海工产品检验员手册

海工产品检验员手册

《海工产品检验员手册》由会员分享,可在线阅读,更多相关《海工产品检验员手册(27页珍藏版)》请在装配图网上搜索。

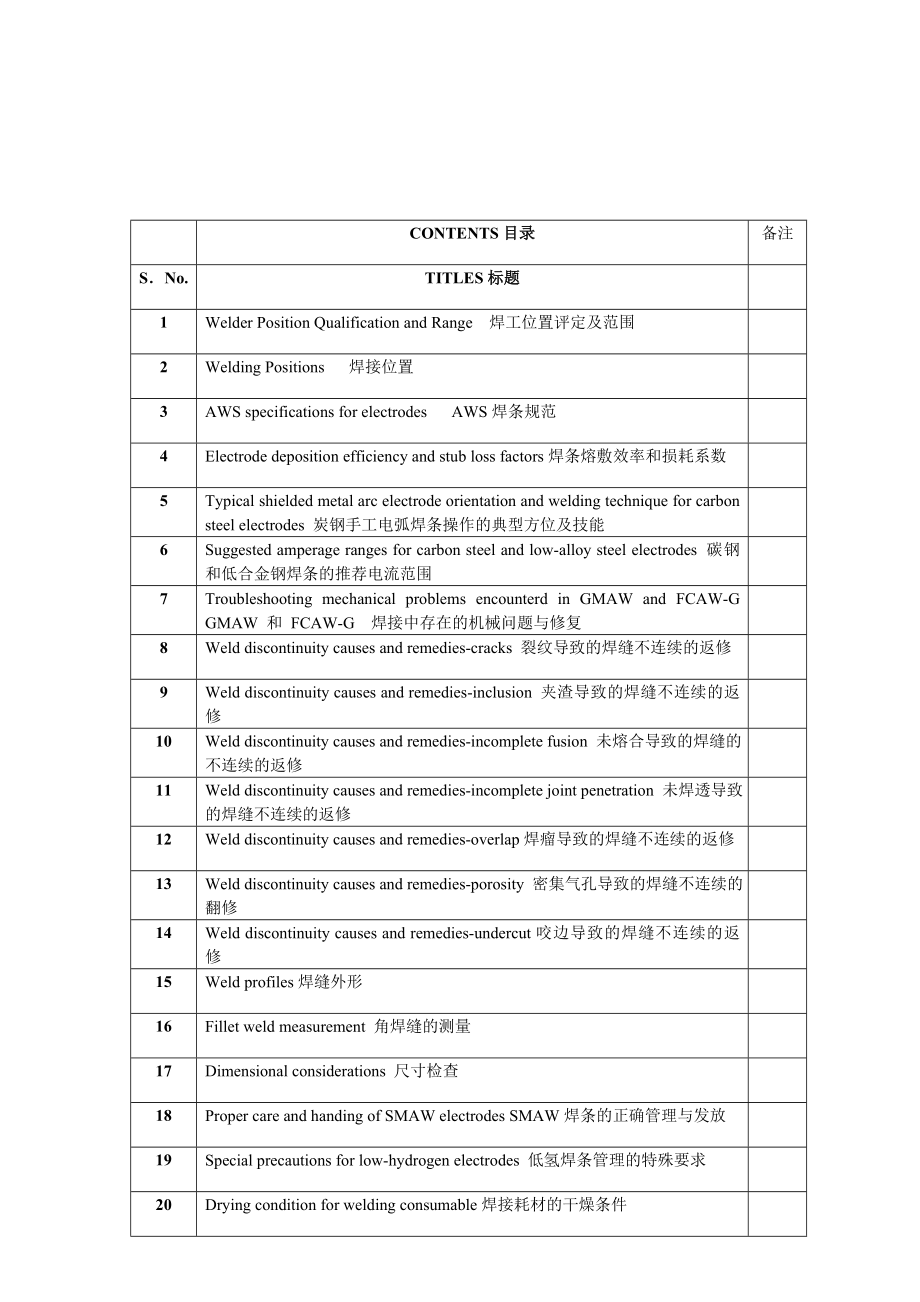

1、CONTENTS目录备注SNo.TITLES标题1Welder Position Qualification and Range 焊工位置评定及范围2Welding Positions 焊接位置3AWS specifications for electrodes AWS焊条规范4Electrode deposition efficiency and stub loss factors焊条熔敷效率和损耗系数 5Typical shielded metal arc electrode orientation and welding technique for carbon steel electr

2、odes 炭钢手工电弧焊条操作的典型方位及技能6Suggested amperage ranges for carbon steel and low-alloy steel electrodes 碳钢和低合金钢焊条的推荐电流范围7Troubleshooting mechanical problems encounterd in GMAW and FCAW-G GMAW 和 FCAW-G 焊接中存在的机械问题与修复8Weld discontinuity causes and remedies-cracks 裂纹导致的焊缝不连续的返修9Weld discontinuity causes and r

3、emedies-inclusion 夹渣导致的焊缝不连续的返修10Weld discontinuity causes and remedies-incomplete fusion 未熔合导致的焊缝的不连续的返修11Weld discontinuity causes and remedies-incomplete joint penetration 未焊透导致的焊缝不连续的返修12Weld discontinuity causes and remedies-overlap焊瘤导致的焊缝不连续的返修13Weld discontinuity causes and remedies-porosity

4、密集气孔导致的焊缝不连续的翻修14Weld discontinuity causes and remedies-undercut咬边导致的焊缝不连续的返修15Weld profiles焊缝外形16Fillet weld measurement 角焊缝的测量17Dimensional considerations 尺寸检查18Proper care and handing of SMAW electrodes SMAW焊条的正确管理与发放19Special precautions for low-hydrogen electrodes 低氢焊条管理的特殊要求20Drying condition

5、for welding consumable焊接耗材的干燥条件一、Welder position qualification and range 焊工位置评定及范围Qualification评定Range qualified评定范围1F2F3F4F5F1G2G3G4G5G6G6GR3F4F3G4G5G6G6GRWelding positionsgroove(plate)焊接位置坡口(板)1G 2G3G4GWelding positionsfillet(plate)焊接位置角焊缝(板)1F(FLAT平焊) 2F(HORIZONTAL横焊) 3F(VERTICAL立焊) 4F(OVERHEAD仰焊

6、)Welding positions pipe焊接位置管1G ROTATED旋转 2GWelding positions pipe (continued)焊接位置管5G 6G 6GR; T.K.Y 连接二、AWS Specifications for electrodes AWS焊条规范Type of electrode焊条类型AWS specifications AWS规范SMAWFCAWSAWGTAW,GMAWCarbon steel 碳钢5.15.205.175.18Low alloy steel 低合金钢5.55.295.235.28Stainless steel 不锈钢5.45.22

7、5.95.9 , 5.22Aluminium and its alloy 铝和铝合金5.35.10Copper and its alloy 铜和铜合金5.65.7Nickel and its alloy 镍和镍合金5.115.145.14三、Electrode deposition efficiency and stub loss factors焊条的熔敷效率和损耗系数CLASS AVERAGE EFFICIENCY * STUB LOSS *等级 平均熔敷效率端头损耗E6010 63.8% STUB(残余长度) 5/32E6010 14in E6011 68.5% LENGTH %DEPOS

8、IT(沉淀物) %LOSSE6012 66.9% 2in 63.8 36.2E6013 66.8% 3in 58.5 41.5E7014 64.6% 4in 53.2 46.8E7016 62.8% 5in 47.9 52.1E7018 69.5% 6in 42.6 57.4E6020 65.2% WEIGHT OF WELD METAL(焊接金属重量)E7024 66.8% EFFICIENCY熔敷效率WEIGHT OF ELECTRODE USED INCLUDING STUB(使用焊条的重量,包括残余部分)E7027 68.3% * INCLUDES 2 in STUB LOSS包括残余

9、部分的2in* E6010 IS 71.57% EFFICIENCY ,LOSS DUE TO SLAG , SPATTER AND SMOKE E6010熔敷效率只有71。57% ,由于焊渣、飞溅和烟的损失四、Typical shielded metal arc electrode orientation and welding technique for carbon steel electrodes 碳钢手工电弧焊条操作的典型方位与技能Type of joint (接头类型)Position of welding焊接位置Work angle degrees操作角度 Travel angl

10、e degrees*运条角度Technique of welding焊接技能Groove坡口Flat平焊905-10*Backhand 反手Groove坡口Horizontal横焊80-1005-10Backhand反手Groove坡口Vertical-up立向上905-10Backhand反手Groove坡口Overhead仰脸905-10Backhand反手Fillet 角焊Horizontal横焊455-10*Backhand反手Fillet 角焊Vertical-up立向上35-555-10Forehand正手Fillet 角焊Overhead 仰脸30-455-10Backhand反

11、手* Travel angle may be 10to30for electrodes with heavy iron powder coatings. 对于重铁粉药皮的焊条运条角度可以成10-30度的角五、Suggested amperage range for carbon steel and low-alloy steel electrodes碳钢和低合金钢焊条的推荐电流范围Electrode 焊条Diameter(in)尺寸(英寸)Amperage (A)电流E6010 and E60113/321/85/323/167/3250-70100-130140-170160-190190-

12、230E60121/85/323/167/321/4100-130165-200220-240275-320320-380E60133/321/85/323/167/3260-75100-135140-180180-220250-290E70183/321/85/323/167/3270-110120-160150-200200-275250-340E70241/85/323/167/321/4140-180180-240245-290320-360400-450六、Troubleshooting mechanical problems encountered GMAW and FCAW-GG

13、MAW 和 FCAW-G 焊接中存在的机械问题与修复Problem 问题Possible cause可能存在的原因Remedy 修复Irregular wire feed and burnback送丝不均及烧穿Insufficient drive roll pressure送丝滚轮压力不足Contact tube plugged or worn焊嘴堵塞或者损坏Kinked electrode wire 焊丝打结Coiled gun cable把线缠绕Conduit liner dirty or worn导管衬垫太脏或者损坏Conduit too long送丝软管太长Adjust调节Clean

14、or replace 清洁或者更换Cut out ,replace spool去除打结部分更换线轴Straighten cable ,hang the wire feeder捋直把线,将送丝装置停止Clean or replace清洁或更换Shorten or use push-pull drive system截短或者用自动伸缩系统Electrode wire wraps around drive roll(birdnesting)焊丝在送丝滚轮和软管进口处发生卷曲或打结Excessive feed roll pressure送丝滚轮压力过大Incorrect conduit liner o

15、r contact tip衬垫或者导嘴不匹配导致Misaligned drive roll or wire guides 送丝滚轮和导丝装置不在一条线上Restriction in gun or gun cable焊枪或把线受阻Adjust调节Match liner and contact trip to electrode size 使用与焊丝尺寸一致的衬垫和导嘴Check and align properly检查并正确调整Remove restriction 去除阻力Heavily oxidized weld deposit熔敷金属严重氧化Air/water leaks in gun an

16、d cable空气或水渗入焊枪或把线中Restriction shield gas flow 保护气体流动受限Check for leaks and repair or replace as necessary必须检查漏点并修理,或更换Check and clean nozzle检查清洁焊枪嘴Electrode wire stops feeding while welding在焊接当中停止送丝Excess or insufficient drive roll pressure送丝滚轮压力过大或者不足Wire drive rolls misaligned or worn送丝滚轮方向偏离或者损坏L

17、iner or contact tube plugged衬垫或软管堵塞Adjust 调节Realign and/or replace重新对接或者更换Clean or replace清洁或更换Wire feeds but no gas flows送丝时没有保护气流入Gas cylinder is empty气瓶内气体不足甚至没气Gas cylinder value closed气瓶阀门关闭Flow meter not adjusted气体计量表未调整Restriction in gas line or nozzle气管或枪口被堵塞Replace and purge lines before we

18、lding焊接前更换气瓶 Open cylinder valve打开气瓶阀门 Adjust to give flow specified in the procedure按照制定的调整程序调整气体流量Check and clean 检查并清理 Porosity in the weld bead焊接中出现气孔Failed gas valve solenoid电磁气阀失灵Gas cylinder valve closed 气瓶阀门关闭Insufficient shielding gas flow 保护气体流量不足Leaks in gas supply lines(including the gun

19、)气管泄漏(包括焊枪)Repair or replace 修复或者更换Turn valve on 打开阀门Check for restrictions in gas line or nozzle and correct检查受限气管或喷嘴并纠正Check for leaks(especially at connections)and correct 查找泄漏并修复(特别注意连接处)Wire feed motor operates but wire does not feed 送丝器启动,但是焊丝并未伸出Insufficient drive roll pressure送丝滚轮压力不足 Incorr

20、ect wire feed rolls送丝滚轮不匹配Excessive pressure on wire spool brake引线卷轴的制动压力过大Restriction in the conduit liner or gun 焊枪与软管不匹配Incorrect liner or contact tube软管与导丝接头不匹配Adjust 调节Match feed rolls to wire size and type使用尺寸型号一致的送丝滚轮Decrease brake pressure 减小制动压力Check liner and contact tip 检查接头垫片Clean and/or

21、 replace清理或者更换Check and replace with correct size检查更换合适的尺寸Welding gun overheats焊枪发热Pinched or clogged coolant line 冷却管受挤压或者堵塞Low coolant level in pump reservoir 冷却液低于泵以下Water pump not functioning correctly水泵不能正常工作Check and correct 检查修正Check and add coolant as necessary按照要求检查增加冷却液Check and repair or

22、replace检查并修理或者更换七、Troubleshooting electrical problems encountered in GMAW and FCAW-G GMAW and FCAW-G 焊接中电气问题的修复Problem 问题Possible cause可能存在的原因Remedy 修复Difficult arc starting起弧困难Wrong polarity电路错误Poor work lead connection工作导线连接不好Check polarity; reverse leads if necessary检查电路,如果需要颠倒导线Secure work lead

23、connection正确连接Irregular wire feed and burnbackl送丝不均,烧穿Power circuit fluctuations 电压不稳定Polarity wrong 电路错误Check line voltage 检查电压Check polarity ; reverse leads if necessary 检查电路,如果需要颠倒导线Welding cables overheating 焊接时电缆发热Cables are too small or too long 电缆太细或者太长Cable connections loose 电缆连接松弛Check curr

24、ent carrying requirementsreplace or shorten if necessary 检查电流输送要求更换或者缩短如果需要Tighten紧固No wire feed speed control 送丝速度控制装置损坏Broken or loose wires in control circuit 控制装置损坏或松散Bad P.C.board in governor 控制面板损坏Check and repair if necessary如果需要检查修复更换控制面板Unstable arc电弧不稳Cable connections are loose 电缆连接松弛Tigh

25、ten connections紧固线路Electrode wont feed不送丝Control circuit fuse blown 控制系统保险丝损坏Fuse blown in power source电源保险丝损坏Defective gun trigger switch or broken wire leads焊把触发开关损坏或者导线连接断开Drive motor burned out驱动电机烧坏Repair fuse修理保险丝Replace fuse更换保险丝Check connections ; replace switch 检查线路;更换开关Check and replace检查更

26、换 Wire feeds but no gas flows送丝时没有保护气流入Failure of gas valve solenoid气阀螺旋管失灵Loose or broken wires to gas valve solenoid 气阀螺旋管松动或者损坏Replace 更换Check and repair if necessary 检查如果需要进行修理Electrode wire feeds but is not energized (no arc)焊丝不产生电弧Poor workpiece connection 焊件连接不好Loose cable connections 导线连接松散P

27、rimary contactor coil or points defective控制继电器的触点烧损或其线圈烧损Contactor control leads broken电流接触器的控制电路损坏Tighten if loose ; clean work of paint, rust, etc.固定;清理焊接区域的油漆,刷锈等Tighten 拧紧Repair or replace修理或者更换Repair or replace修理或者更换Porosity in weld 焊缝产生气孔Loose or broken wire to gas solenoid valve气阀螺旋管松动或已损坏Rep

28、air or replace修理或者更换八、Cracks 裂纹A crack is defined as “A fracture type discontinuity characterized by a sharp tip and a high ratio oflength and width to opening displacement.” Cracks are usually considered the most severe discontinuity because of their tendency to propagate under stress. Cracks are u

29、sually furtherdescribed by their location geometry ,time of occurrence ,or common usage terms ; see figure below for AWS crack terminology .裂纹被定义为: “断裂形不连续,表现为端部尖锐的长宽比很高的位移开裂.” 裂纹通常被认为是严重的不连续,因为在应力的作用下将会延裂纹方向延伸.通常根据裂纹出现的位置和出现的时间或者常用的使用术语进行描述;见下面的插图:AWS裂纹术语学.(A) (B)LEGEND:1. CRATER CRACK弧坑裂纹 2.FACE C

30、RACK表面裂纹 3.HEAT-AFFECTED ZONE CRACK热影响区裂纹 4.LAMELLAR TEAR层状撕裂 5.LONGITUOINAL CRACK纵向裂纹 6.ROOT CRACK根部裂纹 7.ROOT SURFACE CRACK根部表面裂纹 8.THROAT CARCK焊喉裂纹 9.TOE CRACK焊趾裂纹 10.TRANSVERSE CRACK横向裂纹 11.UNDERBEAD CRACK母才内部裂纹 12.WELD INTERFACE CRACK焊接熔合面裂纹 13.WELD METAL CRACK 焊缝裂纹Common causes and remedies of

31、cracking 通常情况下出现裂纹的原因及修复Causes: weld metal joint 原因: 焊接金属接头Remedies: weld metal cracking 修复: 焊接金属裂纹Highly rigid joint 高强度接点Preheat 预热Relieve residual stresses mechanically(peening)机械去除残余应力(锤击)Minimize shrinkage stresses using backstep or block welding sequence采取分段退焊或者分层退焊的方法减小收缩应力Excessive dilution

32、过度稀释Change welding current and travel speed 检查焊接电流和运行速度Weld will covered electrode negative ;butter the joint faces prior to welding 焊接采用药皮焊条直流反接,焊接前接头表面堆焊Defective electrodes 焊条损坏Change to new electrode ; bake electrodes to remove moisture更换焊条,烘烤焊条去除水汽Poor fit-up 组对不当Reduce root opening ; build up

33、the edges with weld metal . increase root opening减小根部间隙;使用焊接金属堆焊. 增大根部间隙Small weld bead 焊缝太小Increase electrode size ; raise welding current ; reduce travel speed增加焊条尺寸,增加焊接电流,降低焊接速度High sulfur base metal含硫很高的母材Use filler metal low in sulfur使用低硫填充金属Angular distortion 角变形Change to balanced welding on

34、both sides of joint 在接头俩边采用对称焊接Crater cracking弧坑裂纹Fill crater before extinguishing the arc ; use a welding current decay device when terminating the weld bead 在电弧熄灭前将弧坑填满, 在焊接结束时使用焊接电流衰减装置Causes : heat-affected zone原因: 热影响区Remedies : heat-affected zone 修复: 热影响区Hydrogen in welding atmosphere焊接环境中含氢Us

35、e low-hydrogen welding process ; preheat and hold for 2 hour after welding or postweld heat treat immediately 使用低氢焊接程序;焊前预热并且在焊后缓冷俩小时或者立刻采用焊后热处理Hot cracking热裂纹Use low heat input ; deposit thin layers ; change base metal and/or filler metal 降低热输入;减薄层接焊道;更换母材和(或)填充金属Low ductility延展性低Use preheat ; anne

36、al base metal prior to welding使用预热;在焊接前母材退火处理High residual stresses很高的残余应力Redesign weldment ; change welding sequence ; apply intermediate stress-relief heat treatment 重新设计焊接件;改变焊接次序;应用热处理的方法消除应力High hardness高硬度Preheat : increase heat input ; heat treat without cooling to room temperature 预热;增加热输入;温

37、度不低于室温时进行热处理Brittle phases in the microstructure在宏观显微结构下呈易碎的相图Solution heat treat prior to welding 在焊接前通过加热固熔退火九、Inclusions夹渣Inclusions are defined as entrapped foreign solid material , such as slag , flux , tungsten , or oxide .” The inclusions may be found as single particles , aligned particles .

38、 Slag inclusions arefrequently found on the weld surfaces , or along the toes of the weld due to improper cleaning techniques . Tungsten inclusions are usually subsurface . Examples of inclusions are shown below. Inclusions on the surface can be detected by VT ; subsurface inclusions require UT or R

39、T.Slag inclusions (darkened areas)内部夹渣(发暗的区域)Repairs of inclusions on the surface require removal by gouging or grinding ,welding if required and reinspection by appropriate NDT method .subsurface inclusions require removal by gouging or grinding .followed by weld repair and reinspection .夹渣被定义为: “陷

40、在焊缝中的外界固体物质,比如焊渣,焊剂,钨,或氧化物. 夹渣可能以单个颗粒或线形颗粒出现. 由于清理方法的不正确夹渣经常出现在焊缝表面或焊趾处。 夹钨出现在焊缝内部。在表面的夹渣可以通过目视检查来发现;内部夹渣需要通过超声波或者X射线来检查发现。表面的夹渣返修可以通过气刨或者打磨去除,修补处如果需要可以使用适当的NDT方法来重新检验。焊缝内部夹渣需要通过气刨或打磨来去除,焊接修补并且重新检验。Common Causes and Remedies of Slag Inclusions通常情况下出现夹渣的原因及返修Causes 原因Remedies修复Failure to remove slag

41、没有清理焊渣Clean surface and previous weld bead 在焊前清理焊道Entrapment of refractory oxides 高熔点的氧化物Power wire brush the previous weld bead 在施焊前用动力钢丝刷清理焊道Tungsten in the weld metal 焊接金属中含钨Avoid contact between the electrode and the work ; use larger electrode避免电极与焊件的接触;使用较大的电极Improper joint design 接头设计不合理Incre

42、ase groove angle of joint 增大坡口对接角度Oxide inclusions 氧化物夹渣Provide proper gas shielding 使用正确的保护气Slag flooding ahead of the welding arc焊渣溢流到焊接电弧的前面Reposition work to prevent loss of slag control通过重新装配来控制焊渣的流失Poor electrode manipulative technique焊条操作技术落后Change electrode or flux to improve slag control通过更

43、换焊条或焊剂来控制焊渣Entrapped pieces of electrode covering 焊条的药皮脱漏Use undamaged electrodes使用未损坏的焊条十、Incomplete fusion未熔合Incomplete fusion is defined as”A weld discontinuity in which fusion did not occur between weld and fusion faces or adjoining weld beads .”incomplete fusion (1F)can occur on both groove wel

44、ds and fillet welds where the weld does not extend to the joint root . see the figure below.未熔合被定义为:焊缝和坡口面或者相邻焊缝面未发生熔合的焊接不连续。未熔合(1F)出现在坡口焊和填角焊中的接头根部。见下图:(A)(B) (C)Detection of incomplete fusion using VT is possible if the discontinuity location is visible on the surface ; oblique angle lighting and

45、10 magnification aid the inspector . Generally ,1F subsurface and is found using UT or RT methods.如果未熔合明显的在表面可以通过目视检验发现;从斜角方向用光照射或10倍放大镜可以帮助检验。通常在表面以下的未熔合需要通过UT和RT来发现。Repairs of incomplete fusion require removal of the discontinuity by gouging or grinding , followed by weld repair and final inspecti

46、on.返修未熔合需要气刨或者打磨来去除缺陷,焊接返修并且做最终检验。Common causes and remedies of incomplete fusion通常产生未熔合的原因及修复Causes原因Remedies修复Insufficient heat input , wrong type of size of electrode , improper joint design , or inadequate gas shielding热输入量不足,焊条型号不对,接头设计不合理或者保护气体不合适Follow correct welding procedure specification按

47、照正确的焊接程序施焊(WPS)Incorrect electrode position 焊条角度不正确Maintain proper electrode position 保持焊条的正确角度Weld metal running ahead of the arc焊缝金属流到了电弧的前边Reposition work lower current or increase weld travel speed重新装配降低电流或者加快焊接速度Trapped oxides or slag on weld groove or weld face 焊接坡口或者焊缝表面有氧化物或者焊渣Clean weld sur

48、face prior to welding在焊接前清洁焊缝表面十一、Incomplete joint penetration未熔透Incomplete joint penetration is defined as “A joint condition in a groove weld in which weld metal does not extend through the joint thickness .”Note that it applies to groove welds only ,not filled welds . Examples of incomplete joint

49、 penetration(IJP)are shown in the following figures .未熔透被定义为:在坡口焊中焊接金属没有完全穿透坡口的接头厚度。以上定义仅适应于坡口焊,填角焊不适用。未熔透实例见下图: Incomplete joint penetration can easily be found by VT if the rood of the groove weld is visible ; oblique angle lighting assists in its detection . For groove welds with the root not vis

50、ible . UT or RT are required for detection . Repairs for IJP , when access to the root of the groove weld is possible:未熔透如果发生在表面通过目视检验会很容易,斜角方向用光照射可以帮助发现缺陷。如果坡口根部不容易看见,就需要用UT或者RT来检查。返修未熔透,当在坡口根部时:1. gouge or grind root to an oval , open shape , permitting access to root .气刨或者打磨根部成椭圆型,形状接近根部焊缝2. weld

51、 , followed by appropriate NDT method .焊接,并且使用适当的NDT方法来检验Repairs for up , where access to the root is not possible :当不能接近根部时从上面返修1. gouge or grind from the weld face the remove entire weld down to joint root从焊缝表面气刨或者打磨至坡口的接头根部2. weld followed by appropriate NDT method.焊接,并且使用适当的NDT方法检验Common causes

52、and remedies of incomplete of incomplete joint penetration通常导致未熔透的原因及修复Causes 原因Remedies修复Excessively thick root face or insufficient root opening 根部钝边太厚或者根部间隙不够Use proper joint geometry使用适当的接头形式Insufficient heat input 热输入量不够Follow welding procedure specification按WPS 焊接Slag flooding ahead of welding

53、 arc焊渣溢到焊接电弧的前面Adjust electrode or work position 调整电极或者焊接方向Electrode diameter too large 焊条直径太大Use smaller electrodes in root or increase root opening 使用小直径的焊条或者增大根部间隙Misalignment of second side weld俩边未对准Improve visibility or backgouge 尽可能改进或者反面气刨Failure to backgouge when specified 在对指定的区域背面气刨失败Back

54、gouge to sound metal if required in welding procedure specification如果需要按照WPS 对母材深度背面气刨Bridging or root opening 支撑或根部间隙Use wider root opening or smaller electrode in root pass增大根部间隙或者使用小直径焊条封底焊接 十二、Overlap焊瘤Overlap is defined as “ the protrusion of weld metal beyond the weld toe or weld root .” examp

55、le are shown below for fillet and groove welds . 焊瘤被定义为“在焊趾或焊跟处焊接金属外溢突出。”关于填角焊或坡口焊焊瘤事例见下图:Detection of overlap is usually found by VT if the surface are visible to the eye ; oblique lighting and 10x magnification are helpful . PT and MT may be require to inspect questionable areas.Repair include rem

56、oval of overlap by gouging or grinding as a minimum , and may require weld repairs to the gouged or areas , followed by reinspection using appropriate NDT method.如果焊瘤明显的在表面通常通过目视检验就可以发现,使用斜光照射或10倍放大镜检查是非常有用的。对可疑的区域可以通过PT和MT检验。返修包括通过气刨或者打磨把焊瘤处理到最小,可能在气刨的区域需要焊接返修,通过适当的NDT方法来重新检验。Common causes and reme

57、dies of overlap通常产生焊瘤的原因及返修Causes 原因Remedies 修复Slow travel speed焊接速度太慢Increase travel speed提高焊接速度Poor electrode manipulation 焊条操作太差Additional welder training 加强焊工的培训Gravity 重力原因Additional welder training 加强焊工的培训十三、Porosity气孔Porosity is defined as “cavity type discontinuities formed by gas entrapment

58、 during solidification or in a thermal spray deposit .” The porosity may be surface or subsurface , a single cavity aligned , or clustered, and is represented by the following figures .气孔被定义为“孔穴型不连续由于气体在金属凝固时或者热量散失前没有溢出形成的。”气孔可能存在于表面或者内部。下图描述了单一的线形气孔和密集气孔:表面分散气孔内部密集气孔Repairs of porosity consist of r

59、emoval of the affected area by gouging or grinding , weld repair, followed by reinspection by the appropriate NDT method .气孔的返修包括通过气刨或者打磨将受影响的区域去掉进行焊接返修,通过适当的NDT方法来重新检验。Common causes and remedies of porosity通常导致气孔的原因及修复Causes 原因Remedies修复Excessive hydrogen , nitrogen , or oxygen in welding atmospher

60、e在焊接气体中含大量的氢、氮、氧气Use low-hydrogen welding process : filler metals high in deoxidizers ; increase shielding gas flow 使用低氢焊接工艺:含高去氧剂的填充金属;增大保护气体的流量High solidification rate 凝固速率太高Use preheat or increase heat input 使用焊前预热或者增加热输入量。Dirty base metal母材不干净Clean joint faces and adjacent surfaces清洁接头面及相邻区域Dirty filler wir

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。