Automatic-Monitoring-and-Control-System-of--Industrial-Sewage-Treatment

Automatic-Monitoring-and-Control-System-of--Industrial-Sewage-Treatment

《Automatic-Monitoring-and-Control-System-of--Industrial-Sewage-Treatment》由会员分享,可在线阅读,更多相关《Automatic-Monitoring-and-Control-System-of--Industrial-Sewage-Treatment(11页珍藏版)》请在装配图网上搜索。

1、 自动监测及工业污水处理控制系统摘要:由于能源的匮乏,人类应该节约资源,甚至回收再利用这些资源。从严肃的角度看,水资源的污染和日益减少的可使用的水成为现在需要研究重要的问题。在本文中,利用工业废水的水处理程序、可编程控制器、MCGS组态软件以及PROFIBUS总线,以便进行监测和控制污水处理。关键词:技术过程自动控制,可编程控制器,现场总线,MCGS软件1 简介随着现代科学的迅猛发展,所有的国家都在世界各地进行工业生产。在同一时间,水资源被破坏的越来越严重。随着人民生活质量的提高,人们更多的是关注环境的保护,尤其是工业废水处理已成为一个非常重要的研究课题。目前,在我国,对于保护水资源和污水处理

2、也并非十全十美,尽管已经出现了一系列的法律和标准,但对于污染水源必须加以处理,从根本改善水质。早期的污水处理技术主要采用现场检测和技术人员的调试。由于污水处理是复杂的,需要用实时项指标检测出多样、复杂的例子。在出水pH值、进水流量、溶解氧含量、曝气池等指标中,如果所有指标的实时检测一个接一个,这将花费太多人力和物力,操作成本高,经济效益差,结果很不理想。因此,引入计算机监控污水处理使其能够节省资源,提高了安全性,可靠性和治疗效果,具有广阔的发展前景。在这方面,外国国家制定了较为完善的制度,相对而言,国内废水处理技术相对比较落后。因此,许多大型污水处理厂采用外部系统一体。由于考虑到造价过于昂贵,

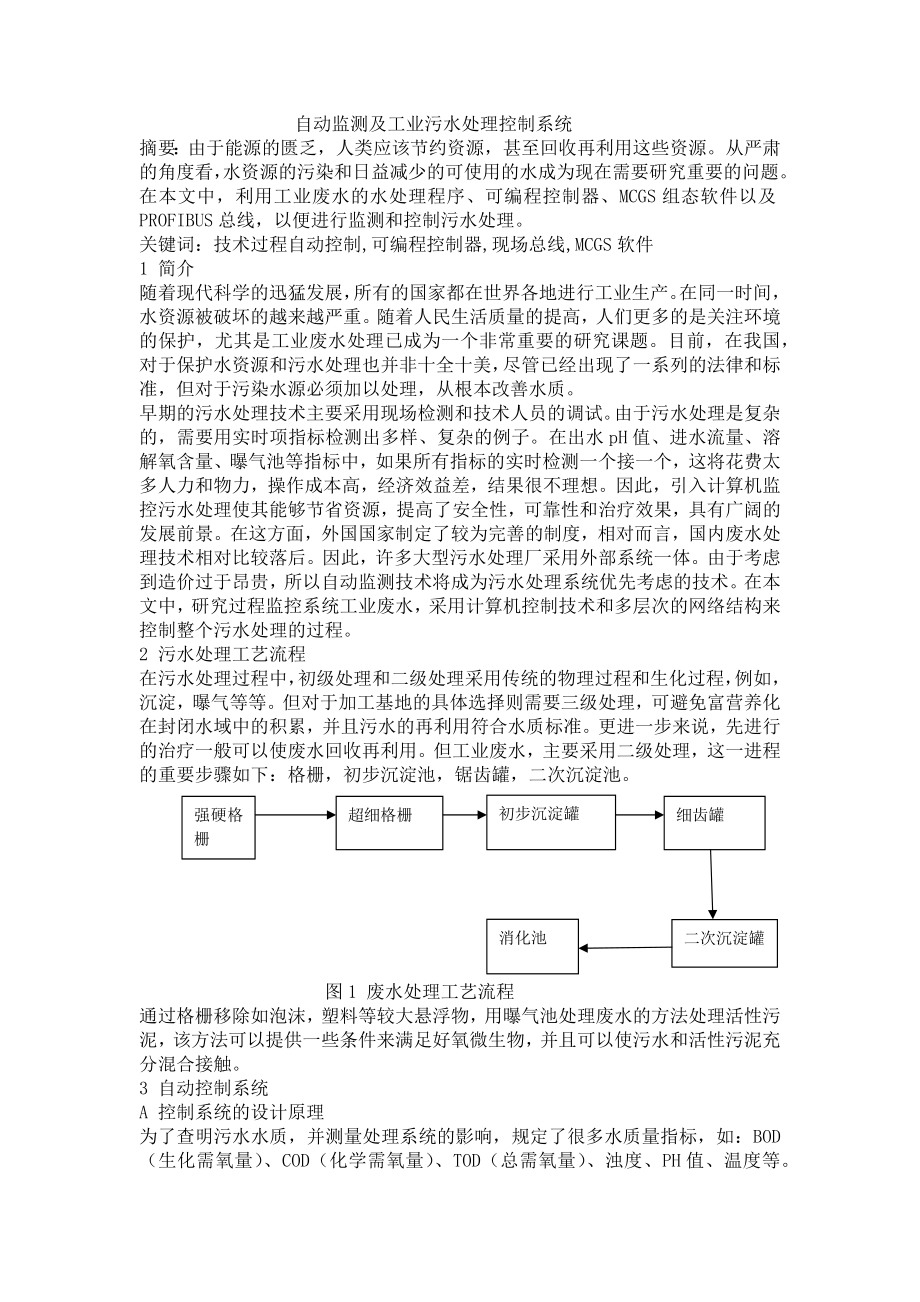

3、所以自动监测技术将成为污水处理系统优先考虑的技术。在本文中,研究过程监控系统工业废水,采用计算机控制技术和多层次的网络结构来控制整个污水处理的过程。2 污水处理工艺流程在污水处理过程中,初级处理和二级处理采用传统的物理过程和生化过程,例如,沉淀,曝气等等。但对于加工基地的具体选择则需要三级处理,可避免富营养化在封闭水域中的积累,并且污水的再利用符合水质标准。更进一步来说,先进行的治疗一般可以使废水回收再利用。但工业废水,主要采用二级处理,这一进程的重要步骤如下:格栅,初步沉淀池,锯齿罐,二次沉淀池。初步沉淀罐强硬格栅细齿罐消化池超细格栅二次沉淀罐 图1 废水处理工艺流程通过格栅移除如泡沫,塑料

4、等较大悬浮物,用曝气池处理废水的方法处理活性污泥,该方法可以提供一些条件来满足好氧微生物,并且可以使污水和活性污泥充分混合接触。3 自动控制系统A 控制系统的设计原理为了查明污水水质,并测量处理系统的影响,规定了很多水质量指标,如:BOD(生化需氧量)、COD(化学需氧量)、TOD(总需氧量)、浊度、PH值、温度等。因此,需要标准衡量这些指标,例如,水温、PH值、BOD、COD、TOD、SS(悬浮物)等。然后,工作人员通过比较可控开关的运行状态,来确定相关的测量值和假设值。因为系统不仅需要控制过程简便,也需要检测过程简便,所以显示器应设置在现场控制中心的区域。在不同的站点,数据应提交给现场总线

5、网络。尽管无线传感器网络技术大大降低了电缆和环保要求,但较先进的技术造价昂贵,现阶段并不能广泛使用。在本文中,选择相对传统的测量方法,研究污水处理系统,从提高控制水平的立场和促进员工为客户服务。B模块的控制系统像阀门、开关信号、电机和水泵等都是被单个的控制,每一个过程都应考虑到每个模块的状态,根据各自的技术和性能的需求去制定自己的控制流程和实现方法。例如,在网格沉沙池中根据加工水量设置参数。当电网前后液位差大于或等于设定的参数时,网格可以实施连锁启动和自动停止。超声波液位计应设置在网格的前后处,然后工作人员可以通过PLC控制启动和停止。提取沉积物液位差异开关控制网格PLC 图2 电网控制系统在

6、初步沉淀池模块中,用安装在进水管道的电磁流量计来测量进水流量,并在显示器上显示数据。根据对技术的要求,通过取水泵站液位值进行预处理,然后进一步控制所有取水泵站。 根据运行状态,让所有水泵运行保持相对平衡。安装PH计测量器显示PH值,以应对waterquality是否满足工艺要求。如果没有,然后发出警告信号。安装氧化还原电位(ORP)在线测定仪,溶解氧(DO)在线测定仪,并检测污泥浓度。检测到的ORP的数值和DO值的数值和鼓风机的曝气强度,这样可以节省资源。当污泥密度相对较高时,系统将减少二次沉淀池中的回流污泥量,并且使污泥排放量增加。当密度相对低时,在一定程度上会增加回流污泥量。设置一个在二次

7、沉淀,它可以测量污泥的上线水平。当数值偏高时,可以调整泥浆吸盘,刮板,排泥自动泵等,以避免沉积物污泥的破坏和堆放,防止排放太多剩余污泥。最后,在最后的消化池中安装一个PH计,COD在线测定仪,污泥浓度监测。与此同时,显示这些数据,使工作人员能够采取在任何时间控制的水质量,然后确定出水标准。C 整个硬件系统PLC是一种新型工业控制装置,它可以适应小批量的生产品种,并开发速度快。由于其灵活的控制性能,所以它广泛适用于所有的自动化工业领域。它的可靠性能适应多种工业环境。根据数字电子类电脑操作系统,它也适用于工业的特殊环境。可编程控制器采用顺序控制、定时、计数、算术操作等来控制各种设备和生产过程。PL

8、C的主要功能是开关的逻辑顺序控制,模拟控制,信号通讯。它可以扮演一个与PC交流的功能较低的电脑。为了控制和完善信息管理的整个过程,PLC具有相同的或更高的水平。 显示PLC模块模块检测信号工控机工业计算机图3 控制系统硬件框图PLC的主站可连接上电脑,然后,可显示图形,分析趋势,管理数据,诊断故障,控制报警等。它具有高层次的语言编程功能。此外PLC与工控机(IPC)可以构成一个强大的开放式控制系统。这里的IPC工业计算机选择Advantech610.D选择控制方法污水处理过程是一个多变的非线性的随机的复杂过程。传统控制方法难以实现实时监控和检测。近年来,污水处理一般采用智能控制,人工控制,专用

9、系统的智能控制。在本文中,选择控制方法是对专用系统的智能控制。对于不同特色,不同阶段,不同特点的经营模块,可以使用不同的控制方法,从而达到最好的效果。E现场总线由于相对分散的功能模块,开发了现场总线技术,这是一个先进的现场工业技术,真正实现分布式控制和集中管理。由于必要的视图系统需要实时性,可靠性和稳定性。并且对负荷具有较高的要求,因此选择PROFIBUS现场总线作为PLC与工控机的通讯线路,其中工控机使用的RS - 485技术。4 软件设计系统上位计算机软件监控系统使用MCGS组态软件,这是一种基于组态软件系统Windows平台,用于构建和迅速生成计算机控制系统。 MCGS组态软件提供了一个

10、完整的项目与开发平台,为用户解决工程问题。例如,现场数据采集,实时和历史数据加工,预警,安全机制,过程控制,动画显示,趋势曲线和报表输出,以及企业监控网络等。此外,它操作方便,具有良好的能见度,可靠性高,性能高的突出特点,所以很适合污水处理。在这个系统中,主要功能设计如下:为PLC控制处理的模块进行配置,这些模块可以给工作人员带来便利并且及时改变系统的运行状态和系统参数;显示液位值,运行时间,PH值,氧化还原电位测量,溶解氧测量,泥浆密度等;显示屏幕,用灯光和声音报警,提供工作状态的选择性,如自动和手动接口操作;查询历史数据; Intranet连接。 图4 软件系统框图5 结束语以污水处理工艺

11、为基础,根据它的控制要求,通过PLC与工业计算机的结合建立基本的控制系统。通过检测液位、泥浆密度、OD值、ORP值和其他信号,来控制运行状态和运行时间。目的是保证水的质量标准是否满足需求。同时,使用MCGS组态软件,开发实时监控系统自动或手动操作,这样才能确保数据、检测、报警、查询历史数据和其他数据带有人性化功能。Automatic Monitoring and Control System ofIndustrial Sewage TreatmentAbstractDue to limitation of the energy, human should save resources, eve

12、n reuse the resources. In view of the serious pollution of water resources, as well as the increasing reduction of available water, sewage treatment becomes important issue to be studied nowadays. In this paper, considering industrial waste water processing procedures, utilize PLC, MCGS software as

13、well as PROFIBUS bus in order to carry out the monitoring andcontrol of sewage treatment.Keywords-Technological process; Automatic control; PLC; Field Bus; MCGS software I. INTRODUCTIONWith the rapid development of modern science and technology, all the countries throughout the world are developing

14、industrial production. At the same time, water resources are damaged more and more seriously. With the improvement in the quality of peoples lives, human gradually pay more attention on environmental protection, especially industrial wastewater treatment has become a very important research issue. A

15、t present, in our country, the protection of water resources and sewage treatment are also not perfect enough, although there have been a series of laws and standards to protect resources, the contaminated water sources must be processed in order to improve the quality of waterfundamentally.Early se

16、wage treatment technology mainly adopts on-site detection and debugging by technicians. Because the sewage treatment is complex, and the item indicators needing real-time detection are various and complicated, for examples, the effluent PH value, influent flow, dissolved oxygen content in the aerati

17、on pool, and so on 1, if detect all indicators real time one by one, it will cost too much labor and material, operation cost is high, economic benefit is poor, and the result of process is not ideal. As a result, computer monitoring is introduced to the sewage treatment gradually, so that it saves

18、resources, improves security, reliability and treatment results greatly, and has a wide development prospect. In this aspect, foreign countries have developed a relatively perfect system, comparatively speaking, development of the domestic wastewater treatment technology compares relatively backward

19、. Therefore many of the large treatment plants adopt a foreign system integrally, but considering the expensive is too high, the development of auto-monitoring technology for domestic sewage treatment system is becoming a matter ofpriority.In this paper, study the process of monitoring system by ind

20、ustrial wastewater, using computer control technology and multi-level network structure to control the whole process of wastewater treatment without man on duty 2. II. TECHNOLOGICAL PROCESS OF SEWAGE TREATMENTRelated to wastewater treatment process, primary treatment and secondary treatment adopt tr

21、aditional physical-chemical and biochemical processes, such as, sedimentation, aeration and so on. But the specific selections for process base on specific needs. Tertiary treatment can avoid eutrophication in closed water area, and meet water quality standards of reutilization of the sewage. Furthe

22、r more, advanced treatment generally can make wastewater recycle. But industrial wastewater, mainly adopt secondary treatment, and the important steps in this process are as follows: grille for desilting, the initial sedimentation tanks, serration tanks, secondary sedimentation tanks, digestion pool

23、.initial sedimentationtanksSerrationtanksGrilleul trafi neGrilletoughdigestionpoolsecondary sedimentationtanks Figure 1. Technological process of wastewater treatmentRemove larger suspended solids such as, foam, plastics, branches and so on through grille, and then fish pollution automatically; the

24、aeration tanks treat wastewater using activated sludge, for this method can provide a stay to meet the oxygen content needed by aerobic microbes, as well as mixed conditions for sewage and activated sludge contacting sufficiently. III. AUTOMATIC CONTROL SYSTEM A. Principle for Control Systems Design

25、In order to identify the wastewater quality, and measure the effect of treatment system, prescribe a lot of water quality indicators, such as: BOD (biochemical oxygen demand), COD (chemical oxygen demand), TOD (total oxygen demand), turbidity, PH value, temperature and so on. Hence need to measure t

26、hese indicators for instance, water temperature, PH value, BOD, COD, TOD, SS (suspended substance) and so on. Then staff can control all switches running state, by comparing the relevant measured values and assumed values. Because this system needs not only to control the process, but also to make c

27、onvenience for detecting, displays should be set at the scene and in the control centre respectively. At different sites, data should be transmitted by field bus networks. Although the wireless sensor network technology has greatly reduced the number of cables and the environmental requirements, the

28、 relatively more advanced technology is more expensive, and nowadays can not be used widely 3. In this paper, choosing relatively traditional methods of measurement, study sewage treatment system from the standpoints of improving control level and facilitating the staff operating. B. Modules of Cont

29、rol SystemThere are signals to be detected, as well as valves, switches, motors and pumps, and so on, to be controlled, in each process. Considering every module, formulate their own control processes and realization method according to respective technology and performance requirements.For example,

30、 in the basin of grid for desilting, set the parameters according to the water volume of processing plant. When the liquid level difference between before and after grids is greater than or equal to the set parameter, the grid can implement chain startup and stop automatically. As a result, the ultr

31、asonic liquid-level meter should be set before and after thegrids, and then staff can control grids starting and stopping by PLC.Swi tchescontrol l i ng gridsExtractingsedimentsPLCLi qui d-l eveldi fference Figure 2. Control system for gridsIn the module of initial sedimentation tanks, install elect

32、romagnetic flow meter in its influent pipes to measure influent flow, and then show the value on displays. According to technology requirements, set liquid-level value of pretreatment intake pump, further then control all intake pump running state, in order to keep all pumps running the relative bal

33、anced time. Install PH meter to measure PH value of the instant water coming-in, so as to respond the coming-in water quality whether or not to meet the process requirements, if not,then give off warning signal, at the same time, close the inset gate.Install oxidation reducing potential (ORP) on-lin

34、e determinator, dissolved oxygen (DO) on-line determinator, and sludge density monitor in the serration tanks. The detected values of ORP and DO decide the number of blowers and aeration intensity, so that can save resources. When the sludge density is relative high, in a timely manner, system will

35、reduce the sludge quantity of reflux in secondary sedimentation tanks, and increase emission amount of sludge; when the density is low, to some degree, will increase the sludge quantity of reflux.Set one mud meter in the secondary sedimentation tank, which can measure mud-level on-line. When the val

36、ue is on the high side, can adjust mud sucker and scraper, sludge discharge pumps and so on automatically, in order to avoid sediment sludge corrupting as well as piling up too much by discharging remaining sludge.At last, in the final digestion pool, install one PH meter, COD on-line determinator,

37、and sludge density monitor. At the same time, display these data, so that staff can take the waterquality in control at any time, and then determine whether or not the effluent water targets the standard. C. The Whole Hardware SystemPLC is a new type of industrial control devices, which can adapt to

38、 varieties of small batch production, and it developed very quickly. Due to its general and flexible control performance, it is applied in all the field of industrial automation widely, with its reliability of adapting to a variety of industrial environment and simple and convenient operational perf

39、ormance. As a kind of digital electronic computing operating system, it is designed for the industrial environment applications specially. PLC adopt programmable memory to store and implement the orders for Boolean calculation, sequence control, timing, counting, arithmetic operation, etc, and contr

40、ol various types of equipment and production process though digital or analog input and output interfaces 4. Therefore, select S7-300 series PLC as the main lower computer.The functions of the PLC mainly represent switch logic, sequence control, analog control, signal chain, and communications. It c

41、an acts as a lower computer, which can communicate with PC or PLC having the same level or upper level, in order to complete information control and management for the whole production process.Module fordetectingsignalPLC moduleIPC industrialcomputerdisplay Figure 3. Hardware block diagram for contr

42、ol systemPLC main station can be connected upper computer, then, can display graphics, analyze trends, manage data, diagnose fault, control warning, etc, with high-level language programming. Furthermore PLC and IPC can constitute a powerful open distributed control system. Here IPC industrial compu

43、ter choose Advantech 610. D. Selection for Control MethodsSewage treatment is a multivariable, nonlinear, time-varying, random, and complex process, and traditional control method is difficult to achieve real-time monitoring and detecting. In recent years, sewage treatment generally adopts intellige

44、nt control, which mainly concludes fuzzy control, neural network, expert control, and so on. In this paper, choice of methods to control is expert system intelligent control. Based on different operating characteristics of modules, and the different characteristics of the different stages, can use d

45、ifferent control methods, so as to achieve the best effect. Complete the whole control and projections for sewage treatment process, with the knowledge of experts, through intelligent computer program system 5. E. Field BusDue to the relatively decentralized function modules, develop the technology

46、of field bus, which is an advanced on-site industrial technology, and really achieve distributed control and centralized management. In view of the need for system, real-time, reliability, and relative stabilities for load under fault and load in transport have a higher requirement, so select PROFIB

47、US field bus as communications network between PLC and IPC, which use RS-485 as transmission technology the most frequently 6. IV. SOFTWARE DESIGN OF SYSTEMThis upper computer software to monitor system use MCGS, which is a configuration software system based on windows platform, and used to constru

48、ct and generate upper computer system quickly 7. MCGS provide a complete project and development platform for users to solve opportunity engineering problems, and can complete functions, such as, on-site data acquisition, real-time and historical data processing, warning, security mechanism, process

49、 control, animation display, output of trend curve and report forms, as well as corporate monitoring network and so on. Moreover it is easy to operate, and has good visibility, high reliability, high performance, and other prominent features, so it is suitable for sewage treatment.In this system, th

50、e main function designed as follows: making configuration for PLC control strategy of the processing modules that can take convenience for staff to change operation states and system parameters in time; showing liquid level value, running time, PH value, ORP measurements, DO measurements, mud densit

51、y and so on dynamically and real-time, as well as the operating states and working methods of every equipment; displaying screen and alarming with light and sound 8; providing selections for working style, such as automatic and manual operation interface; querying historical data; intranet connectio

52、n. V. CONCLUDING REMARKSBased on the sewage treatment process, in view of its control requirements, establish control system on the basic of combination of PLC and IPC industrial computer. Through detected liquid level, mud density, OD value, ORP value and other signals, control running state and op

53、erating time of lift pumps, valves, blowers, sludge discharge equipments, grille for desilting and so on, in order to ensure water quality standards to meet the demand. At the same time, the use of MCGS configuration software develops real-time monitoring system operated automatically or manually, so as to have saving data, detecting, warning, querying historical data, and other functions full of humanness.

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。