模具常用语中英文对照

模具常用语中英文对照

《模具常用语中英文对照》由会员分享,可在线阅读,更多相关《模具常用语中英文对照(64页珍藏版)》请在装配图网上搜索。

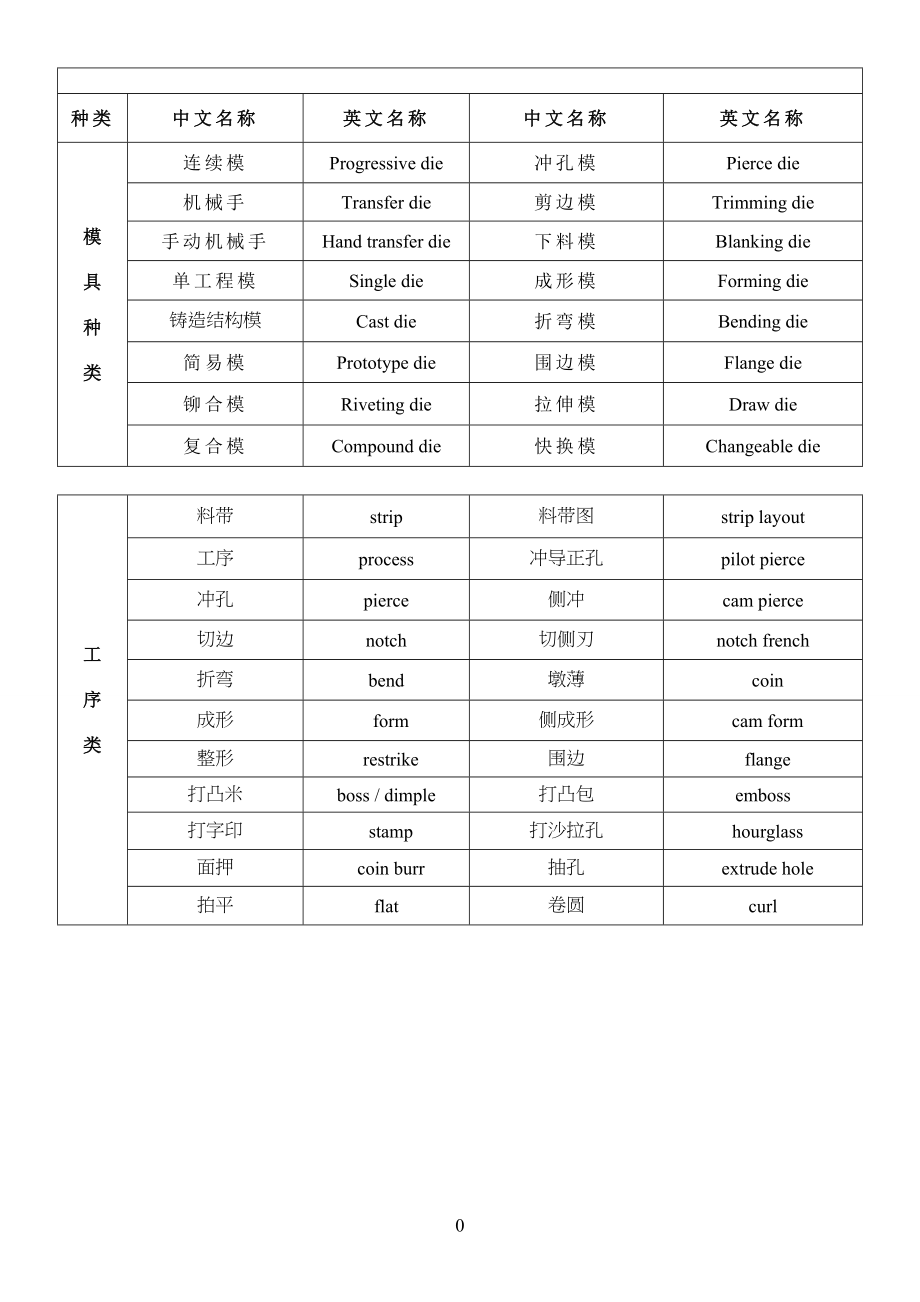

1、种类中文名称英文名称中文名称英文名称模具种类连续模Progressive die 冲孔模Pierce die机械手Transfer die剪边模Trimming die手动机械手Hand transfer die下料模Blanking die单工程模Single die成形模Forming die铸造结构模Cast die折弯模Bending die简易模Prototype die围边模Flange die铆合模Riveting die 拉伸模Draw die复合模Compound die快换模Changeable die工序类料带 strip料带图strip layout工序process冲

2、导正孔pilot pierce冲孔pierce侧冲cam pierce切边notch切侧刃 notch french 折弯 bend墩薄 coin成形 form侧成形 cam form整形 restrike围边 flange打凸米 boss / dimple打凸包 emboss打字印 stamp打沙拉孔 hourglass面押 coin burr抽孔 extrude hole拍平 flat卷圆 curl种类中文名称英文名称中文名称英文名称工序类旋转rotate铆接 rivet产品切边线 trim line铆螺母 stake nut切断 cutoff接刀口 mismatch料带带料处 carri

3、er tab毛刺方向 burr direction压线groove 下料blanking模板类上托板top plate下托板bottom plate上垫脚upper parallel下垫脚lower parallel上模座upper die set下模座lower die set上垫板punch backup 下垫板lower backup上夹板punch holder下夹板die holder上脱料板stripper下模板die plate 冲头punch凹模die零件类浮块 lifter浮料板 lifter plate 成型公 form punch压料块 pressure pad切边冲头

4、trim punch刀口 trim steel沉头孔 counter bore冲孔入子 button顶针 kick off / ejector废料切断刀 slug breaker成型凹模forming die整形公 restrike punch 导尺 rail 导尺顶杆 lifter bolt导料板 rail plate镶件/入子 insert侧冲组件 cam滑块 slide滑块上油槽 oil groove铲机 driver码模槽 mounting slot储运块 storage block限位柱stop block起吊孔 handing hole起吊环 eyebolt靠块 heel脱料拉杆

5、spool模座导正块 thrust heel种类中文名称英文名称中文名称英文名称零件类耐磨片 wear plate垫片 shim压块keeper初始管位 first start pin键槽 key slot键 key氮气弹簧 nitrogen spring螺旋弹簧 coil spring聚氨酯弹簧 urethane 导柱 guide post导套 guide bushing插针 pilot pin插针套 pilot bushing侧刃 french传感器 sensor销 dowel螺丝 screw拔牙 jackscrew垫圈 washer盲销 blind dowel压毛边冲头deburring

6、 punch挡块stopping plate压线冲头groove punch定位块location block字模冲头stamp punch圆冲头round punch压筋冲头ribbon punch气垫板air cushion plate异形冲头special shape punch气垫顶杆air-cushion eject-rod切边冲头trimming punch上压块pressure block加强筋冲头stiffening rib punch弹簧箱spring box定位板guide plate弹簧箱顶杆spring-box eject-rod压边圈binder弹簧箱顶板spring

7、-box eject-plate公差类公差 tolerance公差范围 tolerance range上公差 upper tolerance 下公差 lower tolerance公差+/- 0.05 plus minus 0.05形位公差图 GD&T平面度 flatness直线度 Straightness倾斜度 angularity垂直度 perpendicularity平行度 parallelism圆度 roundness种类中文名称英文名称中文名称英文名称公差类圆柱度 cylindricity面轮廓度 surface profile线轮廓度line profile 位置度 true po

8、sition同轴度 concentricity对称度 symmetry圆跳动 runout全跳动total runout尺寸 dimension角度值 angle degree尺寸全检报告dimensional layout三次元尺寸报告CMM report冲床相关机械冲床 mechanical press油压机 hydraulic press吨位 tonnage行程 stroke / travel冲床上台面 ram冲床下台面 bolster冲床台面布置图 press layout冲床上的快速对正 QDC冲床气垫 air cushion码仔 stirrup闭合高度 shut heightT型槽

9、T-slot送料机 feeder送料高度 feeding height工具卡尺 caliper千分尺micrometer直尺ruler高度尺height gage丝攻 screw tap起子 screwdriver拨牙器 jacker扳手 wrench风磨机hand grinder油石oil stone加工类开料cutting material钻drill (DR)攻牙 tap铰 ream铣 mill车 lathe电脑锣 NC mill线切割 wire cutting(W/C)磨 grind刨 planer电火花 EDM镭射laser cutting倒角 chamferxx的精加工 finis

10、h XX真空热处理 vacuum heat treatment 镀钛 TD coating退磁 demagnetization 烧焊 weld 4.1.2 加工说明对照表:加工说明Machining Note注:有0.00的地方为数据填入处外导套 OUTER GUIDE BUISHING 起吊杆 HANDING PIN实数铣通 MILL THRU 正反两面各铣 TOP SIDE AND OPP SIDE MILLX:-0.00(氮气弹弓过孔,锣穿)单+0.00X:-0.00 (DR.THRU FOR GAS SPRING) S+0.00 X:-0.00(氮气弹弓沉头,正面CNC单+0.00,锣

11、深0.00.)X:-0.00 ( CNC CBORE TOP SIDE FOR GAS SPRING, S+0.00, DP0.00) X:-0.00(氮气弹弓沉头,反面CNC单+0.00,锣深0.00.)X:-0.00 (CNC CBORE OPP SIDE FOR GAS SPRING, S+0.00, DP0.00)X:-0.00(合销孔,铰)X:-0.00 (REAM FOR DOWEL) X:-0.00(合销孔,割)单+0.00X:-0.00 (W/C FOR DOWEL) S+0.00 (正面沉头0.00*0.00深,内攻M0.00*1.5牙) (0.00*0.00 CBORE D

12、P0.00 TOP SIDE, TAP M0.00*1.5 THR) (反面沉头0.00*0.00深,内攻M0.00*1.5牙) (0.00*0.00 CBORE DP.0.00 OPP. SIDE, TAP M0.00*1.5 THR)X:-0.00(合销孔,钻穿)X:-0.00 (DR.THRU FOR DOWEL)X:-0.00(一般孔,钻穿)X:-0.00 (DR.THRU HL)X:-0.00(穿丝孔,钻穿)X:-0.00 (DR.THRU FOR WEDM S.H.)X:-0.00(漏油孔,钻穿) 按向视图加工X:-0.00 (DR.THRU FOR DRAIN HL) ACCOR

13、DING VIEW DRAWING TO MACHININGX:-(漏油槽,反面CNC单+0.00,锣深0.00)X:- (CNC POCKET OPP.SIDE FOR DRAIN, S+0.00, DP0.00)X:-0.00(基准孔,铰)X:-0.00 (REAM FOR DATUM HL)X:-0.00钻穿(螺丝过孔)内攻M0.00牙X:-0.00 (DR.THRU FOR CLEARANCE HL, TAP M0.00 THR) (正面沉头0.00*0.00深) (0.00*0.00 CBORE DP0.00 TOP SIDE) (反面沉头0.00*0.00深) (0.00*0.00

14、 CBORE DP0.00 OPP. SIDE) (侧面沉头0.00*0.00深) (0.00*0.00 CBORE DP0.00 EDGE SIDE)X:-M0.00钻穿,反面攻深0.00,有效牙0.00X:-M0.00 DR.THRU, TAP DP0.00 OPP.SIDE, THR DP0.00)X:-M0.00钻穿,正面攻深0.00,有效牙0.00X:-M0.00 DR.THRU, TAP DP0.00 TOP SIDE, THR DP0.00)X:-M0.00钻穿,正反面攻深0.00,有效牙0.00X:-M0.00 DR.THRU, TAP DP0.00 TOP&OPP. SIDE

15、, THR DP0.00)X:-M0.00盲孔,反面攻深0.00,有效牙0.00X:-M0.00 BLIND HL, TAP WORK DP0.00 OPP. SIDE)X:-M0.00盲孔,正面攻深0.00,有效牙0.00X:-M0.00 BLIND HL, TAP WORK DP0.00 TOP SIDE, THR DP0.00)X:-M0.00盲孔,正反面攻深0.00,有效牙0.00X:-M0.00 BLIND HL, TAP DP0.00 TOP&OPP. SIDE, THR DP0.00)X:-M0.00盲孔,侧面分中攻深0.00,组模自配X:-M0.00 BLIND HL, TAP

16、 DP0.00 ON EDGE FROM CENTER , DIE MAKER FIT) (侧面沉头0.00*0.00深) (0.00*0.00 CBORE DP0.00 EDGE SIDE)X:-M0.00盲孔,侧面分中钻深0.00X:-M0.00 BLIND HL, DR. DP0.00 ON EDGE FROM CENTERX:-M0.00(拨牙螺丝孔,攻穿)X:-M0.00 TAP.THRU FOR JACK SCREWX:-0.00(塞打过孔,钻穿)X:-0.00 DR.THRU FOR SPOOL X:-0.00(弹弓过孔,钻穿)X:-0.00 DR.THRU FOR SPRING

17、X:-0.00(弹弓孔,反面沉深0.00)有效深0.00X:-0.00 (CBORE FOR SPRING DP.0.00 OPP.SIDE, USED DP.0.00)X:-0.00(弹弓孔,正面沉深0.00)有效深0.00X:-0.00 (CBORE FOR SPRING DP.0.00 TOP.SIDE, WORK DP.0.00)X:-(避空孔,锣穿)单+0.00X:- (POCKET THRU)S+0.00X:-(避空孔,正面CNC单+0.00,锣深0.00)X:- (POCKET, CNC MILL S+0.00 DP0.00 TOP SIDE) X:-(避空孔,反面CNC单+0.

18、00,锣深0.00)X:- (POCKET, CNC MILL S+0.00 DP0.00 OPP SIDE)X:-0.00(避空孔,反面CNC单+0.00,锣深0.00)X:-0.00 (POCKET, CNC MILL S+0.00, DP0.00 OPP.SIDE) X:-0.00(避空孔,正面CNC单+0.00,锣深0.00)X:-0.00 (POCKET, CNC MILL S+0.00, DP0.00 EDGE SIDE)X:-0.00(两用销过孔,割)单+0.00X:-0.00 (LIFTER PIN, W/C S+0.00)X:-(导尺避空,CNC单+0.00锣穿)X:- (P

19、OCKET FOR RAIL, CNC MILL THRU, S+0.00)X:-(导尺避空,正面CNC单+0.00,锣深0.00)X:- (POCKET FOR RAIL, CNC MILL DP.0.00 TOP SIDE, S+0.00)X:-(导尺避空,反面CNC单+0.00,锣深0.00)X:- (POCKET FOR RAIL, CNC MILL DP.0.00 OPP. SIDE, S+0.00)X:-(浮块避空,正面CNC单+0.00,锣深0.00)X:- (POCKET FOR LIFTER, CNC MILL DP.0.00 TOP SIDE, S+0.00)X:-(浮块孔

20、,割)单+0.00 (反面避空单+0.00,锣深0.00)X:-(LIFTER HL, W/C)S+0.00 (POCKET DP0.00 S+0.00 OPP.SIDE)X:-(浮块孔,锣)单+0.00 (反面避空单+0.00,锣深0.00)X:-(LIFTER HL, MILL)S+0.00 (POCKET DP0.00 S+0.00 OPP.SIDE)X:-0.00(顶针孔,钻穿) ( 反面沉头0.00*0.00深,内攻M0.00*1.5牙)X:-0.00 (EJECT PIN, DR.THRU.) (0.00 CBORE DP0.00 OPP. SIDE, TAP M0.00*1.5

21、THR)X:-0.00(顶针孔,钻穿) (正面沉头0.00*0.00深,内攻M0.00*1.5牙)X:-0.00 (EJECT PIN, DR.THRU.) (0.00 CBORE DP0.00 TOP SIDE, TAP M0.00*1.5 THR)X:-0.00(导柱(导套)孔,CNC锣)单+0.00X:-0.00 CNC MILL FOR GUIDE PIN(BUSHING) S+0.00X:-0.00(导柱(导套)孔,割)单+0.00X:-0.00 W/C FOR GUIDE PIN(BUSHING) S+0.00 X:-M0.00*1.5(止付螺丝,正面攻深0.00)X:-M0.00

22、*1.5(SET SCREW, TAP DP0.00 TOP SIDE)X:-M0.00*1.5(止付螺丝,反面攻深0.00)X:-M0.00*1.5(SET SCREW, TAP DP0.00 OPP SIDE)X:-(入子孔,CNC单+0.00,锣穿)X:-(INSERT HL, CNC MILL THRU S+0.00) (阴影部分正面沉头单+0.00,锣深0.00) (SHADE AREA, MILL DP0.00 S+0.00 TOP SIDE) (阴影部分反面沉头单+0.00,锣深0.00) (SHADE AREA, MILL DP0.00 S+0.00 OPP SIDE) X:-

23、(入子孔,割)单+0.00X:-(INSERT HL, W/C S+0.00) (阴影部分扣位正面锣深0.00) (SHADE AREA FOR HEAD POCKET, MILL DP0.00 TOP SIDE) (阴影部分扣位反面锣深0.00) (SHADE AREA FOR HEAD POCKET, MILL DP0.00 OPP. SIDE) (正面沉头单+0.00,锣深0.00) (POCKET, MILL DP0.00 TOP SIDE) 注: 此处的沉头不能用CBORE, 只有圆形的沉头才用CBORE. (反面沉头单+0.00,锣深0.00) (POCKET, MILL DP0.

24、00 TOP SIDE)X:-(入子孔,CNC单+0.00,锣穿)X:- (INSERT HL, CNC MILL THRU. S+0.00)X:-(入子孔,正面CNC单+0.00,锣深0.00)X:- (INSERT HL, CNC MILL DP0.00 S+0.00 TOP SIDE)X:-(入子孔,反面CNC单+0.00,锣深0.00)X:- (INSERT HL, CNC MILL DP0.00 S+0.00 OPP. SIDE)X:-0.00(插针孔,铰)单+0.00X:-0.00(REAM S+0.00 FOR PILOT PIN)X:-0.00(插针孔,割)单+0.00 (正面

25、沉头0.00*0.00深)X:-0.00(W/C FOR PILOT PIN) (0.00 CBORE DP0.00 TOP SIDE) X:-0.00(插针孔,钻穿) (正面沉头0.00*0.00深)X:-0.00(DR.THRU FOR PILOT PIN) (0.00 CBORE DP0.00 TOP SIDE) X:-(冲头过孔,割)单+0.00 (正面避空,CNC单+0.00,锣深0.00) (阴影部分扣位正面锣深0.00)X:-(W/C S+0.00 FOR PUNCH CLEARANCE HL) (POCKET, CNC DP 0.00 S+0.00 TOP SIDE) (POC

26、KET SHADE FOR HEAD, DP0.00 TOP SIDE) X:-(冲头过孔,锣穿)单+0.00 (正面避空,CNC单+0.00,锣深0.00)X:-(MILL THRU.FOR PUNCH CLEARANCE HL) (POCKET DP0.00 CNC S+ TOP SIDE)X:-(异形冲孔,直x斜x,割)单+0.00 (双线部分,割)单+0.00X:-(W/C FOR SPECIAL HL, 0.00 LAND 0.00 TAPER, S+0.00) (W/C PER DOUBLE LINE S+0.00)X:-(冲孔,直x斜x,割)单+0.00X:-(W/C FOR P

27、IERCE DIE HL, 0.00 LAND 0.00 TAPER S+0.00)X:-(冲孔,割)单+0.00X:-(W/C FOR PIERCE DIE HL S+0.00)X:-0.00(冲孔漏屎,钻穿)X:-0.00 (DR. THRU FOR CHUTE)X:-(异形冲孔漏屎,CNC单+0.00,锣穿)X:-0.00 (MILL. THRU FOR SPECIAL CHUTE S+0.00)X:-(产品落料斜度,实数斜30锣)X:-(MILL 30 TAPER FOR PART RAMP NO CLEARANCE)X:-(漏屎斜度,直x斜45锣)X:-(MILL FOR CHUTE

28、 0.00 LAND 45 TAPER)反面沉深底面留0.00 MILL UNTIL DP正面沉深底面留MILL UNTIL DP五金模具单词总结模具种类:连续模 progressive die机械手 transfer die手动机械手 hand transfer die单工程模 single die/line die复合模 compound die铆接模 riveting die铸造结构模 cast die能快换的模 changeover die 泡沫模 pattern互换性:公差 tolerance上公差 upper tolerance 下公差 lower tolerance公差范围 to

29、lerance range公差+/- 0.05 plus minus 0.05形位公差图 GD&T平面度 flatness直线度 straightness倾斜度 angularity垂直度 perpendicularity / squareness平行度 parallelism圆度 roundness / circularity圆柱度 cylindricity面轮廓度 surface profile线轮廓度 line profile位置度 true position同轴度 concentricity对称度 symmetry圆跳动 runout全跳动 total runout尺寸 dimensi

30、on角度 angle degree全尺寸报告 dimensional layout工艺性:料带 strip料带图 strip layout工序 process冲导正孔 pilot pierce冲孔 pierce侧冲 cam pierce切边 notch成形后的切边 trim切侧刃 french trim / fringe trim厚料切边后的精修边 shave折弯 bend墩薄 coin折弯处压筋 gusset成形 form侧成形 cam form整形 restrike / rehit围边 flange压线/压长条状筋 ribbon打凸米 boss / dimple打凸包 emboss打字印

31、stamp打沙拉孔 hourglass面押 coin burr抽孔 extrude hole拍平 flat / spanking包边 hem edge压角 cone张角 flare切舌 lance半剪knockout卷圆 curl/热恶劣旋转rotate铆接 rivet铆螺母 stake nut切断 cutoff接刀口 mismatch料带带料处 carrier tabs毛刺方向 burr direction产品切边线 trim line模具零件:模具 die / tool上托板 upper mounting plate上垫脚 upper parallel上模座 upper die set上垫

32、板 punch backup上夹板 punch holder止挡板 traveling stop脱料板 stripper下模板 die plate下垫板 die backup plate下模座 lower die set 下垫脚 lower parallel上托板 base mounting plate浮块 lifter浮料板 lifter plate 成型公 form punch压料块 pressure pad切边冲头 trim punch刀口 trim steel刀口直身位 land直5斜1 5mm Land 1 taper刀口上沉头的深度 die life沉头 counter bore冲

33、头倒斜 shear高低冲 stagger punch球锁冲头 ball-lock punch球锁座 ball-lock retainer冲孔入子 button顶针 kick off / ejector废料切断刀 slug breaker成型凹模form die整形公 restrike form punch 导尺 rail /stock guidance导尺顶杆 lifter bolt导料板 rail plate镶件/入子 insert侧冲组件 cam滑块 slide滑块上油槽 oil groove铲机 driver码模槽 mounting slot储运块 storage block限位柱sto

34、p block起吊孔 handing hole起吊环 eyebolt模柄 shank靠块 heel摆块 rocker bender脱料板拉杆 stripper bolt模座导正块 thrust耐磨片 wear sheet耐磨板 wear plate垫片 shim两用销 lifter pin初始管位 first start pin内限位 standoff压块keeper导柱导套压块 keeper/ boss键槽 key slot键 key氮气弹簧 gas spring / nitrogen spring氮气弹簧安装法兰 mounting flange氮气弹簧系统 nitrogen manifol

35、d螺旋弹簧 coil spring聚氨酯弹簧 urethane 弹簧套 spring cage导柱 guide post导套 guide bushing插针 pilot pin插针套 pilot bushing插针通孔 pilot through hole侧刃 french误检装置 misfeeder 传感器 sensor误检杆 trigger油嘴 oil nipple销针 dowel pin螺丝 screw牙 thread拔牙 jackscrew内六角螺钉 socket head screw垫圈 washer螺塞 screw plug盲销 blind dowel行程,走位 stroke /

36、travel吨位 tonnage机械冲床 mechanical press油压机 hydraulic press冲床下台面 bolster冲床上台面 ram冲床台面布置图 press layout冲床码模槽 press mounting slot冲床气垫 air cushion码模钳 stirrup闭合高度 shut height送料高度 feeding height送料机 feederT型槽T-slot避位 clearance /pocket掏空 pocket挂台 head扣位 pocket of head通气孔 air vent hole漏油孔 drain hole漏料孔 slug hol

37、e 基准孔 datum hole通孔 through hole穿丝孔 first wire hole T型槽T-slot拔牙jackscrew摆块rockerbender闭合高度shutheight避位clearance/pocket侧冲组件cam侧刃french插针pilotpin插针套pilotbushing插针通孔pilotthroughhole铲机driver沉头counterbore成型凹模formdie成型公formpunch冲床码模槽pressmountingslot冲床气垫aircushion冲床上台面ram冲床台面布置图presslayout冲床下台面bolster冲孔入子b

38、utton冲头倒斜shear初始管位firststartpin储运块storageblock穿丝孔firstwirehole传感器sensor弹簧套springcage氮气弹簧gasspring/nitrogenspring氮气弹簧安装法兰mountingflange氮气弹簧系统nitrogenmanifold刀口trimsteel刀口上沉头的深度dielife刀口直身位land导尺rail/stockguidance导尺顶杆lifterbolt导料板railplate导套guidebushing导柱guidepost导柱导套压块keeper/boss垫片shim垫圈washer顶针kicko

39、ff/ejector吨位tonnage废料切断刀slugbreaker浮块lifter浮料板lifterplate高低冲staggerpunch挂台head滑块slide滑块上油槽oilgroove机械冲床mechanicalpress基准孔datumhole键key键槽keyslot聚氨酯弹簧urethane靠块heel扣位pocketofhead两用销lifterpin漏料孔slughole漏油孔drainhole螺塞screwplug螺丝screw螺旋弹簧coilspring码模槽mountingslot码模钳stirrup盲销blinddowel模柄shank模具die/tool模座导

40、正块thrust内六角螺钉socketheadscrew内限位standoff耐磨板wearplate耐磨片wearsheet起吊环eyebolt起吊孔handinghole切边冲头trimpunch球锁冲头ball-lockpunch球锁座ball-lockretainer上垫板punchbackup上垫脚upperparallel上夹板punchholder上模座upperdieset下托板basemountingplate上托板uppermountingplate送料高度feedingheight送料机feeder掏空pocket通孔throughhole通气孔airventhole脱料

41、板stripper脱料板拉杆stripperbolt误检杆trigger误检装置misfeeder下垫板diebackupplate下垫脚lowerparallel下模板dieplate下模座lowerdieset限位柱stopblock镶件/入子insert销针dowelpin行程,走位stroke/travel压块keeper压料块pressurepad牙thread油压机hydraulicpress油嘴oilnipple整形公restrikeformpunch直5斜15mmLand1taper止挡板travelingstop机加工:开料 cutting material钻drill (D

42、R)攻牙 tap铰 ream铣 mill车 lathe电脑锣 NC mill线切割wire cutting (W/C)磨 grind刨 planer电火花 EDM镭射laser cutting倒角 chamfer 精加工 finish XX真空热处理 vacuum heat treatment 镀钛TD coating 退磁 demagnetization 烧焊 weld G :40-M6BLIND HL,TAP DP18.00 OPP SIDE,THR DP18.00) 盲孔,反面攻深*G10:4-M30BLIND HL,TAP DP18.00 EDGE SIDE)盲孔,侧攻深*(%c34.

43、00*14.00 CBORE DP14.00 TOP SIDE) 正面沉头多少多少深G2 :24-%c8.00(REAM FOR DOWEL WORK DP16.00 OPP SIDE,DR%c6.00 HL) G2 :24-%c8.00(合销,背铰深16.00,有效深,内钻%C6.00通孔)G4 :3-%c10.00(基准孔,背铰深20.00)背面锣25.00*25.00方形沉头,深1.00%P0.01(REAM FOR DATUM HL DP20.00,MILL25.00*25.00 OPP SIDE DP1.00%P0.01)M:2-%c15.00(弹簧孔,锣深33.00) (CBORE

44、 OR SPRING DP33.00 TOP SIDE,WORK DP33.00)X :3-%c32.00(导套孔,锣穿,单+0.01)(MILL THRU FOR GUIDE BUSHING S+0.01)G :2-M10盲孔,侧攻深30.00(有效深)(BLIND HL,TAP WORK DP30.00 EDGE SIDE)(沉头5.20%P0.05深)(SLOT DP5.20%P0.05 TOP SIDE) L :2-%c8.000(合销,割)单+0.005 (W/C FOR DOWEL)S+0.005盲孔,攻深20.00(有效深) (BLIND HL,TAP DP20.00 TOP S

45、IDE,THR DP20.00)(插针孔,割,单+0.01) (W/C S+0.01 FOR PILOT PIN)(避位孔,背锣9.80(有效深) (POCKET,MILL DP9.80 OPP SIDE WORK)(冲头过孔,锣穿) (MILL THRU FOR PUNCH CLEARANCE HL)(导柱孔,锣穿,单+0.005) (MILL FOR GUIDE PIN) S+0.005避位槽,背锣深19.00) (POCKET,MILL DP15.40 OPP SIDE)(背,沉头%c14.00,掏深留11.00) (%c14.00 CBORE UNTIL DP14.00 OPP SID

46、E)下模刀口,实数割,直5斜1.5 (内钻%C5.0穿丝孔)W/C S+0.00 TRIM STEEL,5.0LAND 1.5TAPER,(DR THRU%c3.00 WEDM S.H)(MILL FOR INSERT DP30.0%P0.01 S+0.01)(入子槽,锣深30.00%p0.01,单+0.01)(氮气槽,背锣深4.00%P0.1,单+0.1) (GAS SPRING MILL DP4.00 OPP SIDE)S+0.1按向视图加工ACCORDING VIEW DRAWING TO MACHINING试模材料: 热扎板 HRS (hot-roll steel)冷扎板 CRS (c

47、old-roll steel)不锈钢板Stainless steel 镀锌板galvanized steel镀铝锌板galvalume steel 热扎酸洗板HRPO steel (hot-rolled pickled and oiled steel)工具:卡尺 caliper千分尺 micrometer拨牙器 jacker扳手 wrench丝攻 screw tap起子 screwdriver码模钳 stirrup设备/工具:3D Programmable CMM三次元检测仪3D CMMBeam Drilling Machine摇臂钻Bench Drilling Machine钻铣床Calip

48、er卡尺CNC EDM电火花机CNC Machine Center加工中心CNCCNC Milling Machine数控铣床CNCCNC Planer Type Milling Machine龙门刨铣床Hardness Tester硬度计Height Gauge高度仪High Wire Cutting快走丝Hole Puncher 打孔机Horizontal surface grinder小水磨/卧式平面磨床 Horizontal surface large grinder大水磨Lathe车床Measurement Surface Plate测量平台Metal Saw Machine锯床Mi

49、lling Machine铣床Oil Press油压机Pin Gauge标准针规Plastic Injection Machine注塑机Point to Point CMM三次元测量仪Precision surface grinder精密手摇磨Press冲床Projector profile投影机Shear Press剪板机Slow Wire Cutting慢走丝Vertical Milling Machine卧式强力铣床扳手wrench拨牙器jacker卡尺caliper码模钳stirrup起子screwdriver千分尺micrometer丝攻screwtapCARVE 雕刻pothook

50、 挂钩 SPECIAL HL 异形孔漏斗 filler角铁 ANGLE IRON展开 expanding微调开关 INCHING SWITCH合叶 HINGE优力胶 RUBBER球锁垫板 LOCK WASHER双线边刀口,不倒角TRIM STEEL NEAR THE DOUBLE LINE NO CHAMFER滑块座:SLIDE SET 机械:(engine type) liquid cooled, in-line, 4cylinder, carb (发动机型号)水冷,直列,四缸,化油器式(engine) compression ratio (发动机)压缩比(engine) displacem

51、ent (发动机)排量(engine) fuel (发动机)燃料13-mode 13工况3rd gear 三档齿轮3-way seat 三向座椅4WD control device 四轮驱动控制装置4WD indicator switch 四轮驱动指示灯开关4WD lamp electrical connection 四轮驱动指示灯接线4WD switch 四轮驱动开关5th synchromesh assy. 五档同步器总成6PK belt 6PK 多楔驱动皮带A / C compressor assembly 空调压缩机总成A / C control assembly 空调控制装置A/C

52、& heater assy. 空调加热器总成A/C blower 空调鼓风机A/C clutch 空调压缩机离合器A/C compressor MTG bracket 空调压缩机安装支架A/C control assy. 空调控制器A/C housing assy. 空调箱总成A/C low pressure switch 空调低压开关A/C mode select switch 空调状态选择开关abdomen performance criterion 腹部性能指标Abdominal Peak Force 腹部力峰值ABS 防抱死制动系统acceleration fuel system 加速

53、系统acceleration running noise level 加速行驶噪声accelerator interlocking type 加速踏板联锁式accounting foundation 财政基础Actual cycle work 实际循环功Actual torso angle 实际躯干角adapter 连接器additional features 附加装置additional rule 附加法规adjust screw 调整螺钉adjuster cable 调整拉线adjuster plug 调整盖adjuster screw assy. 调整螺栓总成adjuster washe

54、r 调整棘片adjuster, diff. bearing 差速器轴承调整螺母Adjustment system 调节装置Administration and Registration Division 管理科Agreement Concerning the Adoption of Uniform Technical Prescriptions for Wheeled Vehicles, Equipment and Parts Which Can Be Fitted and/or Be Used on Wheeled Vehicles and the Conditions for Recipr

55、ocal Recognition of Approvals Granted on the Basis of These Prescriptions关于对轮式车辆、安装和/或用于轮式车辆的装备和部件采用统一条件并相互认可基于上述条件批准的协定书Agreement Regulations 协定法规air cleaner 空气滤清器air cleaner assy. 空气滤清器总成air cleaner cartridge 空气滤清器滤芯Air compressor 空压机air condition compressor 空调压缩机air direct 空气走向air filter 空气滤清器air

56、 flow 空气流向Air flow meter 空气流量计air jet 空气量孔air metering hole 空气量孔air path 气道Air Pressure of Tire 轮胎气压Air type 空气型air valve 空气阀air-cooled 风冷Aisles 通道Alcohol 酒精all bearing 球轴承alternater bracket 发动机支架alternator 交流发电机alterntor assembly 交流发电机总成alumininum-rim 铝合金钢圈alumininum opposed model 铝制对开式AM/FM cassette stereo radio 调幅/调频立体声收放机ambulance 救护车Amended by 修正文amount of exhaust emission 排气排

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。