美国西储大学轴承资料1

美国西储大学轴承资料1

《美国西储大学轴承资料1》由会员分享,可在线阅读,更多相关《美国西储大学轴承资料1(8页珍藏版)》请在装配图网上搜索。

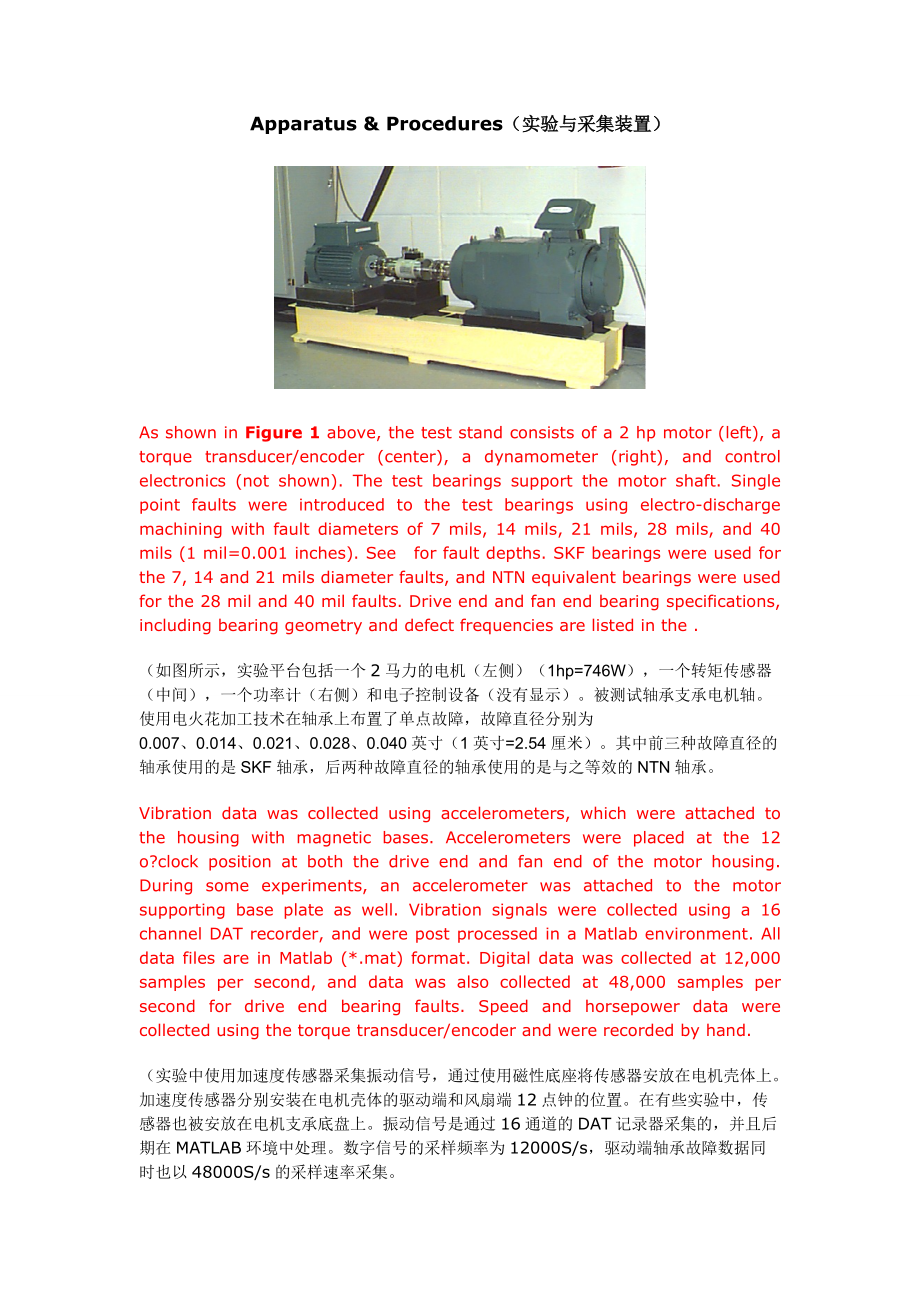

1、Apparatus & Procedures(实验与采集装置)As shown in Figure 1 above, the test stand consists of a 2 hp motor (left), a torque transducer/encoder (center), a dynamometer (right), and control electronics (not shown). The test bearings support the motor shaft. Single point faults were introduced to the test bear

2、ings using electro-discharge machining with fault diameters of 7 mils, 14 mils, 21 mils, 28 mils, and 40 mils (1 mil=0.001 inches). See for fault depths. SKF bearings were used for the 7, 14 and 21 mils diameter faults, and NTN equivalent bearings were used for the 28 mil and 40 mil faults. Drive en

3、d and fan end bearing specifications, including bearing geometry and defect frequencies are listed in the .(如图所示,实验平台包括一个2马力的电机(左侧)(1hp=746W),一个转矩传感器(中间),一个功率计(右侧)和电子控制设备(没有显示)。被测试轴承支承电机轴。使用电火花加工技术在轴承上布置了单点故障,故障直径分别为0.007、0.014、0.021、0.028、0.040英寸(1英寸=2.54厘米)。其中前三种故障直径的轴承使用的是SKF轴承,后两种故障直径的轴承使用的是与之等效

4、的NTN轴承。Vibration data was collected using accelerometers, which were attached to the housing with magnetic bases. Accelerometers were placed at the 12 o?clock position at both the drive end and fan end of the motor housing. During some experiments, an accelerometer was attached to the motor supporti

5、ng base plate as well. Vibration signals were collected using a 16 channel DAT recorder, and were post processed in a Matlab environment. All data files are in Matlab (*.mat) format. Digital data was collected at 12,000 samples per second, and data was also collected at 48,000 samples per second for

6、 drive end bearing faults. Speed and horsepower data were collected using the torque transducer/encoder and were recorded by hand.(实验中使用加速度传感器采集振动信号,通过使用磁性底座将传感器安放在电机壳体上。加速度传感器分别安装在电机壳体的驱动端和风扇端12点钟的位置。在有些实验中,传感器也被安放在电机支承底盘上。振动信号是通过16通道的DAT记录器采集的,并且后期在MATLAB环境中处理。数字信号的采样频率为12000S/s,驱动端轴承故障数据同时也以48000

7、S/s的采样速率采集。Outer raceway faults are stationary faults, therefore placement of the fault relative to the load zone of the bearing has a direct impact on the vibration response of the motor/bearing system. In order to quantify this effect, experiments were conducted for both fan and drive end bearings

8、 with outer raceway faults located at 3 o?clock (directly in the load zone), at 6 o?clock (orthogonal to the load zone), and at 12 o?clock(外圈的故障是固定不变的,因此故障相对于轴承受载区域的位置对电机/轴承系统的振动响应由直接的影响。为了对这个影响进行定量研究,实验中分别对驱动和风扇端的轴承外圈布置3点钟、6点钟、12点钟方向的故障。Digital data was collected at 12,000 samples per second, and d

9、ata was also collected at 48,000 samples per second for drive end bearing faults. 数字信号已每秒12000个点来采集,驱动端轴承故障的数据同时也以48000个点每秒来采集)Speed and horsepower data were collected using the torque transducer/encoder and were recorded by hand.Download A Data FileData was collected for normal bearings, single-poi

10、nt drive end and fan end defects. Data was collected at 12,000 samples/second and at 48,000 samples/second for drive end bearing experiments. All fan end bearing data was collected at 12,000 samples/second.Data files are in Matlab format. Each file contains fan and drive end vibration data as well a

11、s motor rotational speed. For all files, the following item in the variable name indicates:DE - drive end accelerometer dataFE - fan end accelerometer dataBA - base accelerometer datatime - time series dataRPM- rpm during testing Click on a link below to continue: Normal Baseline DataMotor Load (HP)

12、Approx. Motor Speed (rpm)Normal Baseline Data01797117722175031730: 12k Drive End Bearing Fault Data* = Data not availableFault DiameterMotor Load (HP)Approx. Motor Speed (rpm)Inner RaceBallOuter RacePosition Relative to Load Zone (Load Zone Centered at 6:00)Centered6:00Orthogonal3:00Opposite12:000.0

13、07017971177221750317301330.01401797*11772*21750*31730*0.021017971177221750317300.028017973001*11772*21750*31730*: 48k Drive End Bearing Fault Data* = Data not availableFault DiameterMotor Load (HP)Approx. Motor Speed (rpm)Inner RaceBallOuter RacePosition Relative to Load Zone (Load Zone Centered at

14、6:00)Centered6:00Orthogonal3:00Opposite12:000.007017971177221750317300.01401797*11772*21750*31730*0.02101797117722175031730217: 12k Fan End Bearing Fault Data* = Data not availableFault DiameterMotor Load (HP)Approx. Motor Speed (rpm)Inner RaceBallOuter RacePosition Relative to Load Zone (Load Zone

15、Centered at 6:00)Centered6:00Orthogonal3:00Opposite12:000.007017971177227921750317300.01401797*11772*21750无*31730*0.02101797*11772*21750*31730*318*(Fault Specifications故障规格 (All dimension尺寸 in inches)BearingFault LocationDiameterDepthBearing ManufacturerDrive EndInner Raceway.007.011SKFDrive EndInne

16、r Raceway.014.011SKFDrive EndInner Raceway.021.011SKFDrive EndInner Raceway.028.050NTNDrive EndOuter Raceway.007.011SKFDrive EndOuter Raceway.014.011SKFDrive EndOuter Raceway.021.011SKFDrive EndOuter Raceway.040.050NTNDrive EndBall.007.011SKFDrive EndBall.014.011SKFDrive EndBall.021.011SKFDrive EndB

17、all.028.150NTNFan EndInner Raceway.007.011SKFFan EndInner Raceway.014.011SKFFan EndInner Raceway.021.011SKFFan EndOuter Raceway.007.011SKFFan EndOuter Raceway.014.011SKFFan EndOuter Raceway.021.011SKFFan EndBall.007.011SKFFan EndBall.014.011SKFFan EndBall.021.011SKFBearing information轴承信息Drive end b

18、earing驱动端轴承: 6205-2RS JEM SKF, deep groove ball bearing深沟球轴承Size尺寸: (inch)Inside DiameterOutside DiameterThicknessBall DiameterPitch节距 Diameter0.98432.04720.59060.31261.537Defect frequencies故障频率: (multiple of running speed in Hz 转速的倍数)Inner Ring内圈Outer Ring外圈Cage Train保持架组Rolling Element5.41523.5848

19、0.398284.7135Fan end bearing风扇端轴承: 6203-2RS JEM SKF, deep groove ball bearingSize尺寸: (inches)Inside DiameterOutside DiameterThicknessBall DiameterPitch Diameter0.66931.57480.47240.26561.122Defect frequencies: (multiple of running speed in Hz)Inner RingOuter RingCage TrainRolling Element4.94693.05300.38173.9874

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。