.21.622.5max1.511.511.912.312.81min1.261.261.662.062.56max11.31.522.5max1.31.41.62.32.6min1.01.11.21.82.0

22、max1.7522.53.23.8螺纹规格dM4M5M6M8M10L(长度系列)6,8,10,12,16,20,25,30,35,408, 10,12,16,20,25,30,35,40,45,508,10,12,16,20,25,30,35,40,45,50,6010,12,16,20,25,30,35,40,4550,60,70,8012,16,20,25,30,35,40,45,5060,70,80注:1. 标准:GB/T5279; 2. 材料:Q235。表7圆柱销22.5345681012160.350.40.50.630.81.21.622.53的范围5205246306408501

23、060128016952014024180的系列5,6,8,10,12,14,16,18,20,22,24,26,28,30,32,35,40,45,50,55,60,65,70,75,80,85,90,95,100,120,140,160,180,200标注方法销GB/T119.1(d)(公差等级)(公称长度)注:1. 标准:GB/T119.1-2000; 2. 材料:Q235,35,45。三、模具上有关螺钉孔得尺寸1. 螺钉通过孔的尺寸见表8。表8 内六角螺钉通过孔尺寸通过孔尺寸螺钉M6M8M10M12M16M20M247911.513.517.521.525.51113.516.519.525.531.537.5345681012253545557585952. 螺钉旋进的最小深度、窝座最小深度以及圆柱销配合长度见下图所示。螺纹攻螺纹前钻孔直径:1)当螺距时 2)当螺距时 式中 钻孔直径(mm); 螺纹标称直径(mm)。3)装配卸料螺钉的尺寸见表9。表9 卸料螺钉孔的尺寸圆柱头螺钉内六角螺钉M466.593.54M688.51256M81010.514.568M10121317710M12141520812注:,是用垫板时其等于垫板厚度。在扩孔情况下,如使用垫板时可全部打通。卸料板行程。弹簧(橡皮)压缩后的高度。专心-专注-专业

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。