汽轮机详细设计参数

汽轮机详细设计参数

《汽轮机详细设计参数》由会员分享,可在线阅读,更多相关《汽轮机详细设计参数(11页珍藏版)》请在装配图网上搜索。

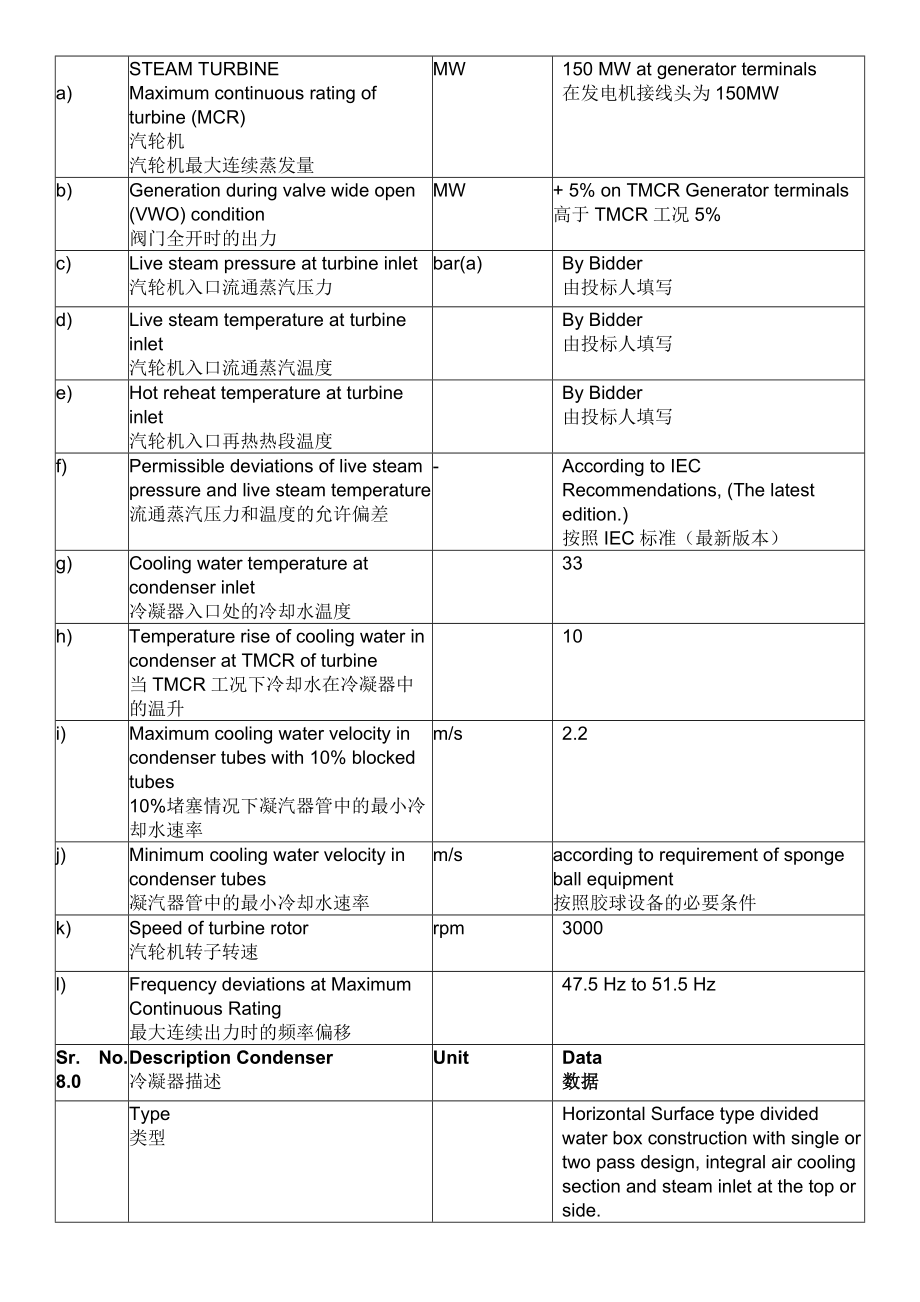

1、a)STEAM TURBINEMaximum continuous rating of turbine (MCR)汽轮机汽轮机最大连续蒸发量MW150 MW at generator terminals在发电机接线头为150MWb)Generation during valve wide open (VWO) condition阀门全开时的出力MW+ 5% on TMCR Generator terminals高于TMCR工况5%c)Live steam pressure at turbine inlet汽轮机入口流通蒸汽压力bar(a)By Bidder由投标人填写d)Live steam

2、temperature at turbine inlet汽轮机入口流通蒸汽温度By Bidder由投标人填写e)Hot reheat temperature at turbine inlet汽轮机入口再热热段温度By Bidder由投标人填写f)Permissible deviations of live steam pressure and live steam temperature流通蒸汽压力和温度的允许偏差-According to IEC Recommendations, (The latest edition.)按照IEC标准(最新版本)g)Cooling water temper

3、ature at condenser inlet冷凝器入口处的冷却水温度33h)Temperature rise of cooling water in condenser at TMCR of turbine当TMCR工况下冷却水在冷凝器中的温升10i)Maximum cooling water velocity in condenser tubes with 10% blocked tubes10%堵塞情况下凝汽器管中的最小冷却水速率m/s2.2j)Minimum cooling water velocity in condenser tubes凝汽器管中的最小冷却水速率m/saccord

4、ing to requirement of sponge ball equipment按照胶球设备的必要条件k)Speed of turbine rotor汽轮机转子转速rpm3000l)Frequency deviations at Maximum Continuous Rating最大连续出力时的频率偏移47.5 Hz to 51.5 HzSr. No. 8.0Description Condenser冷凝器描述UnitData数据Type类型Horizontal Surface type divided water box construction with single or two

5、pass design, integral air cooling section and steam inlet at the top or side.水平表面式、有一个或者二个通道的分水室结构、一体的空气冷却区、蒸汽进口在顶部或侧面Surface area表面面积10% over & above the designed surface area超过设计表面积的或10%Temperature rise温升oC10 oCDesign Heat Load设计热负荷Turbine VWO with 3% make-up and normal condenser vacuum.汽轮机阀门全开和正常

6、冷凝器真空Head Loss through condenser通过冷凝器的压头损失6 m WC6m水柱的压力CW velocity冷却水流速1.6 m/s to 2.2 m/s1.6 m/s to到2.2 m/sMax. oxygen in condensate冷凝器内最大含氧量0.015 cc per litre for 50% to 100% unit load and 0.03cc per litre for loads below 50%50% 至100%机组负荷时每公升含0.015 cc,机组负荷低于50%时每公升含0.03ccCooling water temperature a

7、t inlet进口冷却水温度33 deg CMax. Cooling water temperature at inlet (design)进口冷却水最大温度(设计)36 deg CCooling media冷却介质Clarified water净化水Cooling circuit冷却回路Open recirculating system with Induced draft cooling towers.有阴风冷却塔的开式循环系统Hot well storage capacity热井存储能力Min. 3 min最少3分钟的供应能力Condenser shell design pressure

8、凝汽器外壳设计压力760 mm Hg vacuum & suitable for an emergency internal pressure of 1.08 bar (g) and Full Vacuum760 mm汞柱真空&适用于1.08 bar (g)的紧急内部压力和全真空Codes /standards规范/标准Design, manufacture & testing as per the latest HEI standards设计、制造和测试按照最新HEI标准Material of construction结构材质 1) Shell外壳Mild steel (Min. wall

9、thickness 18 mm)低碳钢(最小壁厚18mm)Sr. No.DescriptionUnitData2) Tubes管子Welded stainless steel type conforming to ASTM A-249, TP304不锈钢焊接型遵照ASTM A-249, TP3043) Water box & covers水箱&盖子Mild steel低碳钢4) Support plates支撑板Mild steel低碳钢Condensate Extraction Pumps(CEPs)凝泵Number of pumps泵的数量Nos3 x 50%Type类型Vertical,

10、 multistage, Cannister, centrifugal diffuser type.垂直、多级、碳罐、离心式Drive驱动器Vertical constant speed squirrel cage induction motor.垂直恒速鼠笼式电动机Design capacity of the pump泵的设计容量kg/s0.5 X maximum condensate flow corresponding to VWO and 3% make-up.0.5x最大凝结水流量与阀门全开补水3%一致Margin on Design capacity设计容量裕度%15% on ab

11、ove15%以上TDH developedbarMaximum deaerator operating pressure + static head & pressure drop under maximum operating condition除氧器最大操作压力+静压头&压降低于最大操作条件Margin on Design Head设计压头裕度%10 %10.0Vacuum Pumps 真空泵No. of pumps 泵数量2x100%Capacity容量Pumps shall be sized as per latest HEI requirements. Capacity of eac

12、h pump in free dry air at standard condition with condenser operating at design pressure of 1 inch (25.4 mm) of Hg (abs) and sub-cooled to 4.170C below temperaturecorresponding to absolute suction pressure shall not be less than 30 scfm (51 m3 per hour) under standard condition (i.e 760 mm of Hg (ab

13、s) and 21.10C).泵的尺寸应依照最新HEI标准。每个泵的容量在标准条件下释放干燥的空气,冷凝器的设计压力为1英寸(25.4mm)汞柱和冷却到4.17摄氏度以下。相应的,绝对负压不得少于30scfm(51立方米每小时)在标准状态下(如下760毫米的汞(abs)和21.10 C)。Sr. No.DescriptionUnitDataType类型Continuous duty single/ two stage pumps liquid ring type sized as per pumps applicable requirements of latest HEI standards

14、.按照最新HEI标准适用规范的连续负载单/两级泵液环型。11.0Condensate Polishing Unit凝结水精处理装置Capacity容量2x50%11.1Deaerator除氧器Type类型Either spray cum tray type or spray type喷洒和托盘型或喷洒型De-aerating capability除氧容量ppb5ppbMode of operation of deaerator for feed water system给水系统除氧器运行模式-Variable pressure with fixed minimum pressure有固定最小压

15、力的变压Storage Capacity of feed water tank for feed water system at 100% BMCR between minimum level and normal regulated level最低液位和正常调整的液位之间100%锅炉最大连续出力下给水系统给水箱的存储容量min6 minutes6分钟11.2HP-LP Heaters高压-低压加热器Design pressure of LP feed heaters, condensate coolers (Shell side), feed water tank and Deaerator

16、低压给水加热器,凝结水冷却器(壳体侧),给水箱和除氧器的设计压力-120% of respective maximum turbine bleed pressure but at least 3 bar (g) and full vacuum.至少在3 bar (g)和全真空120%的各自最大汽轮机排放压力。Design pressure of LP feed heaters and condensate coolers (Tube side)低压给水加热器,凝结水冷却器(管道侧)Shut off head of CEP at maximum speed and full vacuum最大速度

17、和全真空时的凝结水泵的断流水头。Design pressure of HP feed heaters and desuperheater (Shell side)高压给水加热器和减温器的设计压力(壳体侧)-120% of maximum bleed steam pressure120%的最大排放蒸汽压力。Design pressure of HP feed heater and desuperheater heater (Tube side)高压给水加热器和减温器(管道侧)的设计压力Shut off head of BFP at maximum speed and full vacuum.最大

18、速度和全真空时的锅炉给水泵的断流水头。Design temperature of LP feed heaters, feed water tank and deaerator, HP feed heaters and desuperheater低压给水加热器,给水箱和除氧器,高压给水加热器和减温器的设计温度According to HEI standards.根据HEI标准。Arrangement of heaters加热器布置Horizontal卧式Gland Steam Condenser汽封凝汽器Vapour Extractors蒸汽提取器Quantity数量2x100% A.C Dri

19、ven2x100%交流驱动12.0BOILER FEED WATER PUMPS (BFPs)锅炉给水泵Type类型Horizontal, multistage centrifugal, with barrel type outer casing with end rotor removal. The pump shall be fully cartridge designed.卧式,多级离心,带有筒式外壳体,带有端部转子移除。该泵是夹头设计的。Number of feed water pumps给水泵数量-Three (3)三台Capacity per feed water pump每台给水

20、泵的容量-50% each每台50%Drive驱动-AC motor driven交流电机驱动Control of motor driven feed pumps电机驱动给水泵控制-Variable speed control by hydraulic variable speed coupling通过液压变速联轴器的变速控制Rated capacity额定容量Note: Discharge flow of the pump shall not include any seal flow, warm up flow and balance drum leakage flow.注意:该泵的排放流

21、量不包含任何密封流量,温启动流量和平衡汽包渗漏流量。Tonnes/hrThe combined flow of 2x50% boiler feed pumps shall have 10% margin over feed flow corresponding to turbine VWO condition, 3% makeup, design back pressure and corresponding head + design spray requirement of reheater attemperators.2x50%锅炉给水泵的组合流量在给水流量上有10%余量,符合汽轮机阀门

22、全开工况,3%补给,设计背压和相应压头+加热器恒温器的设计喷洒要求。Rated head developed by each of the pump每台泵的额定压头barNot less than 3% over steam generator highest safety valve set pressure corresponding to BMCR锅炉最大安全阀设置压力不少于3%,与锅炉最大连续出力一致considering the static and dynamic system requirements with friction losses in piping and feed

23、 water heaters.考虑该静止和动力系统规范且管道和给水加热器中摩擦损失。Best efficiency point最佳效率点The best efficiency point of the pump shall correspond to 100% TMCR under rated condition.该泵的最佳效率点符合额定工况下100%汽轮机最大连续出力。Shut off head断流水头The shut off head of the pumps shall be between 120% and 130% of total developed head (TDH) unde

24、r rated condition.额定工况下该泵的断流水头在120%和130%总水头之间。Minimum flow through pump通过泵的最小流量 25%Motor rating for MDBFP (The maximum continuous motor rating corresponding to maximum cooling water temperature to cooler inlet)电动给水泵的电机额定值(最大连续电机额定值符合打冷却器进口的最大冷却水温度)Not be less than the maximum load demand of driven e

25、quipment at its entire range of operation at frequency variations from 47.5 Hz to 51.5 Hz and motor shall not be overloaded during any mode of operations of the driven equipment任何驱动设备运行模式期间从47.5 Hz到51.5 Hz频率变动运行的整个范围内不小于最大负载要求的驱动设备和电机不过载。12.1BFP Booster Pump锅炉增压泵Single casing, double suction, horizo

26、ntal single stage centrifugal pump with mechanical seals单缸,双吸,卧式单级离心泵且带有机械密封12.2Steam turbine drive for BFP锅炉给水泵的汽轮机驱动Number of drives驱动数量Nos.Two (2)两个Steam inlet conditions to drive turbine蒸汽进口状况到驱动汽轮机barTo be decided by Bidder投标人决定Steam outlet pressure蒸汽出口压力barMain condenser pressure主凝汽器压力13.0Turb

27、ine Bypass System汽轮机旁路系统Capacity of HP Bypass system高压旁路系统的容量%60% TMCR60%汽轮机最大连续出力Capacity of LP Bypass system低压旁路系统%Matching with HP bypass capacity of 60% TMCR.和60%汽轮机最大连续出力匹配14.0Chemical Dosing System化学加药系统1 set for each unit每台机组一台14.1HP Dosing System高压加药系统HP dosing system高压加药系统1 No. solution Pre

28、paration Stainless Steel (SS316) tank with basket & motorized agitator1组溶液配制不锈钢(SS316)箱且带有垫圈和电动搅拌器。1 No. metering tank of Stainless Steel (SS316) construction with motorized agitator1组不锈钢(SS316)计量箱结构且带有搅拌器。HP Dosing Pumps高压加药泵Qty数量2x100%Type类型Reciprocating plunger positive displacement type pumps wi

29、th drive motor.往复式冲杆容积式泵且带有驱动电机Material材料SS 30414.2LP Dosing System低压加药系统1 set of NH3 and Hydrazine dosing system for each unit每台机组1台NH3和肼加药系统LP dosing system低压加药系统1 No. solution Preparation Stainless Steel (SS316) tank with basket & motorized agitator1组溶液配置不锈钢箱(SS316)且带有垫圈和电动搅拌器。1 No. metering tank

30、 of Stainless Steel (SS316) construction with motorized agitator1组不锈钢计量箱(SS316)且带有电动搅拌器。LP Dosing Pumps低压加药泵Qty数量2x100%Type类型Reciprocating plunger positive displacement type pumps with drive motor.往复式冲杆容积式泵且带有驱动电机Material材料SS 30415.0ACW System空冷水系统1 set for each unit每台机组1台Closed Cycle DM Cooling wat

31、er Pumps (Qty.)闭式循环除盐冷却水泵(数量)3 x 50%Plate Heat Exchangers (PHE) (QTY.)板式热交换器(数量)3 x 50%PHE Capacity板式热交换器容量To meet the requirements of BTG islands equipments + customer supplied auxiliaries viz. air compressors etc with 25% spare capacity on heat transfer area selected.为了满足BTG岛设备+客户供应辅助既在热交换选择区域上带有2

32、5%备用容量的空气压缩机等的规范ACW Booster Pumps空冷水增压泵3x50%Cooling water冷却水Tapped from CW inlet header outside STG building从锅炉汽轮发电机组外冷却水进口加热器Cooling Water inlet temperature冷却水进口温度oC33 oCDesign Cooling water inlet temperature for PHE板式热交换器的设计冷却水进口温度oC36 oCPrimary water outlet temperature一次水出口温度oC39 oC (Maximum)最大Pr

33、imary circuit cooling water quality一次回路冷却水量Passivated DM water钝化除盐水16.0Condenser Make-upNumber of Condenser Make-up Pumps凝汽器补给凝汽器补给泵的数量3x50%17.0Boiler Initial Filling锅炉初始填充Boiler Initial fill Pump Qty锅炉初始填充泵数量2x100% (One working + one standby )2x100%(1用+1备)18.0Passenger cum Goods Lift客运和货运电梯18.1Loca

34、tion位置Steam generator锅炉18.2No. of lift起重机数量Nos.118.3Travel移动Ground floor level to Drum level地面到汽包液位18.4Type of Operation运行类型-With/without attendant有/无值班人员18.5Minimum Carrying Capacity最小输送容量Tonnes218.6Speed速度m/sec1.518.7Size of the Machine room (LxWxH)机器室尺寸(长X宽X高)MBidder to indicate投保人指出Sr. No.Descri

35、ption描述Unit单位Data资料18.8Car Size梯室尺寸mmBidder to indicate由投标人指定18.9Size of lift well电梯井道尺寸mmBidder to indicate由投标人指定18.10Car enclosure梯室外壳-Painted Sheet steel油漆的钢板18.11Car doors轿门-Collapsible可折叠式Door opening (WXH)厅门(尺寸)mm1500 x 200018.12Hoist way door opening厅门打开方式-Collapsible可折叠式18.13Drive驱动-Electric

36、al Variable Speed drive.电气变速传动18.14Controls控制器-Fully automatic Microprocessorbased full collective logic基于总逻辑的全自动微处理器18.15Operation of car and hoist way doors轿门和厅门的运行方式-Manual with interlock safety feature具有连锁安全特点的手动式18.16Car floor梯室地板-Steel chequered plate网纹钢板19.0Passenger Lift客梯19.1Location位置:STG

37、building汽轮发电机建筑19.2No. of lift电梯数量Nos.119.3Travel运行区域Ground floor to operating floor including mezzanine floor.地下一层到工作台包括阁楼。19.4Type of Operation运行类型-With/without attendant有/无服务人员19.5Minimum Carrying Capacity最小载重量Tonnes12 person12人19.6Speed速度m/sec1.519.7Size of the Machine room(LxWxH)机房尺寸(LxWxH)MBid

38、der to indicate由投标人指定19.8Car Size梯室尺寸mmBidder to indicate由投标人指定19.9Size of lift well电梯井道尺寸mmBidder to indicate由投标人指定19.10Car enclosure梯室外壳-Painted Sheet steel油漆的钢板19.11Car doors轿门-Collapsible可折叠式Door opening (WXH)厅门(尺寸)mm1500 x 200019.12Hoist way door opening厅门打开方式-Collapsible可折叠式19.13Drive驱动-Electrical Variable Speed drive.电气变速传动19.14Controls控制器-Fully automatic Microprocessorbased full collective logic基于总逻辑的全自动微处理器19.15Operation of car and hoist way doors轿门和厅门的运行方式-Manual with interlock safety feature具有连锁安全特点的手动式19.16Car floor梯室地面-Steel chequered plate网纹钢板

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。