OTS文件汇总表

OTS文件汇总表

《OTS文件汇总表》由会员分享,可在线阅读,更多相关《OTS文件汇总表(17页珍藏版)》请在装配图网上搜索。

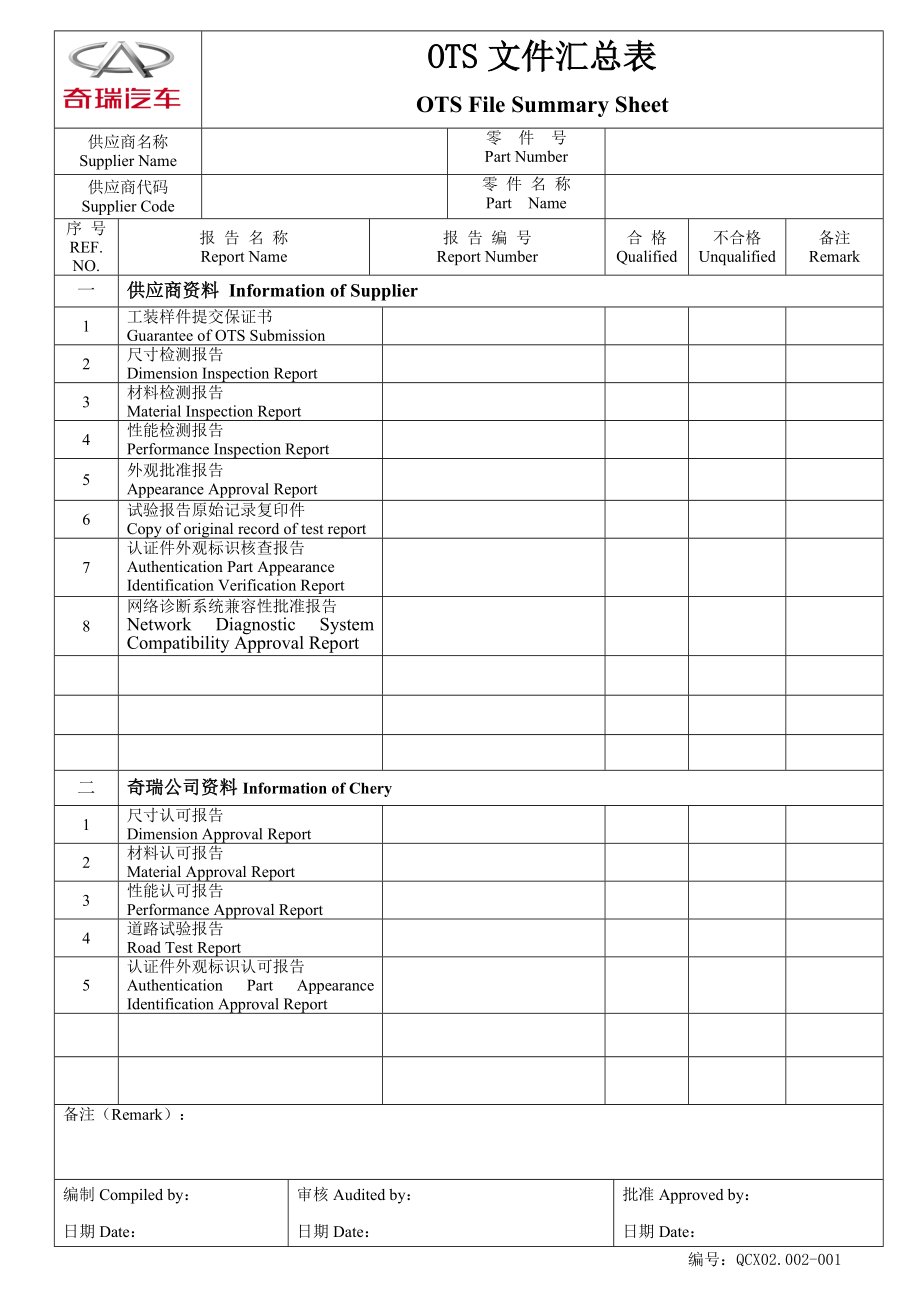

1、OTS文件汇总表OTS File Summary Sheet供应商名称Supplier Name零 件 号Part Number供应商代码Supplier Code零 件 名 称Part Name序 号REF. NO.报 告 名 称Report Name报 告 编 号Report Number合 格Qualified 不合格Unqualified 备注Remark一供应商资料 Information of Supplier1工装样件提交保证书Guarantee of OTS Submission2尺寸检测报告Dimension Inspection Report3材料检测报告Material

2、Inspection Report4性能检测报告Performance Inspection Report5外观批准报告 Appearance Approval Report6试验报告原始记录复印件Copy of original record of test report7认证件外观标识核查报告Authentication Part Appearance Identification Verification Report8网络诊断系统兼容性批准报告Network Diagnostic System Compatibility Approval Report二奇瑞公司资料Informatio

3、n of Chery1尺寸认可报告 Dimension Approval Report2材料认可报告 Material Approval Report3性能认可报告 Performance Approval Report4道路试验报告 Road Test Report5认证件外观标识认可报告Authentication Part Appearance Identification Approval Report备注(Remark):编制Compiled by:日期Date:审核Audited by:日期Date:批准Approved by:日期Date: 编号:QCX02.002-001 工装

4、样件提交保证书报告编号:零件名称: 零件号: 安全和/或法规项 是 否 工程图样更改等级: 更改日期: 适用车型: 重量(kg): 图样号: 采购订单号: 采购工程师: 检具号: 工具更改等级: 批准日期: 供应商资料供应商名称: 供应商代码: 地址: 邮编: 主机厂名称:奇瑞汽车股份有限公司提交原因首次提交 改为其它选用的结构或材料工程更改 偏差校正 其它 注:该部件是否含有任何限制的或需要报告的物质。 是 否 零部件是否标注了相应的产品标识。 是 否要求的提交等级(选择一项)等级1只向本公司提交保证书(若指定为外观项目,还应该提交外观件批准报告)等级2向本公司提交保证书和工装样件及有限的支

5、持数据等级3向本公司提交保证书和工装样件及完整的支持数据等级4向本公司提交保证书和本公司规定的其它要求等级5在供应商制造厂备有保证书、工装样件和完整的支持数据以供评审提交资料及产品状态 1、产品检具、夹具是否标定合格? 是 否 2、产品是否符合合格标定的检具、夹具? 是 否 3、产品提交时是否同时提交尺寸检验简图? 是 否 4、是否提交合格尺寸结果或尺寸检查报告? 是 否 5、是否提交同设计部门共同签字确认 DVP&R? 是 否 6、是否用指定材料制造(包含指定材料供应商)? 是 否 7、是否提交合格材料结果及材料试验报告? 是 否 8、是否提交合格性能结果或性能试验报告? 是 否 9、产品是

6、否满足功能要求? 是 否 10、提供的产品是否有样件标识,并标识顺序号? 是 否提交结果评价以上提交结果满足所有图样和规范要求以上提交结果不完全满足所有图样和规范要求,其解释是 声明我在此声明,本保证书使用的工装样件是我们的代表性零件,已符合奇瑞公司图样和规范的要求。并且,所提交的资料真实可靠。解释/说明: 印刷体姓名: 职务: 电话号码: 传真号码: 供应商授权代表签字: 日期: 以下由奇瑞公司填写工装样件提交保证书处理意见:批准 拒绝 零件功能批准:批准 其它 放弃 奇瑞公司代表确认: 日期: 编号:QCX02.002-002Guarantee of OTS SubmissionRepor

7、t Number:Part Name: Part Number: Safety and/or RegulationsYes No E/C Level Drawing: Date of Change: Applicable Vehicle: Weight (kg): Drawing No.: Purchase Order No.: Purchase Engineer: Test Tool No.: Change Level of tool: Date of Approval: Information of SupplierSupplier: Supplier No.: Address: Zip

8、Code: Engine Manufacturer: Chery Automobile Company Limited.Reason for SubmissionFirst Submission Changed to other optional structures or materialsEngineering Modification Error Correction Others Note: Does this part contain any restricted material or material that a report is required Yes No Is the

9、 part labeled with corresponding product symbols? Yes NoSubmission Level Required (Select one of the following levels)Level 1Submit only the Guarantee to the Company (if it is determined as an appearance item, the appearance approval report is required.)Level 2Submit the Guarantee and OTS, as well a

10、s limited support data, to the CompanyLevel 3Submit the Guarantee and OTS, as well as complete support data, to the CompanyLevel 4Submit the Guarantee and other documents required by the Company Level 5Prepare the Guarantee, OTS and complete support data in the factory of the supplier for reviewsDoc

11、uments Submitted and Product State 1. Is the test tool and fixture of the product calibrated correctly? Yes No 2. Does the product conform to qualified calibrated test tools and fixtures? Yes No 3. Is a dimension inspection drawing submitted attached to the product? Yes No 4. Is the qualified dimens

12、ion result or dimension inspection report submitted? Yes No 5. Is the DVP&R signed together with the Design Department submitted? Yes No 6. Is the specified material used for manufacturing (including the specified supplier)? Yes No 7. Is the qualified material result or material test report submitte

13、d? Yes No 8. Is the qualified performance result or performance test report submitted? Yes No 9. Is the product compliant with requirements on the function? Yes No 10. Is the product provided with the sample symbol and sequence number? Yes NoAppraisal on Submission ResultsThe above submission result

14、s comply with requireemnts of all drawings and criterions. The above submission results are not fully in compliance with requirements of all drawings and criterions, for which the reason is .DeclarationI, hereby, declare that OTS used in the guarantee is our typical part and comply with the requirem

15、ent of drawings and criterions of Chery, and all documents submitted are true and reliable.Explanation: Printed name: Title: Tel: Fax: Signed by authorized representative of supplier: Date: Filled by CheryOpinion on guarantee of OTS submission:Approval Disapproval Others Approval of part functions:A

16、pproval Abandon Confirmed by representative of Chery: Date: 编号:QCX02.002-002样件检测报告Sampling Test Report报告编号Report Number:01尺寸检测Dimension Test02材料检测Material Test03性能检测Performance Test04其他Others首次抽样First sampling再次抽样Second sampling第三次抽样Third sampling新的零部件New parts产品变更Product modification生产迁移Production

17、transition生产过程变更Change of production process长期生产停顿Long-term production stop新的二级供应商 The new second-level supplier供应商名称 Supplier NamePart Number零件号 Part No.供应商代码 Supplier No.Part Name零件名称 Part Name编号S/N要求 Requirement供应商测量结果 Supplier Test Results评价 Appraisal合格/不合格 Qualified/ Unqualified奇瑞公司测量结果 Chery T

18、est Results评价 Appraisal合格/不合格 Qualified / Unqualified 供应商确认:Confirmed by Supplier:备注:Remark:奇瑞公司结论:Chery Conclusion:通过 Pass带条件通过 Pass with conditions拒收,要求再次抽样 Reject, re-sampling required姓名:Name:部门:Department:电话/传真 Tel/Fax签名:Signature: 日期:Date:姓名:Name:部门:Department:电话/传真 Tel/Fax主管签名:Signed by Superv

19、isor: 日期:Date:编号:QCX02.002-003第一联 存档 第二联 质保部 第三联 采购公司 第四联 设计部门 第五联 供应商尺寸认可报告Dimension Approval Report报告编号Report Number:供应商名称SupplierPart Number零 件 号Part Number检 验 机 构 名 称Name of Inspection FacilityPart Name零 件 名 称Part Name项目Item尺 寸 / 规 范Dimension/Specification奇 瑞 公 司 测 量 结 果Chery Test Results合格Quali

20、fied 不合格Unqualified 备注(Remark):认可结论Validation Results: 认可 Approval 临时认可 Temporary Approval 拒绝Disapproval编制Compiled by:日期Date:审核Audited by:日期Date:编号:QCX02.002-004 材料认可报告Material Approval Report报告编号Report Number:第一联 存档 第二联 质保部 第三联 采购公司 第四联 材料部门 第五联 设计部门 第六联 供应商总成零件号:Assy Part No总成零件名称:Assy Part Name总成

21、零部件厂家:Assy Part Supplier序号No.分零件号Part No.分零件名称Part Name材 料Material检测标准Inspection Standard原材料厂商Raw Material Supplier实验报告编号Test Report No.检测机构Test Facility123456789101112131415认可结论Validation Results: 认可 Approval 临时认可 Temporary Approval 拒绝Disapproval备注Remark:编制:Compiled by审核:Audited by 批准:Approved by 编

22、号:QCX02.002-005性能认可报告Performance Approval Report报告编号 Report Number:零件号:Part No零件名称:Part Name供应商:Supplier应用车型:Applied Car检验依据:Test Basis试验机构:Test Facility:试验报告编号:Test Report No认可结论Validation Results: 认可 Approval 临时认可 Temporary Approval 拒绝Disapproval等效认可 Equivalent Approval产品设计工程师/日期:Product Design En

23、gineer/ Date 采购质量工程师/日期:Procurement Quality Engineer/ Date 说明:Explanation:备注:性能认可结论包括以下三种Remark: The result of performance approval may be:1 认可:满足产品材料定义,材料标准或双方认可的技术要求;1、Approval: meet the definition and standard of product material or technical requirements approved by both parties;2 拒绝:材料性能不满足产品定义

24、要求;2、Disapproval: The material performance shall not meet the requirements of product definition;3 临时认可:材料某项性能不合格,但对产品功能要求影响不大。3、Temporary Approval: Some performance of the material is unqualified but without serious impact on product function.编制Compiled by:日期Date:审核Audited by:日期Date:第一联 存档 第二联 质保部

25、第三联 采购公司 第四联 设计部门 第五联 供应商编号:QCX02.002-006外观批准报告Appearance Approval Report报告编号Report Number:(Part Number):零 件 号(Applicable Vehicles):图 样 号(Drawing Number)适用车型(E/C Level):(Part Name):零件名称(Modification Date):工程更改等级更改日期(Supplier Code):(Supplier Name):供应商名称(Tel.& Add.):供应商代码电话及地址提交原因: 零件提交保证书 特殊样品 再提交 表面

26、预处理 第一批发运 工程更改 其它 Reason for Submission: Part Submission Guarantee Special Sample Resubmission Surface Pretreatment First batch for delivery Engineering Modification Others 表 面 品 质 评 价 Appraisal on Surface Quality纹理代码 Texture No.供 应 商 表 面 加 工 资 料 及 评 价 Surface Treatment Information and Appraisal of

27、Supplier 奇瑞公司判定判定标记 Determination Marks of Chery表面处理工艺 Surface Treatment Process供应商意见 Opinion of Supplier纠正并继续 Correction and Continuity纠正和再提交 Correction and Resubmission表面特性合格 Qualified Surface Characteristics颜 色 评 价Appraisal on Color综 合 评 价 结 果 Comprehensive Appraisal Results外观评定工程师(奇瑞公司)Appearanc

28、e Appraisal Engineer (Chery)Three-color data颜色代码Color No.奇瑞公司判定标记 Determination Marks of CheryDL*Da*Db*DE*纠正并继续Correction and Continuity正式认可 Formal Approval纠正和再提交Correction and Resubmission临时认可Temporary Approval拒 绝 Disapproval 色差合格 Qualified Color Difference 备注Remark::供应商代表:Representative of Supplie

29、r:日期:Date:设计部门造型科科长: Modeling Section Chief of , Design Department:日期: Date: 编号:QCX02.002-007第一联 存档 第二联 质保部 第三联 采购公司 第四联 生产管理部 第五联 零部件物流部 第六联 销售公司 第七联 设计部门 第八联 供应商工 装 样 件 认 可 报 告供应商名称:详细地址:邮政编码: 联系人:传真号码:电话号码: 部 门:供应商报告编号:奇瑞公司报告编号:供应商代码:供应商:用户(订货单):零件号:更改日期:零件号:更改日期:名 称:名 称:样品数量:工装样件检验标准: 图纸:是否是“D”零

30、件(有义务存档件) 是 否 一种新的零件或产品(如:从前未曾生产的某种零件、材料或颜色) 对以前提交内容不符合的纠正 由于设计文件、规范或材料方面的设计更改引起产品的改变 加工方法发生了变化 使用新的或更改的工装(不包括易损非关键工装)、模具、铸模、模型等,包括附加或替换用的工装 在工装和设备转移到不用的工厂或在一个新厂址进行的生产 在工装设备停止批量生产达到或超过6个月以后重新启用而生产的产品检验结果见工装样件检验报告有义务存档的“D”检测项目用“D”标记,外委检测结果用“E”标记,实际值按工装样件顺序填写。没有达到技术要求的项目在底下划横线标记。备注:备注:供应商确认奇瑞批准我们确认:1、

31、提供的工装样件是完全用正式生产设备在正式生产条件下生产的。2、正确地进行了工装样件检验和工装样件检验报告里的内容(有偏差的项目在此报告里特别注明)。3、工装样件的认可并不解除供应商按有效图纸、检具和规定的性能要求供货的责任。供应商负责人签字: 日期: 尺 寸认可临时认可拒绝材 料性 能决 定正式认可临时认可拒 绝设计部门:工程师签字/日期: 部长签字/日期: 编号:QCX02.002-008Off Tools Sample Approval ReportFirst Page: Filed Second Page: Quality Assurance Department Third Page

32、:Purchasing Department Fourth Page: Production Management DepartmentFifth Page: Component logistics Department Sixth Page: Sales Company Seventh Page: Design Department Eighth Page: Supplier Supplier Name:Address:Zip code: Contact:Fax:Tel: Department:Supplier Report No.:Chery Report No.: Supplier No

33、.: Supplier:User (Order No): Party No.:Date modified:Part No.:Date modified:Name:Name:Sample Quantity:Standard of OTS Inspection: Drawing:Is it a “D” part (with the obligation for filing)Yes No A new part or product (a part, material or color having never been produced ) Correction to nonconforming

34、items submitted before Product change due to design modification of design document, criterion or material; Changes of processing method New or modified tooling (exclusive of non-key consumable tooling), die, casting, model is used, including tooling to be added or replaced. Tooling and equipment ar

35、e transferred to an unused factory or a new factory for production Products manufactured by tooling or equipment that is put into use again after having not been used for mass production for six month or more. For the inspection result, refer to the OTS inspection report. “D” inspection items with t

36、he obligation for filing will be marked with “D”, outsourced inspection results will be marked with “E”, and the actual value will be filled in the sequence of OTS. Any item that has not reached the technical requirements will be underlined. Remark: Remark: Confirmation of SupplierApproval of CheryW

37、e confirm: 1. The OTS provided is all produced in the normal production conditions with formal production equipment.2. OTS inspection and items in the OTS inspection report are performed correctly (items with errors are specially indicated in this report).3. The OTS approval will not relieve of the

38、suppliers responsibility to supply as per valid drawings, test tools and performance requirements. Supplier Signed by Principal: Date: DimensionApprovalTemporary ApprovalDisapprovalMaterialPerformanceDecisionFormal ApprovalTemporary ApprovalDisapprovalDesign Department:Signed by Engineer: Date:Signe

39、d by Director: Date:临时认可评审表 Temporary Approval Appraisal Sheet供应商 Supplier供方名称:Supplier Name 零件名称:Part Name 供方代码:Supplier No 零件编号:Part No 再次提交OTS日期:Date of OTS Resubmission 临时认可的终止日期:Expiration Date of Temporary Approval 适用性:Applicability 提交等级Submission Level: 重量(kg):Weight(kg) 样品编号:Sample No: 检验员:I

40、nspector: 附加样品:Sample Attached 包装编号:Package No 顾客 Customer状态:(A=认可, I=临时, N=无)State:(A = Approval, I = Temporary Approval, N = N/A)尺寸:Dimension: 材料:Material: 外观:Appearance: 性能:Performance: 路试:Road Test: 供应商 Supplier不能正式认可的理由(页面不够,可附页):The reason for not formally approved (another page can be attache

41、d if there is not enough room):正式认可计划(提供完成日期):Formally approved plan(completion date supplied)供应商(授权签字):Supplier (authorized signature): 电话:Tel: 姓名和职务:(印刷体)Name and Title: (Print) 传真:Fax: 为处理您的申请,必须附有顾客批准的工装样件提交保证书,并送交奇瑞公司。The application must be attached with an OTS submission guarantee approved by

42、 the customer and submitted to Chery. Review/Conclusion of Chery 临时认可风险评估Temporary approval risk assessment产品设计工程师:Product Design Engineer采购质量工程师:Procurement Quality Engineer项目总监:Project director设计分管领导(A类件时):Leader in charge of designing (A class part)管理者代表(A类件时):Manager representative(A class part)

43、第一联 存档 第二联 质保部 第三联 采购公司 第四联 设计部门 第五联 供应商 编号:QCX02.002-009 工装样件标识OTS Identification供应商名称 Supplier Name送样人员签字 Signed by sample deliverer零件生产日期 Production Date入库日期 Date warehoused零件号 Part Number零件名称 Part Name数量 Quantity接收人员签字 Signed by receiver图纸版本号 Drawing Version Number顺序号(生产流水号) Sequence Number (Pro

44、duction Number)备注 Remark此样件可用于Application of the sample 尺寸认可 Dimension Approval 性能认可 Performance Approval 外观认可 Appearance Approval编号No: QCX02.002-010认证件外观标识核查报告Authentication Part Appearance Identification Verification Report报告编号:Report Number车型号Vehicle Model 供应商名称Supplier Name零件号Part No供应商代码Supplie

45、r Code零件名称Part Name编号S/N产品定义标识要求Product Definition Identification Requirement 供应商核查结果 Verification Result of Supplier 合格Qualified不合格Unqualified奇瑞零件号标识Part Number Identification of Chery奇瑞产品型号标识Product Model Identification of Chery供应商代码标识Supplier Code Identification 4追溯标识Retrospective Identification 53C标识3C Identification 6E-mark标识E-mark Identification7清晰度Articulation

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。