钢的化学成分及机械性能表

钢的化学成分及机械性能表

《钢的化学成分及机械性能表》由会员分享,可在线阅读,更多相关《钢的化学成分及机械性能表(23页珍藏版)》请在装配图网上搜索。

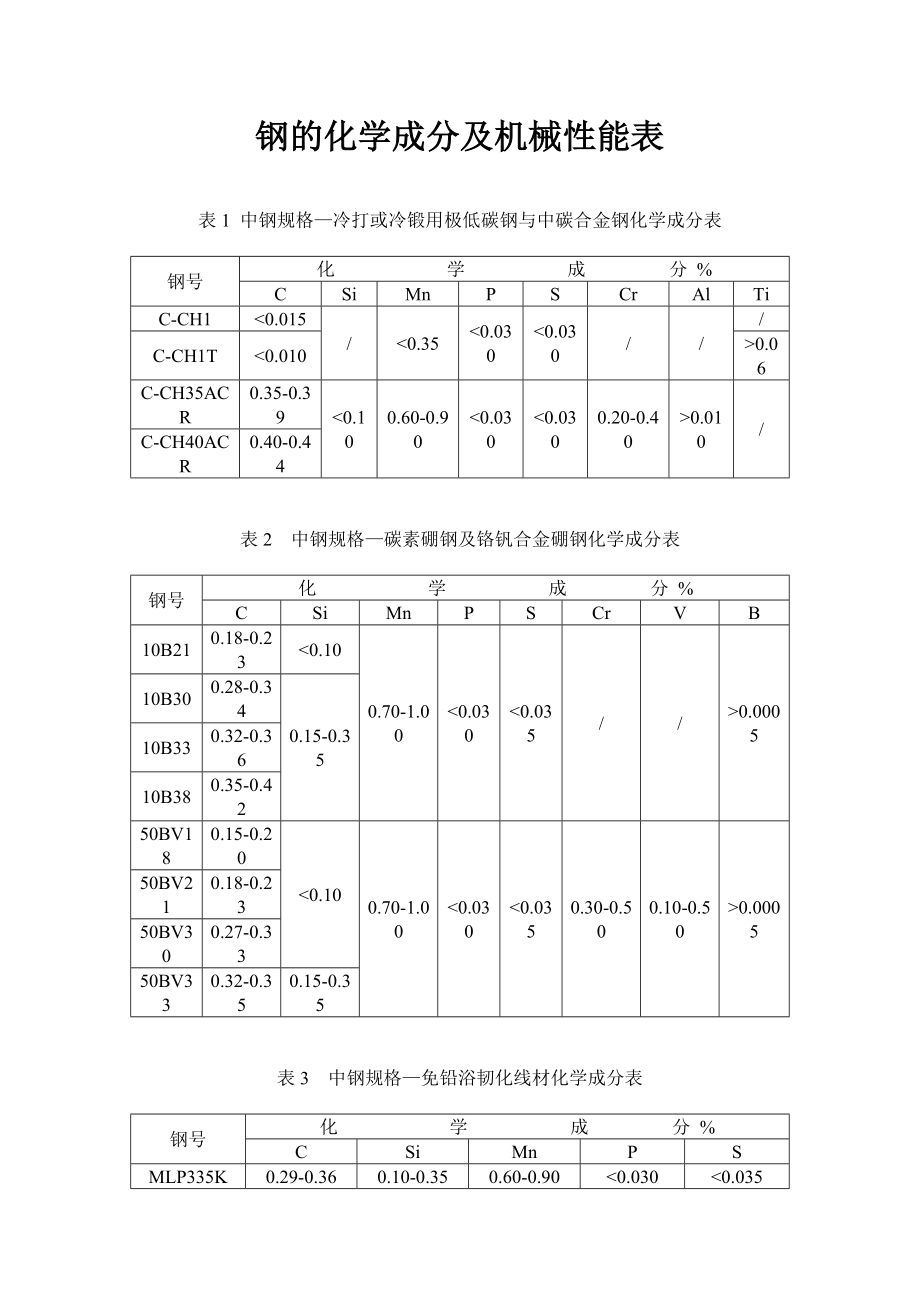

1、钢的化学成分及机械性能表表1 中钢规格冷打或冷锻用极低碳钢与中碳合金钢化学成分表钢号化 学 成 分 %CSiMnPSCrAlTiC-CH10.015/0.350.0300.030/C-CH1T0.06C-CH35ACR0.35-0.390.100.60-0.900.0300.010/C-CH40ACR0.40-0.44表2 中钢规格碳素硼钢及铬钒合金硼钢化学成分表钢号化 学 成 分 %CSiMnPSCrVB10B210.18-0.230.100.70-1.000.0300.000510B300.28-0.340.15-0.3510B330.32-0.3610B380.35-0.4250BV18

2、0.15-0.200.100.70-1.000.0300.000550BV210.18-0.2350BV300.27-0.3350BV330.32-0.350.15-0.35表3 中钢规格免铅浴韧化线材化学成分表钢号化 学 成 分 %CSiMnPSMLP335K0.29-0.360.10-0.350.60-0.900.0300.035NLP77B0.74-0.810.15-0.350.0250.025NLP82B0.79-0.85表4 JIS G3104 铆钉用钢化学成分表钢 号化 学 成 分 %PSSV3300.0400.040SV440表5 JIS G3105链条用钢化学成分表钢号化 学

3、成 分 %CSiMnPSSBC3000.130.040.500.0400.040SBC4900.250.15-0.401.00-1.50表6 JIS G3503 被覆焊条心线用钢材化学成分表钢号化 学 成 分 %CSiMnPSCuSWRY110.090.030.35-0.650.0200.0230.20SWRY210.10-0.15表7 JIS G3505 低碳软钢化学成分表钢 号化 学 成 分 %CMnPSSWRM 60.080.600.0450.045SWRM 80.10SWRM 100.08-0.130.30-0.60SWRM 120.10-0.15SWRM 150.13-0.18SWR

4、M 170.15-0.20SWRM 200.18-0.23SWRM 220.20-0.25表12 JIS G4102 镍铬合金钢化学成分表钢号化 学 成 分 %CSiMnPSNiCrSNC2360.320.400.150.350.500.800.0300.0301.001.500.500.90SNC4150.120.180.350.652.002.500.200.50SNC6310.270.352.503.000.601.00SNC8150.120.183.003.500.701.00SNC8360.320.400.601.00表13 JIS G4103 镍铬钼合金钢化学成分表钢号化 学 成

5、分 %CSiMnPSNiCrMoSNCM2200.170.230.150.350.600.900.0300.0300.400.700.400.650.150.30SNCM2400.380.430.701.00SNCM4150.120.180.400.701.602.00SNCM4200.170.23SNCM4310.270.350.600.900.601.00SNCM4390.360.43SNCM4470.440.50表8 JIS G3505硬钢线材化学成分表钢号化 学 成 分 %CSiMnPSSWRH270.240.310.150.350.300.600.0400.040SWRH320.29

6、0.36SWRH370.340.41SWRH42A0.390.460.300.60SWRH42B0.600.90SWRH47A0.440.510.300.60SWRH47B0.600.90SWRH52A0.490.560.300.60SWRH52B0.600.90SWRH57A0.540.610.300.60SWRH57B600.90SWRH62A0.590.660.300.60SWRH62B0.600.90SWRH67A0.640.710.300.600.0300.030SWRH67B0.600.90SWRH72A0.690.760.300.60SWRH72B0.600.90SWRH77A0

7、.740.810.300.60SWRH77B0.600.90SWRH82A0.790.860.300.60SWRH82B0.600.90注:上表之含碳量可由买卖双方协议,由原规定之成分范围上、下限各缩窄0.01%.表14 JIS G4104 铬合金钢化学成分表钢号化 学 成 分 %CSiMnPSCrScr4150.130.180.150.350.600.850.0300.0300.901.20Scr4200.180.23Scr4300.280.33Scr4350.330.38Scr4400.380.43Scr4450.430.48表9 JIS G3507冷打或冷锻用碳钢化学成分表钢号化 学 成

8、 分 %CSiMnPSAlSWRCH6A0.080.100.600.0300.02SWRCH8A0.10SWRCH10A0.080.130.300.60SWRCH12A0.100.15SWRCH15A0.130.18SWRCH16A0.600.90SWRCH18A0.150.20SWRCH19A0.701.00SWRCH20A0.180.230.300.60SWRCH22A0.701.00SWRCH10K0.080.130.100.350.300.600.0300.035/SWRCH12K0.100.15SWRCH15K0.130.18SWRCH16K0.600.90SWRCH17K0.150

9、.200.300.60SWRCH18K0.600.90SWRCH20K0.180.230.300.60SWRCH22K0.701.00SWRCH24K0.190.251.351.65SWRCH25K0.220.280.300.60SWRCH27K0.220.291.201.50SWRCH30K0.270.330.600.90SWRCH33K0.300.36SWRCH35K0.320.38SWRCH38K0.350.41SWRCH40K0.370.43SWRCH41K0.360.441.351.65SWRCH43K0.400.460.601.90SWRCH45K0.420.48SWRCH48K0

10、.450.51SWRCH50K0.470.53钢号化 学 成 分 %CSiMnPSS 10 C0.080.130.150.350.300.600.0300.035S 12 C0.100.15S 15 C0.130.18S 17 C0.150.20S 20 C0.180.23S 22 C0.200.25S 25 C0.220.28S 28 C0.250.310.600.90S 30 C0.270.33S 33 C0.300.36S 35 C0.320.38S 38 C0.350.41S 40 C0.370.43S 43 C0.400.46S 45 C0.420.48S 48 C0.450.51S

11、 50 C0.470.53S 53 C0.500.56S 55 C0.520.58S 58 C0.550.61S 09 CK0.070.120.150.350.300.600.0250.025S 15 CK0.130.18S 20 CK0.180.23注:S09CK,S15CK及S20CK之不纯物不得超过Cu 0.25%,Cr 0.20%,Ni 0.20%,Ni+Cr 0.30%,其余种类之不纯物不得超过Cu 0.30%,Ni 0.20%,Cr 0.20%,Ni+Cr 0.35%。表16 JIS G4106达式 机械构造用锰钢及锰铬合金钢化学成分表钢号化 学 成 分 %CSiMnPSCrSMn

12、4200.170.230.150.351.201.500.0300.030/SMn4330.300.36SMn4380.360.410.150.35SMn4430.400.46SMnC4200.170.230.150.350.0300.0300.350.70SMnC4430.400.46注:各种类钢料中不纯物,Ni不得超过0.25%,Cu不得超过0.30%,又锰钢钢料之Cr不得超0.35%.表11 JIS G4052 保证硬化能之构造用合金钢化学成分表钢号化 学 成 分 %CSiMnPSNiCrMoMn系SMn420H0.160.230.150.351.151.550.0300.030/SMn

13、433H0.290.36SMn438H0.340.411.301.70SMn443H0.390.46MnCr系SMNC420H0.160.230.150.351.151.550.0300.030/0.350.70SMnC443H0.390.461.301.70Cr系Scr415H0.120.180.150.350.550.900.0300.030/0.851.25/Scr420H0.170.23Scr430H0.270.34Scr435H0.320.39Scr440H0.370.44CrMo系Scm415H0.420.490.150.350.550.900.0300.030/0.851.250

14、.150.35Scm418H0.150.21Scm420H0.170.23Scm435H0.320.39Scm440H0.370.44Scm445H0.420.49Scm822H0.150.250.350.45NiCrMo系SNCM220H0.170.230.150.350.600.950.0300.0300.350.750.350.650.150.30SNCM420H0.170.230.400.701.552.00注:各种类钢料中之不纯物,Cu不得超过0.30%, Ni除在Ni-Cr钢及Ni-Cr-Mo钢外不得超过0.25%,双锰钢料中之Cr含量不得超过0.35%。表15 JIS G4105

15、 铬钼合金钢化学成分表钢号化 学 成 分 %CSiMnPSCrMoSCM4150.130.180.150.350.600.850.0300.0300.901.200.150.30SCM4180.160.21SCM4200.180.23SCM4210.170.230.701.00SCM4300.280.330.600.85SCM4320.270.370.300.601.001.50SCM4350.330.380.600.850.901.20SCM4400.380.43SCM4450.430.48SCM8220.200.250.350.45注:不纯物Cu不得超过0.30%,Ni不得超过0.25%.

16、表17 JIS G4801 弹簧钢化学成分表钢号化 学 成 分 %CSiMnPSCr其它SUP 30.750.900.150.350.300.600.0350.0005SUP 120.510.591.201.600.600.900.600.90/SUP 130.560.640.150.350.701.000.701.00Mo:0.250.35注:不纯物Cu不得超过0.30%。表18 JIS Z3312 CO2熔接用碳钢焊条钢化学成分表钢号化 学 成 分 %CSiMnPSCuAlTi+ZrYGW110.150.551.101.401.900.0300.0300.500.100.30YGW121.

17、251.90/YGW131.351.900.100.500.30YGW14/YGW150.401.001.001.500.100.13YGW160.851.60/YGW17/表19 SAE/AISI 条钢、线材、锻造用半成品碳钢化学成分表钢号化 学 成 分 %CMnPS10050.060.350.0300.05010060.080.250.4010080.100.300.5010100.080.130.300.6010120.100.1510150.150.1810160.600.9010170.150.200.300.6010180.600.9010200.180.230.300.60102

18、10.600.9010220.701.0010230.200.250.300.6010250.220.2810260.600.9010290.250.3110300.280.3410350.320.3810370.701.0010380.350.420.600.9010390.370.440.701.0010400.600.9010420.400.4710430.701.0010440.430.500.300.6010450.600.9010460.701.0010490.460.530.600.9010500.480.5510530.701.0010550.500.600.600.90106

19、00.550.6510650.600.7010700.650.7510780.720.850.300.6010800.750.880.600.9010860.800.930.300.5010900.850.980.600.9010950.931.030.300.50注:1、铅(Lead)为改良车削性,可在普通碳钢中加入0.150.35之铅,而在代号的第二位与第三位中间加“L”,如10L45、10L12。2、硼(Boron)在细晶净静钢Fine Grain,Killed Steel中,加入0.00050.0030%的硼,可增进硬化能,而在代号的第二位与第三位中间加“B”,职10B21、10B38

20、。3、矽Silicon条钢及半成品,当矽有要求时,其范围如下:0.10%以下0.100.20%,0.150.35%,0.200.40%,0.300.60。线材,当矽有要求时,其范围如下:0.10以下,0.070.15%,0.100.20%,0.150.35%,0.200.40%,0.300.60%。4、某些品质、产品之磷、硫可降低成分上限要求。表21 SAE/AISI 条钢、线材、锻造用半成品高锰碳钢化学成分表钢号化 学 成 分 %CMnPS15220.180.241.101.400.0300.0500.250.190.251.351.6515260.220.291.101.4015271.2

21、01.5015410.360.441.351.6515480.440.521.101.4015520.470.551.201.5015660.600.710.851.15表22 SAE/AISI 保证硬化能(淬火性)之碳钢及硼钢化学成分表钢号化 学 成 分 %CMnPSSi其它1038H0.340.430.501.000.0400.0500.150.35/1045H0.420.511522H0.170.251.001.501524H0.180.261.251.751526H0.210.301.001.501541H0.350.451.251.7515B21H0.170.240.701.200.

22、0400.0500.150.35B:0.00050.00315B28H0.250.341.001.5015B30H0.270.350.701.2015B35H0.310.3915B37H0.300.391.001.5015B41H0.350.451.251.7515B48H0.430.531.001.5015B62H0.540.670.400.60表20 SAE/AISI 条钢、线材半成品合金钢化学成分表钢号化 学 成 分 %CMnPSSiNiCrMo其它13350.330.381.601.900.0300.0400.150.35/13400.380.4340230.200.250.700.9

23、00.0300.0400.150.35/0.200.30/40270.250.3040370.350.4040470.450.5041180.180.230.700.900.0300.0400.150.35/0.400.600.080.15/41200.901.200.130.2041300.280.330.400.600.801.100.150.2541370.350.400.700.9041400.380.430.751.0041420.400.4541450.430.4841500.480.5343200.170.220.450.650.0300.0400.150.351.652.000

24、.400.600.200.30/43400.380.430.600.800.700.9046200.170.220.450.650.0300.0400.150.351.652.00/0.200.30/48200.180.230.500.703.253.7550B460.440.490.751.000.0300.0400.150.35/0.200.35/B:0.00050.00351200.170.220.700.900.700.90/51300.280.330.801.1051320.300.350.600.800.751.0051400.380.430.700.900.700.9051500

25、.480.5351600.560.640.751.0051B6061500.480.530.700.900.0300.0400.150.35/0.801.10/V:0.15以上86150.130.180.700.900.0300.0400.150.350.400.700.400.600.150.25/86170.150.2086200.180.2386220.200.2586300.280.3386400.380.430.751.0086450.430.4887200.180.230.751.000.200.3088220.200.250.700.900.300.4092590.260.640

26、.751.000.0300.0400.701.10/0.450.65/92601.802.20/注:残留元素Cu:0.35%,Ni:0.25%,Cr:0.20,Mo0.06%表23 SAE/AISI 保证硬化能(淬火性)之合金钢化学成分表钢号化 学 成 分 %CMnPSSiNiCrMo其它1330H0.270.331.452.050.0350.0400.150.35/1335H0.320.381340H0.370.441345H0.420.494027H0.240.300.601.000.0350.0400.150.35/0.200.30/4028H0.350.054032H0.290.350

27、.0404037H0.340.414042H0.390.464047H0.440.514118H0.170.230.601.000.0350.0400.150.35/0.300.700.080.15/4120H0.180.230.901.200.400.600.130.204130H0.270.330.300.700.751.200.150.254135H0.320.380.601.004137H0.340.414140H0.370.440.651.104142H0.390.464145H0.420.494147H0.440.514150H0.470.544161H0.550.650.650.

28、950.250.354320H0.170.230.400.700.0350.0400.150.351.552.000.350.650.200.30/4340H0.370.440.550.900.650.954620H0.170.230.350.750.0350.0400.150.351.552.00/0.200.30/4718H0.150.210.600.950.0350.0400.150.350.851.250.300.600.300.40/4720H0.170.230.450.750.150.254815H0.120.180.300.700.0350.0400.150.353.203.80

29、/0.200.30/4817H0.140.204820H0.170.230.400.8050B40H0.370.440.651.100.0350.0400.150.35/0.300.70/B:0.00050.00350B44H0.420.495046H0.430.500.130.43/50B46HB:0.00050.00350B50H0.470.540.300.7050B60H0.550.65未完下页:接上页钢号化 学 成 分 %CMnPSSiNiCrMo其它5120H0.170.230.601.000.0350.0400.150.35/0.601.00/5130H0.270.330.601.

30、100.751.205132H0.290.350.500.900.651.105135H0.320.380.701.155140H0.370.440.601.000.601.005147H0.450.520.601.050.801.255150H0.470.540.601.000.601.005155H0.500.605160H0.550.650.651.1051B60HB:0.00050.0036118H0.150.210.400.800.0350.0581B45H0.420.490.751.050.0350.0400.150.350.150.450.300.600.080.15B:0.00

31、050.0038617H0.140.200.650.950.0350.0400.150.350.350.750.350.650.150.25/8620H0.170.238622H0.190.258625H0.220.288627H0.240.308630H0.270.3386B30HB:0.00050.0038637H0.340.410.701.05/8640H0.370.448642H0.390.468645H0.420.4986B45HB:0.00050.0038650H0.470.54/8655H0.500.608660H0.550.658720H0.170.230.600.950.03

32、50.0400.150.350.350.750.350.650.200.30/8740H0.370.440.701.058822H0.190.250.300.409259H0.560.640.651.100.0350.0400.701.20/0.450.65/9260H0.550.651.702.20/94B15H0.120.180.701.050.0350.0400.150.350.250.650.250.550.080.15B:0.00050.00391B17H0.140.2094B30H0.270.33注:残留元素Cu:0.35%以下,Ni:0.25%以下,Cr:0.20%以下,Mo:0

33、.06%以下.表24 ANSI/AWS A5.1780 潜弧熔接用碳钢焊条化学成分表钢号化 学 成 分 %CMnSiPSCuEL80.100.250.600.070.0300.0300.030EL8K0.100.25EL120.040.140.10EM120.060.150.801.250.10EM12K0.050.150.100.35EM13K0.060.160.901.400.350.75EM15K0.100.200.801.250.100.35EH141.702.200.10注:1、除表列元素外,其它刻意增加的元素也必须报列。2、刻意增加的元素与残留元素之总和不得超过0.50%。3、钢之

34、含量,为焊线镀铜及残留量之总和。表25 ANSI/AWS A5.1879 气体掩护电弧熔接用碳钢焊条化学成分表钢号化 学 成 分 %CMnSiPSCuER70S-30.060.150.901.400.450.750.0250.0350.50ER70S-40.070.151.001.500.650.85ER70S-60.060.151.401.850.801.15注:1、铜之含量,为为焊线镀铜及残留量之总和。2、镍、铬、钼、钒等残留量之总和不得超过0.50%。国家和标准 德国 中国 英国 法国 意大利 比利时 瑞典 西班牙 日本 美国 材料编号 DIN GB BS EN AFNOR UNI NB

35、N SS UNE JIS AISI/SAE P 1 1.0401 C15 15 080M15 - CC12 C15C16 - 1350 F.111 - 1015 1 1.0402 C22 20 050A20 2C CC20 C20C21 C25-1 1450 F.112 - 1020 1/2 1.0501 C35 35 060A35 - CC35 C35 C35-1 1550 F.113 - 1035 2 1.0503 C45 45 080M40 - CC45 C45 C45-1 1650 F.114 - 1045 2/3 1.0535 C55 55 070M55 - - C55 C55-1

36、1655 - - 1055 3 1.0601 C60 60 080A62 43D CC55 C60 C60-1 - - - 1060 1 1.7015 9SMn28 Y15 230M07 - S250 CF9SMn28 - 1912 11SMn28 SUM22 1213 1 1.0718 9SMnPb28 - - - S250Pb CF9MnPb28 - 1914 11SMnPb28 SUM22L 12L13 1 1.0722 10SPb20 - - - 10PbF2 CF10Pb20 - - 10SPb20 - - 2 1.0726 35S20 - 212M36 8M 35MF4 - - 1

37、957 F210G - 1140 1/2 1.0736 9SMn36 Y13 240M07 1B S300 CF9SMn36 - - 12SMn35 - 1215 1/2 1.0737 9SMnPb36 - - - S300Pb CF9SMnPb36 - 1926 12SMnP35 - 12L14 2/3 1.0904 55Si9 55Si2Mn 250A53 45 55S7 55Si8 55Si7 2085 56Si7 - 9255 2/3 1.0961 60SiCr7 - - - 60SC7 60SiCr8 60SiCr8 - 60SiCr8 - 9262 1 1.1141 Ck15 15

38、 080M15 32C XC12 C16 C16-2 1370 C15K S15C 1015 2 1.1157 40Mn4 40Mn 150M36 15 35M5 - - - - - 1039 1/2 1.1158 Ck25 25 - - - - C25-2 - - S25C 1025 2/3 1.1167 36Mn5 35Mn2 - - 40Mn5 - - 2120 36Mn5 SMn438(H) 1335 2/3 1.1170 28Mn6 30Mn 150M28 14A 20M5 C28Mn 28Mn6 - - SCMn1 1330 2/3 1.1183 Cf35 35Mn 060A35

39、- XS38TS C36 C36 1572 - S35C 1035 2/3 1.1191 45 Ck45 080M46 - XC42 C45 C45-2 1672 C45K S45C 1045 2/3 1.1203 Ck55 55 070M55 - XC45 C50 C55-2 - C55K S55C 1055 3/4 1.1213 Cf53 50 060A52 - XC48TS C53 C53 1674 - S50C 1050 3/4 1.1221 Ck60 60Mn 080A62 43D XC60 C60 C60-2 1678 - S58C 1060 91.1274 Ck101 - 060

40、A96 - - - - 1870 - SUP4 1095 10 1.3401 X120Mn12 - Z120M12 - X120M12 XG120Mn12 - - X120Mn12 SCMnH/1 - 9 1.3505 100Cr6 Gr15;45Gr 534A99 31 100C6 100Cr6 - 2258 F.131 SUJ2 52100 9 1.5415 15Mo3 - 1501-240 - 15D3 16Mo3KW 16Mo3 2912 16Mo3 - ASTM A20Gr.A 8 1.5426 16Mo5 - 1503-245-420 - - 16Mo5 16Mo5 - 16Mo5

41、 - 4520 5 1.5622 14Ni6 - - - 16N6 14Ni6 18Ni6 - 15Ni6 - ASTM A350LF5 9 1.5662 X8Ni9 - 1501-509;510 - - X10Ni9 10Ni36 - XBNi09 - ASTM A353 9 1.5680 12Ni19 - - - Z18N5 - 12Ni20 - - - 2515 6 1.5710 36NiCr6 - 640A35 111A 35NC6 - - - - SNC236 3135 6 1.5732 14NiCr10 - - - 14NC11 16NiCr11 - - 15NiCr11 SNC4

42、15(H) 3415 6 1.5752 14NiCr14 - 655M13;655A12 36A 12NC15 - 13NiCr12 - - SNC815(H) 3415;33106 1.6511 36CrNiMo4 - 816M40 110 40NCD3 38CrNiMo4(KB) - - 35CrNiMo4 - 9840 6 1.6523 21NiCrMo2 - 850M20 362 20NCD2 20NiCrMo2 - 2503 20NiCrMo2 SNCCM220(H) 86206 1.6546 40NiCrMo2 - 311-Type7 - - 40NiCrMo2(KB) 40NiC

43、rMo2 - 40NiCrMo2 SNC240 8740 6 1.6582 34CrNiMo6 40CrNiMoA 817M40 24 35NCD6 35CrNiMo6(KB) 35CrNiMo6 2541 - - 4340 6 1.6587 17CrNiMo6 - 820A16 - 18NCD6 - 17CrNiMo7 - 14CrNiMo13 - - 2 1.7015 15Cr3 15Cr 523M15 - 12C3 - 15Cr2 - - SCr415(H) 5015 6 1.7033 34Cr4 35Cr 530A32 18B 32C4 34Cr4(KB) 34Cr4 - 35Cr4

44、SCr430(H) 5132 6 1.7035 41Cr4 40Cr 530M40 18 42C4 41Cr4 42Cr4 - 42Cr4 SCr440(H) 5140 6 1.7045 42Cr4 40Cr - - - - - 2245 42Cr4 SCr440 51406 1.7131 16MnCr15 18CrMn (527M20) - 16MC5 16MnCr15 16MnCr15 2511 16MnCr15 - 5115 6 1.7176 55Cr3 20CrMn 527A60 48 55C3 - 55Cr3 - - SUP9(A) 5155 6 1.7218 25CrMo4 30CrMn 1717CDS110 - 25CD4 25CrMo4(KB) 25CrMo4 2225 55Cr3 SCM420;SCM430 4130 6 1.7220 34CrMo4 35CrMo 708A37 19B 35CD4 35CrMo4 34CrMo4 2234 34CrMo4 SCM432;SCRRM3 4137;4135 6 1.7223 41CrMo4 40CrMoA 708M40 19A 42CD4TS 41CrMo4 41CrMo4

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。