甲醇—水汽液平衡

甲醇—水汽液平衡

《甲醇—水汽液平衡》由会员分享,可在线阅读,更多相关《甲醇—水汽液平衡(17页珍藏版)》请在装配图网上搜索。

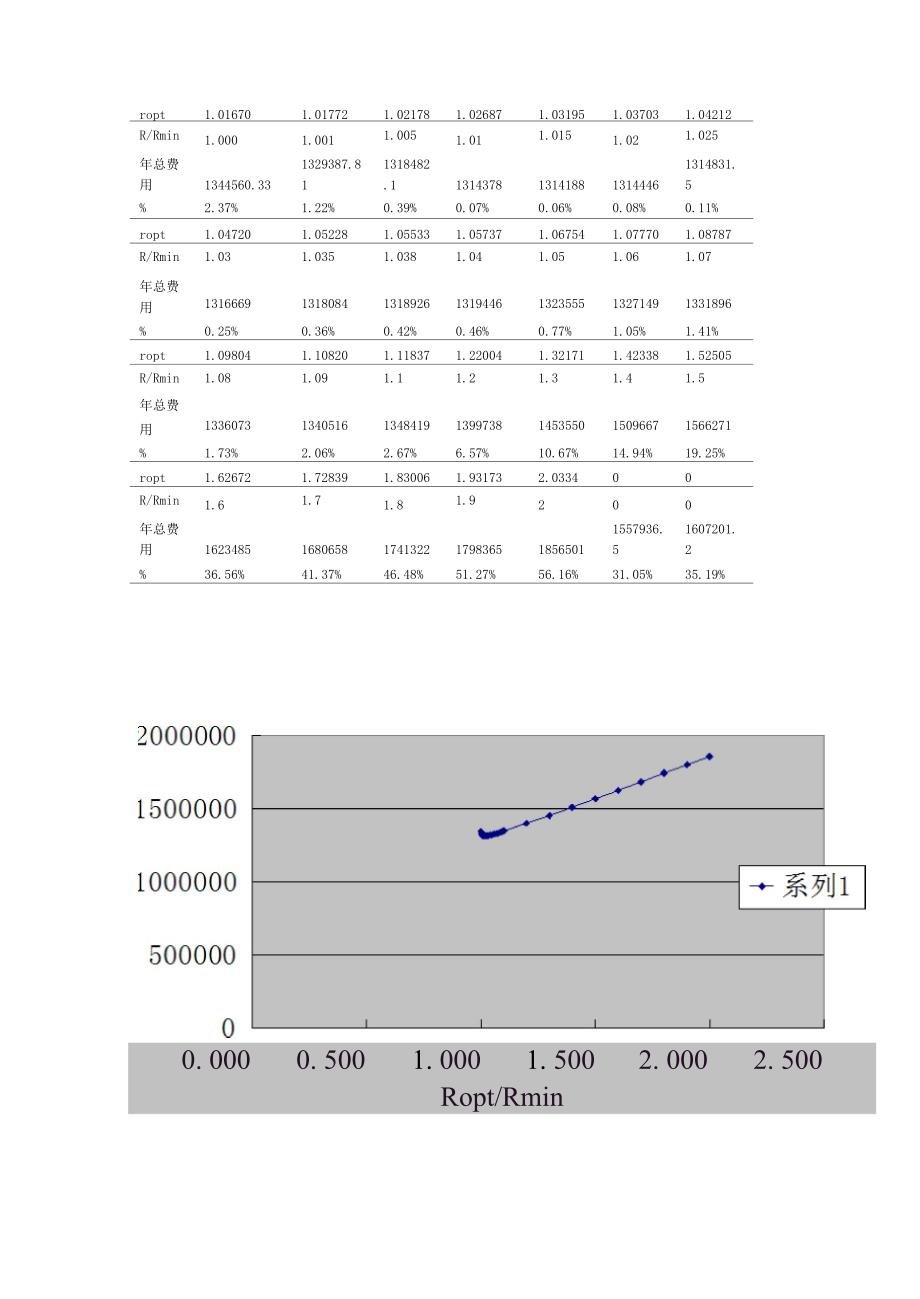

1、ropt1.016701.017721.021781.026871.031951.037031.04212R/Rmin1.0001.0011.0051.011.0151.021.025年总费1329387.813184821314831.用1344560.331.11314378131418813144465%2.37%1.22%0.39%0.07%0.06%0.08%0.11%ropt1.047201.052281.055331.057371.067541.077701.08787R/Rmin1.031.0351.0381.041.051.061.07年总费用1316669131808413

2、189261319446132355513271491331896%0.25%0.36%0.42%0.46%0.77%1.05%1.41%ropt1.098041.108201.118371.220041.321711.423381.52505R/Rmin1.081.091.11.21.31.41.5年总费用1336073134051613484191399738145355015096671566271%1.73%2.06%2.67%6.57%10.67%14.94%19.25%ropt1.626721.728391.830061.931732.033400R/Rmin1.61.71.81.

3、9200年总费1557936.1607201.用1623485168065817413221798365185650152%36.56%41.37%46.48%51.27%56.16%31.05%35.19%0. 0000. 5001. 0001. 5002. 0002. 500Ropt/Rmin附录二甲醇一水汽液平衡数据(摩尔组成)txytxy100.000.000.00075.300.400.72996.400.020.13473.100.500.77993.500.040.23471.200.600.82591.200.060.30469.300.700.87089.300.080.36

4、567.600.800.91587.700.100.41866.000.900.95884.400.150.51765.000.950.97981.700.200.57964.501.001.00078.000.300.665甲醇-水溶液汽液相平衡00.20.40.60.81附录一 甲醇_水系统的主要物理性质附一甲醇-水系统的主要物理性质一、甲醇主要的物理性质:相对分子质量;32.03;常压下沸点= 64. 7 C;在20C时的密度:792 kg/mJ,在64. 7 C时的蒸发潜热:1 100. 8 kJ/kg二、甲醇液体及其饱和蒸气的密度(kg/m3)温度/C-100102030405060

5、70百/kg m-381830980179278277276475474 6阿/kg m_s-一一h 0温度代8090100110120130140160160/kg -7367257147026&0677664650634py/kg m_i2. 6r_-3. 04+0乩0I 7.09-012. 0M+Q19.0温度代170180190200210220230240円/kg m7616598577553526490440272/kg 35.032. 0go45757. 486. 0119.0272.0三、甲醇水溶液的密度(kg/m3)CHjDH 质量分数X102温度心CHSOH质量分数X10S

6、温度/个010200102059519&199050929922916109849839826090902895159789769747088787987L!2097397096780863&55847309609509529083782982040946940935100810801792四、甲薛的比热容1/VJ - kgT -r/CJ kgT 5J 检一! - C-1f 502 135.37-102344.72302 554. 07f 402 177. 2402386. 59402 595.942 219, 11102470. 33SO2 637. 81-202 302.35202512,

7、 20&02 679. 68附录三优化设计程序源代码 优化程序定义全局变量Dim JI#, J2#, J3#, J4#, JJ#zongtagao#,Dim N#, R#, Ropt#Dim lilunbanshu#, jinliaoweizhi%, tajing#, chukouwendu#, chuanremianji#, tiliuduanbanshu#, jinliuduanbanshu#Dim XF#, F#, q#, XD#, D#, td#, rD#, po#, u#, Rmin#, tl#, Cw#, Cp#, SI#, HETP#Dim Co#, HA#, f1#, f2#,

8、 a#, b#, FL#, 0 #, p #, bo#, Fc#优化所需参数Public Sub Form_Load()XF = 0.3151: F = 402.34: q = 1XD = 0.982: D = 128.97: td = 64.93: rD = 35373.48: po = 101.3 u = 5.4464: Rmin = 1.0167t1 = 20: Cw = 0.0002: Cp = 4.1875: Co = 0.03: cpa = 15674.4HETP = 0.462: HA = 6f1 = 1: f2 = 6.5: a = 487: b = 0.72: SI = 3.

9、73FL = 6.22: 0 = 7200: p = 7860: bo = 0.005: Fc = 0.125Text1.Text = 402.34Text2.Text = 0.3151Text3.Text = 128.97Text4.Text = 0.982Text5.Text = 35373.48Text6.Text = 64.93Text7.Text = 1Text8.Text = 1.0167Text9.Text = 7200Text10.Text = 3.73Text11.Text = 0.125Text12.Text = 6.22Text13.Text = 0.005Text14.

10、Text = 7860Text15.Text = 5.4464Text16.Text = 0.462Text17.Text = 6Text18.Text = 15674.4Text19.Text = 0.0002Text20.Text = 4.1875Text21.Text = 20Text22.Text = 2000Text23.Text = 1Text24.Text = 6.5Text25.Text = 487Text26.Text = 0.72Text27.Text = 0.03Text28.Text = 1.01Text29.Text = 2Text30.Text = 0.0001Te

11、xt31.Text =Text32.Text =Text33.Text =Text34.Text =Text35.Text =Text36.Text =Text37.Text =Text38.Text =Text39.Text =Text40.Text =Text41.Text =Text42.Text =Text43.Text =Text44.Text =Text45.Text =Text46.Text =Text47.Text =End Sub主程序Private Sub Command1_Click()菲波拿契法求 RoptDim Aa#, Bb#, W#(1 To 50), i%, K

12、%, N#, M%, R1#, R2#, #Dim JJ1#, JJ2#Aa = 1.01 * Rmin: Bb = 2 * Rmin 搜索区间Aa,BbW(1) = 1: W(2) = 2: W(3) = 3: i = 1: = 0.0001Do While W(i + 2) = (Bb - Aa) / )i = i + 1W(i + 2) = W(i) + W(i + 1)LoopR1 = Aa + (Bb - Aa) * W(i) / W(i + 2): JJ1 = j(Rl)N = i + 2: K = 1: M = 0Do While K N - 1If M = 0 ThenR2 =

13、 Aa + (Bb - Aa) * W(N - K) / W(N - K + 1) JJ2 = j(R2)ElseR1 = Aa + (Bb - Aa) * W(N - K - 1) / W(N - K + 1) JJ1 = j(R1)End IfIf JJ1 JJ2 ThenBb = R2: R2 = R1: JJ2 = JJ1: M = 1ElseAa = R1: R1 = R2: JJ1 = JJ2: M = 0End IfK = K + 1LoopR = (Aa + Bb) / 2Ropt = RJJ = j(R)Text31.Text = RoptText32.Text = Rmin

14、Text45.Text = Ropt / RminText33.Text = lilunbanshuText34.Text = zongtagaoText40.Text = J1Text41.Text = J2Text42.Text = J3Text43.Text = J4Text44.Text = JJText37.Text = tajingText38.Text = chukouwenduText39.Text = chuanremianjiText46.Text = Ropt * DText47.Text = (Ropt + 1) * DText35.Text = tiliuduanba

15、nshu * HETPText36.Text = jinliuduanbanshu * HETPEnd SubJ函数Public Function j(R#) As DoubleCall jjjl(R#, JI#)Call jjj2(R#, J2#)Call jjj3(R#, J3#)Call jjj4(R#, J4#)j = J1 + J2 + J3 + J4End Function求J1Public Sub jjj1(R#, J1#)Dim DT#, H#, Ws#, CH#Call tabanshu(R#, N#)DT = Sqr(R + 1) * D * 22.4 / (3600 *

16、0.785 * u) * (273 + td) / 273 * 101.3 / po)H = N * HETP + HAWs = 3.14 * DT * (H + 0.8116 * DT) * bo * p p 为碳钢的密度CH = FL * Exp(6.95 + 0.1808 * Log(Ws) + 0.02468 * (Log(Ws)人 2 + 0.0158 * H / DT)J1 = SI * (Fc + 0.06) * CHtajing = DTzongtagao = HEnd Sub求J2Public Sub jjj2(R#, J2#)Dim xx1#, xx0#, CD#, ff#

17、, df#, t2#, AD#, KD#KD = 2000: xx1 = 70Do牛顿迭代法求冷却水最佳出口温度t2xx0 = xx1CD = 1.3 * SI * a * b * f1 * f2 * Fc * (R + 1) * D * rD / (td - t1)人(b - 1) / KD 人 bff = -Cw * 0 / Cp + CD * (xx0 - 1) / xx0 / Log(xx0)人(1 - b) * (xx0 - 1 - Log(xx0)df = CD * (xxO - 1) / xxO / Log(xxO)人(2 - b) * (b - 1) * (xxO - 1 -

18、Log(xxO)人 2 / (xxO - 1)人 2 + Log(xxO)xx1 = xx0 - ff / dfLoop Until Abs(xxl - xx0) XF ThenY(i + 1) = R * X(i) / (R + 1) + XD / (R + 1)n1 = i + 1 + (X(i) - XF) / (X(i) - X(i + 1)ElseY(i + 1) = W * (X(i) - XW) / VIf X(i) XW Then Exit DoEnd Ifi = i + 1xx(i) = (Y(i) / (3.3874 * (1 - Y(i)人(1 / 0.7977)X(i)

19、 = xx(i) / (1 + xx(i)LoopN = i - 1 + (X(i - 1) - XW) / (X(i - 1) - X(i)lilunbanshu = Ntiliuduanbanshu = n1jinliuduanbanshu = N - n1End Sub调整ROPT程序:定义全局变量Dim J1#, J2#, J3#, J4#, JJ#Dim N#, R#, Ropt#Dim lilunbanshu#, jinliaoweizhi%, tajing#, chukouwendu#, chuanremianji#, zongtagao#, tiliuduanbanshu#,

20、jinliuduanbanshu#Dim XF#, F#, q#, XD#, D#, td#, rD#, po#, u#, Rmin#, t1#, Cw#, Cp#, SI#, HETP#Dim Co#, HA#, f1#, f2#, a#, b#, FL#, 0 #, p #, bo#, Fc#优化所需参数Public Sub Form_Load()XF = 0.3151: F = 402.34: q = 1XD = 0.982: D = 128.97: td = 64.93: rD = 35373.48: po = 101.3 u = 5.4464: Rmin = 1.0167t1 = 2

21、0: Cw = 0.0002: Cp = 4.1875: Co = 0.03: cpa = 15674.4HETP = 0.462: HA = 6f1 = 1: f2 = 6.5: a = 487: b = 0.72: SI = 3.73FL = 6.22: 0 = 7200: p = 7860: bo = 0.005: Fc = 0.125Textl.Text = 402.34Text2.Text = 0.3151Text3.Text = 128.97Text4.Text = 0.982Text5.Text = 35373.48Text6.Text = 64.93Text7.Text = 1

22、Text8.Text = 1.0167Text9.Text = 7200Text10.Text = 3.73Text11.Text = 0.125Text12.Text = 6.22Text13.Text = 0.005Text14.Text = 7860Text15.Text = 5.4464Text16.Text = 0.462Text17.Text = 6Text18.Text = 15674.4Text19.Text = 0.0002Text20.Text = 4.1875Text21.Text = 20Text22.Text = 2000Text23.Text = 1Text24.T

23、ext = 6.5Text25.Text = 487Text26.Text = 0.72Text27.Text = 0.03Text28.Text = 1.01Text29.Text = 2Text30.Text = 0.0001Text31.Text =Text32.Text =Text33.Text =Text34.Text =Text35.Text =Text36.Text =Text37.Text =Text38.Text =Text39.Text =Text40.Text =Text41.Text =Text42.Text =Text43.Text =Text44.Text =Tex

24、t45.Text =Text46.Text =Text47.Text =End Sub主程序Private Sub Commandl_Click()菲波拿契法求 RoptR = Text31.TextRopt = RJJ = j(R)Text32.Text = RminText45.Text = Ropt / RminText33.Text = lilunbanshuText34.Text = zongtagaoText40.Text = J1Text41.Text = J2Text42.Text = J3Text43.Text = J4Text44.Text = JJText37.Text

25、= tajingText38.Text = chukouwenduText39.Text = chuanremianjiText46.Text = Ropt * DText47.Text = (Ropt + 1) * DText35.Text = tiliuduanbanshu * HETPText36.Text = jinliuduanbanshu * HETPEnd SubJ函数Public Function j(R#) As DoubleCall jjj1(R#, J1#)Call jjj2(R#, J2#)Call jjj3(R#, J3#)Call jjj4(R#, J4#)j =

26、JI + J2 + J3 + J4End Function求J1Public Sub jjjl(R#, JI#)Dim DT#, H#, Ws#, CH#Call tabanshu(R#, N#)DT = Sqr(R + 1) * D * 22.4 / (3600 * 0.785 * u) * (273 + td) / 273 * 101.3 / po)If DT 1 ThenDT = Int(DT * 10 + 1) / 10ElseDT = Int(DT * 5 + 1) * 0.2End IfH = N * HETP + HAWs = 3.14 * DT * (H + 0.8116 *

27、DT) * bo * p p 为碳钢的密度CH = FL * Exp(6.95 + 0.1808 * Log(Ws) + 0.02468 * (Log(Ws)人 2 + 0.0158 * H / DT)J1 = SI * (Fc + 0.06) * CHtajing = DTzongtagao = HEnd Sub求J2Public Sub jjj2(R#, J2#)Dim xx1#, xx0#, CD#, ff#, df#, t2#, AD#, KD#KD = 2000: xx1 = 70Do牛顿迭代法求冷却水最佳出口温度t2xx0 = xx1CD = 1.3 * SI * a * b *

28、f1 * f2 * Fc * (R + 1) * D * rD / (td - t1)人(b - 1) / KD 人 bff = -Cw * 0 / Cp + CD * (xx0 - 1) / xx0 / Log(xx0)人(1 - b) * (xx0 - 1 - Log(xx0) df = CD * (xx0 - 1) / xx0 / Log(xx0)人(2 - b) * (b - 1) * (xx0 - 1 - Log(xx0)人 2 / (xx0 - 1)人 2 + Log(xx0)xx1 = xx0 - ff / dfLoop Until Abs(xx1 - xx0) XF ThenY

29、(i + 1) = R * X(i) / (R + 1) + XD / (R + 1) n1 = i + 1 + (X(i) - XF) / (X(i) - X(i + 1)ElseY(i + 1) = W * (X(i) - XW) / VIf X(i) XW Then Exit DoEnd Ifi = i + 1xx(i) = (Y(i) / (3.3874 * (1 - Y(i)人(1 / 0.7977)X(i) = xx(i) / (1 + xx(i)LoopN = i - 1 + (X(i - 1) - XW) / (X(i - 1) - X(i) lilunbanshu = N t

30、iliuduanbanshu = n1 jinliuduanbanshu = N - n1End Sub1 前言12方案论证2.1精馏塔类型12.2精馏压力12.3进料方式12.4填料类型22.5加热方式22.6塔材料类型23数学模型的建立3.1精馏塔塔体年投资折旧费及维修费用33.2冷凝器年运转费用43.3直接蒸汽加热费用53.4填料年折旧费54数学模型的求解4.1数学模型决策变量分析54.2 主要工艺参数的求解54.2.1 塔径的计算54.2.2塔板数的计算64.2.2.1 相平衡关系的表示64.2.2.2 N 的计算64.2.3冷凝器年运转费用的计算74.2.3.1冷却水用量及冷凝器传热

31、面积的计算74.2.3.2 冷凝器冷却水最佳出口温度的确定74.2.4直接加热蒸气费用的计算84.3数学模型的求解84.3.1单变量最优化方法84.3.2优化设计程序框图84.3.2.1函数调用关系95优化设计计算5.1数据预处理105.1.1 进塔物料的计算105.1.2塔顶蒸气温度的计算105.1.3等板高度的计算10I5.1.4产品汽化潜热的计算115.1.5最小回流比的确定115.1.6填料单价的计算115.1.7 空塔气速的计算115.2.塔径的计算135.3填料层高度的计算135.4精馏塔塔体年投资折旧费及维修费用的计算135.5冷凝器年运转费用的计算145.5.1 冷凝器冷却水最

32、佳出口温度的确定145.5.2冷却水用量及冷凝器传热面积的计算145.5.3精馏塔塔体年投资折旧费及维修费用的计算-155.6再沸器年运转费用的计算155.7填料年折旧费用的计算155.8汽液负荷155.8.1气相负荷155.8.2液相负荷155.9年总费用与回流比的关系156填料塔水力学性能校核6.1泛点率校核176.2径比校核176.3喷淋密度校核176.4填料塔压降177附属设备的设计与选型7.1 塔顶冷凝器187.1.1 冷凝器传热量187.1.2冷凝器传热推动力187.1.3初估冷凝器传热面积197.1.4冷凝器传热系数的校核197.1.5冷凝器传热面积的校核227.1.6冷凝器壳程

33、、管程流动阻力227.2 接管选型247.2.1 进料口接管的选型247.2.2 冷却水接管的选型257.2.3塔顶蒸气接管选型25117.2.4塔顶产品接管选型257.2.5塔底产品接管选型267.2.6塔顶产品回流接管选型267.2.7塔底加热蒸气接管选型267.3冷却水输送泵7.3.1 塔高的计算277.3.2 冷却水输送泵选型277.4填料支承结构287.5液体分布装置287.6填料压紧装置297.7液体收集再分布装置298设计结果汇总299设计心得31参考文献31附录一甲醇和水部分物性参数32附录二 甲醇一水汽液平衡数据(摩尔组成)33附录三优化设计程序源代码34化工原理课程设计学生姓名:黄圣楠学 号:081000115专业班级:10级生工(1)班指导教师:张星2013年1月24日

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。