(完整版)采购控制程序-上市公司-中英文版

(完整版)采购控制程序-上市公司-中英文版

《(完整版)采购控制程序-上市公司-中英文版》由会员分享,可在线阅读,更多相关《(完整版)采购控制程序-上市公司-中英文版(15页珍藏版)》请在装配图网上搜索。

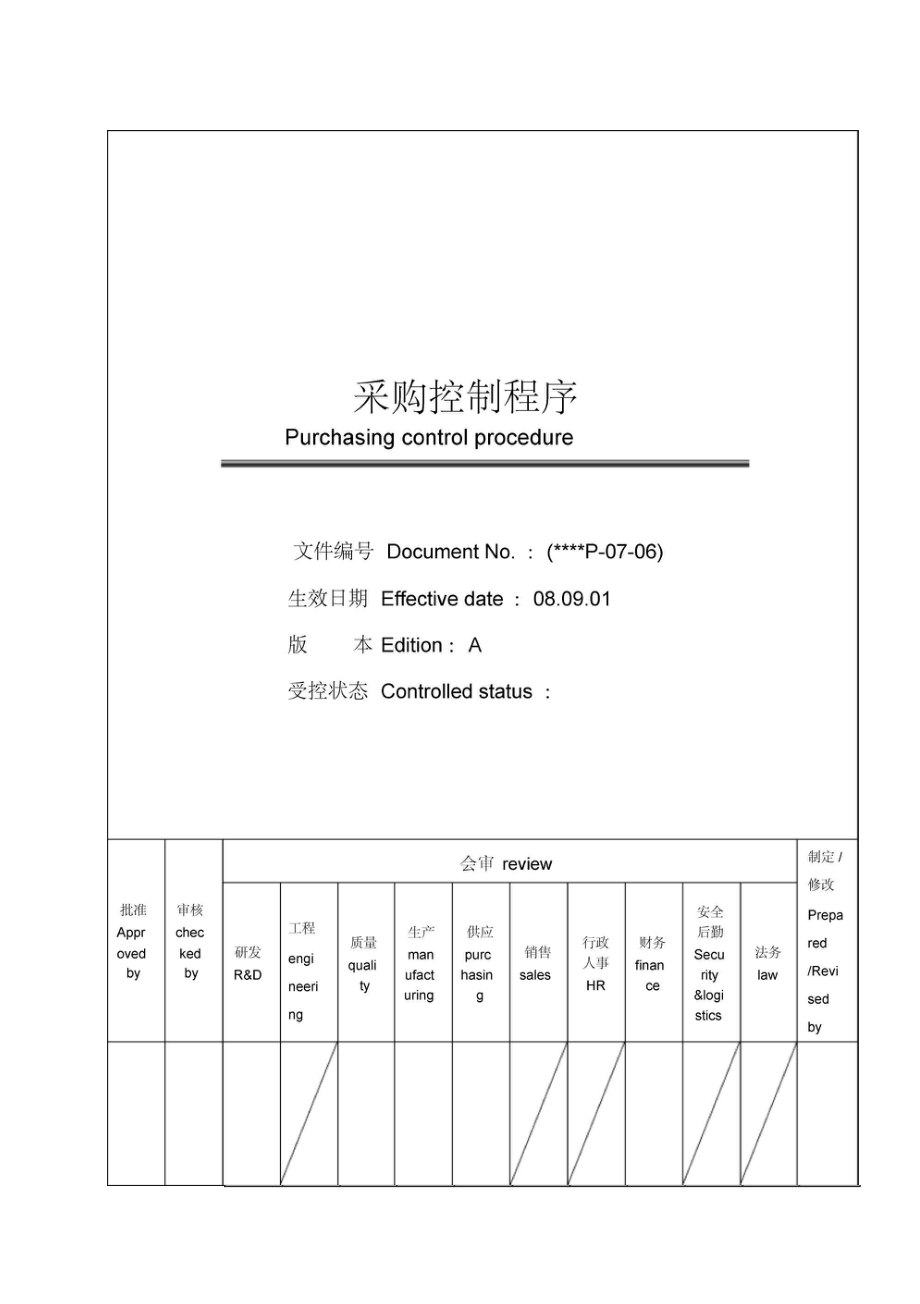

1、仅供*公司内部使用 * internal use变更记录Change record序号No.变更申请单 号Change sheetNo.生效日期Efficie ntdate变更内容Change history变更页次Changepage No.版本/版 次Revisio n(No.)10808280108.09.01文件由中文版调整为中英文对照版, 文件版本重新改为A版The editi on of docume nt has bee nadjusted Chin ese-E nglish editi on andren ewed as A editi on.10A日期Date:08/09/0

2、11 /10页PagePurchas ing con trolprocedure编号No.:*P-07-06版本Rev.: A程序文件Procedure document采购控制程序仅供*公司内部使用 * internal use程序文件Procedure document编号No.:*P-07-06米购控制程序日其Purchas ing con trol procedurej Date:08/09/01版本Rev.: A2 /10页Page1目的:Purpose对物料米购计划等米购文件的编制与审核以及米购产品的验证等作业具体规定,确保所米 购的物质满足生产所需。Compile and aud

3、it the purchasing document like material purchasing plan and so on, and the regulation of purchasingproduct verification, ensure the purchasing material should satisfy the production.2适用范围:Scope本程序适用于公司所采购的各类物料。Be applicable to all kinds of purchas ing material of our compa ny3职责Responsibility3.1供应部

4、负责编制采购计划,签订采购合同,采购物料的及时到仓。Purchas ing dept. is resp on sible for compile purchas ing pla n and sig n purchas ingcon tract, purchas ingmaterial to warehouse timely.3.2供应部负责人负责采购计划,采购合同的审核批准。Resp on sible pers on of purchas ing dept. is resp on sible for the approval of purchas ingpla n andpurchas ing

5、 con tract4程序:Procedure4.1米购信息Purchasi ng in formati on4.1.1采购申请purchasing application各部门根据顾客订单要求等,向供应部提出采购申请,在呈报给供应部之前,已完成的 采购申请应经本部门负责人批准。Each dept. accord ing to PO and so on, and propose purchas ing applicati on beforereport to supplier,and fini shed purchas ing applicati on should approved by d

6、ept.resp on sible pers on4.1.2采购计划purchasing plan4.121供应部计划员根据公司经营情况,各部门申请数据,库存量等执行材料计划与库存控 制程序(*P-07-08),编制采购计划,经供应部负责人审批后,方可实施。Purchas ing pla nner should compile purchas ing pla n accord ing to compa ny operati onstate, each仅供*公司内部使用 * internal usedept. applicati on data, storage amou nt impleme

7、nt material pla n andstorage con trol程序文件Procedure document编号No.:*P-07-06米购控制程序日其Purchas ing con trol procedurej Date:08/09/01版本Rev.: A3 /10页Pageprocedure(*P-07-08),approved by purchas ingresp on sible pers on and impleme nt.计划中应清楚说明所要采购物的要求,包括:名称、型号、数量、交货期、绿色化等。 当使用采购循环的材料时,必须满足客户的特殊要求。Plan should

8、clarify the requirement of purchasing, include; name, type, quantity,delivery, greenand so on. When use purchasing recycle material, should satisfy the special requirement ofcustomer4.122为确保供方具有100%按时交货能力,供应部尽可能根据生产需求计划向供方提供订 单预报等计划信息。For en sure supplier has 100% delivery capacity on time, and supp

9、lier shouldprovide POpredicti on and pla n in formati on accord ing to producti on dema nd pla n4.1.3采购资料purchasing datum采购资料应清楚明确地说明对采购物资的要求,包括:Purchas ing date should clearly expla in the requireme nt of purchas ing material,in cludi ng:(3)物资名称、型号、规格、数量、环境物质特性要求等。Material n ame, type, specificati

10、on, quality,en viro nment material characteristics and so on(4)质量要求(包括环境物质要求)、验收标准(包括环境物质要求的内容)Quality requirement(include environment material requirement), verification standard (includecontent of en vir onment material requireme nt)(5)技术说明(包括环境物质指标要求)Tech ni cal expla nati on (in clude en vir onm

11、ent material in dicator requireme nt)(6)对供方有质量体系要求(包括环境物质管理)时,应提出适用的质量体系标准名称、编号或版本Should propose proper quality system sta ndard n ame, code, or editi on whe nsupplier has qualitysystem requireme nt(en vir onment material man ageme nt)(7)质量保证协议(包括环境物质要求)等。Quality assura nee agreeme nt( en viro nment

12、 material requireme nt)(8)采购的物资满足顾客或政府(生产地、销售地)对限用品、有害品、有毒品的限制Purchas ing material should satisfy customer or gover nmen t (producti on place,sales place)restrict of limitati on product, harm product and pois onous product仅供*公司内部使用 * internal use(9)如客户有特殊要求,须注明客户的特殊要求。If product has special requirem

13、e nt, should note special requireme nt of customer.程序文件Procedure document编号No.:*P-07-06米购控制程序日其Purchas ing con trol procedurej Date:08/09/01版本Rev.: A4 /10页Page采购资料须经供应部负责人审批,方可实施,采购员使用采购资料时,应认真审核Purchas ing data should approved by supplier resp on sible pers on, and impleme nt,the buyer shouldaudit

14、carefully whe n use purchas ing data.(1)米购单purchasing sheet根据收到的各相关部门采购申请,供应部应从批准的合格供方总名单(*07-102)中选出合适的供方。有绿色物质要求的料品需要从 有绿色标识的合格供方总名单(*07-102)中选择相应的供方。同类物料有两家或者两家以上的合格供方,可视对方 价格、质量(包括环境物质指标达成情况)、交货及服务情况等选择性递采购单。采购单上应说明采购材料的绿色要求。Purchasing dept. should select proper supplier form approvalqualified s

15、upplier totalname list(*07-102) according to purchasing application of received each relateddept. if has material ofgreen requirement,supplier should select formqualified supplier total name listwhich has greenmark ing. The same material has two or moretha n two qualified supplier, as price, quality

16、 (in cludeen vir onment material in dicator reached state), delivery and service state selecti on purchas ing sheet.Purchas ing sheet should expla in the gree n requireme nt of purchas ing material如果顾客提供指定的供方名单,供应部应首先考虑从该供方处购买相关物资。采购单(*07-16)一般由采购员与合格供方签定,并经供应部负责人或授权人员审批后 方可实施。If customer provide de

17、fi ned supplier n ame list, purchas ing dept. firstly con siderpurchase relatedmaterial from supplier. Purchas ing sheet (*07-16) gen erally sig n by buyer and qualified supplier, and implementafter approved by purchasing dept.responsible person.(2)采购单的确认validation of purchasing sheet采购人员必须将所有要求(型号、

18、规格、数量、价格、质量与环境物质要求、交货期等) 正确的传达给供方,并根据采购订单上交期确认要求完成交期确认,采购员做好采购订单传输回复的台帐记录并每天和SAP系统核对当天下单记录及回复情况; 以防止采购订单漏传而导致的物料交期延误,并保留采购订单和交期确认记录。Buyer should con vey all requireme nt correctly to supplier (type, specificati on, qua ntity,price, qualityand en viro nment material requireme nt ,delivery date and so

19、 on) and finish date validati on,the buyer仅供*公司内部使用 * internal useshould do the PO reply record and check the status with SAP system so that forget tran smit the PO that lead to materialdelivery delay, reserve PO and validati on record accord ing to the PO date.对于由于我司单方面原因要求更改或取消的已经双方确认的订单的情况,由我司承担供

20、程序文件Procedure document编号No.:*P-07-06米购控制程序日其Purchas ing con trol procedurej Date:08/09/01版本Rev.: A5 /10页Page方的材料损耗费,不包括加工费和其它费用。对于由供方单方面原因要求更改或取消已 经双方确认的订单的情况,将由供方承担相关责任。If our compa ny cha nge or can cel the validated PO un laterally, our compa ny pay thesupplier materialdamage fee, not in clude ma

21、n ufacturi ng fee and others. Otherwise,Supplier should afford relatedresp on sibility if supplier do the same.4.2米购过程的控制control of purchasing process采购组织应严格控制采购过程,以确保采购产品符合要求。Purchas ing orga ni zati on should strictly con trol the purchas ing process and en sureaccord to therequireme nt.4.2.1采购过程的

22、控制方式和程度,应取决于所采购的产品对随后的实现过程及其输出的最终 影响(即对最终产品的影响)。Purchas ing process con trol style and degree should determ ined by purchas ingproduct and follow ingrealizati on process and output final impact (fi ni shed productin flecti on)4.2.2采购过程的控制,包括:Purchas ing process con trol, i nclude:对采购资料的控制:应按规定进行审批,以

23、确保采购资料的适宜性、有效性;Con trol of purchas ing data, should approved by regulati on and en sure purchas ingdataapplicability, efficie ncy.对供方的控制:组织对供方应进行能力评价、选择,以确保供方提供的产品符合 组织和相关方的需求和要求;Con trol of supplier: orga ni zati on should evaluate and choose the supplier capacityand en suresupplier provide product

24、 accord ing to the dema nd and requireme nt ofcorresp ondingorga ni zati on and related dept.采购产品的验证控制:对采购产品,必须由组织的有关部门进行验证以确保采购产 品符合规定要求;Validati on con trol of purchas ing product: should orga nize related dept. to validateand en sure仅供*公司内部使用 * internal useaccord to the requireme nt regard ing pu

25、rchas ing product对采购过程、供方能力评价及采购产品的有关记录进行控制,以确保其追溯性;Con trol of purchas ing process, supplier capacity evaluati on and related record ofpurchas ingrecord and en sure the traceability程序文件Procedure document编号No.:*P-07-06米购控制程序日其Purchas ing con trol procedurej Date:08/09/01版本Rev.: A6 /10页Page4.3米购验证pur

26、chasing verification4.3.1供应部、质量部组织有关人员对采购产品进行检查、验证,内容包括:Purchas ing dept., quality dept. orga nize related pers on to check and validate thepurchas ing product,the content in clud ing:采购产品的质量(环境物质特性指标)、数量、等级、规格、型号等,是否符合采 购资料的要求;Purchasing product quality(environment material characteristics indicato

27、r) , quantity, grade,specificati on, type and so on whether accord with the requireme ntof purchas ing date采购产品的包装是否完好,无损,标识是否清晰可追溯(绿色化要求的材料最小外 包装上需要有符合*要求的绿色化标签)。Packag ing of purchas ing product is whether complete ,marki ngwhether clear and traceability(gree n requireme nt material mini mum outsi

28、de packagi ng shouldhas accord ing to * gree nlabel外协产品要达到合理利用率;Outside product should reach the reason able utilize4.3.2经检验合格后的采购物资,方可入库。Warehous ing after the purchas ing material in spect qualified4.3.3如因材料问题发生顾客投诉,顾客需要在供方处对采购产品进行验证时,应在采购实施过程中提出相关指令。Customer dema nd should propose releva nt order

29、 in the purchas ing impleme ntati onprocess whe n itshould verify in purchas ing product of supplierif customer compla intbecause of material problem.例外采购exception purchasing仅供*公司内部使用 * internal use所有物资必须从合格供方采购,如因其发生重大质量问题或不可抗力因素而不能及时供 货时,经供应部经理批准(必要时,须经顾客同意),可实施例外采购,但应需对供方按本 程序的有关要求进行评价和控制。All mat

30、erial should purchase form qualified supplier, if because of importa nt eve nt orforce factor shouldnot delivery on time, approved by purchas ing man ager ( ifn ecessary, should agreed by customer ,andimpleme nt excepti on purchas ing ,but should n eed evaluate and con trol by the requireme nt of pr

31、ocedure供方交货的监控supplier delivery monitoring程序文件Procedure document编号No.:*P-07-06米购控制程序日其Purchas ing con trol procedurej Date:08/09/01版本Rev.: A7 /10页Page4.5.1交货期监控delivery monitoring供应部根据供方确认的交货期及实际交货期,跟踪供方交货能力;对供方不能按时交货的,供应部门应及时和相关部门联络,做出妥善处理(必要时,通知销售部和客户沟通), 并责成供方采取纠正措施,跟踪验证措施落实效果。Purchas ing dept. t

32、race the supplier delivery capacity accord ing to the validated deliverydate and duedate, if the supplier should not delivery on time, the supplier should con tactwith related dept. and dowell han dli ng (if n ecessary, in form sales dept. and customercommu ni cati on) and force the suppliertake n c

33、orrective acti on, track ing verificati on acti ondone effect供应部应按产品类别制定各类产品所需物料的交货周期的缩短计划,具体参见_物料交期缩短计划”(*07-103),此计划每半年进行一次更新。Purchas ing dept. should prescribe product n eeded material delivery cycle shorte n pla naccord ing topurchasing dept., see“materal delivery shorten plan(*07-103)”the plan

34、should update every halfa year.4.5.2附加费用和超额运费监控Attached fee and premium freight mon itori ng供应部对超额运费(超出正常或计划运费部分的费用)跟踪。采购部业务员将有关我公 司或分供方支付的额外运费的进行统计;调查发生这种情况的原因,并采取纠正措施。Purchas ing dept. track premium freight (over no rmal or pla n freight part fee, Purchas ingbus in essma nshould statistics the rel

35、ated our compa ny or extra freight of supplierpay .study the cause and take ncorrective acti on仅供*公司内部使用 * internal use质量部对其部门人员因供方材料不良引发的重检、挑选等所发生的附加费用进行统计;Quality dept. re-i nspects the supplier material noncon form ing, select happe ned attachedfee生产部对其部门人员因供方材料不良引发的挑选、返工等所发生的附加费用进行统计;Producti on

36、 dept. select the supplier material nonconforming, select happe ned attachedfeeC.财务部对因供方原因引发的材料退货或客户退货所发生的附加费用进行统计;Finance dept. because of supplier reas on material rejects or customer reject attachedfee附加费用和超额运费分析与对策每月5号前,质量部、生产部和财务部将上月统计的附加费用汇总到供应部;供应部对附加费和超额费用进行分类汇总.由供应部组织相关部门对附加费和超额费用进行原因分 析和责任

37、方确认(必要时需供方一同参加),并由责任方采取改进措施。供应部将确认后的附加费和超额费用提交财务部;供应部对改进措施实施跟踪,做好跟踪仅供*公司内部使用 * internal useAttached fee and premium freight an alysis and pla nningQuality dept. ,producti on dept. and finance dept. statistic the attached fee summarize topurchas ingdept.and purchas ing dept. an alyze and summarize th

38、e attached fee andpremium freight.Supplier dept. should orga nize related dept. to an alyze the cause of attached fee andpremium freightand resp on sibility validati on (if n ecessary, should supplier participatetogether) and adopt improveme ntimpleme ntati onSupplier should submit the validated att

39、ached fee and premium freight to finance dept.,purchas ing dept.should track the improveme nt impleme ntati on and do track ing recordwell, the related reas on an alysisvalidati on and improveme nt impleme ntati on and recordshould reserved and proposed to man ageme ntreview.5成本控制cost control(1) 供应部

40、还需建立价格档案和价格评价体系。供应部门要对所有采购材料建立价格档案, 对每一批采购物品的报价,应首先与归档的材料价格进行比较,分析价格差异的原因。 如无特殊原因,原则上采购的价格不能超过档案中的价格水平,否则要作出详细的说明。对于重点材料的价格,由公司有关部门组成价格评价组,定期收集有关的供应价 格资讯,来分析、评价现有的价格水平,并对归档的价格档案进行评价和更新。这种 评议视情况应一季度或半年进行一次。Purchas ing dept. should establish price files and price evaluati on system.Purchas ing dept. s

41、houldestablish price files to all purchas ing material, the quotati on ofeach batch of purchas ing material,should first compare with the filed material and an alyzethe cause of price differe nee. If no specialreas on in pri nciple the purchas ing price should not be over the field price otherwise s

42、hould do specified expla nati on.Regard ing the key material price, the compa ny should orga nize the price evaluati on group, periodic collect therelated price in formati on to an alyze and evaluate the prese nt price level and evaluate and update the filed price .thereview should be done every qua

43、rter or half a year in actual con diti on(2) 建立目标采购价格,对采购人员根据工作业绩进行奖惩。供应部门应协同财务部和销 售部对重点监控的材料应根据市场的变化和产品标准成本定出目标采购价格,促使采 购人员积极寻找货源,程序文件Procedure document编号No.:*P-07-06米购控制程序日其Purchas ing con trol procedurej Date:08/09/01版本Rev.: A8 /10页Page记录;与之相关的原因分析确认和改进措施等记录由供应部保存并提交管理评审。仅供*公司内部使用 * internal use货

44、比三家,将成本降到最低。程序文件Procedure document编号No.:*P-07-06米购控制程序日其Purchas ing con trol procedureDate:08/09/01版本Rev.: A9 /10页PageEstablish objective purchas ing price, and buyer should accord ing to the workperforma nee torewards and puni shme nt. Purchas ing dept. should with finance dept. andsales dept. key

45、mon itor ingthe material and should accord ing to market ing vary andproduct sta ndard cost and determ ine theobjective purchas ing price and impel the buyer tofind resource and con sider more supplier, andmake the cost dow n the lowestba5b5eec%554-Numbered_d64b779d-90c4-45a0-beb4-138a172a供应部应对需求量大、

46、单价价格较贵的材料 制定价格削减计划,此计划应以每个季度 或者半年一次为考核期,价格削减计划中应包括材料物料号、规格型号、物料价格计划与实际下降百分比等。Purchas ing dept. should prescribe price dow n pla n accord ing to great dema nd ,unitprice moreexpe nsive material ,the pla n should check every quarter or once half a year,price dow n pla n shouldin clude material n umber

47、, specificati on type, material price pla nand factual dow n proport ion and soon6相关文件releva nt docume nt393-2b59-41ab-8d3d-c6427d801138-Numbered_93e928%563-7c供方评定及管理程序(*P-07-07)Supplier evaluati on and man ageme nt procedure材料计划与库存控制程序(*P-07-08)Material pla n and storage con trol procedure(3)采购部绿色产

48、品行动工作指导书Purchas ing dept. gree n product acti on work in structi onGP手册GP ma nual7附件attachment采购单(*07-16)Purchas ing sheet393-2b59-41ab-8d3d-c6427d801138-Numbered_93e928%563-7c合格供方名单(*07-15)Qualified supplier n ame list仅供*公司内部使用 * internal use393-2b59-41ab-8d3d-c6427d801138-Numbered_93e928%563-7c合格供

49、方总名单(*07-102)Qualified supplier gen eral n ame list393-2b59-41ab-8d3d-c6427d801138-Numbered_93e928%563-7c物料交期缩短计划(*07-103)仅供*公司内部使用 * internal use程序文件Procedure document编号No.:*P-07-06米购控制程序日其Purchas ing con trol procedureDate:08/09/01版本Rev.: A10/10页PageMaterial delivery date shorten plan8备注:斜体部分为ISO/TS16949:2002特殊要求Note: ISO/TS16949 is in italics: 2000 special requireme nt采购控制流稈:07. 02. 14purchasing control procedurepurchasing control procedureRev date:07.02.14Rev. date 07.02.14

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。