油漆工艺H1007FPSOIP油漆

油漆工艺H1007FPSOIP油漆

《油漆工艺H1007FPSOIP油漆》由会员分享,可在线阅读,更多相关《油漆工艺H1007FPSOIP油漆(34页珍藏版)》请在装配图网上搜索。

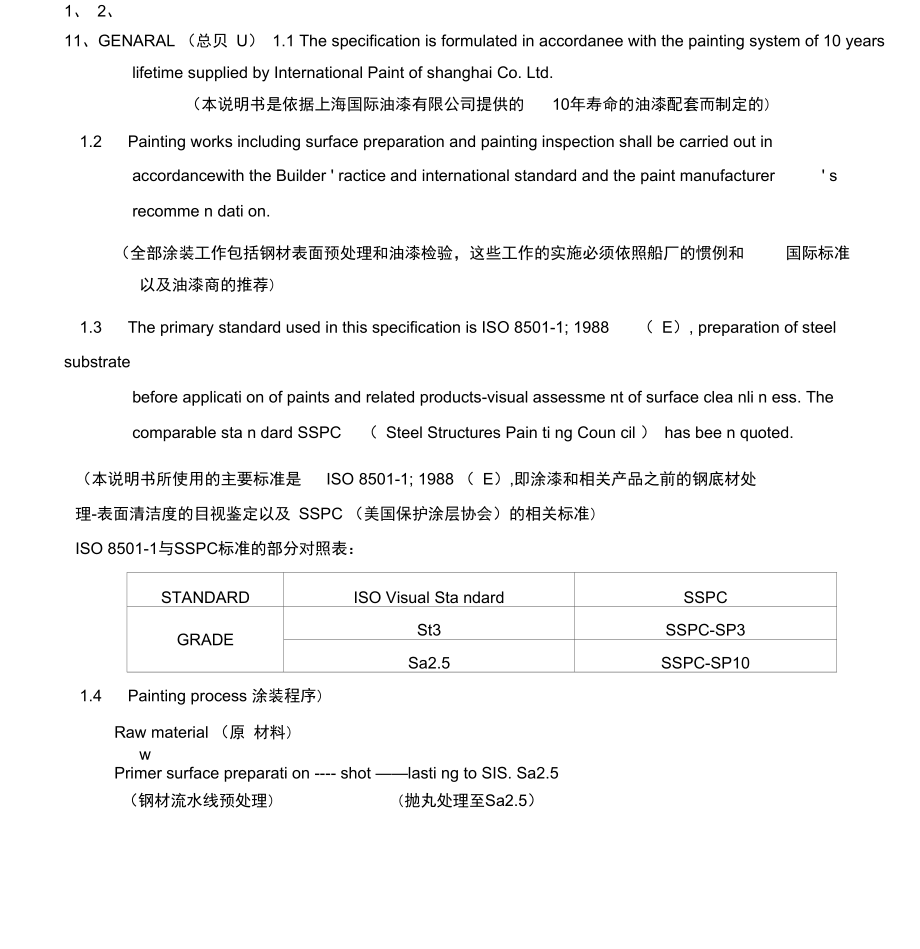

1、1、 2、11、GENARAL (总贝 U) 1.1 The specification is formulated in accordanee with the painting system of 10 years lifetime supplied by International Paint of shanghai Co. Ltd.(本说明书是依据上海国际油漆有限公司提供的10年寿命的油漆配套而制定的)1.2 Painting works including surface preparation and painting inspection shall be carried out

2、 inaccordancewith the Builder ractice and international standard and the paint manufacturer srecomme n dati on.(全部涂装工作包括钢材表面预处理和油漆检验,这些工作的实施必须依照船厂的惯例和国际标准以及油漆商的推荐)1.3 The primary standard used in this specification is ISO 8501-1; 1988( E), preparation of steel substratebefore applicati on of paints

3、and related products-visual assessme nt of surface clea nli n ess. The comparable sta n dard SSPC( Steel Structures Pain ti ng Coun cil ) has bee n quoted.(本说明书所使用的主要标准是ISO 8501-1; 1988 ( E),即涂漆和相关产品之前的钢底材处理-表面清洁度的目视鉴定以及 SSPC (美国保护涂层协会)的相关标准)ISO 8501-1与SSPC标准的部分对照表:STANDARDISO Visual Sta ndardSSPCGR

4、ADESt3SSPC-SP3Sa2.5SSPC-SP101.4 Painting process 涂装程序)Raw material (原 材料)wPrimer surface preparati on - shot lasti ng to SIS. Sa2.5(钢材流水线预处理)(抛丸处理至Sa2.5)s inorganic zinc silicate shepprimerPrimed with 18micr ons Taica ng Lanyan Paint FactoryW(喷涂太仓兰燕的无机硅酸锌车间底漆膜厚约18卩m)Cutt ing & prefabricati on(切割和装配)

5、在组立车间:一旦完成焊接,那些焊缝容易在外界空气中锈蚀。因此应用机械打磨至St2或St3,然后用太仓兰燕的车间底漆进行修补,膜厚在20卩m左右Sec: ndary surface preparation 二次表面处理)In specti on 检验)W、,App ication of subsequent coatings后道涂层施工)WIn specti on (检验)2、Surface Preparation 表面处理)2.1 Primary surface preparatio n(钢材流水线预处理)1)The hull structure steel plates ( 6mm and

6、above) are to be abrasive blasted to ISO 8501-1Sa2.5, the bar secti ons are to be abrasive blasted to ISO 8501-1 Sa2, and primed with 18microns Taicang Lanyan Paint Factory s inorganic zinc silicate shopp-0m.er W53(船体结构用钢板(6伽以上厚度)都要进行抛丸处理达到Sa2.5,型钢材抛丸除锈 达到Sa2,处理后立刻用太仓兰燕的无机硅酸锌车间底漆喷涂,干膜厚约为18卩m)2)The s

7、teel plates less than 6mm and the pipes which are considered to be impractical for sandblast ing shall be clea ned by pickli ng or power tool in accorda nee with the Builder practice.(6伽以下钢板及不能进行打砂的管子按照船厂的惯例采用酸洗或动力工具处理)3)The painting manufacturer shall confirm the compatibility between the painting

8、systemand shopprimer.(油漆商应确认下问底漆与后疗;涂层配套的菲容性)2.2 Application of Touch-up primer(跟踪补漆)1)In block fabricatio n stage, welded joints and parts where could be easily rusted by the weather exposure duri ng assembly an could have damaged shopprimer shall be mecha ni cally clea ned to Swedish Sta ndard SIS

9、 St3, and immediately touched up less tha n 20 microns Taica ng Lanyan Paint Factory s shopprimer.(在分段拼装阶段,烧焊部分和接头在外界空气中容易锈蚀,还有那些车间底漆被破坏的部分都要机械打磨至St3,之后立刻用太仓兰燕的车间底漆进行修补至20卩左右)2)Erect ion joints shall be touch-up with Taica ng Lanyan Paint Factory shopprimer at pre-erecti on stage or dry dock stage p

10、rior to the air tests.(上层建筑的大焊缝接头在吊装和干船坞的空气试验前要用太仓兰燕的车间底漆进行修补 )3)The surface of steel structure in clud ing all weld ing beads shall be pain ted as specified hereafter PAGE: 3 before leak test. However, fillet weldi ng joi nts and erect ion seams/butts joi nts formi ng tankboun dary may be touch-up

11、less tha n 30 micro ns of D.F.T. with Taica ng Lanyan Pai nt Factory s shopprimer to prevent corrosion before leak test.(所有钢质构件表面包括之后要进行密性试验的焊缝都要进行涂装,然而那些构成舱室 密性的 焊缝在密性试验前要用太仓兰燕的车间底漆刷涂干膜厚度不能超过30 卩 m)2.3 Secondary surface preparation 二次表面处理 )1)Secon dary surface preparatio n shall be carried out as b

12、elow table and A, B, C, D, E inthe table show the surface preparati on method as below:(二次表面处理方法见下表,其中 A, B, C, D, E 分别代表以下处理方式: )A: surface preparati on in block stage for welded parts and burnt and damaged parts ofshop primer to be shot blasted to Sa2.5 and in tact shop primer surface to be swept

13、to the remain der shop primer to be no more tha n 30%.(分段阶段焊接及烧损部位喷砂至 Sa2.5 级,车间底漆完好部位扫砂至车间底漆残留 面积不超过 30% )B: surface preparati on in block stage for welded parts and burnt and damaged parts ofshop primer to be power tool clea ning to St3.(分段阶段焊接及烧损部位打磨至 St3 级)C: surface preparati on after the block

14、 assembly and erect ion for the welded parts andbur nt and damaged parts to be power tool clea ning to St3.(分段总组合拢后焊接及烧损部位打磨至 St3 级)D: no treatme nt in block stage and to be blasted to Sa2.5 after erect ion.(分段阶段不处理,合拢后喷砂至 Sa2.5 级)E: no treatme nt in block stage and to be power tool clea ning to St3

15、 after erecti on.分段阶段不处理,合拢后打磨至 St3 级)(部位)(处理等级)Outside shell (except boat landing area )外板(靠船区域除外)A, CBoat berthi ng area靠船区域DWeather deck主甲板A, COutside accommodati on上层建筑外围壁A, CIn side accommodati on, E/P room上层建筑内表面,机泵舱B, CWater ballast tank(in clude fore and after peak tanks)压载舱(包括首尾尖舱)PAGE: 4Ca

16、rgo oil tanks (coated area)货油舱(涂装部分)A, CSlop tanks and process tanks污油舱和工艺舱DFresh water tank淡水舱DFuel oil/lube oil tank燃油舱/滑油舱EHelicopter deck直升机甲板A, C2)Degrease and removal of dust, water shall be carried out before start ing of the surface preparation. Steel defects, spatters, blowholes must be rep

17、aired and ground smooth.(表面处理前,应清除油污及其它杂物,对钢板缺陷,焊接飞溅等应进行修补)3)Leakage test for weld ing seams at block should be fini shed before sec on dary surfacepreparation; The welding seams for which the leakage test have not been carried out shall be brushed with shop primer the n covered with adhesive tape.

18、Whe n the stage painting in specti on work fini shed, shipyard should remove the adhesive tape immediately.(在二次表面处理前,在分段上的密性焊缝应完成密性试验;对于没有完成密性试验的密性焊缝,在喷砂交验后,应刷涂车间底漆,然后贴压敏胶带,当涂装检验工 作结束时,应立即拆除 密性焊缝上的压敏胶)4)The weld ing seams and bur n t/damaged parts shall be treated by power tooli ng after thepaint ap

19、plicati on of block assembly. For these areas touch up work, first grindidamaged area, the roughe n area should be in cli ne form and the width is about 50100mm, the n touch up the coati ng as pain ti ng scheme.(总组后,总组焊缝及烧损破坏处需打磨处理。对于这些部位的修补,首先将损坏处拉毛呈斜坡状,宽度为50100mm左右,并按油漆明细表的要求逐层修补)2.4 Painting work

20、s (涂装作业)2.4.1 Painting color ( 油漆颜色 )s color standar1)The finish color shall be decided in accordance with the Owner(面漆颜色依照船东的颜色标准决定 )2)Colors for each coat except finish color shall be decided in accordancewith the paint manufacturer s recommendation and Buildactice . s pr ( 除了面漆之外的各道油漆颜色由油漆服务商的推荐

21、和船厂的惯例来决定PAGE: 53)Color for machinery and equipment shall be generally in line with manufacturer scolor scheme. Unless otherwise specified.(机器和设备上的油漆颜色在没有特殊要求的情况下通常按建造厂商的方案 )242 Painting 即 plications ( 涂装施工 )1)Painting works shall be carried out by airless spray. However, hand brush or roller may be

22、 used where it is impracticable to use spray.(涂装施工一般采用无气喷涂,在无法使用此方法的部位可以采用刷涂和辊涂 )2)Painting works for the parts or spaces which are not specified in this specification shall be similar to surroundings or comparable spaces.(在此说明书中未指出说明的区域和部位可以采用邻近区域或相类似区域的涂料进行施 工)3)Time schedule for the application o

23、f each coat shall be decided according to recoating interval between coats recommended by paint manufacturer .The finish coat shall be applied as close up as possible to the launching or delivery.(施工的时间计划应该依照油漆商推荐的复涂间隔来决定, 最后的面漆施工应尽可能地 在靠近下 水或交船的时间进行施工 )4)The painting of the exposed of steel structu

24、re such as shell outside. Deckhouse ,funnel ,etc, an of living spaces incl. Passages shall be free from sags and runs.(船体外壳、甲板室、烟囱等,以及包括通道在内的住舱外露的钢结构的涂层表面应避 免产生 流挂和颜色不均匀 )5)After application of the coating. The damagedparts of coated film shall be repaired in adequate time. When such a damaged does

25、not reach up to the steel surface. It shall be cleane by sand paper and touch-up to achieve the specified D.F.WT.hen such a damage reaches up to the steel surface, it shall be cleaned by wire brush and/or disc sander to SIS St 3 as specified in the secondary surface preparation and shall be coated a

26、s originally specified with care forproper paint adhesion.(在使用了指定的涂料后,涂层的损坏部分应在适当时间进行修补,当涂层破损未延伸 至钢材 表面时,用砂皮纸拉毛后油漆修补至规定的干膜厚度既可;当涂层破损延伸至 钢材表面时,进 行二次表面处理时用钢丝刷或打磨枪处理至St3,使涂层获得适当的 结合力)6)When the light color epoxy paint is applied in water ballast tanks, mechanical and burnt damage which affect the perfo

27、rmance and quality of coating shall be repaired in accordance with the paint manufacture rescommendation. Howe PvAeGr,E:d6is-coloration, stains and surface contamination which do not affect the performance and quality of the coating may not be repaired.(当淡颜色的环氧涂料用在压载水舱时, 影响涂料性能和质量的机械和热损伤处应 依照油漆服务商的建

28、议进行修补,但是那些不影响涂层质量的褪色,污点和表面 灰尘则不需要 修补)2.4.3 Painting works for outfittings (舾装件的涂装施工 )1)machinery, electrical equipment, fittings valves, deck machinery, navigation equipment,furniture and so on shall be painted in accordance with the manufacture standotherwise specified. Equipment shall be well prot

29、ected to prevent damage to the finished paint. After above machinery, equipment and outfittings are installed, damaged part shall be touched up.(机械、电器设备、配件、阀门、甲板机械、导航设备、备件等除有特别指明外都 依据制造厂 的标准进行涂装。设备应受到完好的保护,避免面漆的破坏。机械、 设备、配件在安装后,如 涂层有损坏则需修补 )2)The steel outfitting not including pipes shall be primed

30、withIP s intergard 269, to 50 micronsof dry film thickness. The epoxy primer to be universally compatible according to application of the specified coating system per each location on“ 3. Pa(所有铁舾装件不包括管子在内做一度intergard 269底漆50卩m。该底漆必须与“3.油漆明细表”中指定的油漆配套有好的相容性)3)The outside of the steel pipes shall be c

31、oated with the painting system specified in this specification before installing. For the invisible part of the pipes outside under U-bolt or pipe support after installation no need to coat any more.U 型 螺栓或管子(在安装前铁管的外表应按本明细表的要求做好相应的涂层。对于安装后在支架下的不可见部分无需再涂装 )4)The surfaces of copper, copper alloy, alu

32、minum alloy, stainless steel, galvanized steel and non-corrosive materials shall not be painted unless otherwise specified.( 铜、铜合金、铝合金、不锈钢、镀锌件或其他耐腐蚀材料的表面不涂装,除非有 另外说明 )5)Small steel outfittings manufactured by a subcontractor shall be treated and painted based on Builder s practice like as above-2 (

33、2) .u4n.3less otherwise specified.(外协的小型钢制舾装件依照 2.4.3-2 中所写的船厂惯例来进行处理和涂装, 除非 有另外说明 ) PAGE: 76)Fixtures adjacent coated surface, label plates, rubber gaskets, etc. shall be properly protected during surface preparation and painting.(在靠近涂装施工区域的铭牌、橡胶垫圈等应在表面处理和油漆时加以适当的保 护)2.4.4 Matters to demand special

34、 attention for painting 涂 ( 装施工时需特别注意地事项 )1)Painting works shall not be performed in open air during the period of rain, snow, fog, dust and also shall not be carried out when the weather conditions may cause condensation i.e. when the relative humidity exceeds85%, or steel temperature is not higher

35、 by at least 3.0C than the dewpoint.(在露天的环境下,下雨、下雪、有雾、有扬尘的天气不能进行涂装作业,也不能 在相对湿度 超过 85%或钢板表面温度不超过露点 3C 下的条件下施工 )2)Dis-coloration , stains and surface contamination which do not affect the performance and quality of the coating may not be repaired, however detrimental poor appearance of the above of th

36、e ship outside, shall be cleaned by means of water, thinner, etc., or otherwise restored as necessary.(不影响涂层性能和质量的变色、污点、表面灰尘不必修补,但影响船舶外观的上 述缺陷要用 水、溶剂等清洁或用其它可修复的方法进行处理 )3)Stripe coat shall be applied after application of each full coat at the edges of small holes( slots,scallops, drain holes, air hol

37、es, etc., )corners of frame and free edges of structural members and welding seams in heavy corrosive areas such as ballast tanks, peak tanks, fresh water tanks.(在易受腐蚀部位如压载舱、尖舱、淡水舱等中的小孔边缘(狭缝、扇形边、排水 孔、通风孔 等)结构死角、结构自由边和焊缝在预涂完毕后方进行涂装 )4)Technical requirements for painting works such as mixing, thinning

38、 ratio, atmospheric temperature, humidity, recoating interval and drying time shall be in accordance with the paint manufacturer p rodsuct catalogue recommendation.(涂装施工的工艺要求如混合比、稀释率、大气温度、湿度、覆涂间隔、干燥时间 应依据 油漆公司的产品说明书推荐 )2.5 Inspection ( 检验 )1)The condition of secondary surface preparation prior to fi

39、rst coating and the total dry film thickness after final coating shall be inspected by three parties(Builder, Paint maker andOwner ) .PAGE: 8The clearing condition and dry film thickness of between coats shall be inspected by two parties (Builder and Paint maker ). Spot check shall be carried out du

40、ring Owner inspection randomly.(第一度涂装之前的二次除锈和完工涂层的干膜厚度应由三方(船厂、油漆商、船东)来检验。 )(中间各涂层之间的清洁状况与中间涂层的干膜厚度由油漆商和船厂两方面检查,船东可随时抽检。 )2)Dry film thickness shall not be measured for outfitting, pipe supports, machinery seats, small fittings, structural members and welding beads, etc. owner reserve the authority o

41、f spot check.(舾装件,如:管支架、机座、小型舾装件、构件及焊缝的干膜厚度不进行检验。 船东保 留抽检的权利 )3)The 85% of measured points are in accordance with the specified thickness or over, and the remaining 15% are at least 85% of the specified thickness.However, for hull and W.T the dry film thickness specified in the painting schedule to

42、be attained on at least 90% of the measuring points and at least 90% thickness of specified one to be attained on remaining 10% measuring points except plate edges, etc. ( 至少有 85% 的测量点应该达到说明书中所指定的干膜层厚度,剩下15% 的测量点 至少达到规定厚度的85%)(但是,对于外板及液舱, 至少有 90% 的测量点要达到油漆明细表中指定的干膜层 厚度, 剩下 10%的测量点至少达到规定厚度的 90% )4) P

43、ull off test should be applied in Hull, Ballast Tanks, Cargo Tanks, Slop Tanks. Abouttest result: Hull 3Mpa , Tanks 2.5Mpa外板及液舱需进行附着力试验。结果要求为:外板3Mpa,液PAGE: 9PAGE: 9PAGE: 9上海外高桥造船有限公司共20页SWS第10页序号NO涂装部位PAINTINGAREAS二次除锈等级SECONDARYSURFACEPREPARATION道数COATS涂料名称和编号PAINTS NAMEAND QUOTE每道膜厚DFT/COA T(MIC.)

44、颜色COLOUR备注REMARK1Bottom up to ballast waterl ineBlock stageSa2.51stIn tershield 300 ENA300/A175Bronze2ndIn tershield 300 ENA301/A175Alumi n ium3rdIn tershield 300ENA300/A150Bronze2Sea chests and stone of STPBlock stageSa2.51stIn tershield 300ENA300/A150Bronze2ndIn tershield 300ENA301/A150Alumi n ium

45、3rdIn tershield 300ENA300/A125Bronze4thIn tergard 263 FAJ034/A75Light Gray5thIn terspee d340BQA34150Brow n3Boat berth ingareaOther stageSa2.51stIn terz one5054502ndIn terz one5054503rdIn terthane504th990 In terthane50990上海外高桥造船有限公司共20页SWS第11页序号NO涂装部位PAINTINGAREAS二次除锈等级SECONDARYSURFACEPREPARATION道数CO

46、ATS涂料名称和编号PAINTS NAME每道膜厚DFT/COA T(MIC.)颜色COLOUR备注REMARKAND QUOTE4Topside and boottopBlock stageSa2.51stIn tergard 269EGA088/A50RedOther stageSt32ndIn tershield 300ENA300/A150Bronze3rdIn tershield 300ENA301/A150Alumi n ium4thIn terthane505th990 In terthane505Weather deckBlock stageSa2.51st990tergard

47、 269EGA088/A50RedOther stageSt32ndIn tershield 300ENA300/A175Bronze3rdIn tershield 300ENA301/A175Alumi n ium4thIn terthane506Helicopter deckBlock stageSa2.51st990 In terz one5054502ndIn terz one5054503rdIn terthaneqnn50Other stageSt34th990In terthane50990面积0.06就上海外高桥造船有共20页限公司SWS第12页涂料名称和编序涂装部位二次除锈等

48、级号SECONDARY道数每道膜厚颜色备注号PAINTINGSURFACEPAINTSDFT/COATCOATS(MIC.)COLOURREMARKNOAREASPREPARATIONNAME ANDQUOTEHelicopter deck supports and the back surface of helideckBlock stageSa2.51stIn tergard 269 EGA088/A50RedOther stageSt32ndIn tershield300ENA300/A150Bronze3rdIn tershield300ENA301/A150Alumi n ium4t

49、hIn terthane 990508Outside superstructureBlock stageSa2.51stIn tergard 269EGA088/A50RedOther stageSt32ndIn tershield300ENA300/A150Bronze3rdIn tershield300ENA301/A150Alumi n ium4thIn terthane 990509Cargo oil tanks (ta nk bottom and up to 2.0m,ta nk ceili ng and below dow n to 2.0m)Block stageSa2.51st

50、In tergard 403 KBA400/A150Buff2ndIn tergard 403 KBA402/A150Gray10Slop tanks and process tanks & Scum. TkOther stageSa2.51stIn tergard 403 KBA400/A150Buff2ndIn tergard 403 KBA402/A150Gray面积0.06就上海外高桥造船有限公司sws序号NO涂装部位PAINTING AREAS二次除锈等级SECONDARYSURFACEPREPARATION道数COATS涂料名称和编号PAINTS NAME AND QUOT11Ba

51、llast tanks in clude fore and after peak tanksBlock stageSa2.51stIn tergard 403 KBA400 丿2ndIn tergard 403 KBA402 丿12Void space and cofferdamBlock stageSa2.51stIn tergard 403 KBA400/2ndIn tergard 403 KBA402/13Freshwater tanksOther stageSa2.51stIn terli ne 850 TLA850/2ndIn terli ne 850 TLA851/3rdIn te

52、rli ne 850 TLA850/14Ven tilati on ducts in sideBlock stageSt31stIn tergard 400 EPA0012ndIn tergard 400 EPA00315Ven tilati on ducts outsideBlock stageSt3Same as surro undineJ16Torch tower exter n al (10m below top )Block stageSa2.51stIn terzi nc 22 QHA028/2ndIn tertherm 50 HTA093rdIn tertherm 50 HTA0

53、9面积0.06就上海外高桥造船有限公司SWS序号NO涂装部位PAINTING AREAS二次除锈等级SECONDARYSURFACEPREPARATION道数COATS涂料名称和编号PAINTS NAME AND QUOT17Torch tower exter n al (the rest area)Block stageSa2.51stIn tergard 269 EGA0882ndIn tershield 300 ENA30C3rdIn tershield 300 ENA3014thIn tertha ne 99018Sea water pipe system in sideSa2.51s

54、tIn tershield 300 ENA3002ndIn tershield 300 ENA30119Sea water pipe system outsideSa2.51stIn tershield 300 ENA3002ndIn tershield 300 ENA30120Cargo oil pipes & inert gas pipe system in sideSa2.51stIn tergard 403KBA400/2ndIn tergard 403KBA402/21Cargo oil pipes & inert gas pipe system outsideSa2.51st300

55、 In tershieldENA30C2nd300 In tershieldENA30122High temperature pipe exterior surface beh ind in sulati onSa2.51stIn terz inc 22QHA028/2ndIn tertherm 891 HTA00面积0.06就上海外高桥造船有限公司SWS序号NO涂装部位PAINTING AREAS二次除锈等级SECONDARYSURFACEPREPARATION道数COATS涂料名称和编号PAINTS NAME AND QUOT23Fire equipme nt and life equip

56、me ntManufacturer s sta24Weathered woode n outfittingsManufacturer s sta25Steel outfitti ng on weather deckBlock stageSt31stIn tergard 269Other stageSt32ndIn tershield 3003rdIn tershield 3004thIn tertha ne 99026Bilge tan k,bilge well,waste oil tank and sewage tank etc.Block stageSa2.51stIn tergard 4

57、03 KBA400 丿2ndIn tergard 403 KBA402/27Ship s name,draft marks a shell markspBlock stageSa2.51stSame primer as surro un(Other stageSt32ndIn tertha ne 99028Fueloil,diesel oil and lube oil tanksOther stageSt3An ti-rust oil29Tank top and walls belowBlock stageSt31stIn tergard 403 KBA400/the steel floor

58、in engineroom2ndIn tergard 403 KBA402/上海外高桥造船有限公司sws序号NO涂装部位PAINTING AREAS二次除锈等级SECONDARYSURFACEPREPARATION道数COATS涂料名称和编号PAINTS NAME AND QUOT30The walls and ceili ng above the steel floor in engine roomBlock stageSt31stIn tergard 400 EPA001Other stageSt32ndIn tergard 400 EPA0033rdIn tergard 740 EC s

59、erie31Engine room beh ind in sulati on steel surfaceBlock stageSt31stIn tergard 400 EPA001Other stageSt32ndIn tergard 400 EPA00132Engine room deck and flatBlock stageSt31stIn tergard 400 EPA001Other stageSt32ndIn tergard 400 EPA0033rdIn tergard 740 EC serie33Deck un der deck compositi on and ceme nti ng in engine roomNo pai n ti ng面积0.06就上海外高桥造船有限公司SWS序号NO涂装部位PAINTING AREAS二次除锈等级SECONDARYSURFACEPREPARATION道数COATS涂料名称和编号PAINTS NAME AND QUOT34In side boiler and pump room34.1Bare steel of

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。