patran弹簧单元有限元分析

patran弹簧单元有限元分析

《patran弹簧单元有限元分析》由会员分享,可在线阅读,更多相关《patran弹簧单元有限元分析(22页珍藏版)》请在装配图网上搜索。

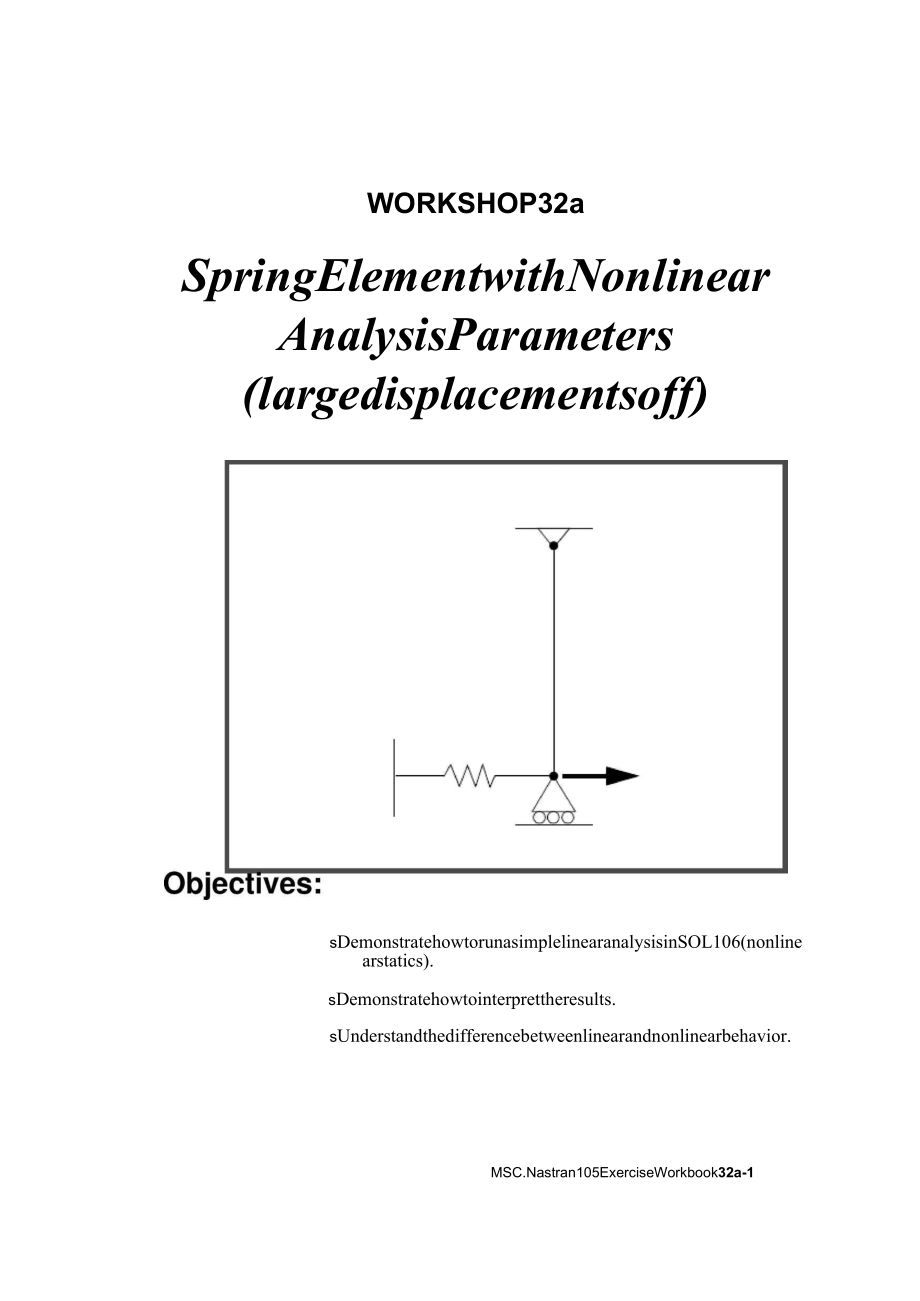

1、WORKSHOP32aSpringElementwithNonlinearAnalysisParameters(largedisplacementsoff)sDemonstratehowtorunasimplelinearanalysisinSOL106(nonlinearstatics).sDemonstratehowtointerprettheresults.sUnderstandthedifferencebetweenlinearandnonlinearbehavior.MSC.Nastran105ExerciseWorkbook32a-1WORKSHOP32aSpringElement

2、w/NonlinParams32a-2MSC.Nastran105ExerciseWorkbookModelDescription:Forthestructurebelow:CRODA=0.01in2E=1.E7psiL=10.0inCELAS1K=1.E3lb/inP=29.E3lbsXAddCaseControlcommandsandBulkDataEntriesto:1.PerformageometriclinearanalysisinSOL106(nonlinearstatics)withthelargedisplacementsoptionturnedoff.2.Applya29xl

3、03lbsloadinasinglesubcasewithfourincrementedsteps.Usethedefaultvaluesforallothersubcaseparameters.Requesttheoutputofallgriddisplacementsandallelementforces.SuggestedExerciseSteps:sModifytheexistingMSC.Nastraninputfilebyaddingtheappropriateloadingconditionsandnonlinearstaticanalysiscontrolparameters.

4、sSelectElementForcesaspartoftheoutput(FORCE=ALL).sForCaseControl,insertthestaticloadsetselection(LOAD)andthenonlinearstaticanalysisparameterselection(NLPARM).sForBulkData,inserttherelevantnonlinearstaticanalysisparameter(NLPARM).sPreparethemodelforageometriclinearstaticanalysis(turnofflargedisplacem

5、ents).xPARAM,LGDISP,-1sGenerateaninputfileandsubmitittotheMSC.Nastransolverforanonlinearstaticanalysis.sReviewtheresults.MSC.Nastran105ExerciseWorkbook32a-3WORKSHOP32aSpringElementw/NonlinParamsInputFileforModification:prob32a.datIDNAS103,WORKSHOP32ATIME10SOL106$NONLINCENDTITLE=SIMPLERODSPRING-COLDA

6、NALYSISANDRESTARTWORKSHOPSUBTITLE=GEOMETRICNONLINEARECHO=BOTHDISP=ALLOLOAD=ALL$APPLYXLOAD$SUBCASE10$LOAD=29.E03LABEL=APPLYLOADPINXDIRECTION=29E+03OUTPUT(PLOT)SET1ALLMAXIDEFO5.AXESZ,X,YVIEW0.,0.,0.FINDSCALEORIGIN1SET1PLOTSTATIC0MAXIMUMDEFORMATION5.SET1BEGINBULKGRID,1,0,0.0,0.0,0.0,23456GRID,3,0,0.0,1

7、0.0,0.0,123456CROD,3,3,3,1CELAS1,2,2,1,1,0PROD,3,3,.01PELAS,2,1.0E3MAT1,3,1.0E7FORCE,1,1,0,1.6E4,1.0FORCE,2,1,0,2.4E4,1.0FORCE,3,1,0,2.9E4,1.0ENDDATAMSC.Nastran105ExerciseWorkbook32a-5WORKSHOP32aSpringElementw/NonlinParamsExerciseProcedure:1.UserswhoarenotutilitizingMSC.Patranforgeneratinganinputfil

8、eshouldgotoStep12,otherwise,proceedtostep2.2.Createanewdatabasecalledprob32a.db.File/New.NewDatabaseNameOKprob32aIntheNewModelPreferenceformsetthefollowing:Tolerance:qDefaultAnalysisCode:AnalysisType:OKMSC/NASTRANStructural3.Thosewhodonotwishtosetupthemodelthemselvesmaywanttoplaythesessionfile,prob3

9、2.ses.Ifyouchoosetobuildthemodelyourself,proceedtostep4.File/Session/Play.SessionFileListApplyprob32.sesThemodelhasnowbeencreated.SkiptoStep10.WheneverpossibleclickuAutoExecute(turnoff).4.Createa10unitlongbeam.xGeometryAction:Object:Method:VectorCoordinateListApplyCreateCurveXYZMSC.Nastran105Exercis

10、eWorkbook32a-#WORKSHOP32aSpringElementw/NonlinParamsCreateMeshCurve10Bar2Curve1(Selectthecurve.)5.MeshthecurvewithoneBAR2element.xFiniteElementsAction:Object:Type:GlobalEdgeLengthElementTopology:CurveListApplyForclarity,increasethenodesizeusingthefollowingtoolbaricon:MSC.Nastran105ExerciseWorkbook32

11、a-7WORKSHOP32aSpringElementw/NonlinParamsMSC.Nastran105ExerciseWorkbook32a-#WORKSHOP32aSpringElementw/NonlinParamsMSC.Nastran105ExerciseWorkbook32a-#WORKSHOP32aSpringElementw/NonlinParamsMSC.Nastran105ExerciseWorkbook32a-#WORKSHOP32aSpringElementw/NonlinParams6.Createthematerialpropertyforthebeam.xM

12、aterialsAction:CreateObject:IsotropicMethod:ManualInputMaterialNamemat_1InputProperties.ElasticModulus=1.E7ApplyCancel7. Createthepropertyforthebeam.xPropertiesAction:CreateDimension:Type:PropertySetNameInputProperties.MaterialNameAreaOKSelectMembersAdd1DRodprop_1m:mat_10.01Curve1(Selectthecurve.)Ap

13、ply8. Createagroundedspringatthebottomofthebeam.xFiniteElementsAction:Object:Method:Shape:Topology:Node1=ApplyCreateElementEditPointPointNode1(Selectthebottomnode.)First,createa0-Delementtobeusedforspringconstantassignmentatthebottomofthebeam.MSC.Nastran105ExerciseWorkbook32a-#WORKSHOP32aSpringEleme

14、ntw/NonlinParamsMSC.Nastran105ExerciseWorkbook32a-#WORKSHOP32aSpringElementw/NonlinParamsCreate0DGroundedSpringNext,createthegroundedspringpropertyforthenewlycreatedelement.xPropertiesAction:Object:Method:PropertySetNameprop_2InputProperties.SpringConstant1.E3DofatNode1UXOKYoucaneithertypeinthepoint

15、elementintothedataboxorclickonthepointitself.Thisisdonebyfirst,clickingtheSelectMembersdataboxandthenclickingonthefollowingicon.itElement込SelectMembers:Elm2(Selectthepointelementpreviouslycreated.)AddApply9. CreatetheLoads/BCsforthemodel.First,fixthetopendofthebeam.xLoads/BCsAction:CreateObject:Disp

16、lacementMethod:NodalNewSetNameconstraint_1InputData.TranslationRotationOKSelectApplicationRegion.SelectGeometryEntities:Point2(Selectpointattopofbeam.)AddOKApplyNext,createtheguidedsupportLoad/BCatthebase(freeinx-direction,andfixedinallotherDOFs).NewSetName:constraint_2InputData.TranslationRotationO

17、KSelectApplicationRegion.SelectGeometryEntitiesPoint1(Selectpointatbottomofbeam.)AddOKApply10.Createtheloadingforthemodel.Forthisanalysismodel,theloadwillbeincrementeduptothefinalloadinasinglesubcase.xLoads/BCsAction:CreateObject:ForceMethod:NodalNewSetNameload_3InputData.ForceOKMSC.Nastran105Exerci

18、seWorkbook32a-9WORKSHOP32aSpringElementw/NonlinParamsSelectApplicationRegion.SelectGeometryEntitiesPoint1(Selectpointatbottomofbeam.)AddOKApplyYourviewportshouldnowappearasfollow:WORKSHOP32aSpringElementw/NonlinParamsWORKSHOP32aSpringElementw/NonlinParams11. Nowyouarereadytogenerateaninputfileforana

19、lysis.ClickontheAnalysisradiobuttonontheTopMenuBarandsetupthesubcasesasfollows:WORKSHOP32aSpringElementw/NonlinParamsWORKSHOP32aSpringElementw/NonlinParamsAnalysisAction:Object:YMethod:JobNameAnalyzeEntireModelAnalysisDeckprob32a毋比口3456WORKSHOP32aSpringElementw/NonlinParamsSolutionType.SolutionType:

20、SolutionParameters.(Turnofflargedisplacements.)OKOKSubcaseCreate.AvailableSubcases:SubcaseParameters.NumberofLoadIncrements:OKOutputRequests.OutputRequests:DeleteOutputRequests:DeleteSelectResultType:OKApplyCancelApplyqNONLINEARSTATIC口LargeDisplacementsDefault4STRESS(SORT1.SPCFORCES(SORT1.ElementFor

21、cesMSC.Nastran105ExerciseWorkbook32a-#WORKSHOP32aSpringElementw/NonlinParamsMSC.Nastran105ExerciseWorkbook32a-#WORKSHOP32aSpringElementw/NonlinParamsAninputfilecalledprob32a.bdfwillbegenerated.ThisprocessoftranslatingyourmodelintoaninputfileiscalledtheForwardTranslation.TheForwardTranslationiscomple

22、tewhentheHeartbeatturnsgreen.MSC.PatranusersshouldnowproceedtoStep13.GeneratinganinputfileforMSC.NastranUsers:12. MSC.NastranuserscangenerateaninputfileusingthedatafromtheModelDescription.Theresultshouldbesimilartotheoutputbelow(prob32a.dat):ASSIGNOUTPUT2=prob32a.op2,UNIT=12IDNAS103,WORKSHOP32ASOLUT

23、IONTIME10SOL106$NONLINCENDTITLE=SIMPLERODSPRING-COLDANALYSISANDRESTARTWORKSHOPSUBTITLE=GEOMETRICNONLINEARECHO=BOTHDISP=ALLOLOAD=ALLFORCE=ALL$APPLYXLOAD$SUBCASE10$LOAD=29.E03LABEL=APPLYLOADPINXDIRECTION=29E+03LOAD=3NLPARM=10OUTPUT(PLOT)SET1ALLMAXIDEFO5.AXESZ,X,YVIEW0.,0.,0.FINDSCALEORIGIN1SET1PLOTSTA

24、TIC0MAXIMUMDEFORMATION5.SET1BEGINBULKPARAM,POST,-1PARAM,PATVER,3.0GRID,1,0,0.0,0.0,0.0,23456GRID,3,0,0.0,10.0,0.0,123456CROD,3,3,3,1CELAS1,2,2,1,1,0PROD,3,3,.01PELAS,2,1.0E3MAT1,3,1.0E7FORCE,1,1,0,1.6E4,1.0FORCE,2,1,0,2.4E4,1.0FORCE,3,1,0,2.9E4,1.0PARAM,LGDISP,-1NLPARM,10,4ENDDATAMSC.Nastran105Exerc

25、iseWorkbook32a-13WORKSHOP32aSpringElementw/NonlinParamsSubmittheinputfileforanalysis:13. SubmittheinputfiletoMSC.Nastranforanalysis.13a.TosubmittheMSC.Patran.bdffile,findanavailableUNIXshellwindow.Atthecommandpromptenternastranprob32a.bdfscr=yes.MonitortheanalysisusingtheUNIXpscommand.13b.Tosubmitth

26、eMSC.Nastran.datfile,findanavailableUNIXshellwindowandatthecommandpromptenternastranprob32a.datscr=yes.MonitortheanalysisusingtheUNIXpscommand.14. Whentheanalysisiscompleted,edittheprob32a.f06fileandsearchforthewordFATAL.Ifnomatchesexist,searchforthewordWARNING.DeterminewhetherexistingWARNINGmessage

27、sindicatemodelingerrors.14a.Whilestilleditingprob32a.f06,searchfortheword:DISPLACE(spacesarenecessary).Whatisthex-displacementoftheguidedendattheendoftheanalysis?T1=Whatistheforceinthespringelementattheendoftheanalysis?FORCE=MSC.Nastran105ExerciseWorkbook32a-#WORKSHOP32aSpringElementw/NonlinParams.f

28、06filewiththeComparisonofResults:15. Comparetheresultsobtainedintheresultsonthefollowingpage:MSC.Nastran105ExerciseWorkbook32a-15WORKSHOPLOADSTEP=1.00000E+00DISPLACEMENTVECTORWORKSHOPPOINTID.TYPET1T2T31G2.900000E+010.00.02G0.00.00.0LOADSTEP=1.00000E+00FORCESINSCALARELEMENTFORCEELEMENTFORCEID.ID.22.9

29、00000E+040R1R2R30.00.00.00.00.00.0SUBCASE1SpringESPRINGS(CELAS1)ELEMENTFORCEELEMENTFORCEID.ID.SUBCASE1WORKSHOPWORKSHOPMSC.Nastran105ExerciseWorkbook32a-17WORKSHOP32aSpringElementw/NonlinParams16.ThisendstheexerciseforMSC.Nastranusers.MSC.Patranusersshouldproceedtothenextstep.17.ProceedwiththeReverse

30、Translationprocess,thatis,importingtheprob32a.op2resultsfileintoMSC.Patran.Todothis,returntotheAnalysisformandproceedasfollows:xAnalysisAction:ReadOutput2Object:Method:ResultEntitiesTranslateSelectResultsFile.SelectedResultsFileprob32a.op2OKApply18.WhenthetranslationiscompletebringuptheResultsform.N

31、owwewillgeneratethefringeplotofthemodel.xResultsAction:CreateObject:FringeNowclickontheSelectResultsicon.SelectResultCase(s)Default,PWLinear:100.%ofLoadSelectFringeResultQuantity:Displacements,TranslationalMagnitudeNextclickontheTargetEntitiesicon.瑩盂TargetEntitiesTargetEntity:CurrentViewportNote:Thi

32、sfeatureallowsyoutoviewfringeplotsofspecificelementsofyourchoice.ClickontheDisplayAttributesicon.Style:Discrete/SmoothDisplay:FreeEdgesForbettervisualqualityofthefringeplot,changethewidthoftheline.Width:(Selectthethirdlinefromtop.)Note:TheDisplayAttributesformallowsyoutheabilitytochangethedisplayedg

33、raphicsoffringeplots.NowclickonthePlotOptionsicon.CoordinateTransformation:NoneScaleFactorApply1.0Theresultingfringeplotshoulddisplaythedisplacementspectrumsuperimposedovertheundeformedbar.Thefinalfringeplotdisplayingthephysicaldeformationofthemodelcanbecreatedasfollows:xResultsAction:CreateObject:D

34、eformationNowclickontheSelectResultsicon.SelectResultCase(s)Default,PWLinear:100.%ofLoadSelectFringeResultShowAs:Displacements,TranslationalResultantClickontheDisplayAttributesicon.LineWidth:(Selectthethirdlinefromtop.)Inordertoseethedeformationresultsaccurately,settheScaleInterpretationtoTrueScalew

35、ithaScaleFactorof1.ScaleInterpretationScaleFactorqTrueScale1.0sShowUndeformedLineWidth:(Selectthethirdlinefromtop.)NowclickonthePlotOptionsicon.CoordinateTransformation:NoneScaleFactorApply1.0Theresultingfringeplotshoulddisplaythedisplacementspectruminadditiontothephysicaldeformationofthemodel.Thefo

36、llowingstepwillcombinethetwopreviousplotsintoone.MSC.Patranautomaticallycombinesboththefringeanddeformationplotsintoone.Tobetterfittheresultsonthescreen,zoomoutacoupletimesusingthefollowingtoolbaricon:Alternatively,useanynumberofthetoolbariconstobetterviewtheresultingfringeplot.Yourviewportshouldnow

37、containthefollowingimage:Noticethatthedeflectionisalmost3timesthelengthofthebeam!Thissuggeststhatanonlinearanalysiswhichaccountsforlargedisplacementsisnecessarytoobtainamoreaccurateanswer.Toclearthepost-processingresultsandobtaintheoriginalmodelintheviewport,selecttheResetGraphicsicon.QuitMSC.Patran

38、whenyouhavecompletedthisexercise.MSC.Nastran105ExerciseWorkbook32a-19WORKSHOP32aSpringElementw/NonlinParamsMSC.Patran.bdffile:prob32a.bdf$NASTRANinputfilecreatedbytheMSCMSC/NASTRANinputfile$translator(MSC/PATRANVersion7.5)onJanuary16,1998at$08:27:27.ASSIGNOUTPUT2=prob32a.op2,UNIT=12$DirectTextInputf

39、orFileManagementSection$NonlinearStaticAnalysis,DatabaseSOL106TIME600$DirectTextInputforExecutiveControlCENDSEALL=ALLSUPER=ALLTITLE=MSC/NASTRANjobcreatedon16-Jan-98at08:25:44ECHO=NONEMAXLINES=999999999$DirectTextInputforGlobalCaseControlDataSUBCASE1$Subcasename:DefaultSUBTITLE=DefaultNLPARM=1SPC=2LO

40、AD=2DISPLACEMENT(SORT1,REAL)=ALLFORCE(SORT1,REAL,BILIN)=ALL$DirectTextInputforthisSubcaseBEGINBULKPARAMPOST-1PARAMPATVER3.PARAMAUTOSPCNOPARAMCOUPMASS-1PARAMK6ROT100.PARAMWTMASS1.PARAMLGDISP-1PARAM,NOCOMPS,-1PARAMPRTMAXIMYESNLPARM14AUTO525PWNO+A+A.0011.-7$DirectTextInputforBulkData$ElementsandElement

41、Propertiesforregion:prop_1PROD11.01CROD1112$ElementsandElementPropertiesforregion:prop_2PELAS21000.CELAS12211$ReferencedMaterialRecords$MaterialRecord:mat_1$DescriptionofMaterial:Date:19-Jun-97Time:15:12:40MAT111.+7$NodesoftheEntireModelGRID10.0.0.GRID20.10.0.$LoadsforLoadCase:DefaultSPCADD213LOAD21.1.1$DisplacementConstraintsofLoadSet:constraint_1SPC111234562$DisplacementConstraintsofLoadSet:constraint_2SPC13234561$NodalForcesofLoadSet:load_3FORCE11029000.1.0.0.$ReferencedCoordinateFramesENDDATAc9d4ca67MSC.Nastran105ExerciseWorkbook32a-2132a-24MSC.Nastran105ExerciseWorkbook

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。