储罐预制方案zy

储罐预制方案zy

《储罐预制方案zy》由会员分享,可在线阅读,更多相关《储罐预制方案zy(14页珍藏版)》请在装配图网上搜索。

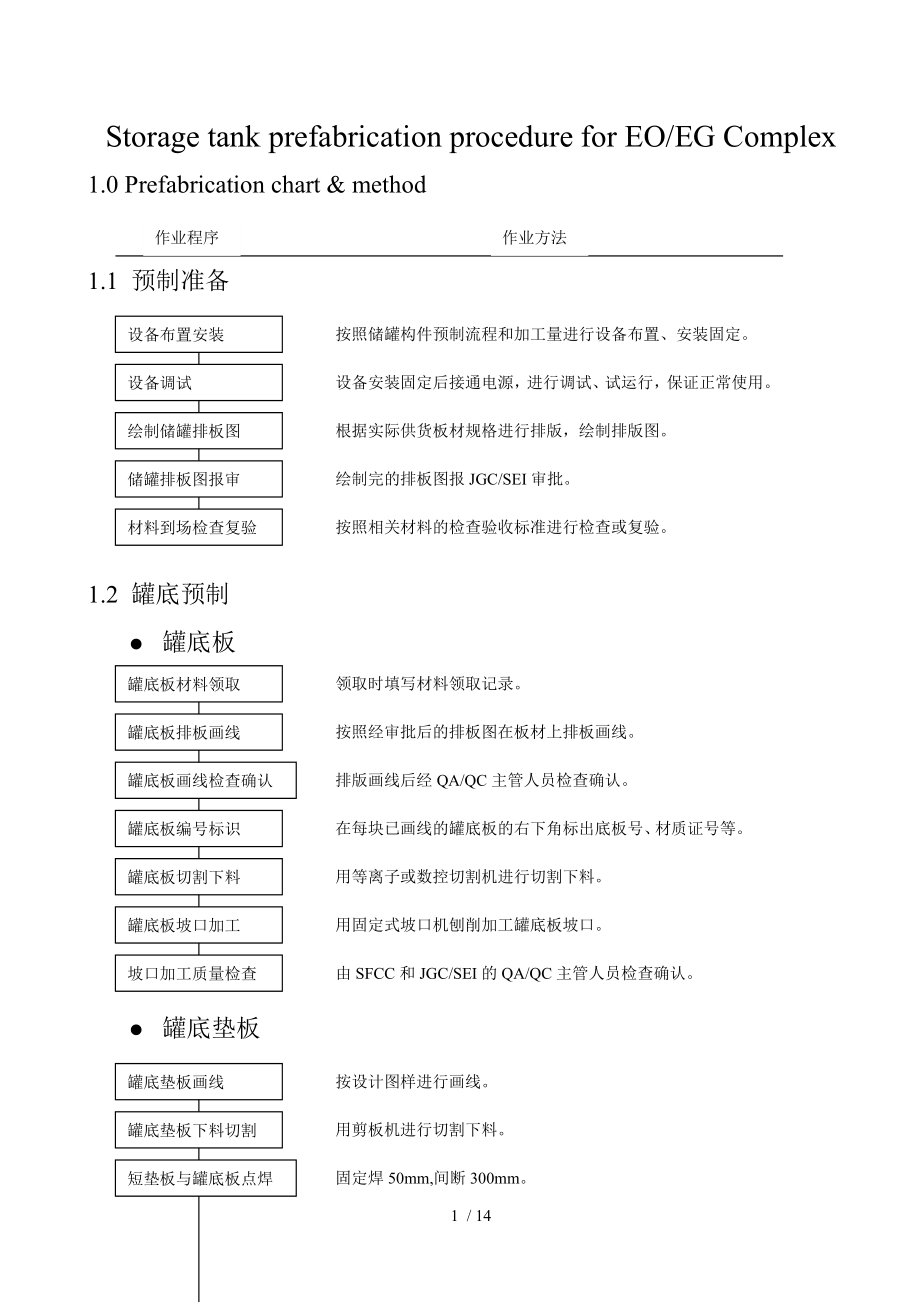

1、Storage tank prefabrication procedure for EO/EG Complex1.0 Prefabrication chart & method作业方法作业程序 1.1 预制准备按照储罐构件预制流程和加工量进行设备布置、安装固定。绘制完的排板图报JGC/SEI审批。设备布置安装设备安装固定后接通电源,进行调试、试运行,保证正常使用。设备调试根据实际供货板材规格进行排版,绘制排版图。绘制储罐排板图储罐排板图报审按照相关材料的检查验收标准进行检查或复验。材料到场检查复验1.2 罐底预制l 罐底板罐底板材料领取按照经审批后的排板图在板材上排板画线。罐底板排板画线排版画

2、线后经QA/QC主管人员检查确认。罐底板画线检查确认在每块已画线的罐底板的右下角标出底板号、材质证号等。罐底板编号标识用等离子或数控切割机进行切割下料。罐底板切割下料用固定式坡口机刨削加工罐底板坡口。罐底板坡口加工坡口加工质量检查领取时填写材料领取记录。由SFCC和JGC/SEI的QA/QC主管人员检查确认。l 罐底垫板罐底垫板画线用剪板机进行切割下料。罐底垫板下料切割固定焊50mm,间断300mm。短垫板与罐底板点焊按设计图样进行画线。用等离子切割机进行切割下料。罐底DEG入口接管画线、切割下料用手工氩弧焊打底、手工电弧焊盖面。罐底DEG入口接管组对、焊接用X光机进行射线探伤,II级合格。由

3、SFCC和JGC/SEI的QA/QC主管人员检查确认。罐底板用等离子切割机开孔,用手工电弧焊焊接。由SFCC和JGC/SEI的QA/QC主管人员检查确认。罐底DEG入口接管与罐底板组焊质量检查罐底DEG入口接管射线探伤罐底DEG入口接管检查确认罐底DEG入口接管与罐底板组焊(CS罐底板下面防腐)CS需要罐底板防腐。SS罐底板不需要防腐。防腐材料为沥青漆。由SFCC和JGC/SEI的QA/QC主管人员检查确认。(CS防腐质量检查)l 地脚螺栓支架在预制平台上根据设计图样按1:1的比例放样并制作样板。地脚螺栓盖板放样用样板在钢板上画出罐底盖板的轮廓线。地脚螺栓盖板画线罐底盖板放样用剪板机切割下料。

4、地脚螺栓盖板切割下料用钻床将罐底盖板钻孔。地脚螺栓盖板钻孔由SFCC的QA/QC主管人员检查确认。地脚螺栓盖板尺寸检查地脚螺栓筋板放样用样板在钢板上画出罐底盖板的轮廓线。在预制平台上根据设计图样按1:1的比例放样并制作样板。用样板在钢板上画出罐底地脚螺栓筋板的轮廓线。地脚螺栓筋板画线用剪板机切割下料。地脚螺栓筋板切割下料由SFCC的QA/QC主管人员检查确认。地脚螺栓筋板尺寸检查罐底筋板放样罐底筋板画线罐底筋板切割下料罐底筋板切割下料地脚螺栓垫板画线在钢板上画出地脚螺栓垫板的轮廓线。用样板在钢板上画出罐底盖板的轮廓线。用剪板机切割下料。地脚螺栓垫板切割下料用钻床将地脚螺栓垫板钻孔。地脚螺栓垫板

5、钻孔由SFCC的QA/QC主管人员检查确认。地脚螺栓垫板尺寸检查在预制平台上根据设计图样按1:1的比例放样并制作样板。地脚螺栓支架垫板制作样板罐底筋板画线用样板在钢板上画出罐壁地脚螺栓支架垫板的轮廓线。地脚螺栓支架垫板画线罐底筋板切割下料用剪板机切割下料。由SFCC的QA/QC主管人员检查确认。预制场设备布置罐底筋板切割下料地脚螺栓支架垫板切割下料地脚螺栓支架垫板尺寸检查按照图样尺寸分段画出罐基础防雨罩的轮廓线。罐基础防雨罩画线用等离子或数控切割机进行切割下料。罐基础防雨罩切割下料l 包装运输罐底预制件运往现场罐底预制件包装用10T卡车将预制件运往EO-EG现场。按照罐底预制件编号顺序分组包装

6、。 1.2 罐顶预制l 罐顶板 制作罐顶板支撑胎架领取时填写材料领取记录。罐顶板材料领取在每块已画线的罐顶板的右下角标出板号、材质证号等。排版画线后经QA/QC主管人员检查确认。按照经审批后的排板图在板材上排版画线。罐顶板画线检查确认罐顶板排板画线用等离子或数控切割机进行切割下料。用手持砂轮机打磨切割面。由SFCC和JGC/SEI的QA/QC主管人员检查确认。用滚板机将罐顶板滚弧成型。由SFCC和JGC/SEI的QA/QC主管人员检查确认。滚弧成型形状尺寸检查 罐顶板滚弧成型 下料形状尺寸检查 罐顶板切割面打磨罐顶板下料切割罐顶板编号标识用钢管、型钢和钢板制作罐顶板支撑胎架。l 罐顶垫板按图样

7、尺寸画线,用等离子或数控切割机进行切割下料。用滚板机将罐顶垫板滚弧成型。罐顶垫板滚弧成型罐顶垫板下料切割用行车或汽车吊(8t)将罐顶板放在支撑胎具上。在支撑胎具上将罐顶垫板与罐顶板焊接在一起。将罐顶板放在支撑胎具上罐顶垫板与罐顶板焊接l 罐顶工字钢罐顶工字钢画线用火焰割具进行切割下料。用型钢煨弯机将罐顶工字钢煨成圆弧型(外委加工)。用手持砂轮机修磨罐顶工字钢端口。罐顶工字钢修磨端口由SFCC和JGC/SEI的QA/QC主管人员检查确认。罐顶工字钢形状检查罐顶工字钢切割下料罐顶工字钢滚弧成型按照图样展开弧长画罐顶工字钢切割线。按照图样展开弧长画锥顶切割线。用等离子或数控切割机切割下料。用压力机或

8、千斤顶将下料的钢板压制成型。罐顶的锥顶号料画线罐顶的锥顶切割下料罐顶的锥顶制作l 罐顶环板用刨边机加工环板坡口。按照图样展开直径画罐顶环板圆周切割线。用火焰割具和数控机床进行切割下料。用压力机床将罐顶环板压制成型(外委加工)。由SFCC和JGC/SEI的QA/QC主管人员检查确认。罐顶环板成型检查罐顶环板加工坡口罐顶环板冲压成型罐顶环板切割下料罐顶环板号料画线l 罐顶筒体用数控机床进行切割下料。按照图样展开周长画罐顶筒体切割线。用刨床加工筒体板对接处的坡口。用滚板机将筒体板滚圆成型。罐顶筒体板滚圆成型罐顶筒体加工坡口罐顶筒体切割下料罐顶筒体号料画线罐顶筒体成型焊接用手工电弧焊焊接滚制成型的罐顶

9、筒体纵缝。l 罐顶筋板按照图样展开弧长画罐筋板切割线,用火焰割具切割。用滚板机将筋板滚弧成型。罐顶筋板滚弧成型罐顶筋板号线下料l 包装运输按照罐顶预制件编号顺序分组包装。罐顶预制件运往现场罐顶预制件包装用10T卡车将罐顶预制件运往EO-EG现场。1.3 罐壁预制l 罐壁板顶圈壁板对口处削薄(如果需要)用刨边机将顶圈壁板对口处削薄。用刨边机加工罐壁板坡口。由SFCC和JGC/SEI的QA/QC主管人员检查确认。用等离子或数控切割机进行切割下料。在每块已画线的罐壁板的右下角标出板号、材质证号等。排板画线后经SFCC的QA/QC主管人员检查确认。按照经审批后的排板图在板材上排板画线。领取时填写材料领

10、取记录。用钢管、型钢和钢板制作罐壁板支撑胎架。罐壁板材料领取罐壁板编号标识罐壁板画线检查确认罐壁板排板画线罐壁板下料切割制作罐壁板支撑胎架罐壁板坡口加工坡口加工质量检查用滚板机将罐壁板滚压成设计图样规定的圆弧形。罐壁板滚弧成型由SFCC和JGC/SEI的QA/QC主管人员检查确认。罐壁板滚弧成型质量检查l 罐壁筋板用铁皮制作罐壁筋板样板。在预制平台上根据设计图样按1:1的比例放样。罐壁筋板放样制作罐壁筋板样板用样板在钢板上画出罐壁筋板的轮廓线。用剪板机切割下料。由SFCC的QA/QC主管人员检查确认。罐壁筋板样板检查确认罐壁筋板画线罐壁筋板切割下料罐壁筋板形状尺寸检查由SFCC的QA/QC主管

11、人员检查确认。l 罐壁加强板按照图样分段画出加强板轮廓线。用等离子或数控切割机切割下料。用手持砂轮机在切割处打磨。罐壁加强板下料切割罐壁加强板切割处打磨罐壁加强板画线用刨边机加工坡口。加工加强板对接处坡口l 罐壁连接板用样板在钢板上画出罐壁连接板的轮廓线。用等离子或数控切割机切割下料。用刨边机或手持砂轮机加工坡口。用滚板机将罐壁连接板分段滚弧成型。由SFCC和JGC/SEI的QA/QC主管人员检查确认。罐壁连接板放样罐壁连接板画线罐壁连接板分段切割下料罐壁连接板对接处坡口加工罐壁连接板分段滚弧成型罐壁连接板成型尺寸检查在预制平台上根据设计图样按1:1的比例放样并制作样板。l 罐壁挡板按照图样画

12、出罐壁挡板轮廓线。用剪板机切割下料。由SFCC的QA/QC主管人员检查确认。罐壁挡板画线罐壁挡板切割下料罐壁挡板尺寸检查l 包装运输用10T卡车将罐壁预制件运往EO-EG现场。按照罐壁预制件编号顺序分组包装。罐壁预制件运往现场罐壁预制件包装1.4 其它附件预制l 罐体管口领取时填写材料领取记录。领取罐体接管、法兰按照图样尺寸画出罐体接管切割线。用等离子或数控切割机切割下料。罐体接管画线罐体接管切割下料罐体接管切割下料罐体接管画线用氩弧焊打底,手工电弧焊盖面。法兰与接管焊接罐体接管切割下料由SFCC和JGC/SEI的QA/QC主管人员检查确认。罐体接管尺寸检查罐体接管尺寸检查l 罐体补强圈罐体补

13、强圈加工信号孔罐体补强圈尺寸检查罐体补强圈尺寸检查罐体补强圈画线罐体补强圈画线罐体补强圈切割下料罐体补强圈切割下料罐体补强圈加工信号孔由SFCC的QA/QC主管人员检查确认。按照图样画出罐体补强圈轮廓线。用等离子或数控切割机切割下料。用钻床加工罐体补强圈信号孔。l 雷达液位计 Radar liquidometerAccording to draft dimension draw the incision line length.Joint pipe lineationCut and lay off with digitally controlled/ plasma cutting machin

14、e Long hole machining with milling machine(machining out)。Joint pipe long hole machiningAccording to draft dimension draw the incision line length.Joint pipe block board lineationCut and lay off with digitally controlled/ plasma cutting machine According to draft dimension draw the incision line len

15、gth.Cut and lay off with digitally controlled/ plasma cutting machine According design drawing on fabrication plant。Orientation bushing wimble part set sampleJoint pipe cut and lay off雷达液位计接管长圆孔加工雷达液位计接管堵板画线雷达液位计接管切割下料Weld with SMAW。Block board and joint pipe weld雷达液位计定位接管画线Orientation bushing linea

16、tion雷达液位计定位接管切割下料Orientation bushing cut and lay off雷达液位计定位接管锥段放样雷达液位计接管堵板切割下料Block board cut and lay off雷达液位计接管堵板与接管焊接According to draft dimension to draw outlineOrientation bushing wimble part lineationCut and lay off with digitally controlled/ plasma cutting machine Orientation bushing wimble par

17、t cut and lay offwimble part and bushing weldQA/Qc of SFCC governor inspectionOrientation bushing size inspectionAccording to draft dimension to draw outlineTank bottom orientation underlay lineationCut and lay off with digitally controlled/ plasma cutting machine Tank bottom orientation underlay cu

18、t and lay offAccording to draft dimension draw the incision line length.Orientation bushing lug tendon lineationCut and lay off with plasma cutting machine Orientation bushing lug tendon cut and lay offAccording to draft dimension draw the incision line length.Cut and lay off with plasma cutting mac

19、hine Orientation bushing Flat steel cut and lay offWeld with SMAW。Orientation bushing flat steel lineationl Nozzle joint pipeAccording to draft dimension draw the incision line length.Central pipe lineationCut and lay off with digitally controlled/ plasma cutting machine Central pipe cut and lay off

20、Drilling hole with drill press。QA/Qc of SFCC and JGC/SEI governor inspectionCentral pipe size inspectionAccording to draft dimension draw the incision line length.Cut and lay off with digitally controlled/ plasma cutting machine Nozzle cut and lay offQA/Qc of SFCC and JGC/SEI governor inspectionNozz

21、le size inspectionWeld with MMAW。Nozzle and central pipe weldFill in material draw note at draw。tee joint and flange drawAccording to draft dimension draw the incision line length.Short pipe lineationCentral pipe drill holeNozzle lineation Cut and lay off with digitally controlled/ plasma cutting ma

22、chine Short pipe cut and lay offCentral pipe、tee joint、short pipe and inner flange weldWeld with MMAWQA/Qc of SFCC and JGC/SEI governor inspectionaspect、geometry size inspection l Nozzle enter material pipeAccording to draft dimension draw the incision line length.Nozzle pipe lineationCut and lay of

23、f with plasma cutting machineNozzle pipe cut and lay offQA/Qc of SFCC governor inspectionNozzle pipe geometry size inspectionFill in material draw note at draw。Flange drawWeld with MMAWNozzle pipe and flange weldaspect、geometry size inspectionQA/Qc of SFCC and JGC/SEI governor inspectionl Nozzle bra

24、cketAccording to draft dimension draw the incision line length.Nozzle bracket angle steel lineationCut and lay off with plasma cutting machineNozzle bracket angle steel cut and lay offAccording to draft dimension draw the incision line length.Nozzle bracket lug tendon lineationCut and lay off with p

25、lasma cutting machine Nozzle bracket lug tendon cut and lay off According to draft dimension to draw underlay plate outlineNozzle bracket underlay lineationCut and lay off with digitally controlled/ plasma cutting machine Nozzle bracket underlay cut and lay offNozzle bracket underlay drillDrill U-ty

26、pe bolt hole with drill press。Welding with MMAW Nozzle bracket underlay and angle iron、lug tendon weldQA/Qc of SFCC and JGC/SEI governor inspectionaspect、geometry size inspectionl Packaging and Transportation按照其它预制件编号顺序分组包装。Other componetss package用10T卡车将其它预制件运往EO-EG现场。Other prefabrication parts are

27、 transported to field1.5 Tank roof plant and handrail l Prepare prefabricationFill in record when draw the material.Draw materialsMaterial sandblast and paintAll CS material need sandblast,then paint two times.l PlantPlant edge angle iron lineationAccording to draft dimension draw the incision line

28、at plant angle iron length.Use blaze incise tool laying off materialFlat edge angle iron incise and laying off materialUse plate roller shape the plat edge angle ironFlat edge angle iron roll and shapedQA/Qc of SFCC governor inspection and affirmFlat edge angle iron roll and shaped inspection平台边缘角钢成

29、型检查On flat roof former on 1:1pro rata according to designFlat plank and make formerFabricate flat plank and make formerUse sheet iron to make flat plank and formerUse former to draw subsection outline Flat plank and draw subsectionUse numerical control incise machine to lay off Flat plank subsection

30、 incise and lay off materialQA/Qc of SFCC governor inspection and affirmFlat plank dimension inspection l SupporterAccording to draft dimension to draw underlay plate outlineUnderlay plate drawUse cutting machine to incise and lay offUnderlay plates incise and lay offQA/Qc of SFCC governor inspectio

31、n and affirmUnderlay dimension inspectionDraw rib plates figure according to draft。Rib plates drawUse cutting machine to incise and lay offRib plates incise and lay offRib plates size inspectionQA/Qc of SFCC governor inspection and affirmSupport angle iron drawAccording to draft dimension draw the i

32、ncision line at support angle iron length.Use blaze cuttin tool laying off materialSupport angle iron cut and lay offQA/Qc of SFCC governor inspection.Support angle iron size inspectionWith MMAWWelding of Support angle iron, underlay plate and rib plateQA/Qc of SFCC governor inspection.aspect、geomet

33、ry size inspectionl Baluster According to draft dimension draw the incision line at stand pole length.Stand pole drawUse blaze cuttin tool laying off materialStand pole cut and lay offQA/Qc of SFCC governor inspection.Stand pole size inspectionhandrail、block waist and feet board rollUse plate roller

34、 shape the plat edge angle ironhandrail、block waist and feet board roll inspectionQA/Qc of SFCC governor inspection.l package & transportationTank tip roof、baluster fabrication components packageWith 10t lorryTank tip roof、baluster fabrication components carried out fieldremark:1 The 50t crane is us

35、ed for arrive material unload、be out of luck and load/unload of heavy packaging box.2 All CS material must be dealed with face sand blasted before use.3 Handrail of baluster only roll in fabrication field, length do not ensured, According fact requirement to cut when field installation. 4 Block wais

36、t and feet board of baluster adopt flat steel, rolled in fabrication field only, length do not ensured, According fact requirement to cut when field installation. 5 Upwards procedure is currency procedure of EO-EG tank farm storage tank fabrication, different storage tank fabrication procedure accor

37、ding to each structure characteristic.2.0 Plane lay of fabrication fieldPlane lay of fabrication field see following “plane lay drawing of fabrication field”. 3.0 Machine and equipment resource planplasma cutting machine 1 set; digitally controlled cutting machine 1 set; Oxygen-ethine cutting tool 2

38、 sets ; Oxygen bottle 4 sets; Ethine bottle 4 sets; Edge planer 1 set; Manual grinding machine 4sets; rolling machine 1set; drill press 1 set; argon welding machine 1 set; Handcraft arc welding machine 4 sets; Traveling crane 2 sets; 10T lorry 1 set; 25T crane 1 set; 50T crane 1 set。4.0 Manpower planManager 6 people;Reveter 15 people;Electric welding worker 6 people;Gas welding worker 2 people;Electrician 1 people;Lifting worker 2 people;Decorator 4 people;Force worker 8 people。5.0 Storage tank fabrication schedule14 / 14

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

最新文档

- 北大纵横-湖北东方化学工业-管理咨询项目建议书课件

- SPSS的认识和基本运用课件

- 房地产企业集团化管控

- Section-B-1最新版新目标七年级pptUnit-7全国青年教师素养大赛一等奖课件

- 戴德梁行深圳市中山公园项目服务建议书

- 房地产项目入伙管理与工程质量投诉集中处理方法要点

- 北大纵横——某房地产公司人力资源-课件

- spss统计(卡方检验和t检验)课件

- 户内燃气设施隐患及事故性质判断课件

- 北大纵横××集团人力资源战略教学课件

- 地产设计部流程进度管理教学课件

- 房地产置业顾问拓客技巧及执行

- 等比数列的概念与通项公式2ppt课件

- 北大纵横-鞍钢新轧-企业文化诊断报告课件

- 递推递归的复杂性分析课件