EUGMP 中英文对照

EUGMP 中英文对照

《EUGMP 中英文对照》由会员分享,可在线阅读,更多相关《EUGMP 中英文对照(21页珍藏版)》请在装配图网上搜索。

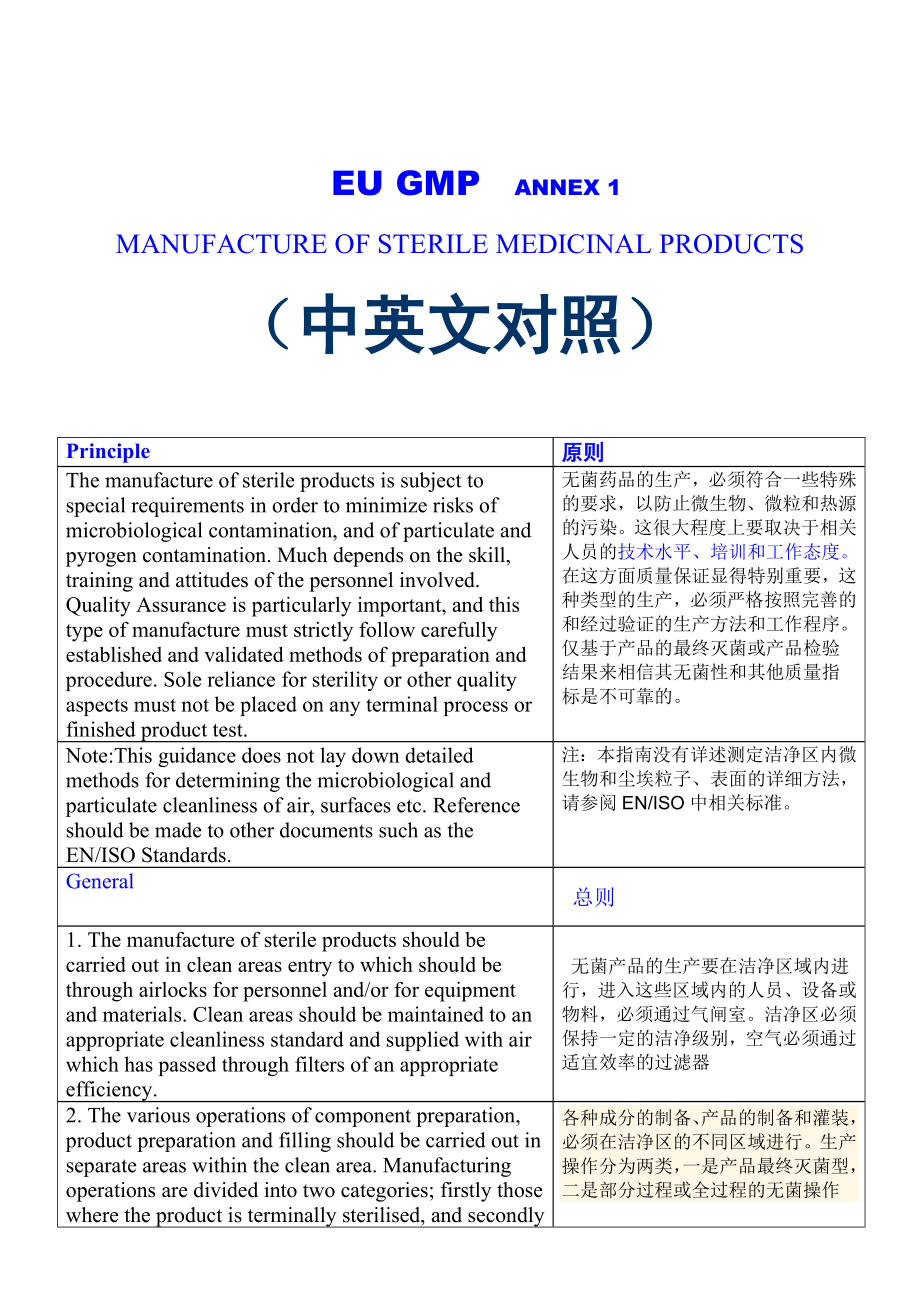

1、 EU GMP ANNEX 1MANUFACTURE OF STERILE MEDICINAL PRODUCTS(中英文对照) Principle原则The manufacture of sterile products is subject to special requirements in order to minimize risks of microbiological contamination, and of particulate and pyrogen contamination. Much depends on the skill, training and attitud

2、es of the personnel involved. Quality Assurance is particularly important, and this type of manufacture must strictly follow carefully established and validated methods of preparation and procedure. Sole reliance for sterility or other quality aspects must not be placed on any terminal process or fi

3、nished product test.无菌药品的生产,必须符合一些特殊的要求,以防止微生物、微粒和热源的污染。这很大程度上要取决于相关人员的技术水平、培训和工作态度。在这方面质量保证显得特别重要,这种类型的生产,必须严格按照完善的和经过验证的生产方法和工作程序。仅基于产品的最终灭菌或产品检验结果来相信其无菌性和其他质量指标是不可靠的。Note:This guidance does not lay down detailed methods for determining the microbiological and particulate cleanliness of air, surfa

4、ces etc. Reference should be made to other documents such as the EN/ISO Standards.注:本指南没有详述测定洁净区内微生物和尘埃粒子、表面的详细方法,请参阅EN/ISO中相关标准。General总则1. The manufacture of sterile products should be carried out in clean areas entry to which should be through airlocks for personnel and/or for equipment and mater

5、ials. Clean areas should be maintained to an appropriate cleanliness standard and supplied with air which has passed through filters of an appropriate efficiency.无菌产品的生产要在洁净区域内进行,进入这些区域内的人员、设备或物料,必须通过气闸室。洁净区必须保持一定的洁净级别,空气必须通过适宜效率的过滤器2. The various operations of component preparation, product prepara

6、tion and filling should be carried out in separate areas within the clean area. Manufacturing operations are divided into two categories; firstly those where the product is terminally sterilised, and secondly those which are conducted aseptically at some or all stages.各种成分的制备、产品的制备和灌装,必须在洁净区的不同区域进行。

7、生产操作分为两类,一是产品最终灭菌型,二是部分过程或全过程的无菌操作3. Clean areas for the manufacture of sterile products are classified according to the required characteristics of the environment. Each manufacturing operation requires an appropriate environmental cleanliness level in the operational state in order to minimize the

8、 risks of particulate or microbial contamination of the product or materials being handled. In order to meet “in operation” conditions these areas should be designed to reach certain specified air-cleanliness levels in the “at rest” occupancy state. The “at-rest” state is the condition where the ins

9、tallation is installed and operating, complete with production equipment but with no operating personnel present. The “in operation” state is the condition where the installation is functioning in the defined operating mode with the specified number of personnel working. The “in operation” and “at r

10、est” states should be defined for each clean room or suite of clean rooms. For the manufacture of sterile medicinal products 4 grades can be distinguished.无菌生产的洁净区,按照产品对环境的要求分级,每一步生产操作,在操作状态,对环境有相应的洁净级别的要求,以防止对所处理的物料或产品造成的粉尘或微生物污染最小。为满足操作的要求,这些区域在设计上要达到“静态”的洁净标准。“静态”指设备已经安装并运行,生产设备就位但是没有操作人员在场。“动态”是

11、指在设备正常运转状态下和有规定数量的工作人员在场的情况下。每个或每套房间都要分别确定“静态”和“动态”。无菌药品的生产有4个环境级别:Grade A: The local zone for high risk operations, e.g. filling zone, stopper bowls, open ampoules and vials, making aseptic connections. Normally such conditions are provided by a laminar air flow work station. Laminar air flow syste

12、ms should provide a homogeneous air speed in a range of 0.36 0.54 m/s (guidance value) at the working position in open clean room applications. The maintenance of laminarity should be demonstrated and validated. A uni-directional air flow and lower velocities may be used in closed isolators and glov

13、e boxes.A级:用于高风险的生产操作,如灌装区、加盖区、安瓿与瓶开口区、和进行无菌连接的地方。通常这种情况是带有层流罩的工作点。在开放的洁净区内的工作点上,层流罩应该能产生风速为0.36 0.54米/秒的均匀气流。层流罩的维护,必须有充分的证明和经过验证。密封隔离箱和手套箱内,可采用单向低速气流。Grade B: For aseptic preparation and filling, this is the background environment for the grade A zone.B级:对于无菌制备和灌装,B级区域是A级区域的背景环境。Grade C and D: Cle

14、an areas for carrying out less critical stages in the manufacture of sterile products.C级和D级:无菌产品非关键生产步骤的洁净区。Clean room and clean air device classification洁净室及洁净空气装置分类4. Clean rooms and clean air devices should be classified in accordance with EN ISO 14644-1. Classification should be clearly differen

15、tiated from operational process environmental monitoring. The maximum permitted airborne particle concentration for each grade is given in the following table.洁净室及洁净空气装置应符合EN ISO 14644-1 。应根据生产操作环境监测明确地加以区分。最大允许尘埃粒子浓度应符合下表要求。Maximum permitted number of particles per m3 equal to or greater than the t

16、abulated sizeAt restIn operationGrade0.5 m5.0m0.5 m5.0mA3 520203 52020B3 52029352 0002 900C352 0002 9003 520 00029 000D3 520 00029 000Not definedNot defined大于等于表中尺寸尘埃粒子最大允许数/ m3静态动态Grade0.5 m5.0m0.5 m5.0mA3 520203 52020B3 52029352 0002 900C352 0002 9003 520 00029 000D3 520 00029 000Not definedNot de

17、fined5. For classification purposes in Grade A zones, a minimum sample volume of 1m3 should be taken per sample location. For Grade A the airborne particle classification is ISO 4.8 dictated by the limit for particles 5.0 m. For Grade B (at rest) the airborne particle classification is ISO 5 for bot

18、h considered particle sizes. . For Grade C (at rest & in operation) the airborne particle classification is ISO 7 and ISO 8 respectively. For Grade D (at rest) the airborne particle classification is ISO 8. For classification purposes EN/ISO 14644-1 methodology defines both the minimum number of sam

19、ple locations and the sample size based on the class limit of the largest considered particle size and the method of evaluation of the data collected. 在A级区,每个采样点取样量应不小于1 m3。A级尘埃粒子分类是根据ISO 4.8粒子 5.0 m的数量定义的。B级(静态)尘埃粒子分类根据ISO 5要考虑两种大小的粒子。C级(静态动态)粒子分类分别根据ISO7和ISO8。D级(静态)粒子分类是ISO 8 。分类是根据EN/ISO 14644-1方

20、法论,既明确了最少的取样点数,也规定了取样量和相适应的级别的最大允许颗粒大小和采集数据评价方法。6. Portable particle counters with a short length of sample tubing should be used for classification purposes because of the relatively higher rate of precipitation of particles 5.0m in remote sampling systems with long lengths of tubing. Iso kinetic s

21、ample heads shall be used in unidirectional airflow systems. 洁净分级应使用一个带有短取样管的便携式颗粒计数器,因为使用长距离的取样管会采集到远距离猛然落下 5.0 m的粒子的几率相对较高。单向气流系统应使用等动力采样头。7. “In operation” classification may be demonstrated during normal operations, simulated operations or during media fills as worst-case simulation is required

22、for this. EN ISO 14644-2 provides information on testing to demonstrate continued compliance with the assigned cleanliness classifications.动态是在正常生产条件下定义的,模拟操作或在无菌分装的情况下,需要这方面的规定。EN ISO 14644-2提供了相关测试资料,以证明连续的符合洁净区的分类。Clean room and clean air device monitoring洁净室及洁净空气监测装置8. Clean rooms and clean air

23、devices should be routinely monitored in operation and the monitoring locations based on a formal risk analysis study and the results obtained during the classification of rooms and/or clean air devices. 洁净室及洁净空气装置应动态条件下定期监测,监测的位置应基于正式的风险评估和日常监测结果。9. For Grade A zones, particle monitoring should be

24、undertaken for the full duration of critical processing, including equipment assembly, except where justified by contaminants in the process that would damage the particle counter or present a hazard, e.g. live organisms and radiological hazards. In such cases monitoring during routine equipment set

25、 up operations should be undertaken prior to exposure to the risk. Monitoring during simulated operations should also be performed. The Grade A zone should be monitored at such a frequency and with suitable sample size that all interventions, transient events and any system deterioration would be ca

26、ptured and alarms triggered if alert limits are exceeded. It is accepted that it may not always be possible to demonstrate low levels of 5.0 m particles at the point of fill when filling is in progress, due to the generation of particles or droplets from the product itself.A级区,粒子监测应覆盖全部的关键操作,包括设备装配,

27、除非有正当理由证明污染物这个进程将损害粒子计数器或具有危险性,例如:活生物体和辐射危害。在这类情况下,日常设定操作的监测应该在暴露之前评估风险,模拟操作期间也应该监测。应该监测A级区域以一定的频率和适当采样量,所有干预、瞬变事件和任何系统恶化都能被捕获,并且如果超出报警限能报警。分装操作过程中,5.0 m微粒可能不总是符合较低的标准要求的,只要证明微粒或小滴是从产品产生的就可以了。10. It is recommended that a similar system be used for Grade B zones although the sample frequency may be d

28、ecreased. The importance of the particle monitoring system should be determined by the effectiveness of the segregation between the adjacent Grade A and B zones. The Grade B zone should be monitored at such a frequency and with suitable sample size that changes in levels of contamination and any sys

29、tem deterioration would be captured and alarms triggered if alert limits are exceeded.推荐B级区也使用和A级区类似的系统。虽然取样频率可能会减少,重要的是粒子监测系统应取决于有效的毗邻A级和B级区的隔离间。B级区也应以一定的频率和合适的取样量监测,污染程度变化的和任何系统恶化都能被捕获,并且如果超出报警限能警报。11. Airborne particle monitoring systems may consist of independent particle counters; a network of

30、sequentially accessed sampling points connected by manifold to a single particle counter; or a combination of the two. The system selected must be appropriate for the particle size considered. Where remote sampling systems are used, the length of tubing and the radii of any bends in the tubing must

31、be considered in the context of particle losses in the tubing. The selection of the monitoring system should take account of any risk presented by the materials used in the manufacturing operation, for example those involving live organisms or radiopharmaceuticals. 尘埃粒子监测系统,可以是独立的颗粒计数器; 也可以是以单个粒子计数器

32、采样点相连的网络,或者两者兼而有之。该系统的选定一定要适合粒子大小。而使用远程取样系统,应考虑取样管的长度及延伸的半径,必须考虑采样管中的粒子损失。选用何种监测系统应考虑当前药品存在的风险,例如那些涉及活生物体或放射性药品。12. The sample sizes taken for monitoring purposes using automated systems will usually be a function of the sampling rate of the system used. It is not necessary for the sample volume to

33、be the same as that used for formal classification of clean rooms and clean air devices. 使用自动化系统的采样量通常会和采用速率有一个函数关系。这样就没有必要采用和正常的洁净室分类及洁净空气装置相同的监测频率。13. In Grade A and B zones, the monitoring of the 5.0 m particle concentration count takes on a particular significance as it is an important diagnosti

34、c tool for early detection of failure. The occasional indication of 5.0 m particle counts may be false counts due to electronic noise, stray light, coincidence, etc. However consecutive or regular counting of low levels is an indicator of a possible contamination event and should be investigated. Su

35、ch events may indicate early failure of the HVAC system, filling equipment failure or may also be diagnostic of poor practices during machine set-up and routine operation.在A级和B区,监测的 5.0 m的粒子浓度计数问题就显得特别重要的意义,因为这是一个重要的诊断工具,以便及早发现失败的。偶尔显示 5.0 m的粒子计数可能是虚假的计数因电子噪声,杂散光,巧合等,但连续或规则的失败可能是污染事件,应该进行调查。这类事件可能表明

36、,早期失效的暖通空调系统,灌装设备故障或可能因为乏味的操作,设备安装和日常运作。14. The particle limits given in the table for the “at rest” state should be achieved after a short “clean up” period of 15-20 minutes (guidance value) in an unmanned state after completion of operations. 在无人状态,15-20分钟(指导值)自净期间,粒子应符合列表中的静态标准。15. The monitoring

37、 of Grade C and D areas in operation should be performed in accordance with the principles of quality risk management. The requirements and alert/action limits will depend on the nature of the operations carried out, but the recommended “clean up period” should be attained. C级和D区的监察应根据质量风险管理的原则动态进行。

38、标准和报警/行动限应根据日常监测制定,还应制定“自净周期”。16. Other characteristics such as temperature and relative humidity depend on the product and nature of the operations carried out. These parameters should not interfere with the defined cleanliness standard.其他特点,如温度和相对湿度在很大程度上依赖于产品和业务活动的性质进行的。这些参数不应该干涉与界定洁净标准。17. Examp

39、les of operations to be carried out in the various grades are given in the table below (see also paragraphs 28 to 35):不同级别的操作实例参看下面内容(亦见第28至35位)A Filling of products, when unusually at riskC Preparation of solutions, when unusually at risk. Filling of productsD Preparation of solutions and component

40、s for subsequent fillingGrade Examples of operations for aseptic preparations. (see paragraphs. 31-35)A Aseptic preparation and filling.C Preparation of solutions to be filtered.D Handling of components after washing.菌准备型操作分级举例:A、无菌准备与灌装B、准备即将过滤的溶液C、在清洗后处理部件18. Where aseptic operations are performed

41、 monitoring should be frequent using methods such as settle plates, volumetric air and surface sampling (e.g. swabs and contact plates). Sampling methods used in operation should not interfere with zone protection. Results from monitoring should be considered when reviewing batch documentation for f

42、inished product release. Surfaces and personnel should be monitored after critical operations. Additional microbiological monitoring is also required outside production operations, e.g. after validation of systems, cleaning and sanitisation.如无菌操作应频繁进行沉降菌,浮游菌和表面微生物(擦拭和接触)的监测。取样的方法不应干涉区域的保护。产品放行审查批记录时

43、应考虑监测的结果。关键操作后,应对表面和人员应当进行监测,在生产操作之外如验证后,清洁和消毒后进行微生物监测。19. Recommended limits for microbiological monitoring of clean areas during operation:建议上限微生物监测的清洁区操作:Recommended limits for microbial contamination (a)Gradeair sample cfu/m3settle plates(diameter 90 mm)cfu/4 hours (b)contact plates(diameter 55

44、mm)cfu/plateglove print5 fingers cfu/gloveA 1 1 1 1B10555C1005025-D20010050-(a) These are average values.(一)这些都是平均值。(b) Individual settle plates may be exposed for less than 4 hours.(二)单个沉降皿放置的时间可以少于4小时。20. Appropriate alert and action limits should be set for the results of particulate and microbio

45、logical monitoring. If these limits are exceeded operating procedures should prescribe corrective action。对尘埃粒子和微生物的监控结果,要设置适当的警戒限度和行动限度。当超出这些限度时,操作规程应说明需要采取的措施。Isolator technology隔离技术21. The utilisation of isolator technology to minimize human interventions in processing areas may result in a signif

46、icant decrease in the risk of microbiological contamination of aseptically manufactured products from the environment. There are many possible designs of isolators and transfer devices. The isolator and the background environment should be designed so that the required air quality for the respective

47、 zones can be realised. Isolators are constructed of various materials more or less prone to puncture and leakage. Transfer devices may vary from a single door to double door designs to fully sealed systems incorporating sterilization mechanisms.在生产区采用人员方面的隔离技术,在无菌产品的生产中,会显著降低周围环境微生物污染的风险。有很多隔离和传递设施

48、可供选择,隔离和背景环境的设计,必须保证各区域相应的空气质量要求。隔离设施的建造材料,多少有些易于穿孔和泄漏。传递设施可以是单门、双门或结合无菌机制的全封闭系统。22. The transfer of materials into and out of the unit is one of the greatest potential sources of contamination. In general the area inside the isolator is the local zone for high risk manipulations, although it is rec

49、ognised that laminar air flow may not exist in the working zone of all such devices.原材料的进出是污染的最大来源之一。尽管人们已经认可,层流罩不可能存在于所有隔离设施的工作区内,但是,通常隔离区内是高风险操作的局部区域。23. The air classification required for the background environment depends on the design of the isolator and its application. It should be controlle

50、d and for aseptic processing it should be at least grade D.背景环境的洁净级别,视隔离区的设计和应用而定。要控制无菌生产的背景环境,并且最低为D级24. Isolators should be introduced only after appropriate validation. Validation should take into account all critical factors of isolator technology, for example the quality of the air inside and o

51、utside (background) the isolator, sanitisation of the isolator, the transfer process and isolator integrity.在经过适当的验证之后,隔离器才能使用。验证必须将隔离技术的所有关键因素考虑在内,如:隔离器的内外部空气质量、隔离器的消毒,传递过程和隔离器的完整性。25. Monitoring should be carried out routinely and should include frequent leak testing of the isolator and glove/slee

52、ve system必须进行常规监控,包括隔离室和手套/袖系统的泄漏检查。 Blow/fill/seal technologym. (26-27)吹/灌/封技术Terminally sterilised products (28-30)最终灭菌产品Aseptic preparation无菌制备31. Components after washing should be handled in at least a grade D environment. Handling of sterile starting materials and components, unless subjected

53、to sterilisation or filtration through a micro-organism-retaining filter later in the process, should be done in a grade A environment with grade B background.清洗后的材料要在最低D级环境下处理。无菌产品的原料和辅料,除非将在生产过程中进行灭菌或采用微生物滞留过滤器过滤除菌,要在B级环境下的A级区处理。32. Preparation of solutions which are to be sterile filtered during

54、the process should be done in a grade C environment; if not filtered, the preparation of materials and products should be done in a grade A environment with a grade B background.采用过滤除菌的溶液的制备,要在C级环境下进行,如果不过滤,要在B级环境下的A级区处理。33. Handling and filling of aseptically prepared products should be done in a g

55、rade A environment with a grade B background.通过无菌方法生产的产品,要在B级环境下的A级区处理和灌装。34. Prior to the completion of stoppering, transfer of partially closed containers, as used in freeze drying should be done either in a grade A environment with grade B background or in sealed transfer trays in a grade B envir

56、onment.在完成加盖前,半密封容器的传递,如在冻干中使用的, 要在B级环境下的A级区进行,或在B级环境中的密封的转移盘中进行。35. Preparation and filling of sterile ointments, creams, suspensions and emulsions should be done in a grade A environment, with a grade B background, when the product is exposed and is not subsequently filtered.如果产品有暴露和不再进行灭菌,软膏、霜剂、混

57、悬剂、栓剂和乳剂的制备和灌装,要在B级环境下的A级区处理。Personnel36. Only the minimum number of personnel required should be present in clean areas; this is particularly important during aseptic processing. Inspections and controls should be conducted outside the clean areas as far as possible.人员只有工作需要的最低人数可以进入洁净区,这对无菌生产过程特别重

58、要。检查和控制都要尽可能在洁净区外面进行。37. All personnel (including those concerned with cleaning and maintenance) employed in such areas should receive regular training in disciplines relevant to the correct manufacture of sterile products. This training should include reference to hygiene and to the basic elements

59、of microbiology. When outside staff who have not received such training (e.g. building or maintenance contractors) need to be brought in, particular care should be taken over their instruction and supervision.所有在这些区域工作的人员(包括清洁和维护人员)都要定期进行与无菌药品生产有关的纪律培训。这些培训要包括卫生和微生物学的基本知识。当外来的没有接受培训的人员(如建造或维修人员)需要进入

60、时,要特别注意给予指导和监督。38. Staff who have been engaged in the processing of animal tissue materials or of cultures of micro-organisms other than those used in the current manufacturing process should not enter sterile-product areas unless rigorous and clearly defined entry procedures have been followed.从事动物

61、组织加工处理或微生物培养的人员,不包括生产在用的材料,除非遵照严格明确的进入程序,不可进入洁净区。39. High standards of personal hygiene and cleanliness are essential. Personnel involved in the manufacture of sterile preparations should be instructed to report any condition which may cause the shedding of abnormal numbers or types of contaminants;

62、 periodic health checks for such conditions are desirable. Actions to be taken about personnel who could be introducing undue microbiological hazard should be decided by a designated competent person.高标准的人员卫生和清洁是非常关键的。要指导涉及生产的人员,及时报告可能产生异常污染的任何情况;要对人员定期进行健康检查。对可能带来微生物污染的人的处理措施,要由指定的合格的人员作出决定。 40. Wr

63、istwatches, make-up and jewellery should not be worn in clean areas.在洁净区内不准戴手表、首饰和化装。41. Changing and washing should follow a written procedure designed to minimize contamination of clean area clothing or carry-through of contaminants to the clean areas. 要按照书面的更换和清洗程序,尽可能降低对洁净区工作服的污染或将污染物带进洁净区。42. T

64、he clothing and its quality should be appropriate for the process and the grade of the working area. It should be worn in such a way as to protect the product from contamination.工作服及其质量必须适应所从事的工作和工作场所的洁净级别。要正确穿戴,防止对产品产生污染。43. The description of clothing required for each grade is given below:下面对各个级别洁净区的工作服的要求进行说明:Grade D: Hair and, where relevant, beard should be covered. A general protective suit and appropriate shoes or overshoes should be worn. Ap

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。