复合材料力学上机编程作业(计算层合板刚度)要点

复合材料力学上机编程作业(计算层合板刚度)要点

《复合材料力学上机编程作业(计算层合板刚度)要点》由会员分享,可在线阅读,更多相关《复合材料力学上机编程作业(计算层合板刚度)要点(15页珍藏版)》请在装配图网上搜索。

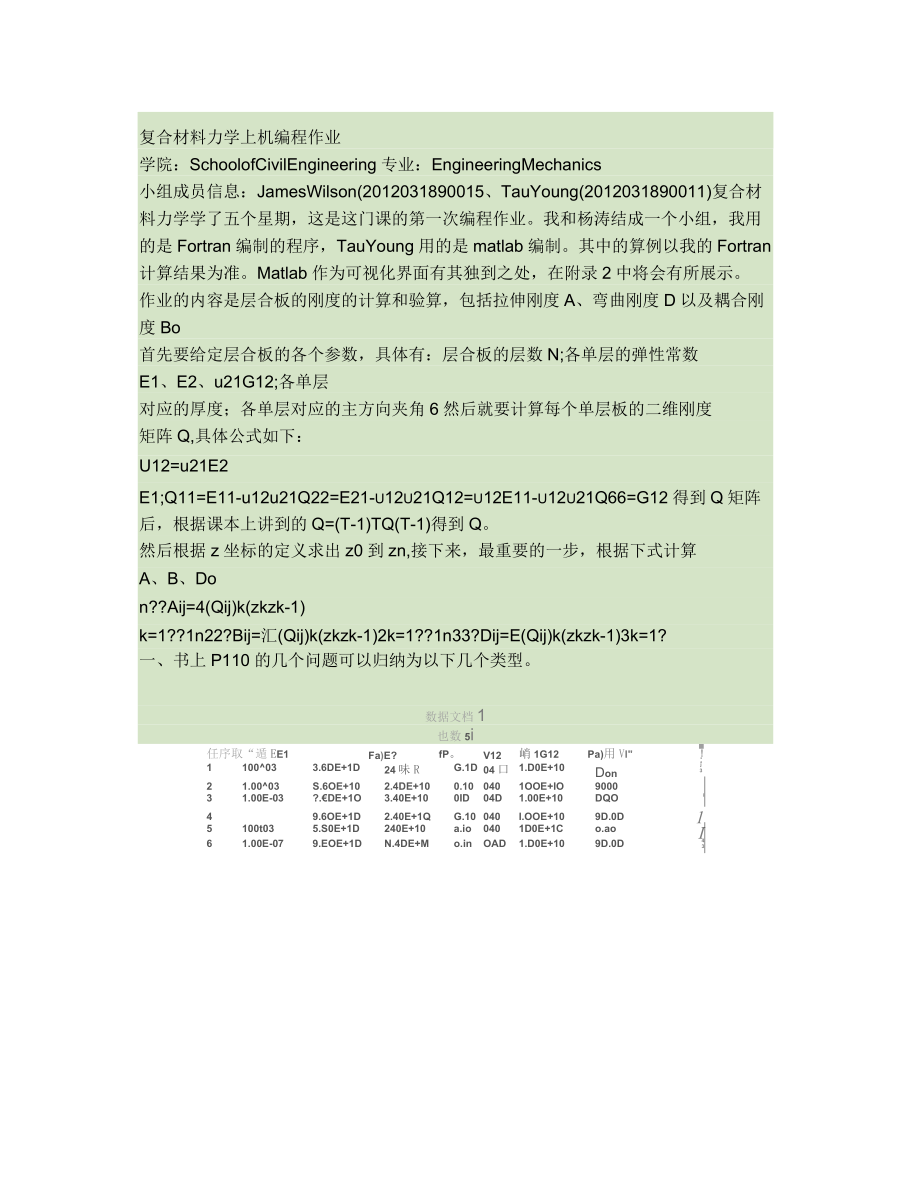

1、复合材料力学上机编程作业学院:SchoolofCivilEngineering专业:EngineeringMechanics小组成员信息:JamesWilson(2012031890015、TauYoung(2012031890011)复合材料力学学了五个星期,这是这门课的第一次编程作业。我和杨涛结成一个小组,我用的是Fortran编制的程序,TauYoung用的是matlab编制。其中的算例以我的Fortran计算结果为准。Matlab作为可视化界面有其独到之处,在附录2中将会有所展示。作业的内容是层合板的刚度的计算和验算,包括拉伸刚度A、弯曲刚度D以及耦合刚度Bo首先要给定层合板的各个参数

2、,具体有:层合板的层数N;各单层的弹性常数E1、E2、u21G12;各单层对应的厚度;各单层对应的主方向夹角6然后就要计算每个单层板的二维刚度矩阵Q,具体公式如下:U12=u21E2E1;Q11=E11-u12u21Q22=E21-u12u21Q12=u12E11-u12u21Q66=G12得到Q矩阵后,根据课本上讲到的Q=(T-1)TQ(T-1)得到Q。然后根据z坐标的定义求出z0到zn,接下来,最重要的一步,根据下式计算A、B、Don?Aij=4(Qij)k(zkzk-1)k=1?1n22?Bij=汇(Qij)k(zkzk-1)2k=1?1n33?Dij=E(Qij)k(zkzk-1)3k

3、=1?一、书上P110的几个问题可以归纳为以下几个类型。数据文档1也数5i任序取“遁EE1Fa)E?fP。V12峭1G12Pa)用VI!:1100033.6DE+1D24味RG.1D04口1.D0E+10donj321.0003S.6OE+102.4DE+100.100401OOE+IO900031.00E-03?.DE+1O3.40E+100ID04D1.00E+10DQOi49.6OE+1D2.40E+1QG.10040l.OOE+109D.0D15100t035.S0E+1D240E+10a.io0401D0E+1Co.aoI61.00E-079.EOE+1DN.4DE+Mo.inOAD

4、1.D0E+109D.0D43仃愀匍/A-由此可以从底本|胖科的:ISODOEU59UWE+4741711M15QQDK+07=7写WON-f119CE*G0-417UMI-illfif-W5MWEfl?A-fOtm-U-rlUlf-l3($1*4-71D16DJ60相助r1BJ1E13H31F11-7OH*E-HJB14E-21-314VX-1DT.D4U&U理rtt*”Dx7T17f*Q?3MJ收*gq7H4EFTItHHAS*g8-E43HEM抖gF.“小4M13片F依就站是善于事粕.呼度mElPa)E2,Fa)mV21Gl?用性1)i1.0QE-0396OE+102.40E+100.1

5、00401.D0E+1C0.001.00E-0?9.EDE+132.4QE+1Q0.1DC.4D1.D0E+1090.00100E-D)3.6DE+1D2.40E+1Q0.100401DOE+10031.00b039.S0E+1D240E10(1100401.D0E+1090.CD10003S.60E+10240E+100.100401D0E+10D00第1页共1页(4)6层反对称角铺设层合板(T5-10)第2页共2页xrs/性叫鹿.* MW*M1 J*?SE-W13313E*0liH*QI3 N11E-1Q-1M7K0IJJM7DI 10ISJllE*DI介脚f/17mmT轴箝HM7 4f

6、好 W17-2 771tt-12工才hose4通”?诙ma7HT曲阐唱0L241U*D11.MJIR62ItHJIE 14“”小n,弼口 E培2J.W*02由北呵门和il木上帆。施 Alfr=A?&=Dlfr=O=(Jtfll1-ft27-BI7H21-6t6-0:UPhjfr.:-层生糠1”上m门Fa)E2FivUv21E卬和友7i1100E-Q396QE+1020E+100100.40XDOE*IO3000i210DE-039OE*10工&怕1。DID0.40laoE-io-3000!a1000J9.&OE*102AO*1DDIO0.401JJ0E1O勃口0jI4100M396mg24Df

7、-100100.401.Q0E-1D川口gj!5100E3.4511*B23274E-O7由此可以林健木t部料的IA16.11*梯时盥小】LW1E皿3M15E*K016.076/*汇:小233ME+0792015*M职”:t口HI则挣.-1jsrstnT*5f1依tXT才/M77M713WIC-1JT13里岛*等于学是14MK-11r附工ti1“吹】T.1H旺*g2.11122“必“十21111025.S*7fiC*QlL435St*a2SJ37K*4t2m3t*i轨擀文榜i层致sI层序赛用电IDE1E?1F*avllv?lG12.Pa-1向441j11Q帼叮电网E+M2.4PE-100.10

8、口白。LDHt*第31210口占的费百24O*1C0100.401Q0E-1D005l31.00E-03改6旧仙2.40-10DID0.40IDOE-IO3&00410。4抬塞6。1240t*100100.40i.oat-IQ-30001i5100E-G33.60E+10ZAOEIOfl1004DlOOElC30005航量宜修口性。A.975&M*0l-4SWJE-m由此可以和课%I-蟒制的工All=A22t$口口麻皿4557E-D1t蚱*DfT-J口AU-1fi0W0t*O7DH-D22iKfHUka1BMjtIC第2#Xt9Al&-A26)164)2&);L*M舞”112S-497OI相商

9、介.J1784E04-45B97E-DJ18102LM方曲帆Itgi1轴中*-H找加Ki1-37518S-M1Mm-3fE-g1tMCE*gj(5)我还想验证一个书上的例题,在课本P114。三层层合板,外层厚度t1,内层10t1,正交铺设比m=0.2,。Rhle3il-l:i(c:rii!-:;i.r-iiiiIn.ilkeviiinyII,/II:ii上:1VlUPwili;mamriri*aanalanaaiMMiiaaaaiiiBaaiiaaiviindriimm,irBiaHiHBiiiMBiiBaaamanaaanJGii(::roj:ixjiiy堂mH15OrllflJBS4-t*

10、3lty3翼久航,iHfl*-1“ri-3一j*”一-ismtojrt.lins二现g值巴期鸣=OljEiLjrr:Li:rsioricoupli:n:I,:i45口3/50/0/1,mfkrthq仁敬琳标4匚:-:-i|ia:ncli口陋andintfiO/O/.s/eO/O-Rai*rhec:川2心:&;=:小曲口山ILeims):I。/iiO/GO/O/一aG/&1%/二、验证Verchery的论文里给出的数值算例。这里一直到Table5的数据都是从Verchery的论文中截获。Verchery论文中的18层序列,第(21)式【laminateswithoutbending-extens

11、ioncoupling的排列有两种材料,一种是Boron-Epoxy,一种是Glass-Epoxy。而且都给出了最终的计算结果Q,A*,D*。下面是我的Fortran计算数据文档和结果文档。(1) Boron-Epoxy材料。第3页共3页(2) Glass-Epoxy材料。第4页共4页数据k111层数18层序数月度mEl(PaE2(Pa)vl2v21G12Pa)向收)11.00E-033.86曰108.27E090.0560.2604.14E*090.0021.00E-033.86810827E090.0560.2604.1铀090.003100E-033.86E*10827E+090.056

12、0.2604.146*0960.0041.00E-033.86108.27E*090.0560.2604.14E*09600051.00E-033.86日108.27E*090.0560.260-09-60.0061.00E-033.86日TO8.27E*090.0560.260-09-60.0071.00E-033.86EU08.27日090.0560.2604.14E*09-60.008100E-033.86A108.27E090.0560.2604.14E*0960.0091ooE-oa?86A-10827109oos0?6041出0900010100E-03386E*10827E*09

13、0.0560.2604.109-60.0011100E-033.861408.27EM90.0560.260-09-60.0012100E-033.86日108.27E*090.0560.2604.14E*0960.00131.00E-033.86日108.27E*090.0560.260-0960.00141.00E-033.86曰108.27日090.0560.2604.1Q090.00151.00E-033.86曰108.27E*090.0560.2604.14E*090.00161.00E-033.86曰10827E090.0560.2604.14E*090.0017100E-033.

14、86E*108.27E-090.0560.2604.14E*0960.00181.00E-033.866*10827E*090.0560.2604.1毋09-60.00 Bororv-Epoxy祟00S.S900*0944447E10S.0S25E-102049M*114.I757E*O94.27S7E091.8S90E*100.0000CMSSSaSES387232.9C74C*10TheN0RMAU5EDcoupknftensorCquih:-2.1719E104599C*O9-1.4444e094”99.O91.27991.1。4M4E.09 L4444E+0909&4599c+8Tht

15、N0RMAL5E0bn6nstrffntw0*equals1.0941Ell2.M99O101.4444092.3S99E*107,49078*104.534481.4444E094.S1MO92.S214C*10(BworEpocy船工档片尊13层序加E2PAvl2v21G12Pi何!Z)11D0E-D3204E+111.8SE+1Q0021Q230ssmem00021QDE-O32D4t+ll185E+100.021D.2305.59&-D900031DDE-032Q4E1-1118EE1-1D二口二0.2305.59E*09E000410DE*O32.Q4E+111.85E1-1D0.0

16、21。一20S.59E+n60.DO1.DDE-Q32.04E4-111.8SE+100.0210.230S9*(J3-BD口6rODE-D32.04E+111.85E+1D00210.230S.59*C9-&D.0071QOE-03204m1E5E+100D21023C5.59E+0a-&00031QOE-03204E+111gE00021Q230SS玲0900031ODE-03204t+H185E+1Qoon02305.59E+090001Q1QQE-O?2Q4E+H185E+W00210.230559E79-6QQ1110DE-O32.1346+11185E1-1D0.021tl.230

17、5.59EW9-SODO121.D0E-O32.044111.8&E10C.0210.230S.59&-09fio.on131.DDE-032.04E+11LgqE1口0X210.230S9EM9ECkOD141.Q0E-O32.04E+11135E+1000210.2305S9E+09000151OOE-032185t+lQ002102305S9E+0S0001&1aDE-O32D4E1118SE+K002102305S9E+05000171QDE-03204E+HLS5E+100021D.2305.59&Q960.001B10DE-O32Q4E+1X18SE1-1D0.0210.2305S

18、9fc+D川口口(3)当然我也验证了第(22)【laminateswithequalelasticpropertiesinbendingandextensiori、(23)【quasi-homogeneouslaminates的排序,材料是Boron-Epoxy,下面给出计算的结果。从下面的两个结果表中可以知道,(22)排序的确是C=0,(23)的排序的确是B=0且C=0。验证成功。第5页共5页BororvEpoxy)结果文档TheACTUALstiffnesstensorofthelaminate:TheextensionstiffnessAequals:15787E*095.1047EM8

19、-2.2981E.085.1047E*08L5787E+09-5.4129E-08-2.2981E-08-5.3951E-085.3412E*08ThecouplingstiffnessBequals:-1.0897E-092.1876E-10-1.7357E-102.1876E-104.2280E-10-4.4705E-10-1.7357E-10-4.5370E-103.7036E-10ThebendingstiffnessDequals:4.26251041.3783E+04-7.3708E-131.3783E*044.2625E+04-2.3412E-127.3708613-2.8932

20、E-121.4421E+04TheNORMALISEDstiffnesstensorofthelaminate:TheNORMALISEDextensionstiffnessA4equals:8.7706E+T02.8359E*10-12767E-062.8359E+108.7706E*10-2.9973E-06.1.2767E-06-3.0072E-062.9674E+10TheNORMALISEDcouplingtensorCequals:-6.9290E.075.3458E.062.3989E-0753458E-061.0632E-051.8201邑0623989心072.9460E-0

21、61.0096E-05TheNORMAUSEDbendingstiffnessD*equals:8.7706E+102.8359140-1.5166E.062.8359E*108.7706E*10-4.8174E.06-1.5166E.06-5.9532E.062.9674E*10.Bwon印my;果档TheACTUALFtiffnesj电ngrofthtlaminate:TheettenjioftstiflnsAequals:157B7E+09S.1D47E+DB-L9M1047日酶1.S787E+D9-3.9050t08-192SGE-DS-5.4129E-0SS.3412E+0SiThe

22、couplingstiffneisBftjuali;-4.0463E*063303BED5S3OS8E+OS23845E+064豺4口白的1.S303E+0623I:4S750E+OS;13D3E+061E,E8E+gIjThebendingstiffnessDequals:+2G25E*Mr1.1783E+041.3733E+O44263SE+Q4-7.3708E-13-3S027E-12,7370B&L3A1602E-121.4421E-04TheNORMALISEDstiffnesstnscroflamPHMc:TherORMAUSEDentennanitiffnessA*equals:

23、377DGE+102.835SE+10-10G9GDG2B35SE+1O8.7706E+1C-21S94E-D6-1D69B&05DD72E-O629574t+10.11TheNOKMAUSEQwuplinfftensorCequals:142?5-O5,力9眸口S448*5邑B5779SE-Dfi耳鼻口E邑跖459口74S174E-02.114E-QCiTheNORMAUSEObntfiqsTiffne5sD*S77QFE+1Q28359E+1020359+lQ8.77Q6E*10-15166F-06-7BM6E-061;equals;-15元营3。6-8E6D1E-D629674E+LD1

24、ii旧山中,ET*#rt*fntiserfnumbiT1n:1.9170C-1Q工ISOEPJIgQWCQQXl2M*09&4血ER30OOOQE-OOOOOOM*MdOOMEfO4J40OE*THtmupbnfslifnenBequtli.-1,IU2E-WS.lOatE11ILlMlt-W-I.LlTiE-lld3E114J171E41IMMtnTlwThNDRMALISEDerCenunnflfFfinuiA*equflia.2-045lE*W5,5HSE+09I1H5SuSIU*O9I,O43U*ID4卬篝E-1.4491E-4TT-4JMM-0774即PTh*NORMiALGEDce

25、uplirifCtqu3lk-UiS*09LliUE*aS-UBOMCMMI.21E*M-70711*Ml.MO*0B7OZITE*如,1MJEOBTnfCfHj现&EDb?iflnD*vquai1.191*1410工E1E*(工KXKH的奉H发7与*1E+OI.aOODCDfi7.07I1C+OB一一一-这里的络显能思=0.而且希利的Q.A*.O师册切论士卜的救泰附件1:计算所用的程序代码。PROGRAMCOMPOSITE!CodedbyJamesWilsonIMPLICITNONEREAL(8):A(3,3),B(3,3),D(3,3),MC(5),TEMP,ROT(3,3)!A拉伸刚度;

26、B耦合刚度;D弯曲刚度;!MC读入材料常数;ROT旋转矩阵REAL(8):TOTAL_TH,HALF_TH!总厚度;半厚度REAL(8),ALLOCATABLE:Q(:,:,:),AL(:),T(:),Z(:),Z1(:),Z2(:),Z3(:)!Q每层板相应刚度;AL转角;T每层板的厚度;Z坐标量INTEGER(4):N,I,J,K,SEQ,L!IJK循环变量;N板的层数;SEQ序数CHARACTER(50):CHR(8),TEMPC,filename1,filename2!CHR、TEMPC:charactervariablesWRITE(*,*)PleaseinserttheINPfil

27、ename(a.txtforexample):READ(*,*)filename1OPEN(8,file=filename1)!Opendatafile!ReadindataREAD(8,*)TEMPC,NALLOCATE(Q(3,3,N),AL(N),T(N),Z(N+1),Z1(N),Z2(N),Z3(N)READ(8,*)CHR(1:8)DOI=1,NREAD(8,*)SEQ,T(I),MC(1:5),AL(I)Q(:,:,I)=0!CalculatestiffnessofeachlayerfortheprincipalaxisTEMP=1./(1-MC(3)*MC(4)Q(1,1,I)

28、=MC(1)*TEMPQ(2,2,I)=MC(2)*TEMPQ(3,3,I)=MC(5)Q(1,2,I)=MC(4)*MC(2)*TEMPQ(2,1,I)=Q(1,2,I)AL(I)=AL(I)*3.1415926535898/180ROT(1,1)=(cos(AL(I)*2!WorkoutRotMatrixROT(2,2)=ROT(1,1)ROT(3,3)=cos(2*AL(I)ROT(2,1)=1-ROT(1,1)ROT(1,2)=ROT(2,1)ROT(3,1)=0.5*sin(2*AL(I)ROT(3,2)=-ROT(3,1)ROT(1,3)=-2*ROT(3,1)ROT(2,3)=-

29、2*ROT(3,2)Q(:,:,I)=MATMUL(MATMUL(ROT,Q(:,:,I),TRANSPOSE(ROT)ENDDOTOTAL_TH=sum(T)HALF_TH=TOTAL_TH/2Z(1)=-HALF_TH!WorkoutZDOI=1,NZ(I+1)=Z(I)+T(I)ENDDOcalculatetensorABandDDOK=1,NZ1(K)=(Z(K+1)-Z(K)Z2(K)=(Z(K+1)-Z(K)*(Z(K+1)+Z(K)/2Z3(K)=(Z(K+1)*3-Z(K)*3)/3ENDDOA=0;B=0;D=0WRITE(*,*)PleaseinserttheOUPfile

30、name(b.txtforexample):READ(*,*)filename2OPEN(9,file=filename2)!WriteinstiffnesstensorforeachsingleplyDOK=1,NWRITE(9,100)K100FORMAT(Thestiffnessofnumber”,1X,I2,2X,plyis:)DOI=1,3WRITE(9,200)Q(I,:,K)200FORMAT(ES12.4,6X,ES12.4,6X,ES12.4)ENDDOWRITE(9,(/)A=A+Q(:,:,K)*Z1(K)B=B+Q(:,:,K)*Z2(K)D=D+Q(:,:,K)*Z3

31、(K)ENDDO!OutputtheactualstiffnessofthelaminateWRITE(9,(/);WRITE(9,(/)WRITE(9,*)TheACTUALstiffnesstensorofthelaminate:WRITE(9,(/)WRITE(9,*)TheextensionstiffnessAequals:DOI=1,3WRITE(9,200)A(I,1:3)ENDDOWRITE(9,(/)”)WRITE(9,*)ThecouplingstiffnessBequals:DOI=1,3WRITE(9,200)B(I,1:3)ENDDOWRITE(9,(/)”)WRITE

32、(9,*)ThebendingstiffnessDequals:DOI=1,3WRITE(9,200)D(I,1:3)ENDDONormalisedtensoroutputWRITE(9,(/);WRITE(9,(/)WRITE(9,*)TheNORMALISEDstiffnesstensorofthelaminate:WRITE(9,(/)WRITE(9,*)TheNORMALISEDextensionstiffnessA*equals:DOI=1,3WRITE(9,200)A(I,1:3)/TOTAL_THENDDOWRITE(9,(/)WRITE(9,*)TheNORMALISEDcou

33、plingtensorCequals:DOI=1,3WRITE(9,200)A(I,1:3)/TOTAL_TH-12*D(I,1:3)/TOTAL_TH*3ENDDOWRITE(9,(/)WRITE(9,*)TheNORMALISEDbendingstiffnessD*equals:DOI=1,3WRITE(9,200)12*D(I,1:3)/TOTAL_TH*3ENDDOWRITE(*,*)OUTPUTsuccessfully,pleasepressanykeytoendprogram!READ(*,*)ENDPROGRAMCOMPOSITE附2杨涛同学的MATLAB(GUI)计算程序。主要

34、程序:(编了个小界面,程序略长,删掉一些程序自带解释语句,添加了一些对关键语句的解释。)界面是:第6页共6页作的一个算例如下:Calculation of Laminated Plate Stiffness该算例结果与组内同伴JamesWilson同学基本一致,其余算例结果也基本一致,仅仅在趋近于零时有略微差异,在此不赘于。后边附上源代码:functionvarargout=composit_plate(varargin)gui_Singleton=1;gui_State=struct(gui_Name,mfilename,.gui_Singleton,gui_Singleton,gui_Op

35、eningFcn,composit_plate_OpeningFcn,gui_OutputFcn,composit_plate_OutputFcn,gui_LayoutFcn,,gui_Callback,);ifnargin&ischar(varargin1)gui_State.gui_Callback=str2func(varargin1);endifnargoutvarargout1:nargout=gui_mainfcn(gui_State,varargin:);elsegui_mainfcn(gui_State,varargin:);endfunctioncomposit_plate_

36、OpeningFcn(hObject,eventdata,handles,varargin)handles.output=hObject;guidata(hObject,handles);ha=axes(units,normalized,position,0011);%!入坐标,为嵌入背景图片准备uistack(ha,down)%(乍为背景II=imread(武汉大学.jpg);%读入图片信息image(II)第7页共7页CalculationofLaminatedPlateStiffnesscolormaphsvset(ha,handlevisibility,off7visible,ofT)

37、functionvarargout=composit_plate_OutputFcn(hObject,eventdata,handles)varargout1=handles.output;functionedit1_Callback(hObject,eventdata,handles)functionedit1_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundCo

38、lor,white);endfunctionedit2_Callback(hObject,eventdata,handles)functionedit2_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionedit3_Callback(hObject,eventdata,handles)functionedit3_Crea

39、teFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionedit4_Callback(hObject,eventdata,)functionedit4_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaul

40、tUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionpushbutton1_Callback(hObject,eventdata,handles)symse1e2v21g12ang%程序采用符号运算v12=v21*e2/e1;q=e1/(1-v12*v21),v21*e2/(1-v12*v21),0v21*e2/(1-v12*v21),e2/(1-v12*v21),00,0,g12;tran=cos(ang)A2,sin(ang)A2,-sin(2*ang)sin(ang)A2,cos(ang)A2,s

41、in(2*ang)sin(2*ang)/2,-sin(2*ang)/2,cos(2*ang);q1=tran*q*tran;%得到Qn=str2num(get(handles.edit2,string);%lt入层数n=floor(n);nn=0;A=0;B=0;D=0;t=str2num(get(handles.edit3,string);%ilt入每层厚度t1=zeros(1,n+1);t1(1)=0;fornn=1:nt1(nn+1)=t1(nn)+t(nn);endang1=str2num(get(handles.edit4,string);%lt入每层角度const=str2num(

42、get(handles.edit1,string);%lt入材料系数t0=sum(t)/2;t1=t1-t0;e1=const(1);e2=const(2);v21=const(3);g12=const(4);q11=subs(q1);fornn=1:nang=ang1(nn);nn=nn+1;A=A+subs(q11*(t1(nn)-t1(nn-1);B=B+subs(0.5*q11*(t1(nn)A2-t1(nn-1)A2);D=D+subs(1/3*q11*(t1(nn)A3-t1(nn-1)A3);end%累加计算set(handles.edit5,string,num2str(A(1

43、,:);%Z下为输出结果set(handles.edit6,string,num2str(A(2,:);set(handles.edit7,string,num2str(A(3,:);set(handles.edit8,string,num2str(B(1,:);set(handles.edit9,string,num2str(B(2,:);set(handles.edit10,string,num2str(B(3,:);set(handles.edit11,string,num2str(D(1,:);set(handles.edit12,string,num2str(D(2,:);第8页共8

44、页set(handles.edit13,string,num2str(D(3,:);functionedit5_Callback(hObject,eventdata,handles)functionedit5_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionedit6_Callback(hObject,eventdat

45、a,handles)functionedit6_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionedit7_Callback(hObject,eventdata,handles)functionedit7_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hO

46、bject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionedit8_Callback(hObject,eventdata,handles)functionedit8_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,Backgrou

47、ndColor,white);endfunctionedit9_Callback(hObject,eventdata,handles)functionedit9_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionedit10_Callback(hObject,eventdata,handles)functionedit1

48、0_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionedit11_Callback(hObject,eventdata,handles)functionedit11_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColo

49、r),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionedit12_Callback(hObject,eventdata,handles)functionedit12_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);endfunctionedit13_Callback(hObject,eventdata,handles)functionedit13_CreateFcn(hObject,eventdata,handles)ifispc&isequal(get(hObject,BackgroundColor),get(0,defaultUicontrolBackgroundColor)set(hObject,BackgroundColor,white);end第9页共9页

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。