制程失效模式及效应分析PFMEA表

制程失效模式及效应分析PFMEA表

《制程失效模式及效应分析PFMEA表》由会员分享,可在线阅读,更多相关《制程失效模式及效应分析PFMEA表(8页珍藏版)》请在装配图网上搜索。

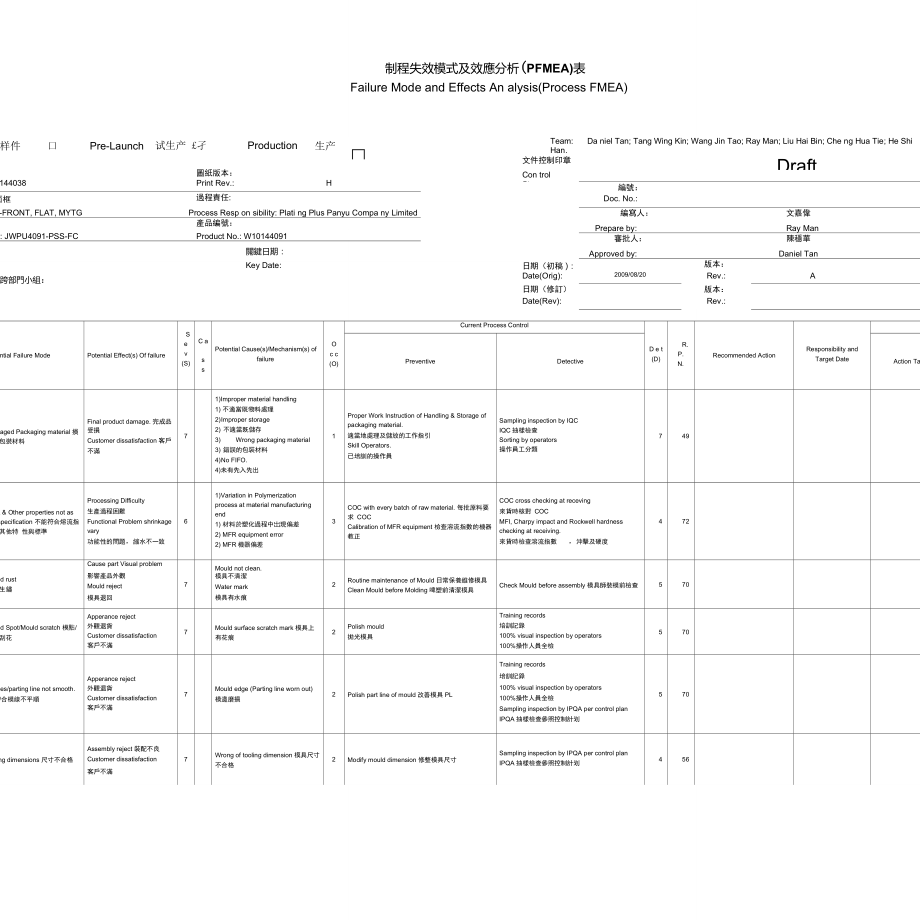

1、制程失效模式及效應分析(PFMEA)表制程失效模式及效應分析(PFMEA)表Failure Mode and Effects An alysis(Process FMEA)Page # of 5FM-PG-0201-01制程失效模式及效應分析(PFMEA)表Page # of 5FM-PG-0201-01制程失效模式及效應分析(PFMEA)表Prototype 样件口Pre-Launch试生产 孑Production生产圖紙編號:圖紙版本:Print # : W10144038Print Rev.:H產品名稱:面框過程責任:tem: COVER-FRONT, FLAT, MYTGProcess

2、 Resp on sibility: Plati ng Plus Panyu Compa ny Limited產品電碼:產品編號:Product code: JWPU4091-PSS-FCProduct No.: W10144091關鍵日期:Key Date:跨部門小組:Team:Da niel Tan; Tang Wing Kin; Wang Jin Tao; Ray Man; Liu Hai Bin; Che ng Hua Tie; He Shi Han.文件控制印章:DraftCon trol Stamp:編號:Doc. No.:編寫人:文嘉偉Prepare by:Ray Man審批人:

3、陳穩華Approved by:Daniel Tan日期(初稿):版本:Date(Orig):2009/08/20Rev.:A日期(修訂):版本:Date(Rev):Rev.:Page # of 5FM-PG-0201-01制程失效模式及效應分析(PFMEA)表Page # of 5FM-PG-0201-01制程失效模式及效應分析(PFMEA)表Operation No.Process function requirementPotential Failure ModePotential Effect(s) Of failureSev(S)C assPotential Cause(s)/Mech

4、anism(s) of failureOc c(O)Current Process ControlD e t(D)R.P.N.Recommended ActionResponsibility and Target DateAction ResultsR.P.N.PreventiveDetectiveAction Taken(S)(O)(D)1000ncoming nspection of raw Material ABS(3001M) 原材料來料檢查 ABS(3001M)Damaged Packaging material 損壞的包裝材料Final product damage. 完成品受損C

5、ustomer dissatisfaction 客戶不滿71)Improper material handling1) 不適當既物料處理2) Improper storage2) 不適當既儲存3) Wrong packaging material3) 錯誤的包裝材料4) No FIFO.4)未有先入先出1Proper Work Instruction of Handling & Storage of packaging material.適當地處理及儲放的工作指引Skill Operators.已培訓的操作員Sampling inspection by IQCIQC抽樣檢查Sorting by

6、 operators操作員工分類749MFR & Other properties not as per specification 不能符合熔流指數及其他特 性與標準Processing Difficulty生產過程困難Functional Problem shrinkage vary功能性的問題,縮水不一致61)Variation in Polymerization process at material manufacturing end1) 材料於塑化過程中岀現偏差2) MFR equipment error2) MFR機器偏差3COC with every batch of raw

7、material. 每批原料要求 COCCalibration of MFR equipment 檢查溶流指數的機器教正COC cross checking at receving來貨時核對 COCMFI, Charpy impact and Rockwell hardness checking at receiving.來貨時檢查溶流指數,沖擊及硬度4721500Mould模具Mould rust模具生鏽Cause part Visual problem影響產品外觀Mould reject模具退回7Mould not clean.模具不清潔Water mark模具有水痕2Routine ma

8、intenance of Mould 日常保養維修模具Clean Mould before Molding 啤塑前清潔模具Check Mould before assembly 模具師裝模前檢查570Mould Spot/Mould scratch 模點/模面刮花Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Mould surface scratch mark 模具上有花痕2Polish mould拋光模具Training records培訓記錄100% visual inspection by operators100%操作人員全檢570z

9、lashes/parting line not smooth.披鋒/合模線不平順Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Mould edge (Parting line worn out)模邊磨損2Polish part line of mould 改善模具PLTraining records培訓記錄100% visual inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Wrong dimensio

10、ns 尺寸不合格Assembly reject 裝配不良Customer dissatisfaction客戶不滿7Wrong of tooling dimension 模具尺寸不合格2Modify mould dimension 修整模具尺寸Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划4563050Dre drying of3001M焗乾膠料 3001MHigh Moisture content in raw material.膠料濕度過高Moulded part with void,bubble,silver strea

11、kes,delayering.膠件有空隙,膠泡Coustomer dissatisfaction 客戶不滿31) Predrying mechanism is not working.1) 焗乾機器壞掉2) Predrying time & Temp not set as per MI2) 焗乾時間及溫度不是按作業指 示書3) Un skilled operators.3)操作員工未有培訓1Display of predrying process instruction/process parameters. 於操作地方展示焗乾程序及指示Trained and skilled operator

12、. 培訓操作員工Resin Pre-drying time and temperature is controlled by injection.注塑部控制焗料時間及溫度Shiftwise perdrying process parameter recordi ng每班記錄局爐參數6183100InjectionMolding注塑Sink Marks縮水Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Less cooling time冷卻時間不足Mould cooing lines are blocked. 運水不通Injection pres

13、sure less注塑壓力不足2Display of process parameters instructions 展示注塑參數Trained & Skilled operators to set machine 培訓操作員工調機Preventive maintenance of Machine預防性保養機器Training records培訓記錄100% visual inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Short shot走膠不齊Appe

14、rance reject外觀退貨Customer dissatisfaction客戶不滿7Injection speed is too slow 射速太慢Injection perssure less注塑壓力不足Melt temprature low 料溫太低2Display of process parameters instructions 展示注塑參數Trained & Skilled operators to set machine 培訓操作員工調機Preventive maintenance of Machine預防性保養機器Training records培訓記錄100% visu

15、al inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Burn燒膠Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Injection speed high射速太快Venting no engough排氣不良Large capacity machine used for moulding鎖模力太大2Display of process parameters instructions 展示注塑參數Trained

16、 & Skilled operators to set machine 培訓操作員工調機Preventive maintenance of Machine預防性保養機器mould design;add venting loacation改善工模,增加排氣Training records培訓記錄100% visual inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Flashes披鋒Apperance reject外觀退貨Customer dissatisf

17、action客戶不滿7Less clamping tonnage. 鎖模力不足Mould spotting is improper.模具定位不合適Injection pressure too high. 注塑力太大Material feeding too much. 射膠量太多Mould edge (Parting line worn out)模邊磨損melt temprature too high.料溫太咼2Display of mould loading instructions & Process parameter instructions展示上模作業指岀書及注塑參數Trained &

18、 Skilled operators to set mould & Machine培訓操作員工調機Preventive maintenance of Mould預防性保養機器Training records培訓記錄100% visual inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Particle膠屎Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Contamination in raw materia

19、l. 原料被污染Material not properly dehumidify. 膠料焗乾不足Mould not clean.模具不清潔2Display of storage instructions on store 於倉庫展示庫存指引Trained & Skilled operators for material handling培訓操作員工處理物料Routine maintenance of Mould & MI for mould loading日常保養維修模具及上落模Training records培訓記錄100% visual inspection by operators100

20、%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Blister/Voids膠泡Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Contamination in raw material.物料污染Material not properly dehumidify. 物料未有合適除濕More material temperature料溫太咼Less Injection & Holdingpressure射膠及保壓壓力不足2Display of storage in

21、structions on store 於倉庫展示庫存指引Trained & Skilled operators for material handling培訓操作員工處理物料Routine maintenance of Mould & MI for mould loading日常保養維修模具及上落模Training records培訓記錄100% visual inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Weldine夾紋Apperance reje

22、ct外觀退貨Customer dissatisfaction客戶不滿7The temperature of mould isnt enough模具溫度不足Venting location insufficient排氣不良2Checking cooling system of the mould is whether normal檢查運水是否正常mould design;add venting loacation改善工模,增加排氣Training records培訓記錄100% visual inspection by operators100%操作人員全檢Sampling inspection

23、 by IPQA per control planIPQA抽樣檢查參照控制計划556Spaly mark氣烘Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Injection speed is too high射速太快The temperature of mould is too low模溫太低2Display of process parameters instructions 展示注塑參數Trained & Skilled operators to set machine 培訓操作員工調機Preventive maintenance of

24、Machine預防性保養機器mould design;add venting loacation改善工模,增加排氣Training records培訓記錄100% visual inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划556Page 3 of 5FM-PG-0201-01制程失效模式及效應分析(PFMEA)表3100Injection Molding 注塑Scratches/Pit marks 刮花/點Apperance reject外觀退貨Custom

25、er dissatisfaction客戶不滿7Mould surface scratch mark 模具上有花痕Component ejection is not smooth.產品頂岀不順Gate trimming not proper.水口加工不良Part stacking improper 產品擺放不良Part falling while ejection.頂出時產品掉下2Display of mould loading instructions &Process parameter instructions展示上模作業指岀書及注塑參數Trained & Skilled operator

26、s to set mould & Machine培訓操作員工調機Preventive maintenance of Mould預防性保養機器Training records培訓記錄100% visual inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Warpage變形Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Uneven Mould-temperature模溫不平均Injection speed h

27、igh射速太快Ejection not smooth頂出不順Less cooli ng/Hold ing time 冷卻/保壓時間不足Wrong Gate positi oning 進膠位置不當2Display of mould loading instructions &Process parameter instructions展示上模作業指岀書及注塑參數Trained & Skilled operators to set mould & Machine培訓操作員工調機Preventive maintenance of Mould預防性保養機器Training records培訓記錄100

28、% visual inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Wrong dimensions尺寸不合格Assembly reject裝配不良Customer dissatisfaction客戶不滿7Unskilled Inspectors未有培訓檢查員Measuring instrument wrong 測量工具錯誤No calibration of measuring instrument未有對檢查工具教正Specification not cle

29、ar標準不清楚Wrong process parameters 不正確的過程參數Wrong of tooling dimension模具尺寸不合格2Training to inspectors培訓檢查員Visual ability test for inspectors操作員目視能力測試Identification of measuring instrument測量工具標示Calibrati on of measur ing in strume nt 測量工具教正MSA study測量系統分析Specificati ons for con trol dime nsions in CP於控制計劃

30、中標示控制尺寸及標準Display of process parameters展示過程參數Training records培訓記錄Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划4563150修剪水口及包裝Trimming the gate and PackageTrim improperly after mold 射塑后加工不良Assembly reject 裝配不良7Untrained operators未有培訓操作員Not followed the instructions未有按指示書操作1Training to ope

31、rators 培訓操作員Maufacturing instructions 指示書100% inspection by operators100%操作人員全檢535Quantity not correct產品數量不正確Effect Production影響生產7Untrained operators未有培訓操作員Not followed the packaging instructions未有按包裝指示書操作1Training to operators培訓操作員Packaging instructions包裝指示書Training records培訓記錄100% visual inspecti

32、on by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划535Part damage產品損傷Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Untrained operators未有培訓操作員Not used the standard packaging 未有使用標準包裝Not followed the packaging instructions未有按包裝指示書操作2Training to operators培訓操作員Packagin

33、g instructions包裝指示書Training records培訓記錄100% visual inspection by operators100%操作人員全檢Sampling inspection by IPQA per control planIPQA抽樣檢查參照控制計划570Wrong Labeling and Package包裝及標籤錯誤Failure in traceability for part影響跟蹤性6Untrained Operators沒經驗的操作員Wrong Package material包裝來料錯誤1Training to operators培訓操作員Pac

34、kaging instructions包裝指示書Training records培訓記錄100% inspection by operators100%操作人員全檢Sampling inspection by IPQA per 2hrsIPQA每兩小時抽檢424Parts Damage/Dirty/Scrat ches產品損傷/污物/刮花Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Untrained operators沒有培訓操作員Wrong packaging material錯誤包裝物料Unreasonable Material tre

35、at不適當的物料處理1Adequate place and containers for storage使用合適的地方及包裝Materialhandling as per material handling storage instruction按物料處理指導書處理Storage audit庫存檢查Check the shelf life and package per lot每批檢查使用期限及包裝5354000涂絕緣油MaskingWrong location / missed涂錯位置/漏涂Have matel on the in sulated area有金屬層在絕緣位置上Customer

36、 dissatisfacti on客戶不滿7Untrained operators沒有培訓操作員Notfollowed the manufacturing instructions未有按工作指示書操作1Training to operators培訓操作員100% inspection by operators100%操作人員全檢4284050Racking上撐Loose / wrong racking of parts/part damage 撐不穩/撐錯產品/產品損壞Apperance reject 外觀退貨Reliability fails 可靠性試驗不合格Customer dissati

37、sfaction 客戶不滿7Rack design wrong撐具設計問題Componenet racking wrong 上撐方式不正確racking tabs wrong/broken 撐位斷2Rack design validation 撐具設計確認Training to operators 培訓操作員MI for components racking 上撐作業指導書100% inspection by operators100%操作人員全檢5701600電鍍Plating星塵Pitting外觀影響Visual reject3不適當的電鍍參數Improper plating parame

38、ters4控制光劑添加量Control the content of bringhtener生產線上1003檢查(目測)100% inspection by line operators (Visual inspection )560花Scrath外觀影響Visual reject7鍍液固體雜質多Dross in plating soution2定期清洗電鍍缸Clean the plating vessel regularly生產線上1003檢查(目測)100% inspection by line operators (Visual inspection )570表面有點或坑 Pitting

39、 on A surface外觀影響Visual reject4不適當的電鍍參數Improper plating parameters2定期清洗電鍍缸Clean the plating vessel regularly生產線上1003檢查(目測)100% inspection by line operators (Visual inspection )540表面蒙Haze appearance on some surface area外觀影響Visual reject7光劑過底及導電不良Lessbringhten dosage and improper conductivity2控制光劑添加量C

40、ontrol the content of bringhtener生產線上1003檢查(目測)100% inspection by line operators (Visual inspection )570燒焦Chrome burn外觀影響Visual reject7電鍍參數不適當Improperplating condition2改善電鍍參數Improve the plating condition生產線上1003檢查(目測)100% inspection by line operators (Visual inspection )570黃Yellow color外觀影響Visual re

41、ject7導電不良,電流過底Improper conductivity and too low current2增加電流Add current生產線上1003檢查(目測)100% inspection by line operators (Visual inspection )570油印Oil mark外觀影響Visual reject7工件自身原因Plastic parts cause2加強檢查Inspection生產線上1003檢查(目測)100% inspection by line operators (Visual inspection )570膠泡Bubble外觀影響Visual

42、reject7工件自身原因Plastic parts cause2加強檢查Inspection生產線上1003檢查(目測)100% inspection by line operators (Visual inspection )570麻點Pock mark外觀影響Visual reject71. 光劑過底Less bringhten dosage2. 粗化溫度過高Hight temperature21. 補充光劑Complement bringhten dosage2. 降低溫度Less temprature3. 更換鍍液Change plating solution1. 生產線上100%檢

43、查(目測)100% inspection by line operators (Visual inspection )2. 每班測4個Check 4pcs/ shift684顏色、光度Colour and Lightness外觀影響Visual reject7光劑過底Lessbringhten dosage2補充光劑Complement bringhten dosage操作者100%檢查(目測)100% inspection by operator at machine(Visual inspection )570云霧Clouds and mist外觀影響Visual reject7鍍液污染C

44、ontaminate plating solution2定期清洗電鍍缸Clean the plating vessel regularly生產線上100%檢查(目測)100% inspection by line operators (Visual inspection )570漏鍍Voids/skip plating/excessack mark外觀影響Visual reject7粗化時間不夠Not enough etching2增加時間Add time生產線上100%檢查(目測)100% inspection by line operators (Visual inspection )57

45、0離層Peeling外觀影響Visual reject4鍍液污染,酸洗不干淨Contaminate plating solution/ incomplete acid cleaning2更換鍍液Change plating solution生產線上100%檢查(目測)100% inspection by line operators (Visual inspection )756電鍍泡Blisters外觀影響Visual reject4帶電臂導電不良Contaminate plating solution/ incomplete acid cleaning3加強檢查Inspection生產線上

46、100%檢查(目測)100% inspection by line operators (Visual inspection )672水漬Water marks外觀影響Visual reject3水洗不干淨Imcomplete water cleaning2加強檢查Inspection操作者100%檢查(目測)100% inspection by operator at machine(Visual inspection )742污漬Stain外觀影響Visual reject3水洗不干淨Imcomplete water cleaning2加強檢查Inspection操作者100%檢查(目測)

47、 100% inspection by operator at machine(Visual inspection )742氣烘Gas mark外觀影響Visual reject2工件自身原因Plastic parts cause2加強檢查Inspection操作者100%檢查(目測)100% inspection by operator at machine(Visual inspection )7281700解撐Derack刮花Scratch外觀影響Visual reject4不正確的操作Improper handling2加強檢查Inspection生產線上1003檢查(目測)100%

48、inspection by line operators (Visual inspection )540Page 6 of 5FM-PG-0201-01制程失效模式及效應分析(PFMEA)表1800掃紋Brushing錯誤的掃紋方向Wrong texturing direction外觀影響Visual reject7不正確的操作Improper handling2加強檢查Inspection生產線上100%查(目測)100% inspection by line operators (Visual inspection )570尺寸測量不合格Dimension measure fail影響裝配

49、Assembly failure4電鍍層過厚或過薄Too thin/ thick plating layer2改善電鍍參數Improve the plating condition每批測3啤Check 3 pcs / cycle432鍍層厚度不合格Thickness test壽命影響Reliability reject4電流過大或過小Too large / low current3改善電鍍參數Improve the plating condition每批測3啤Check 3 pcs / cycle4482000噴油塵點外觀影響Visual reject4噴房中有灰塵3清潔噴房生產線上100%檢

50、查(目測)100% inspection by line operators (Visual inspection )560油點外觀影響Visual reject4噴油掛具上殘留粉塵3定期清潔噴油掛具生產線上100%檢查(目測)100% inspection by line operators (Visual inspection )560刮花Scratch外觀影響Visual reject4不正確的操作Improper handling3佩戴手套作業生產線上100%檢查(目測)100% inspection by line operators (Visual inspection )5605

51、050實驗室測試QA Lab testing冷熱循環測試不合格Thermal cycle test fail壽命影響Reliability reject4膠件應力影響Internal stress is too high3改善啤塑參數Improve the molding parameter每年測1啤1 shot per year448靜態溫度測試不合格Static Temperature test fail壽命影響Reliability reject4鍍層附者力不夠Adhesion of the plating layer is not enough 油層附著力不夠The thickness

52、 of painting layer is toothing3改善電鍍參數Improve the plating condition改善噴油參數Improve the painting condition每年測1啤1 shot per year448濕度測試不合格Humidity test fail壽命影響Reliability reject4j鍍層附著力不夠Adhesion of the plating layer is not enough 油層附著力不夠The thickness of painting layer is toothing3改善電鍍參數Improve the platin

53、g condition改善噴油參數Improve the painting condition每年測1啤1 shot per year448鹽水噴霧不合格Salt spray fail壽命影響Reliability reject4鍍層厚度不夠The thickness of plating layer is toothing油層厚度不夠The thickness of painting layer is toothing3改善電鍍參數Improve the plating condition改善噴油參數Improve the painting condition每年測1啤1 shot per

54、year4482200包裝Pack ing混裝和漏裝Mixed hand packaging退貨Return supplier3過程操作不適當Improper process handling2Packaging instructions 包裝指示書操作者100%檢查(目測)100% inspection by operator at machine(Visual inspection )424Quantity not correct產品數量不正確Customer dissatisfaction客戶不滿7Untrained operators未有培訓操作員Not followed the pa

55、ckaging instructions未有按包裝指示書操作1Training to operators培訓操作員Packaging instructions包裝指示書MIfor material handling物料處理操作指引Training records培訓記錄100% inspection by operators100%操作人員全檢535Part damage 產品損傷Apperance reject外觀退貨Customer dissatisfaction客戶不滿7Untrained operators未有培訓操作員Not used the standard packaging 未有使用標準包裝Not followed the packaging instructions未有按包裝指示書操作1Training to operators培訓操作員Packaging instructions包裝指示書MI for material handl

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。