TS16949来料检验作业指导书中英文

TS16949来料检验作业指导书中英文

《TS16949来料检验作业指导书中英文》由会员分享,可在线阅读,更多相关《TS16949来料检验作业指导书中英文(14页珍藏版)》请在装配图网上搜索。

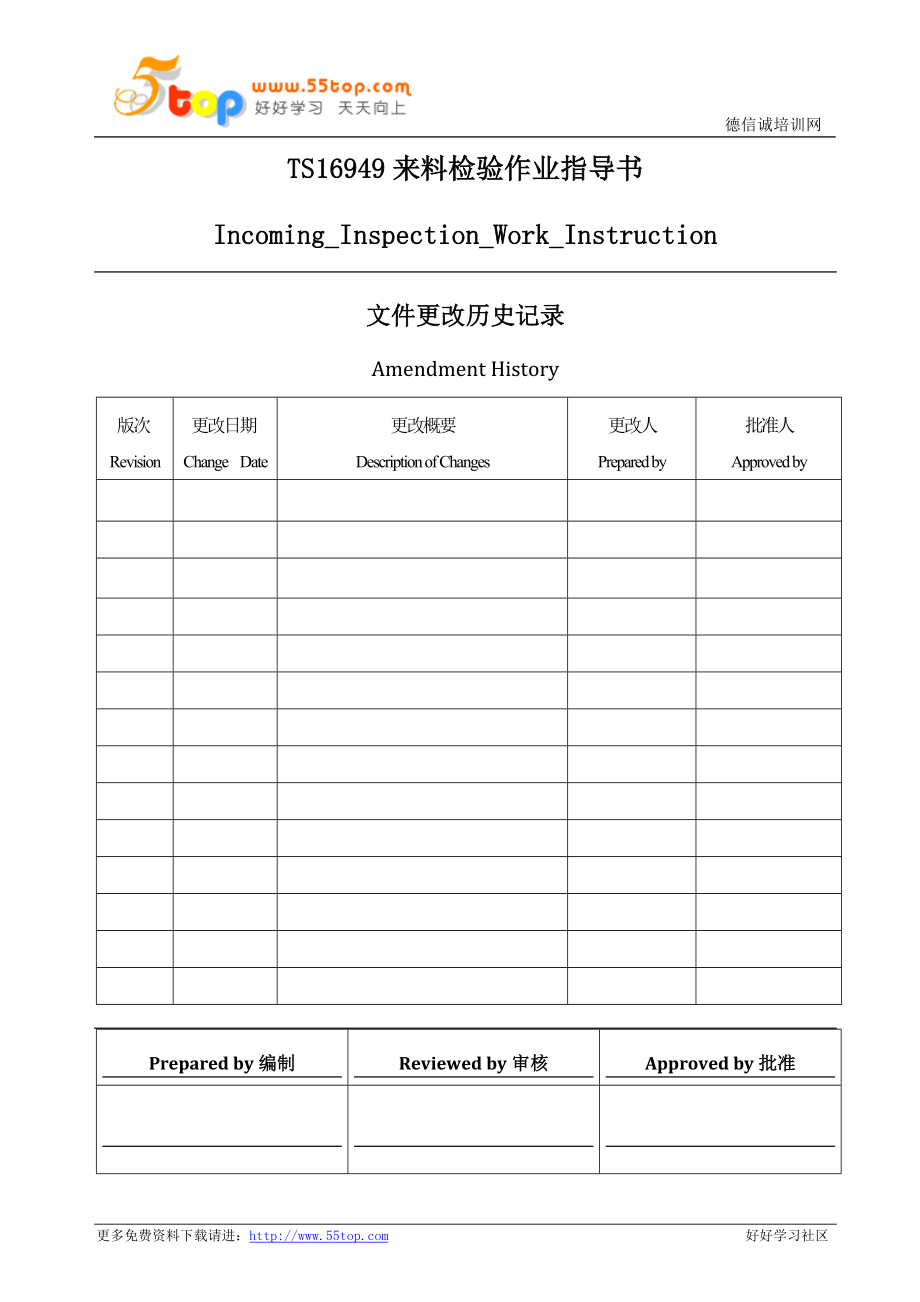

1、德信诚培训网TS16949来料检验作业指导书Incoming_Inspection_Work_Instruction文件更改历史记录Amendment History版次Revision更改日期Change Date更改概要 Description of Changes更改人 Prepared by批准人 Approved byPrepared by编制Reviewed by审核Approved by批准TS16949来料检验作业指导书Incoming_Inspection_Work_Instruction1.0 Purpose目的The objective of this procedure

2、 is to define a standard inspection method in performing inspection and testing of components or materials. 本程序目的在于定义对元件或材料进行检验/测试的标准操作方法。 Scope适用范围This procedure is applicable to all components and materials that require the relevant inspection and testing, as specified in the individual Part or Ma

3、terial Specification.本程序适用于所有按照元件和材料规格进行检验和测试的元件和材料。2.0 Sampling / Equipment Used 取样 / 使用设备2.1 Per sampling plan stated in the Incoming Inspection Procedure: AQL:MA=0.4、MI=1.0 按照来料检验程序所规定的抽样计划;AQL:MA=0.4、MI=1.0级别进行抽样.2.2 Inspection Aids检验工具4.2.1 LCR Meter / LCR 测量仪4.2.2 Fluke Multimeter / Fluke 万用表

4、4.2.3 Caliper / Plug Gauge / Pin Gauge / 游标卡尺/ 塞规/针规4.2.4 Magnifier / Microscope / 放大镜 / 显微镜 3.0 Reference Documents参考文件3.1 Customers AVL / 客户接受的供应商清单3.2 Manufacturer Part Specification / 供应商的元件规格3.3 Yamaoka AVL List / 本公司的AVL3.4 QAP-010 : Incoming Inspection Procedure / 来料检验程序3.5 SOP-QA-003 : Mater

5、ial Aging Control Procedure / 物料保质期控制程序4.0 Inspection Criteria / 检验要点4.1 MFG AVL Verification / 生产厂商确认Verify that the parts are from the authorized vendor per AVL list.根据AVL清单验证元件是否为承认厂商。4.2 MFG Part Number Verification / 生产厂商料号确认 Verify that manufacturer part number and description are correct per

6、PO and DO. 根据PO 和DO验证生产厂家料号和元件种类.5.3 Packaging&RoHS Verification / 包装、环保确认Verify that the part is packed in correct/proper packaging as indicated in manufacturer p/n and/or engineering requirement. Check if there are part number and vendor name marked on every packing box or container. Whether RoHS

7、materials? The Customer material should pay attention to whether have original packaging label;验证元件的包装与厂家料号和/或工程需要是否一致适当,是不是环保材料。检查每个包装箱外是否标明品名和厂商名. 对客供物料需注意包装上是否有原厂标签;5.4 Visual Inspection / 外观确认Carry out visual inspection on samples, if confirmation of defects is required, use visual aids or equip

8、ment such as 5X magnifying glass, microscope etc to check.对来料样品进行外观检验,如果必要,可使用5倍放大镜,显微镜等辅助设备进行检验。5.5 Part Dimensional Check / 尺寸确认Measure samples on critical dimensions that are highlighted in the respective part drawing or specification. 5 data to be recorded.根各元件的规格对抽样样品进行尺寸检验;记录5个检验数据; 5.6 Part V

9、alue Measurement / 测值For inductors/capacitors/resistors, need to perform value measurements using LCR meter that record 5PCS per datecode according to AVL and manufacturers specifications. 5 data to be recorded.对于电感/电容/电阻元件,需按照AVL和厂家的标准,利用L/C/R测量仪进行测值,每D/C抽样5PCS。各记录5个数据 ; 5.7 Date Code Verification

10、/ 生产日期确认For PCB, D/C should be within 6 months from date of manufacture,machine part 、LED、connecter 、moisture sensitive components within 1year. For other electronic components(passive、disperse), D/C should be within 2 years and for chemistries, the expiry date shall be verified according to Materia

11、l Aging Control Procedure, SOP-QA-003 .对于印刷线路板,保质期需控制在生产日期后半年之内;结构件、LED、连接器、湿敏元件为1年内,其他的电子(被动和离散)元件,生产日期需控制在2年之内。对于化学药品,失效日期按照物料保质期控制流程执行,文件号码:SOP-QA-003.5.8 Certificate of Conformance (COC) Verification / 出厂检验报告确认For PCB and Chemical items, COC must be provided by supplier for every delivery lot.对于

12、印刷线路板 和化学药品需要供应商对每一批次提供COC.5.9 Solderability & Electrical Test / 可焊性/电气测试If the component has exceeded their shelf life, solderability and/or electrical test shall be conducted according to Material Age Control Procedure. 如果元器件超过保质期限,按照物料保质期控制流程执行可焊性测试和/或电气测试。5.0 Procedure / 程序6.1 PCB Inspection Cri

13、teria / 印刷线路板的检验要点元器件COMPONENT检验要点 (INSPECTION CRITERIA)仪器设备EQUIPMENT1Per AVL, check the MFG name按照系统客户许可供应商列表核对生产厂家五至八倍放大镜5X-8X Magnifier2Per AVL, check MPN按照系统客户许可供应商列表核对生产厂家料号游标卡尺Caliper3Verify if package is proper and in good condition检查包装是否合适并完好针规Needle Gauge4Verify UL logo and flammability cla

14、ss; for example:94V-0;检查安全认证标记和防火等级 例如:94V-0显微镜Microscope5Verify Electrical Test Stamp检查电气测试章塞规Plug Gauge6Verify the body marking and REV检查本体标示和版本7Solder mask adhesion test is OK or NG which include incoming QA report content that it must be checked by inspector剥皮测试检查供应商出货报告内容是否有阻焊膜粘贴性试验是否OK8Visual

15、check外观检查a. Surface checking with naked eyes 裸眼作表面可视性检查 印刷电路板(PCB)b. Use 5X/8X magnifier check the defect area 用五至八倍放大镜对有缺陷可能的位置进行检查 c. Use microscope to determine the defects (refer to PCB inspection SOP) 用显微镜对有缺陷的位置进行确认.具体缺陷标准参照PCB检验SOP 9Per drawing or spec, do warp and twist inspection 按照图纸要求检验翘曲

16、度和扭曲度10Per drawing or spec, measure the dimensions按照规格说明书或图纸检验尺寸11Verify the D/C should be within half a year检查生产日期必须在半年以内12Verify if PO# and QTY of COC provided by supplier are meeting our requirement检查生产厂家出厂报告上的内容是否符合我司要求13Solderability Test: under FA or out of D/C condition可焊性检查: 首件检查或保质期过期时检查该项N

17、ote: Shall be wearing ESD gloves when inspecting PCB注意:检验印刷电路板时必须戴好静电防护手套6.2 L/C/R Inspection Criteria / 电感,电容,电阻检验要点元器件(COMPONENT)检验要点(INSPECTION CRITERIA)仪器设备(EQUIPMENT)1Per AVL, check the MFG name按照系统客户许可供应商列表核对生产厂家游标卡尺Caliper2Per AVL, check MPN按照系统客户许可供应商列表核对生产厂家料号五至八倍放大镜5X-8X Magnifier3Verify i

18、f package is proper and in good condition检查包装是否合适并完好LCR表L/C/R Meter4Visual check外观检查a. No distortion ,missing , damaged本体无变形,缺损和断裂 电阻(R)、电容(C)、b. No oxidation, plating surface badly, bend and missing with naked eyes.引脚无肉眼可见的氧化,镀层不良,弯曲和缺损 电感(L) 5Per spec or drawing, measure the dimensions and perform

19、 visual checking根据规格说明书或图纸进行尺寸和外形检验6Verify component orientation极性标识方向一致7Verify the components per AVL system:按照系统中元件描述:a. Verify the type of material, for example: 1206 0805确认元件型号大小,如1206,0805 b. For Resistor, Capacitance, Inductor, should do value test,refer to L/C/R meter operation procedure对电阻、电

20、容、电感进行测值,参考L/C/R仪器操作程序 8Verify the D/C should be within 2 years or record the Lot Number检验生产日期必须在两年以内或记录生产批号6.3 Switch / Transformer Inspection Criteria / 开关 , 变压器检验要点元器件(COMPONENT)检验要点(INSPECTION CRITERIA)仪器设备(EQUIPMENT)1Per AVL, check the MFG name按照系统客户许可供应商列表核对生产厂家游标卡尺Caliper2Per AVL, check MPN按照

21、系统客户许可供应商列表核对生产厂家料号五至八倍放大镜5X-8X Magnifier 开关(SWITCH)3Verify if package is proper and in good condition检查包装是否合适并完好变压器(TRANSFORMER)4Visual check: no distortion ,missing ,damaged外观检查:本体无变形,缺损和断裂5Per spec or drawing measure dimension visual checking,then it must be recorded 5PCS perpart; 按照规格说明书或图纸检验尺寸和

22、外形(5PCS重要尺寸)6Operate switch操作开关键7Verify the D/C should within 2 years or record the Lot No检验生产日期必须在两年以内或记录生产批号6.4 IC Inspection Criteria / 集成电路的检验要点元器件(COMPONENT)检验要点(INSPECTION CRITERIA)仪器设备(EQUIPMENT)1Per AVL, check the MFG name按照系统客户许可供应商列表(AVL)核对生产厂家五至八倍放大镜5X-8X Magnifier2Per AVL, check MPN按照系统客

23、户许可供应商列表(AVL)核对生产厂家料号(MPN)显微镜Microscope3Verify if package is proper and in good condition检查包装是否合适并完好游标卡尺Caliper4Visual check外观检查a. No distortion ,missing, damaged 本体无变形,缺损和断裂 集成电路(IC)b. No oxidation, plating surface badly, bend and missing with naked eye引脚无肉眼可见的氧化,镀层不良,弯曲和缺损5Verify component orienta

24、tion极性标识方向一致6Record body marking记录元件本体标示(MARKING)7Verify the D/C should within 2 years or record the Lot No; moisture sensitive record 5PCS per datecode检验生产日期必须在两年以内或记录生产批号,湿敏元件1年内8For program part, need to do program and perform master check;testing 5PCS per lot;如果来料是程序料,项目要求检验时(有夹具或客户已提供烧录程序)需要测试来

25、料是否已经烧入程序,每批次抽测5PCS9If the part is moisture sensitive, need to vacuum pack timely after checking如果是湿敏元件,检验完后需要及时的进行真空包装6.5 Diode/LED/Transistor/Fuse/Crystal/Rectifier Inspection Criteria 二极管/发光二极管/三极管/晶振/保险丝/整流器的检验要点元器件(COMPONENT)检验要点(INSPECTION CRITERIA)仪器设备(EQUIPMENT)二极管 (DIODE)发光二极管 (LED)三极管 (TRA

26、NSISTOR)晶振 (CRYSTAL)保险丝 (FUSE)整流器 (RECTIFIER)1Per AVL, check the MFG name按照系统客户许可供应商列表核对生产厂家游标卡尺Caliper2Per AVL, check MPN按照系统客户许可供应商列表核对生产厂家料号三至五倍放大镜3X-5X Magnifier3Verify if package is proper and in good condition检查包装是否合适并完好显微镜Microscope4Visual check外观检查a. No distortion ,missing, damaged本体无变形,缺损和断

27、裂 b. No oxidation, plating surface badly, bend and missing by naked eye引脚无肉眼可见的氧化,镀层不良,弯曲和缺损 5Fuse and crystal, should record body marking per electricity and frequency in the AVLs description保险丝和晶振要按照系统中元件描述中最大电流和频率核对本体标示6Per spec or drawing, measure the dimensions and perform visual checking根据规格说明

28、书或图纸检验尺寸和外形确认7Verify the D/C should be within 2 years or record the Lot No,moisture rensitive within 1 year;检验生产日期必须在两年以内或记录生产批号,来料为湿敏封装时按一年6.6 Connector/Plug/ Socket Inspection Criteria / 连接件/ 插头/ 插座检验要点元器件(COMPONENT)检验要点(INSPECTION CRITERIA)仪器设备(EQUIPMENT)1Per AVL, check the MFG name按照系统客户许可供应商列表核

29、对生产厂家游标卡尺Caliper2Per AVL, check MPN按照系统客户许可供应商列表核对生产厂家料号五至八倍放大镜5X-8X Magnifier3Verify if package is proper and in good condition检查包装是否合适并完好连接件(CONNECTOR)4Visual check外观检查插头(PLUG)a. No distortion, missing, damaged,lost PIN;本体无变形、缺损、断裂 、少PIN脚插座(SOCKET)b. No oxidation, plating surface badly, bend and m

30、issing by naked eye引脚无肉眼可见的氧化,镀层不良,弯曲和缺损 5Verify the visual and QTY of pins per spec or drawing按照规格说明书或图纸检查元件外形及引脚数量 6Per spec or drawing or spec, do dimension inspection and visual check按照规格说明书或图纸检验尺寸和外观确认7Verify the D/C should be within 2 years or record the Lot Number检验生产日期必须在两年以内或记录生产批号 6.7 Cabl

31、e Inspection Criteria / 电缆线检验要点元器件(COMPONENT)电缆线(CABLE&WIRE)检验要点(INSPECTION CRITERIA)仪器设备(EQUIPMENT)1Per AVL, check the MFG name按照系统客户许可供应商列表核对生产厂家游标卡尺Caliper2Per AVL, check MPN按照系统客户许可供应商列表核对生产厂家料号五至八倍放大镜5X-8X Magnifier 3Verify if package is proper and in good condition检查包装是否合适并完好4Visual check: no

32、broken, insulated broken missing外观检查:无断裂,绝缘破损,缺失5Per spec or drawing, measure the dimensions and perform visual check按照规格说明书或图纸检验尺寸和外形确认6Verify the D/C should be within 2 years or record the Lot Number确认生产日期在2年之内,或者记录生产批号6.8 Metal FAB/ Plastic FAB Inspection Criteria / 金属结构件/塑料结构件的检验要点元器件(COMPONENT)

33、检验要点(INSPECTION CRITERIA)仪器设备(EQUIPMENT)1Per AVL, check the MFG name按照系统客户许可供应商列表核对生产厂家游标卡尺Caliper2Per AVL, check MPN按照系统客户许可供应商列表核对生产厂家料号五至八倍放大镜5X-8X Magnifier金属结构件(METAL FAB)3Verify if package is proper and in good condition检查包装是否合适并完好针规Needle gauge塑料结构件(Plastic Part)4Visual check: no leak, broken

34、, Paint surface bad,oxidation, smearing, scratch, stab,bubble, color discrepancy, flow line, sink mark and marking not clear .外观检查-缺损,断裂,镀层不良,氧化,污点,划伤,毛刺, 气泡,色差, 流痕,缩水及印字不清等.塞规Plug gauge5Verify the visual per specification or drawing按照图纸或规格说明书检验外形6Per spec or drawing, do dimension inspection按照规格说明书或

35、图纸检验尺寸6.9 Chemical Material Inspection Criteria / 化学品检验要点元器件COMPONENT检验要点INSPECTION CRITERIA仪器设备EQUIPMENT1Per AVL, check the MFG name按照系统客户许可供应商列表核对生产厂家2Per AVL, check MPN按照系统客户许可供应商列表核对生产厂家料号3Verify the package if in good condition, is there dry ice in the package检查包装是否完好,包装盒内有没有放干冰.化学品4Verify if t

36、he Lot Number in COC matches materials(Chemical 核对厂家出厂报告上的生产批号是否与来料生产批号一致Material)5Verify if the chemical type in COC & MFG label are same as we required in AVL核对厂家出厂报告上的化学品型号&来料标签上的型号是否与我们AVL清单描述中的型号一致6Verify D/C: should 2 or 6 months before the EXPIRY date, refer to Material Age Control Procedure检

37、查来料有没有过期,必须在失效日期前2或6个月,具体参考物料有效期控制流程.7Viscosity test report or COC should be provided by supplier for solder paste如果是焊膏需要有厂商黏度测试报告。8Fill in the inspection report per COC按照厂家出厂报告填写检验报告 元器件(COMPONENT)检验要点(INSPECTION CRITERIA)仪器设备(EQUIPMENT)1Per AVL, check the MFG name按照系统客户许可供应商列表核对生产厂家N/A2Per AVL, ch

38、eck MPN按照系统客户许可供应商列表核对生产厂家料号塑料粒子( Plastic Resin)3Verify if packaging is proper and in good condition检查包装是否合适并完好4Visual check: Color and cleanliness.外观检查-材料本色,胶料颗粒均匀、干燥、无杂色、杂质、水份,油污、脏物。5Each lot need a color card 每批塑料粒子需提供色板6COC and RoHS report is required 必须有材质证明书和RoHS报告6.0 Document Checking / 文档的检验

39、6.1 Part Specification or Drawing checking / 规格说明书或图纸的检查6.2 First Article (FA) Report checking / 首检报告检查6.3 PCB Inspection Instruction / 印刷线路板的检验指导6.4 Fabricated Part Inspection Instruction / 结构件的检验指导6.5 L/C/R Meter Operating Instruction / L/C/R测量仪的操作指导7.0 Lot Disposition / 批的处理7.1 Accept the lot if

40、no reject found from visual check, dimensional measurement and solderability/electrical tests. Stamp a “IQA ACCEPT” stamp on the GRN label. Record result of lot disposition on the “IQA Inspection Report”. Stamps ACCEPT on the receiver/DP and forward the lot to Store via receiver.如果任何测试和检验都未发现不良,可将该批

41、允收。在收料标签上盖上IQA接受章;在IQA检验报告上记录检验结果,并将该批物料转至IQA检验PASS区域,待仓库收料员入库7.2 Reject lot if discrepancy found in any of the above tests/inspections. After completing the inspection, affix a “QA REJECT” label on the carton/container/reel/bag, forward the reject lot to MRB co-ordinator. Record result of lot dispo

42、sition on the “IQA Inspection Report”如果上述的任何测试/检验发现不良,按AQL规定不符合允收要求则将该批拒收。在完成所有的检验项目后,在外箱/容器/卷轴外贴上“MRB”标签,将拒收材料交给MRB协调判定,依据判定结果盖章,若MRB判定为让步接收,则盖让步接收章,若判退则盖NG章,将该批的检验结果记录入“IQA检验告”。 8.0 Incoming Quality Special Instruction / 来料质量特殊检验指导IQSI: This instruction is released by SQE when quality issue found

43、or feedback by customer, supplier or production that requires special or immediate attention. SQE shall provide the instruction to IQA inspector how to inspect and control the quality for a specified period. 来料质量特殊检验指导是由供应商质量工程师在客户供应商的生产线反馈的质量问题时发出的要求特殊或紧急注意的指导文件。供应商工程师应指导来料检验员在一定的时间段内怎样去检验控制质量问题。更多免费资料下载请进:好好学习社区

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。