进料检验与不良品处置流程

进料检验与不良品处置流程

《进料检验与不良品处置流程》由会员分享,可在线阅读,更多相关《进料检验与不良品处置流程(6页珍藏版)》请在装配图网上搜索。

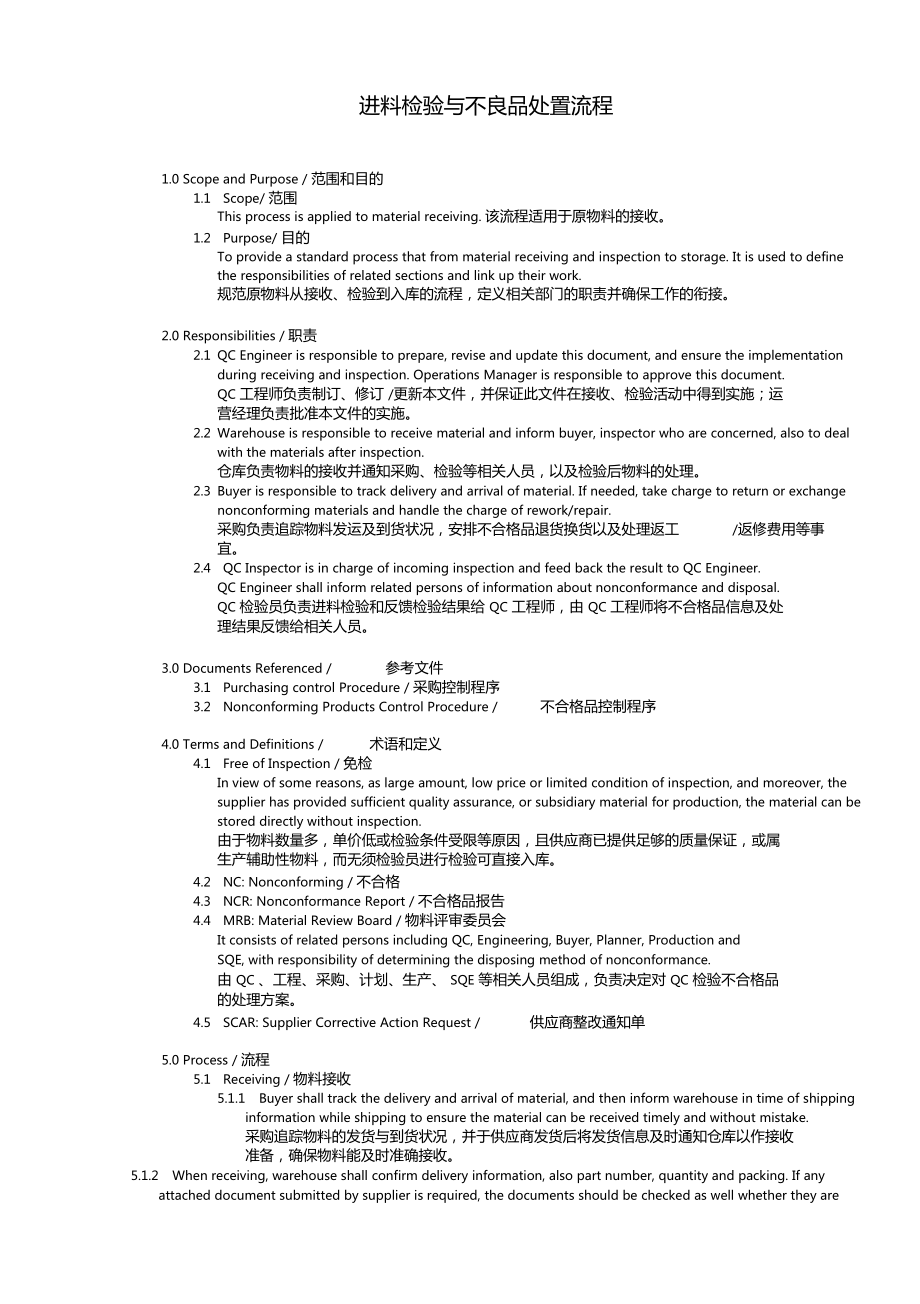

1、进料检验与不良品处置流程1.0 Scope and Purpose / 范围和目的1.1 Scope/ 范围This process is applied to material receiving. 该流程适用于原物料的接收。1.2 Purpose/ 目的To provide a standard process that from material receiving and inspection to storage. It is used to define the responsibilities of related sections and link up their work.

2、 规范原物料从接收、检验到入库的流程,定义相关部门的职责并确保工作的衔接。2.0 Responsibilities / 职责2.1 QC Engineer is responsible to prepare, revise and update this document, and ensure the implementation during receiving and inspection. Operations Manager is responsible to approve this document.QC 工程师负责制订、修订 /更新本文件,并保证此文件在接收、检验活动中得到实施

3、;运 营经理负责批准本文件的实施。2.2 Warehouse is responsible to receive material and inform buyer, inspector who are concerned, also to deal with the materials after inspection. 仓库负责物料的接收并通知采购、检验等相关人员,以及检验后物料的处理。2.3 Buyer is responsible to track delivery and arrival of material. If needed, take charge to return or

4、 exchange nonconforming materials and handle the charge of rework/repair. 采购负责追踪物料发运及到货状况,安排不合格品退货换货以及处理返工/返修费用等事宜。2.4 QC Inspector is in charge of incoming inspection and feed back the result to QC Engineer.QC Engineer shall inform related persons of information about nonconformance and disposal.QC

5、 检验员负责进料检验和反馈检验结果给 QC 工程师,由 QC 工程师将不合格品信息及处 理结果反馈给相关人员。3.0 Documents Referenced /参考文件3.1 Purchasing control Procedure / 采购控制程序3.2 Nonconforming Products Control Procedure /不合格品控制程序4.0 Terms and Definitions /术语和定义4.1 Free of Inspection / 免检In view of some reasons, as large amount, low price or limite

6、d condition of inspection, and moreover, the supplier has provided sufficient quality assurance, or subsidiary material for production, the material can be stored directly without inspection. 由于物料数量多,单价低或检验条件受限等原因,且供应商已提供足够的质量保证,或属 生产辅助性物料,而无须检验员进行检验可直接入库。4.2 NC: Nonconforming / 不合格4.3 NCR: Nonconfo

7、rmance Report / 不合格品报告4.4 MRB: Material Review Board / 物料评审委员会It consists of related persons including QC, Engineering, Buyer, Planner, Production andSQE, with responsibility of determining the disposing method of nonconformance.由 QC 、工程、采购、计划、生产、 SQE 等相关人员组成,负责决定对 QC 检验不合格品 的处理方案。4.5 SCAR: Supplier

8、 Corrective Action Request /供应商整改通知单5.0 Process / 流程5.1 Receiving / 物料接收5.1.1 Buyer shall track the delivery and arrival of material, and then inform warehouse in time of shipping information while shipping to ensure the material can be received timely and without mistake. 采购追踪物料的发货与到货状况,并于供应商发货后将发货

9、信息及时通知仓库以作接收 准备,确保物料能及时准确接收。5.1.2 When receiving, warehouse shall confirm delivery information, also part number, quantity and packing. If any attached document submitted by supplier is required, the documents should be checked as well whether they are missing. 仓库收货时需确认送货信息,然后核对零件号、数量并检查包装完好状况,如有随货资

10、 料要求,应检查所需资料是否提供齐全。5.1.3 Warehouse shall place received materials, filling the “ Material identification Card dis tinction, at Incoming Inspection Waiting Area, and inform buyer of the “ Incoming Inform Sheet ” to confirm the arrival of material, meanwhile inform inspector to do inspection. 仓库收货后应将物

11、料暂放在进料待检区,填写“物料标识卡”做好物料区分和标识,然 后开“进料检验通知单”及时通知采购以确认物料到货状况,同时通知检验员做进料检 验。5.2 Incoming Inspection / 进料检验5.2.1 Inspector shall check the information of inspection waiting materials when receive the “ Incoming Inform Sheet”, and prepare for inspection.检验员收到“进料检验通知单”后,核对现场待检物料信息,做好检验准备工作。5.2.2 Inspector

12、should check whether the material is free of inspection according to the “List of Inspection -free Material”. Materials can be accepted directly as beinginspection-free. 检验员依据“免检物料清单”判断待检物料是否免检,如为免检则可直接判定合格。5.2.3 Inspection shall be based on the document relevant including drawing, standard and insp

13、ecting working instruction. Inspector shall fill out the“ Incoming Material InspectionReport ” and other required records after inspection. 检验员依据图纸、标准和检验指导书等进行检验,并填写“进料检验报告”及其它所需 检验记录。5.2.4 Inspector shall transfer accepted materials and the “ Material identification Card ” pasted with green tag to

14、store waiting area, and feed back the “ Incoming Inform Sheet ” with remark of judgment to warehouse. 检验合格的物料由检验员转移至待入库区,在“物料标识卡”上贴“合格”标签,并在 “进料检验通知单”上给出检验结论通知仓库入库。5.2.5 For material which is primarily judged as nonconformance, inspector shall place them at Incoming Nonconforming Product A rea, and

15、make out the“ NonconformanceEvaluation Report ” and then submit to QC Engineer along with the“ Incoming MaterialInspection Report”. The nonconforming materials shall be distinguished and identifiedwith “ Nonconformance Label ”, which should contain information of nonconformance. 检验后初步判定不合格的物料由检验员转移至

16、进料不合格品区,并填写“不合格品处置报告”(NCR )附在“进料检验报告”后交给 QC工程师处理,同时用“不良品标签” 将不合格物料进行标识并区隔放置,标签上应填写不合格品相关信息。5.3 Review of Nonconformance / 不合格品评审5.3.1 After receive and check the NCR, QC Engineer should call a MRB meeting or only sign it together with related persons when necessary to review the nonconformance, othe

17、rwise dispose of the nonconformance in accordance with the recommendation from QC.QC 工程师接到 NCR 并确认后,如有需要可召集相关人员开 MRB 会议或以会签形式对 不合格品进行评审,否则依照 QC 处置意见处理不良品。5.3.2 MRB should consist of QC, Engineering, Buyer and Planner. Production should be involved if rework or repair is needed. According to the seve

18、rity and Repeatability of nonconformity, SQE should be invited as well. The reviewing method is on the basisof the “ Nonconforming Products Control Procedure ”. The members have the responsibility and play the role as below:MRB应由QC、工程、采购和计划相关人员组成,如有返工或返修需要则生产也应参 加,视不合格的严重性和重复性则可邀请 SQE 参加。评审依据“不合格品控制

19、程序” 要求进行, MRB 各成员职责与角色如下:1) QC: Provide detail information of nonconformity; evaluate the quality risk of product and economy of sorting; check and review any complaint from customer before. QC :提供详细不合格信息,评估产品质量风险与筛选经济性,审查以往客户投诉。2) Engineering: Analyze and evaluate the impact of nonconformity on pro

20、duction or product, also any bad consequence would be caused; evaluate the feasibility and economy of rework or repair; decide the requirement of rework or repair and acceptable standard of concession if needed; provide analyzing description or testing evidence when necessary. 工程:分析和评估不合格对生产或产品本身的影响

21、及可能导致的不良后果,评估返工 或返修可行性与经济性,根据需要提供返工或返修的要求与让步接收的标准,必要时 提供分析说明或试验结果。3) Buyer: Provide information of lead time; evaluate the feasibility of return or exchange; any cooperation and charge should be from supplier if need rework or repair. 采购:提供物料交期信息,评估退货、换货的可行性,如需要返工或返修供应商可提 供的配合及承担的相关费用。4) Planner: Pr

22、ovide information of material demand and production schedule; delivery schedule of product should be provided by inside sales if necessary. 计划:提供物料需求及生产排程信息,必要时由销售提供出货交期信息。5) Production: Evaluate and arrange rework or repair. 生产:返工或返修的评估及安排。6) SQE: Evaluate that whether it is necessary for supplier

23、to provide improvement report and check inventory and work in process. SQE :评估要求供应商提供改善报告和清查库存及在制品的必要性。5.3.3 All the members shall make an agreement after review and sign on the NCR with disposing method. 评审后所有成员需达成一致意见,在 NCR 上给出评审处置意见并签字确认。5.3.4 The NCR reviewed and signed in MRB shall be submitted

24、 to Manager for final judgment and approval.评审会签后应将 NCR 转呈部门经理做最终判定和批准。5.4 Disposal of Nonconformance / 不合格品处理5.4.1 After finished review finally, the white and yellow page shall be respectively kept by inspector and warehouse on file, and the red page shall be attached to the nonconformance. Inspec

25、tor shall record the information of NCR on the“ NCR ListNCR 最终评审结束后,白、黄联分别交由检验员和仓库归档保存,红联随附在不合格 品上,检验员将有关信息录入“不合格品报告清单”中。5.4.2 For rework or repair, a“ Rework/Repair Sheet l”d bsehmouade out by inspector andsubmitted to Engineering for determining the method and requirement of rework or repair. Acco

26、rding to the“ Rework/Repair Sheet ” , production arranges rework or repairand then record the work hours spent and other expense when finish. Finally the materials which have been reworked or repaired shall be re-inspected by inspector. Go on as per item 5.4.1 if pass re-inspection, or else NCR shou

27、ld be re-issued and submitted to QC Engineer.如需返工或返修,则先由检验员开“返工/ 返修单”,转交工程确定返工或返修方式及要求,生产接到“返工 / 返修单”后按要求执行返工或返修,完成后填上所耗费工时和其 它费用,最后交由检验员对返工或返修后的物料再次检验确认。如检验合格则依 5.4.1 执行,如检验后仍判不合格,需重新开 NCR 提报 QC 工程师处理。5.4.3 After the NCR is closed, QC Engineer shall communicate the disposing information from “ NCR

28、List ” and the expense of rework /repair to buyer, war ehouse, planner and SQE in time.QC 工程师在 NCR 处理结束后应及时将“不合格品报告清单”中的不合格品处理信息 和返工 /返修的相关费用信息传达给采购、仓库、计划、SQE 等相关人员。5.4.4 Complying with the final result of NCR, the disposal should follow the method as below: 不合格品依据 NCR 最终评审结果应按以下方式处理:1) Reject /retu

29、rn: Warehouse moves nonconformance to Material Return Area pending return.拒收 /退货:由仓库将不合格品转移至退货区等待退货处理。2) Scrap: Warehouse moves nonconformance to Scrap Area for scraping. 报废:由仓库将不合格品转移至报废品区作报废处理。3) Rework /repair: The materials which have been reworked or repaired and passed the re-inspection shall

30、be transferred to Store Waiting Area; keep the material if unacceptable at Incoming Nonconforming Product Area for reevaluation. 返工 /返修:返工 /返修后经检验合格的,由检验员转移至待入库区;如有检验不合格 的则仍放置在进料不合格品区等待重新评审。4) Accept under concession: Inspector transfers the materials to Store Waiting Area. 回用 /让步接受:由检验员将物料转移至待入库区。5

31、.4.5 Buyer shall inform the supplier of the nonconformance information when have notice from QC, and negotiate about return or exchange and charge of rework/repair with supplier if needed. 采购在接到不合格品处理信息后将相关不合格信息告知供应商,并视需要与供应商联系 退货或换货、返工 /返修费用承担等事宜。5.4.6 If necessary for the supplier to correct the n

32、onconformity, SQE shall issue SCAR to require the supplier to analyze the root cause and take corrective actions. The corrective actions shall be reviewed by SQE and its result shall be verified based on follow-up quality or field witness.如需要供应商对不合格进行整改,由 SQE 发出“供应商整改通知单”要求供应商分析 原因和制定措施, SQE 需对供应商提出

33、的整改措施进行评审,并通过后续质量状况追 踪或实地确认以验证整改措施的有效性。6.0 Applied records List / 适用记录清单6.1 Material Identification Card / 物料标识卡6.2 List of Inspection-free Material /免检物料清单6.3 Incoming Inform Sheet / 进料检验通知单6.4 Incoming Material Inspection Report /进料检验报告6.5 Nonconformance Evaluation Report (NCR) /不合格品处置报告6.6 Rework

34、/Repair Sheet / 返工 /返修单6.7 Supplier Corrective Action Request /供应商整改通知单7.0 Flow Chart / 作业流程图公司SupplierWarehouseBuyerPlannerProductionEngineering一QC EngineerDelivery track交货追踪Goodsdeliver交货Receive接收Incominginform来料通知Redeliver J重新送货i計 Delivery inform交货通知Receivingconfirm到货确认Reject/Return拒收/退货Return or

35、 exchange arrange/ Rework pay back ! 联系退货、换!货、费用承担Material Review BoardScrap ; Accept under 报废concession让步接受NC product dispose 不合格品处理Store 入库NQC Inspectornspection-free?是否免检NMRB?NNC Area不合格品区Inspect进料检验NCR confirmNCR 确认cceptable?是否合格Rework/Repair !返工/返修Requirement I or standard 要求或标准Rework/Repair返工/返修NCRRew./Rep. Sheet返工/返修单NCR ListNCR清单NCR informNCR通知Store AwaitingArea待入库区

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。