通用汽车-持续改进管理体系培训教材

通用汽车-持续改进管理体系培训教材

《通用汽车-持续改进管理体系培训教材》由会员分享,可在线阅读,更多相关《通用汽车-持续改进管理体系培训教材(77页珍藏版)》请在装配图网上搜索。

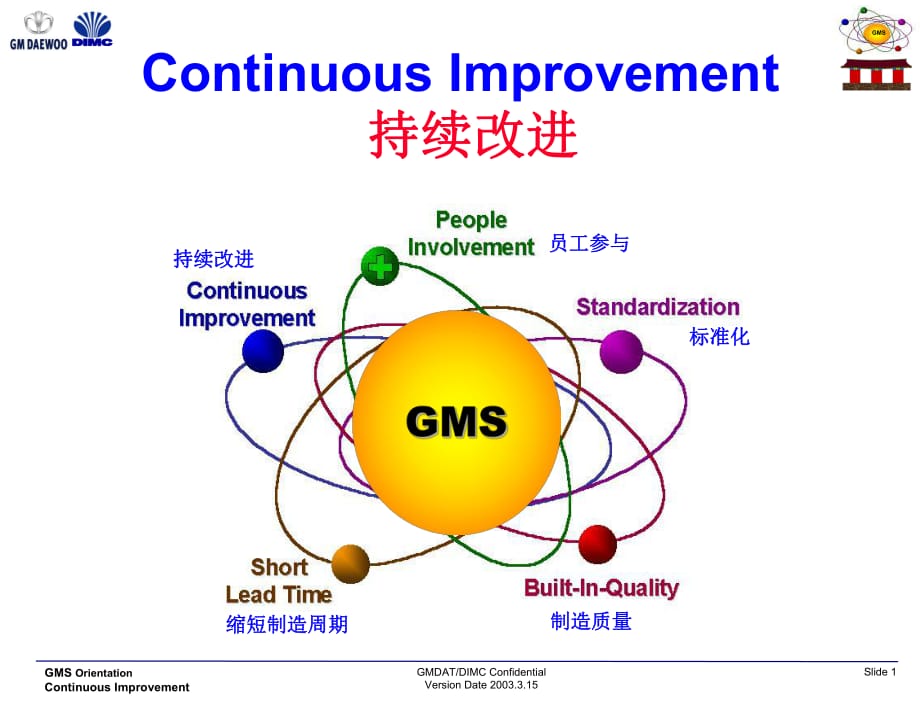

1、GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 1 GMSContinuous Improvement持续改进员工参与标准化 制造质量缩短制造周期持续改进 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 2 GMS 32 GMSContinuous Improvement Built-InQualityShort LeadTime P

2、eopleInvolvementStandardizationContinuous ImprovementHealth andSafety Priority Qualified People Team ConceptPeopleInvolvement OpenCommunicationProcess ControlledExternal TransportationManufacturingProcess Validation ProductQualityStandards QualitySystemManagement ScheduledShipping /ReceivingLevel Ve

3、hicleOrder Schedules SupplyChainManagementValuesVision/Mission Shop FloorManagement Internal Pull /Delivery AndonConcept ProblemSolving SimpleProcessFlowIn-ProcessControl &Verification StandardizedWork Small LotPackaging TemporaryMaterialStorageQualityFeedback/Feed-forward VisualManagementManagement

4、by TAKT Time Work-placeOrganization Early Mfg. and DesignIntegration (DFM / DFA)ContinuousImprovementProcessLean Design of Facilities, Equipment,Tooling and Layout Business PlanDeployment Total ProductiveMaintenance Fixed Period Ordering System/ Order Parts GMS OrientationContinuous Improvement GMDA

5、T/DIMC ConfidentialVersion Date 2003.3.15 Slide 3 GMSContinuous Improvement Company持续改进的公司Small, steadyimprovements toconstantly improveThe Standard! 从细小、稳定的改进到标准的不断提高No Company Today Can Survive Without Having All Employees Focused on Continuous Improvement 没有改进就难以生存 GMS OrientationContinuous Impro

6、vement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 4 GMSContinuous ImprovementWhat Is Absolutely Necessary Before Continuous Improvement Can Occur?在能够进行持续改进前什么工作是绝对必要的? Stability Through Standardization!通过标准化获得稳定发展 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 200

7、3.3.15 Slide 5 GMS StandardizationImprovement改进Standardization Standardization StandardizationImprovement改进Improvement改进 Continuous ImprovementStandardization Before Continuous Improvement! 在进行持续改进前的标准 标准化标准化标准化标准化 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 S

8、lide 6 GMSPlan 计划Do 实施Check 检查Action 运作 The PDCA CyclePDCA GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 7 GMSThe PDCA Cycle is One Of The Most Important Concepts In A CompanyP D REACT PPoor companies do little planning, mostly doing, do not check their st

9、atus and then react to everything没有远见的公司很少做计划,大多数情况是直接实施,从不检查实施情况,此后对每件事都是如此 D C AWorld-Class companies do excellent planning, always perform checks that enable to take corrective action and stay on schedule 世界级的大公司会做非常周详的计划,对每件工作进行跟踪检查以便及时采取纠正措施并按进度表运行 BADG OOD GMS OrientationContinuous Improvement

10、 GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 8 GMSLets go to Kyong Ju! Plan 计划 Prepare for the tripTwo days before leaving, check engine OIL LEAK!Fix oil leak & leave on time Our Family Has Not Had A Vacation In A Long Time! PDCA Can Be Used For AnythingDo 实施Grasp the Situation掌握情况 Check 检查A

11、ction 运作 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 9 GMS ManufacturingProcess Validation ProductQualityStandards QualitySystemManagementIn-ProcessControl &Verification QualityFeedback/Feed-forward StandardizedWorkVisualManagement Managementby TAKT Time

12、 Work-placeOrganization ControlledExternal TransportationScheduledShipping /Receiving Level VehicleOrder Schedules SupplyChainManagementInternal Pull /Delivery SimpleProcessFlowSmall LotPackaging TemporaryMaterialStorage Fixed Period Ordering System/ Order PartsHealth andSafety Priority Qualified Pe

13、ople Team Concept PeopleInvolvement OpenCommunicationProcessValuesVision Shop FloorManagement Continuous Improvement AndonConcept ProblemSolving Early Mfg. and DesignIntegration (DFM / DFA)ContinuousImprovementProcessLean Design of Facilities, Equipment,Tooling and Layout Business PlanDeployment Tot

14、al ProductiveMaintenance AndonConcept ProblemSolving Early Mfg. and DesignIntegration (DFM/DFA)ContinuousImprovementProcessLean Design of Facilities, Equipment,Tooling and Layout Business Plan Deployment Total ProductiveMaintenance暗灯概念TPM业务计划实施解决问题持续改进的过程早期管理及综合设计(DFM/DFA)厂房,设备,工具及布置的精益化设计 GMS Orien

15、tationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 10 GMS ManufacturingProcess Validation In-ProcessControl andVerificationProductQuality Standards QualityFeedback/Feed-forwardStandardized WorkVisualManagementManagementby TAKT Time Work-placeOrganization AndonConcept Pr

16、oblemSolvingContinuousImprovementProcessBusiness PlanDeployment Total ProductiveMaintenance ControlledExternal TransportationScheduledShipping /ReceivingLevel VehicleOrder Schedules SupplyChainManagementInternal Pull /Delivery SimpleProcessFlowSmall LotPackaging TemporaryMaterialStorage Fixed Period

17、 Ordering System/ Order PartsHealth andSafety Priority Qualified PeopleTeam ConceptPeopleInvolvement OpenCommunicationProcessValuesVision Shop FloorManagement Continuous ImprovementBusiness PlanDeployment业务计划实施 QualitySystemManagement Early Mfg. and DesignIntegration (DFM / DFA)Lean Design of Facili

18、ties, Equipment,Tooling and Layout GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 11 GMSA common process which enables our Global Organization made up of multiple parts, to act in unison to achieve company wide goals in five key categories:DefinitionBusines

19、s Plan Deployment定 义 Safety People Quality Responsiveness CostBPD是一种共有的方法,它能使多个部分组成我们的全球团队,通过五个核心范畴统一行动以达到公司的总体目标:安全员工质量 响应成本 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 12 GMS?Division Director ? different directionsno ownership conflicting goals MISSIO

20、N ? duplicationBefore BPD 部门主管通过不同的途径没有落实责任目标向冲突任务重复ONLY HE KNOWS THE GOALS GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 13 GMS MISSION TRACK PERFORMANCE DEPLOY RESOURCES GME-BPD Guide FOCUSTARGETS CLEAR DIRECTIONCOMMON GOALS任务对工作进行跟踪调动资源 关注目标 思路清晰共同目标Div

21、ision Director部门主管EVERYONE KNOWS THE GOALS After BPD GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 14 GMS Concrete GOALSRegular and Consistent Reviews CoordinationVision/Mission Achieving Our VisionIn Order for GMDAT/DIMC to Achieve Its VISION, we have to

22、achieve our goals SPECIFIC OBJECTIVESCLEAR & MEASURABLE TARGETSA METHOD TO RESEARCH THE TARGETS为了实现GMDAT/DIMC的宗旨, 我们必须实现我们的 目标宗旨/任务定期坚持审议协调具 体 目标明 确 目标清晰 的 , 可 量 化 的 目标有 搜寻目标的 方 法 我们的宗旨 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 15 GMS Safe working envi

23、ronment for all employeesRegular and Consistent Reviews CoordinationVision/Mission Achieving Our VisionIn Order for GMDAT/DIMC to Achieve Its VISION, we have to achieve our goals No safety incidents零 事 故 Lost Work Day没有损失 工 作 日 事 故Increase Compliance of PPE增 加对PPE的 使 用定期坚持审议协调 我们的宗旨宗旨 / 任务 为所 有员工创造

24、安 全 的 工 作环境为了实现GMDAT/DIMC的宗旨, 我们必须实现我们的 目标 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 16 GMSWhy Engage the Workforce? 为何 要 雇佣工 人 ?Why? Why? Why? Why? Why? 1-6 6-10 10-20 20-40 40-10050%40%30%20%10% of People Involvement % of Possible Improvement 员工的参与率参

25、与的 可 能 性为什么?为什么?为什么?为什么?为什么? Who is involved in BPD? Everyone! 那 些 人与BPD有关? 每个人 ! ! ! GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 17 GMS Mission/Strategy Goals & Objectives Clear Targets Action Plans Review Process 任务/对策 目标实施计划 The Cascading Process(catc

26、h balling 抓住 要 点 )Level 2 Level 3 Level 4 Level 1Detailed Action Plans and CountermeasuresCascading Strategies and Objectives详细的实施计划及应急 措 施层层实施计划并实现目标 Action Plans Clear Targets Review Process实施计划 目标清晰 Clear Targets Review Process 目标清晰 回顾流 程 层层递进的 流 程 Goals & Objectives Clear Targets Action Plans Re

27、view Process 目标 目标清晰实施计划 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 18 GMSEach Level of Leadership Must Hand Down Targets to Their TeamBupyung 100 Press - 10Body - 30Paint - 15G.A. - 45For Example, Defects Per Hundred Vehicles (DPHV)Trim 1 - 10Trim 2 -

28、15Trim 3 - 10Trim 4 - 10Production Director Shop ManagerPlant Shop Group TeamTeamsGroup Leader TeamsTeams GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 19 GMSBut The Targets Dont Always Have To Measure The Same Thing, But Something That Will Affect the Nex

29、t Level Up对于 同 一 目标中 相 同 的 事 情 不 需 要 都 量 化 , 但 有 些 事 情 却会影响到 下 一层次 的 改进 S.M.A.R.T. Targets: Specific, Measurable, Aligned, Realistic & Timed 目标是:特定 的 , 可测量 的 , 校 正 的 , 现实的 定时的Targets Have To Have Meaning To People!目标对员工 必须有 意义! Team Leader I have to achieve 0.000135 Hours/Vehicle? GMS OrientationCon

30、tinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 20 GMSGMDAT/DIMCCost per VehicleTEAM - COCKPIT INSTALLTop Scrap Item (# of Gloves Consumed) GROUP LEADER TRIM 1Top 3 Scrap SHOP MANAGER G.A.Budget AccountsCHANGWON PLANTTotal Manufacturing CostI understand my piece of the pie?我

31、知 道 自 己应得 的馅饼有 多 大班组驾驶座 安 装主 要 耗 材 ( 手 套 ) GMDAT/DIMC每辆车的 成 本 大 宇 昌 原 整车厂总制 造 成 本总装车间主 任预算调整 一 工 段 工 段长三种主 要 耗 材 Target Cascade - ExampleEveryone Gets A Piece Of The Pie That Is Easy To Bite Into! S.M.A.R.T. Targets: Specific, Measurable, Aligned, Realistic & Timed 指 定 的 , 可测量 的 , 校 正 的 , 现实的 定时的 GM

32、S OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 21 GMSTargets Are A Good Start, But We Need Good Methods To Achieve Them目标是个好开端,但需要好方法才能达到。GOAL = Lead a Healthy Lifestyle 以 一种健 康 的 生 活 方 式 生 活OBJECTIVE Maintain a Light Weight 保 持 苗条TARGET 65 kgMETHODS - Exerci

33、se Regularly (3x/week) 有计划地锻炼 (每 周 3次 ) - Cut Down On Fast Food (1x/week) 减少 吃 快 餐 的 次数( 每 周 1次 ) The Concept Can Be Applied To Anything In Life! GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 22 GMSGOAL =OBJECTIVE =TARGET =METHOD(S) =BPD Exercise Think of

34、an example at work or at home where you can establish a Goal, Objective, Target and at least one Method 想想工作或生活中设立的目标及实现方法。 Discuss as a team and report Take 10 minutes 团队讨论及汇报-十分钟 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 23 GMSPlan 计划Do 实施Check 检查Act

35、ion 运作 PDCA is the foundation of BPDPDCA是 BPD的 基础 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 24 GMS Below ExpectationsNeeds ImprovementMeets Expectation How does it work?Actions Annual Business Plan X Activities行动 PLAN DOPROBLEM SOLVING问题解决CHECKACT 0501

36、00 1st 3rd PDCA如 何运作 ? 未 完 成需 要 改进完 成Regular ReviewsGoals, Objectives, Targets, MethodsCountermeasures对策 Open, Team Discussion Coaching & Learning Get Support & Resources Go To See GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 25 GMSBPD We Will Be Successf

37、ul When Everyone Focuses On What They Can Control! 当每个人都集中力量做事,我们就一定能成功做到BPD。Why cant they design better cars? What can I do in my area to improve? Ask Not What Others Can Do Ask What Can You Do On Your B.P.D.! 不追问别人做的,关键在你的自己BPD能做的。 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersi

38、on Date 2003.3.15 Slide 26 GMSu Visual Management Status at a Glance 可视化 管 理 让信 息 容 易读取 - Makes out of standard condition highly visible. 突 出 超标的 情况。u Open Communication/Team Concept - Enables all to focus on action plan/countermeasures and discuss as a team. 让所 有 人 像 一个团队一样共 同关注 某个行动的计划或对策并参与讨论。KEY

39、 BPD CONCEPTSBPD的 核 心 理 念 u BPD a critical tool to achieve Continuous Improvement. BPD是评定 是 否获得 持续改进的 工 具 - Achieve targets and then “raise the bar”. 达到 了 目标, 接 着 制 定 更 高 的 目标。u PDCA - Discipline & Follow-up 一种规则并需 要 持续进行u “Go-To-See” Leadership Style “Go-To-See” 领导模 式 - Dont just sit at desk and re

40、ceive reports. 不 要 只 是 坐 在办公 室 等 待别人来汇报。 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 27 GMS ManufacturingProcess Validation QualitySystemManagementQualityFeedback/Feed-forwardStandardizedWorkVisualManagementManagementby TAKT Time Work-placeOrganization A

41、ndonConcept ProblemSolvingEarly Mfg. and DesignIntegration (DFM / DFA)ContinuousImprovementProcessBusiness PlanDeployment Total ProductiveMaintenanceControlledExternal TransportationScheduledShipping /ReceivingLevel VehicleOrder Schedules SupplyChainManagementInternal Pull /Delivery SimpleProcessFlo

42、wSmall LotPackaging TemporaryMaterialStorage Fixed Period Ordering System/ Order PartsHealth andSafety Priority Qualified People Team ConceptPeopleInvolvement OpenCommunicationProcessValuesVision/Mission Shop FloorManagement Continuous ImprovementAndonConcept 暗 灯概念 Lean Design of Facilities, Equipme

43、nt,Tooling and LayoutIn-ProcessControl andVerificationProductQuality Standards GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 28 GMSWhat is an Andon System? 什么是 暗 灯 系统? The ANDON System allows team members to pull the cord and call for help when there is a

44、problem or out of standard situation. The ANDON System is an enabler to control quality while keeping the line running by pulling in support to address problems before they stop the line 暗 灯 系统允许员工 在 出现问题或 有 超标情况时拉绳索 以寻求帮助 暗 灯 系统可 以 在 保 持 流 水线继续运行 的 情况下 ,员工 拉 下绳索寻求 支 持 人员在停线前 到 出现问题的 工 位 解决问题, 以满足对质

45、量 的 控 制 。 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 29 GMSAlways Remember The PrioritiesSafety (安 全 )People (员工 )Quality (质量 )Responsiveness (响应)Cost (成 本 )Importance 重要性 For Example, Sometimes We Have To Sacrifice Responsiveness to Achieve Quality比如,有

46、时我们为了达到质量要求而不得不放弃响应 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 30 GMS10 131211 FPS FPS FPSZone 2Step 1 - Andon cord is pulled, station light goes on and music begins第 一 步 : 拉 暗 灯 控 制绳索 , 工 位 的 指 示 灯会亮 起并伴随着 音乐When there is a problem or out of standard s

47、ituation which can not be fixed by the team member, then 当员工 不 能单独解决出现的问题或 超标的 情况时 Andon Steps GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 31 GMSAndon Steps (Contd)Step 2 - Zone light on main Andon board turns yellow, Team Leader responds to the Andon 第

48、二 步 : 在 暗 灯 系统主 看 板 上 相应区域 的 指 示 灯变成黄色 , 班组长对暗 灯系统的 信号做 出 反应STV CON EQUIP STOPTRIM 1EQUIP1 2 543 61 2 543 6BLK Q1Q2Q3 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 32 GMSStep 3 - Help comes immediately and problem solving begins. Team Leader takes the Ando

49、n responsibility 第 三 步 : 支 持 人员立 刻 到达并开始 解决问题,班组长对此负责 Andon Steps (Contd) GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 33 GMSStep 4 - Line continues to move to fixed position stop 第 四 步 : 生产线继续运行 直 到定点停10 131211FPS FPS FPS FPSZone 2 Andon Steps (Contd) GM

50、S OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 34 GMSStep 5 - Problem is addressed, Andon is deactivated by Team Leader to keep the line running. 第 五 步 :问题解决,班组长解 除 暗 灯 信号以 保 持 生产线继续运行 。SHORTCONVEQUIP FULL541 2 3TRIM 1EQUIP Q1Q2Q3 Andon Steps (Contd) GMS Orie

51、ntationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 35 GMSStep 6 If Andon is not deactivated by Team Leader when vehicle reaches FPS, line stops and board flashes red - Downtime clock begins第 六 步 : 如 果车辆到达定点停时班组长仍 然没有 解 除 暗 灯 信号, 生产线停 止并且 主看 板 上红灯开始闪烁, 停线铃开始响起Downtime C

52、lockSHORTCONV EQUIP FULL541 2 3TRIM 1EQUIP Q1Q2Q3Andon Steps (Contd) GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 36 GMS FPS FPS FPSSet Line at 70% of Takt or Cycle Time & Relate to Specific Step in Standardized WorkPull the Andon as Early As Possible (at

53、 or before 70% Line) to Address Problems Before They Stop the Line! 在线停之前,尽早拉动暗灯线宣告出现问题。(在70%线位或之前), Purpose of “70% Line” 70% LineReaction Time GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 37 GMS MgrGroup LeaderTeam LeaderTeam Member DecisionDecisionDeci

54、sionPull AndonSupportSupportSupportNeeds help Function of everyone including managers and staff is to support production team members.主 管 及 所 有 人员都 有职责支 持 生产一线的员工班组成员班组长工 段长 主 管寻求帮助支 持支 持支 持决定决定决定拉 下 暗 灯 拉 索 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 38

55、 GMSAndon ConceptRole of Team Member Follow Standardized Work Actively Watch for Out-of-Standard Situations If an Abnormality or Defect Is Discovered That Cannot Be Immediately Corrected, Pull the Andon, and Continue With Rest of Cycle Until Support Arrives. Support Team Leader With Problem Solving

56、As Required. 班组成员的职责 按 照标准 化 要 求 作业 主动查找 超标情况 如 果发现了异常状况或 缺 陷 但 无 法 及时解决, 拉 下 暗 灯 拉索 ,并继续做 自 己 的 工 作 直 到 支 持 人员到达。 支 持 的 班组长按 要 求 解决问题Focus On Standardized Work! GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 39 GMSAndon ConceptRole of Team Leader: Team Lea

57、der goes immediately to area of Andon call to investigate and support. Team Leader begins immediate correction of the problem. Team Leader releases the Andon when TL has determined a correction can be made. TL begins problem solving with support of TM. Team Leader manages the Andon system 班组长职责 在 暗

58、灯 信号发出 后 立 刻 赶 到发生问题的区域查明 原 因并实施支 持 到达问题区域 后 立 刻开始 解决问题 当班组长认为可 以 把问题解决时解 除 暗 灯 信号。 班组长与班组成员共 同开始 解决问题。班组长管 理 暗 灯 系统Address Non-StandardConditions! GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 40 GMSAndon ConceptRole of Group Leader Support Team Leader if

59、 (s)he is not able to countermeasure the problem, and get the line running as soon as possible. Call additional support as needed (i.e. maintenance, quality, etc.) Work with team leader to make sure root cause is identified and countermeasures implemented. Monitor downtime, identify problem areas an

60、d work with all available resources to eliminate problems. 工 段长职责当班组长不 能 解决问题时要 提 供 支 持并尽快让生产先运转起来 如 果 需 要 可 以寻求 外 部 支 持 ( 如 :维修 ,质量 等 部门人员)与班组长一 起 确 定问题的 起 因 是 否 已经被 确认出来并且 保证解决措 施 得 到实施 在 停线时进行监控 , 确 定问题区域并调动一 切 可 利 用资源 解决问题Support The Team! GMS OrientationContinuous Improvement GMDAT/DIMC Confide

61、ntialVersion Date 2003.3.15 Slide 41 GMSAndon ConceptTeam ConceptSmall Team SizeStandardized WorkClear Quality StandardsProblem Solving ProcessEmployee TrainingMutual Trust/RespectConstant Takt TimeFixed Position Stop Decouplers/BuffersProcess CapabilityENABLERS Irreversible correction action Qualit

62、y in station Inspection and Feedback Open Communication Teamwork Improved ProductivityBENEFITSMotionCorrectionWaiting5 1 2 3 4 5 6 PROCESS NO.3O.D. Reference 4团队概念缩小团队规模工 作标准 化 (FPS)明 确质量标准职员培训相 互 信 任 /尊 重保 持单件 工时停线点缓冲 架加 工 能 力 好处实施 的纠正 措 施 不 能复原 在 工 位 控 制质量检查和 反馈开放 式 交 流团队合 作提高生产力 GMS OrientationCo

63、ntinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 42 GMSWhy is Andon Part of C.I.?Use Andon Data to Continuously Improve by Identifying Bottlenecks and Issues Affecting Throughput使 用 暗 灯数据 通过确 定瓶颈及 影响产出 的问题来达到 持续改进TRIM 1 GROUP Andon Report 2003/1/24Station 001R 10Station 003L

64、4Station 004R 2 Analyze Reports分 析报告 Discuss Countermeasures讨论对策 Improve!改进 GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 43 GMSAndon Is Not Just a System Of Wires and Lights暗 灯 系统不仅仅是 一个由电线和 灯 泡组成 的 系统It is a Concept of Calling For Help它是 一种寻求帮助 的 理 念Pull

65、 Your Andon!在 需 要帮助时拉 下 拉 索 ! ! !EVERYONE HAS AN “ANDON CORD”每个人 都 有 一 根 “暗 灯 拉 索 ” GMS OrientationContinuous Improvement GMDAT/DIMC ConfidentialVersion Date 2003.3.15 Slide 44 GMS ManufacturingProcess Validation ProductQualityStandards QualitySystemManagementIn-ProcessControl &Verification QualityF

66、eedback/Feed-forwardStandardizedWorkVisualManagementManagementby TAKT Time Work-placeOrganization AndonConcept ProblemSolvingEarly Mfg. and DesignIntegration (DFM / DFA)ContinuousImprovementProcessLean Design of Facilities, Equipment,Tooling and Layout Business PlanDeployment Total ProductiveMaintenanceControlledExternal TransportationScheduledShipping /ReceivingLevel VehicleOrder Schedules SupplyChainManagementInternal Pull /Delivery SimpleProcessFlowSmall LotPackaging TemporaryMaterialStorage

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。