SMT生产常用英文

SMT生产常用英文

《SMT生产常用英文》由会员分享,可在线阅读,更多相关《SMT生产常用英文(10页珍藏版)》请在装配图网上搜索。

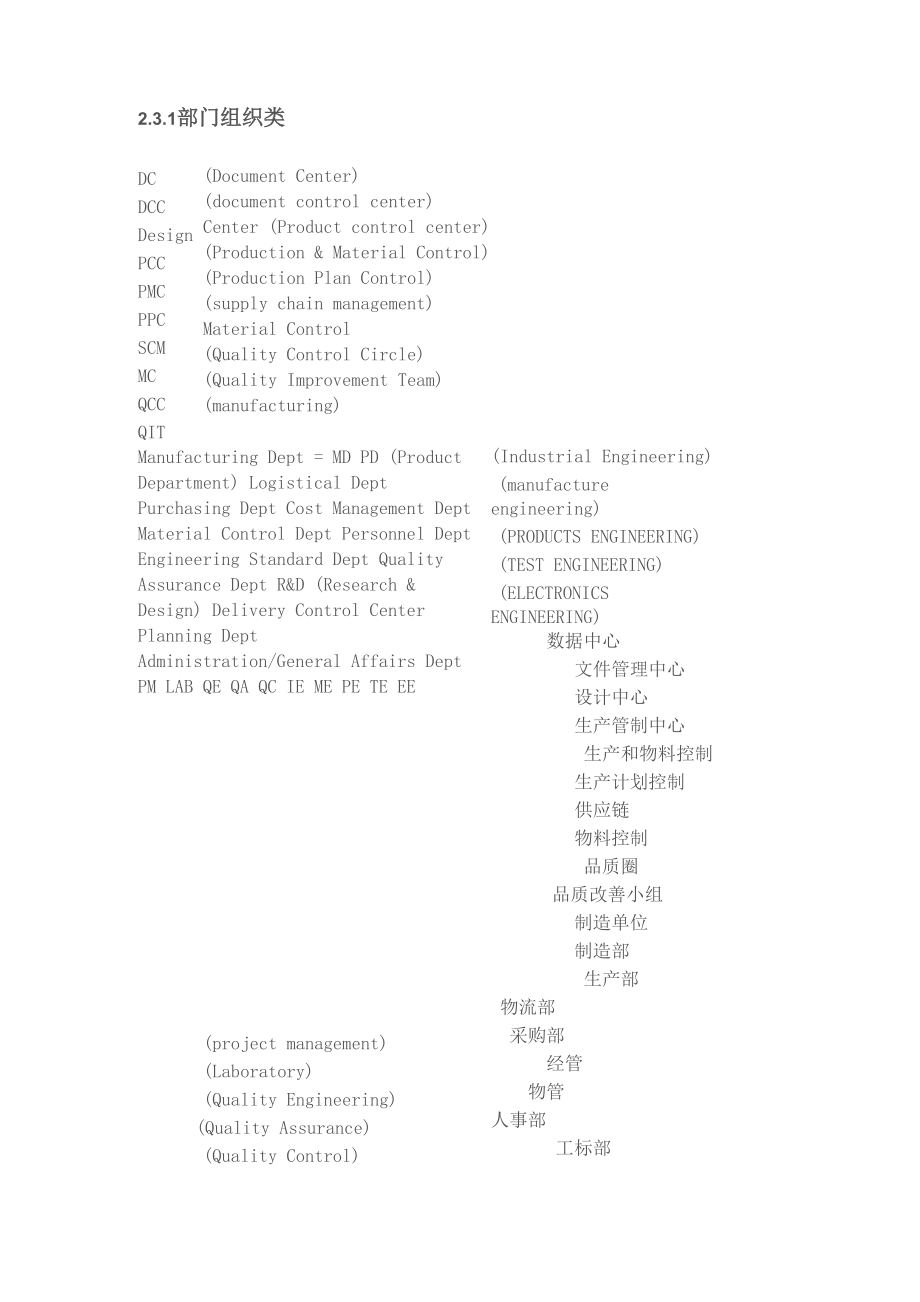

1、2.3.1部门组织类DCDCCDesignPCCPMCPPCSCMMCQCCQITMFG(Document Center)(document control center) Center (Product control center) (Production & Material Control) (Production Plan Control) (supply chain management) Material Control(Quality Control Circle) (Quality Improvement Team) (manufacturing)Manufacturing

2、Dept = MD PD (Product Department) Logistical Dept Purchasing Dept Cost Management Dept Material Control Dept Personnel Dept Engineering Standard Dept Quality Assurance Dept R&D (Research & Design) Delivery Control Center Planning DeptAdministration/General Affairs Dept PM LAB QE QA QC IE ME PE TE EE

3、(project management)(Laboratory)(Quality Engineering)(Quality Assurance)(Quality Control)(Industrial Engineering)(manufacture engineering)(PRODUCTS ENGINEERING)(TEST ENGINEERING)(ELECTRONICS ENGINEERING)数据中心文件管理中心设计中心生产管制中心生产和物料控制生产计划控制供应链物料控制品质圈品质改善小组制造单位制造部生产部物流部采购部经管物管人事部工标部品保部设计开发部交管企划部总务部专案管控实验

4、室品质工程(部)品质保证(处)品质管理(课)工业工程制造工程产品工程测试工程电子工程国际标准化组织工程标准2.3.2系统文件类ISO (International Standard Organization)ES (Engineering Standard)IWS GS SIP SOP IS POP BOM PS SPEC DWG SWR APP CHK ECO PCN PMP CAR TPM MRP OS SSQA AVL PDCS工艺标准一般规格标准检验规范制造作业规范成品检验规范包装操作规范物料清单包装规范规格图面特殊工作需求核准,认可,承认确认工程改动要求工序改动通知生产管制计划改善报

5、告全面生产保养物料需计划操作系统合格供货商质量评估允许的供货商清单制程异常联络单工程(设计)变更通知主要绩效指标E(D)CN (Engineering(Design) change notice) KPI (Key performance index)计算机消费性电子产品 通讯类电子产品 原设备制造 个人计算机6M4MTH (Man, Material, Money, Method, Time, How)人力,物力,财务,技术,能力指数制程能力参数失效模式分析(International Workman Standard)(General Specification)(Standard Ins

6、pection Procedure)(Standard Operation Procedure)(Inspection Specification)(packing operation procedure)(Bill Of Material)(Package Specification)(Specification)(Drawing)(Special Work Request)(Approve)(Check)(Engineering Change Order)(Process Change Notice)(Product Management Plan)(Correction Action R

7、eport)(Total Production Maintenance)(Material Requirement Planning)(Operation System)(standardized supplier quality audit)(acceptable vendor list)(process defect contact sheet)2.3.3生产工站类ComputerConsumer ElectronicsCommunicationOEM (Original Equipment Manufacture)PC Personal Computer5W1H (When, Where

8、, Who, What, Why, How to)(Man, Machine, Material, Method, Measurement, Message)时间(资源)CP (capability index)CPK (capability process index)FMEA (failure model effectiveness analysis)SMT(surface mount technology)表面贴装技术PTH(Plate Through hole)镀层穿孔(手插件)PCBA(Printing circuit board Assembly)组装印刷电路板PO(Purchas

9、ing Order)米购订单MO(Manufacture Order)生产单PC#(product code)产品编码MM#(material master number)主件料号AA#(altered assembly number)成品料号PBA#(printed board assembly number)半成品料号PPID(Product part Identification)产品料号标识符L/N(Lot Number)批号P/N(Part Number)料号N/A(Not Applicable)不适用S/N(serial number)序列号CHK(check)检查SPEC(spe

10、cification)规格ID:(Identify)鉴别号码Barcode条形码barcode scanner条形码扫描仪WDR(Weekly Delivery Requirement)周出货要求PPM(Percent Per Million)白万分之一PCs(Pieces)个(根,块等)PRS(Pairs)双(对等)CTN(Carton)卡通箱PAL(Pallet/skid)栈板D/C(Date Code)生产日期码ID/C(Identification Code)(供货商)标识符QTY(Quantity)数量I/O(input/output)输入/输出Flux助焊剂Cleaning sol

11、vent清洁剂Cleaning paper擦拭纸Handsolder烙铁Solder Paste锡膏Feeder供料器Stencil钢网Nozzle吸嘴PAD焊垫Squeegee刮刀Pinter Machine锡膏印刷机器Buffer Loader收板机Material物料Mounting Machine贴片机器REFLOW Machine回流焊炉Profile回焊温度曲线图自动光学检测波峰焊线路测试功能测试功能测试贴装设备BGA维修站湿度敏感元件表面贴装元件表面贴装元器件元件脚端头脚件无源器件有源器件基本输入输出系统Transistor)铁芯中央处理器直接记忆体存取集成电路电源箱加速图形端口

12、软式磁盘机硬盘驱动器北桥南桥集成电路设备,智能磁盘网络,局域网,本地网Transistor)周边元件扩展接口小计算机系统的界面通用串行总线AOI (automatic optical inspection)W/S (wave solder)ICT (in circuit test)IFT (integrate function test)FCT (Function check Test)SMD (Surface Mounting Device)BGA Rework Station2.3.4零件认识类MSD (moisture sensitive device)SMC (Surface Moun

13、t Component)SMD (Surface Mount Device)LeadsTerminationsPassive ComponentActive ComponentBIOS: (Basic Input Output System)CMOS: (Complementary Metal-Oxide-Semiconductor互补型金属氧化物半导体CoreCPU: (Central Processing Unit)DMA: (Direct Memory Access)IC: (Integrated Circuit)SPS (Switching power supply)AGP (Acce

14、lerated Graphic Port)FDD (Floppy Disk Drive)HDD (Hard Disk Drive)North BridgeSouth BridgeIDE: (Integrated Drive Electronics)设备LAN: (Local Area Network)MOSFET:(Metal-Oxide Semiconductor Field Effect金属氧化物半导体场效应晶体管PCI: (Peripheral Component Extended Interface)SCSI: (Small Computer System Interface)USB:

15、 (Universal Serial Bus)SDRAM: (Synchronous Dynamic Random Access Memory) 同步动态随机存取RP存储器KEYBOARD键盘CABLE LINE扁平电缆HEADERJACKCABLETUNER头/排针插头电缆/扁平电缆调频器2.3.5质量管理类QC FQC IPQC OQC IQC TQC PQC QA OQA QE QPA OQM SQA DQA MQA SSQA SPC SQC GRR(quality control)(final quality control)(in process quality control)(o

16、utput quality control)(incoming quality control)(total quality control)(passage quality control)(quality assurance)(output quality assurance)(quality engineering)(Quality Process Audit)(output quality measure)(Strategy Quality Assurance)(Design Quality Assurance)(Manufacture Quality Assurance)(Sales

17、 and service Quality Assurance)(Statistical Process Control)(Statistical Quality Control)品质管理人员终点品质管理人员制程中的品质管理人员最终出货品质管理人员进料品质管理人员全面品质管理段检人员品质保证人员出货品质保证人员品质工程人员制程品质稽核出货品质检验策略品质保证设计品质保证制造品质保证销售及服务品质保证统计制程管制统计品质管理量具之再制性及重测性(Gauge Reproductiveness & Repeatability)判断量可靠与否 8SClassification organization)

18、-seiri Regulation tidiness)-seiton Cleanliness Conservation cleanliness)-seiktsu Culture Safety SecurityPDCA (Plan Do Check Action) FAI (first article inspection) FAA (first article assurance)整理整顿清扫清洁教养安全保密(sorting,(arrangement,(sweeping, purity)-seiso(cleaning,(discipline)-shitsuke计划执行检查总结 新品首件检查 首

19、件确认AQL(Acceptable Quality Level)允收品质水准S/S(Sample size)抽样检验样本人小FPIR(First Piece Inspection Report)首件检查报告ACC(Accept)允收REJ(Reject)拒收CR(Critical)极严重的MAJ(Major)主要的MIN(Minor)轻微的Q/R/S (Quality/Reliability/Service)品质/可靠度/服务ZD(Zero Defect)零缺点NG(Not Good)不行,不合格QI(Quality Improvement)品质改善QP(Quality Policy)目标方针

20、TQM(Total Quality Management)全面品质管理RMA(Return Material Audit)退料认可LRR(Lot Reject Rate)批退率NDF(no defect found)误判7QCTools (7 Quality Control Tools)品管七大手法ESD(Electric Static Discharge)静电释放DPPM(Defective Percent Per Million)每百万单位的产品不合格率2.3.6不良类型类Misalignment偏位Tombstone墓碑Missing parts缺件Insufficient solder少锡Solder ball锡珠Short bridge短路Open空焊Partdamaged零件破损Coolsolder冷焊Wrong parts错件

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

最新文档

- 《认识角》ppt教学讲解课件

- 《从数据谈节水》数据的收集、整理与描述优秀教学ppt课件

- 人员配置-公司组织架构与人员配置计划课件

- 《认识分式》ppt课件

- 《从百草园到三味书屋》第一课时ppt课件

- 公路工程概预算三课件

- 中考物理专题突破-综合能力题教学课件

- 《创新设计》高考英语二轮复习(江苏专用)ppt课件:第二部分-基础语法巧学巧练-专题八-非谓语动词

- 中考物理专题复习课件:滑轮及滑轮组

- CIM安全标识统一规划课件

- 中考物理专题复习教学课件-质量和密度

- 《处理民族关系的原则平等团结共同繁荣》ppt课件

- 中考物理专题复习之物理实验和探究题复习指导教学课件

- 《十二人人都会有挫折》初中心理健康教育闽教版《中学生心理健康》七级课件

- Cisco无线网络-安全-Brief课件