WA600 FOR CUSTOMER4

WA600 FOR CUSTOMER4

《WA600 FOR CUSTOMER4》由会员分享,可在线阅读,更多相关《WA600 FOR CUSTOMER4(14页珍藏版)》请在装配图网上搜索。

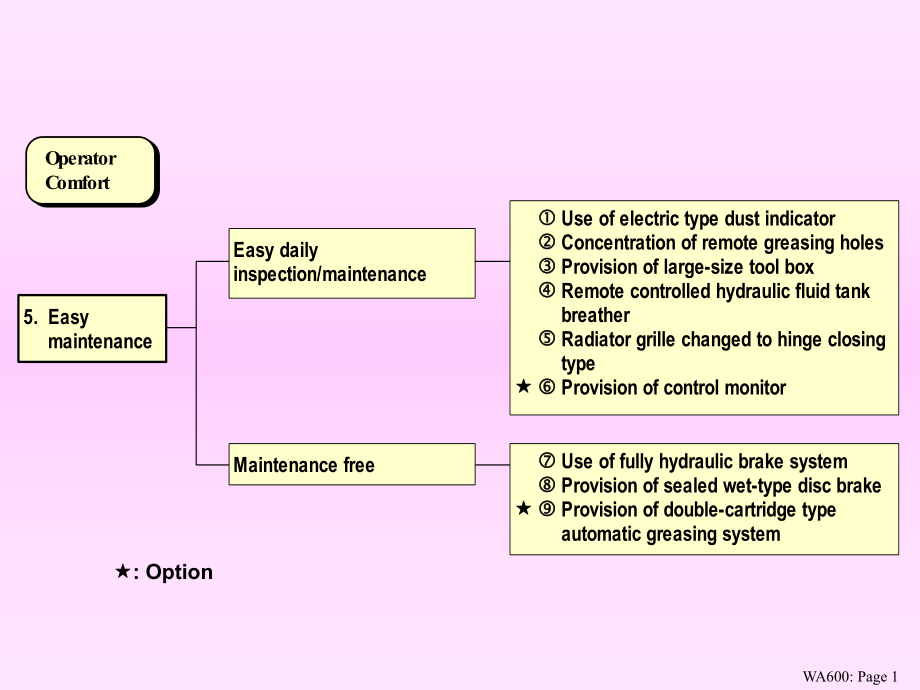

1、WA600:Page 1OperatorComfort:Option5.EasymaintenanceEasy dailyinspection/maintenanceMaintenance free Use of electric type dust indicator Concentration of remote greasing holes Provision of large-size tool box Remote controlled hydraulic fluid tankbreather Radiator grille changed to hinge closingtype

2、Provision of control monitor Use of fully hydraulic brake system Provision of sealed wet-type disc brake Provision of double-cartridge typeautomatic greasing systemWA600:Page 2Centralized remote-greasing portThe remote-greasing port has been centralized to the left side of the center hingeportion to

3、 improve the ease of maintenance.T/M mount trunnionRear axle supportBoom pivotCenter hingePillow blockS/T cylinderT/M mount trunnionRear axle supportS/T cylinderBoom pivotCenterhingePillow blockWA600:Page 3 Large tool boxemployed Remote workingoil tank breather Radiator grillhinge open/closeRemoving

4、 bolts and makes it possible to openand close the rear grillBreatherTool boxWA600:Page 4Fully hydraulic brakes installed Two independent fully hydraulic brake lines are used for the brake control system.(1)Use of no air in the brake circuit ensures no dew condensation in the circuit,providing mainte

5、nance-free system.(2)Charging time after the engine is started up is reduced to 1/4 of that used in the conventional system,ensuring remarkable reductionof waiting time.(3)Brake pedal depressing force is reduced to approximately 2/3 of that used in the conventional system,ensuring great improvement

6、offine-operability.Comparison of brake systemsFully hydraulicAir over hydraulicKOMATSUModelItemWA600-3WA600-1CAT988F2KAWASAKIKLD115ZA-2TCM890-3Brake control system-Fully hydraulicsystemAir-over hydraulicsystemFully hydraulicsystemFully hydraulicsystemFully hydraulicsystemCharging timesecBrake pedal

7、depressing forcekgWA600:Page 5Double-cartridge type automatic greasing available(option)Except for the drive shaft,the preset amount of grease is applied automatically to the periodicpressing points at the set interval by the microcomputer built into the service meter memory.Grease is supplied to th

8、e automatic greasing simply by replacing the grease cartridge.Two 1-litercartridges are used in this system.The WA is the first model in this type of model class,which isequipped with the cartridge system.KOMATSUModelItemWA600-3WA600-1CAT988F2KAWASAKIKLD115ZA-2TCM890-3Automatic greasingAvailable(opt

9、ion)Parallel activationAvailable(option)Serial activationNot availableNot availableNot availableGrease cartridgeControllerWA600:Page 65 Automatic greasing system available(option)Except for the drive shaft,the preset amount of grease is applied automatically to the periodic greasing points at the in

10、terval setby the microcomputer including the service meter memory.Grease is applied to the automatic greasing system by simplyreplacing the grease cartridge.This gives the following advantages.(1)The greasing and maintenance work load can be greatly reduced.(2)Wear or other problems around the pins

11、caused by lack of grease or missing to add grease can be prevented.(3)The serviceman does not get his hand or clothing dirty.Setting itemsWA600:Page 7WA600:Page 8WA600:Page 9WA600:Page 10OperatorComfort6.FurtherImprovedSafetyHigh meter visibilityWide visual rangeEasy to get on or get offthe machineR

12、edundant functions Improved monitor panel visibility(Main monitor and maintenance monitor)Use of steering column integrated type electronicdisplay panel Large-size pillar-less flat glass cab Good forward visibility also when raising boom by singleZ bar link It is possible to get on or off from both

13、sides of themachine Wide ladder steps1 11 1Standard provision of ROPS1 12 2Tooth tip guard provided for handrail1 13 3Provision of handrail at vehicle rear Use of large-size work equipment safety lock lever Provision of emergency brake Attachment of fan net which clears SAE regulations Standard prov

14、ision of emergency steeringProtection of operator incase of overturningSlip/fall preventionWA600:Page 11 Wide ladder steps1 12 2Tooth tip guard provided for handrail Use of large-size work equipmentsafety lock lever Provision of emergency brake It is possible to get on or off fromboth sides of the m

15、achine1 11 1Standard provision of ROPS1 13 3Provision of handrail at vehicle rear Attachment of fan net whichclears SAE regulations Standard provision of emergency steering6.Further Improved Safety Improved monitor panel visibility(Main monitor and maintenance monitor)Use of steering column integrat

16、ed typeelectronic display panel Large-size pillar-less flat glass cab Good forward visibility also whenraising boom by single Z bar linkWA600:Page 127.Harmony withEnvironmentDesign harmonized withenvironmentRust resistant externalpartsPreventing splash ofmud/waterEnvironmentalpreservation Use of new

17、 design Cationic undercoat and melamine glazedtop coat maintain painting quality Mud splash prevention cover is provided atfront fender Use of engine conforming to USA exhaustgas regulationsWA600:Page 13 Use of engine which clears the exhaust gas regulations(regulations in USA,Europe)Environment-fri

18、endly engine which suppresses NOX,CO,HC,particulate,andother air pollutants to within the strictly regulated range.Innovative external appearance with smart form and coloringA well-balanced and powerful design employing relaxed coloring with gray on anatural yellow base is used together with a curve

19、d design for the large cab andfender to give the machine a rounded appearance.Front fender extension covers employedFront fender extension covers have been employed to prevent mud from beingthrown up on the machine or being splashed around the machine when it istraveling.This displays its authority

20、in operations where travel is frequent,such asin mud and long-distance traveling.HARMONY WITH ENVIRONMENTWA600:Page 14Rust resistant external partsExternal parts made of resin,and sheet metal external partsgiven an undercoat of paint by cationic electrodeposition anda melamine glazed top coat are em

21、ployed.This improves thefinishing quality of the external parts,reduces rust even insevere environment,and maintains the luster of the externalsurface for a long period.(Paint by cationic electrodeposition was introduced inNovember 1989.However,for the cab it was introduced inAugust 1990.)Resin external parts Steering column,Front grille inside cab Left console boxMain cationic electrodeposition painted parts1 Cab,2 Front fender,3 Front,4 Right console box5 Ladder,6 Rear fender,7 Side panel,8 Hood,9 Rear light support

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。