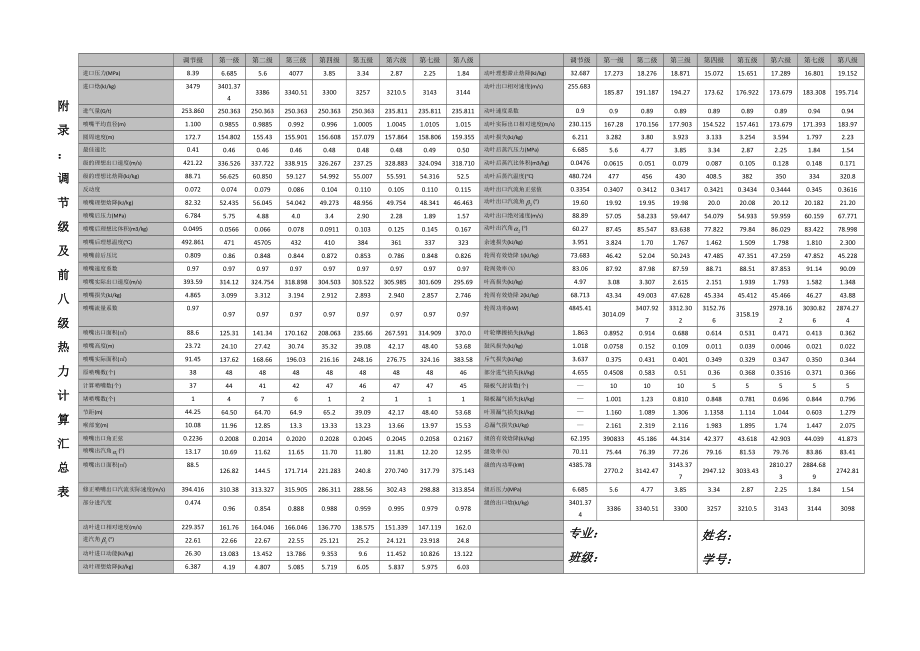

前调节级及八级热力计算汇总表

前调节级及八级热力计算汇总表

《前调节级及八级热力计算汇总表》由会员分享,可在线阅读,更多相关《前调节级及八级热力计算汇总表(1页珍藏版)》请在装配图网上搜索。

1、调节级第一级第二级第三级第四级第五级第六级第七级第八级调节级第一级第二级第三级第四级第五级第六级第七级第八级进口压力(MPa)8.396.6855.640773.853.342.872.251.84动叶理想滞止焓降(kJ/kg)32.68717.27318.27618.87115.07215.65117.28916.80119.152进口焓(kJ/kg)34793401.37433863340.51330032573210.531433144动叶出口相对速度(m/s)255.683185.87191.187194.27173.62176.922173.679183.308195.714进气量(

2、G/t)253.860250.363250.363250.363250.363250.363235.811235.811235.811动叶速度系数0.90.90.890.890.890.890.890.940.94喷嘴平均直径(m)1.1000.98550.98850.9920.9961.00051.00451.01051.015动叶实际出口相对速度(m/s)230.115167.28170.156177.903154.522157.461173.679171.393183.97圆周速度(m)172.7154.802155.43155.901156.608157.079157.864158.8

3、06159.355动叶损失(kJ/kg)6.2113.2823.803.9233.1333.2543.5941.7972.23最佳速比0.410.460.460.460.480.480.480.490.50动叶后蒸汽压力(MPa)6.6855.64.773.853.342.872.251.841.54级的理想出口速度(m/s)421.22336.526337.722338.915326.267237.25328.883324.094318.710动叶后蒸汽比体积(m3/kg)0.04760.06150.0510.0790.0870.1050.1280.1480.171级的理想比焓降(kJ/kg

4、)88.7156.62560.85059.12754.99255.00755.59154.31652.5动叶后蒸汽温度()480.724477456430408.5382350334320.8反动度0.0720.0740.0790.0860.1040.1100.1050.1100.115动叶出口汽流角正弦值0.33540.34070.34120.34170.34210.34340.34440.3450.3616喷嘴理想焓降(kJ/kg)82.3252.43556.04554.04249.27348.95649.75448.34146.463动叶出口汽流角()19.6019.9219.9519.

5、9820.020.0820.1220.18221.20喷嘴后压力(MPa)6.7845.754.884.03.42.902.281.891.57动叶出口绝对速度(m/s)88.8957.0558.23359.44754.07954.93359.95960.15967.771喷嘴后理想比体积(m3/kg)0.04950.05660.0660.0780.09110.1030.1250.1450.167动叶出汽角()60.2787.4585.54783.63877.82279.8486.02983.42278.998喷嘴后理想温度()492.86147145705432410384361337323

6、余速损失(kJ/kg)3.9513.8241.701.7671.4621.5091.7981.8102.300喷嘴前后压比0.8090.860.8480.8440.8720.8530.7860.8480.826轮周有效焓降1(kJ/kg)73.68346.4252.0450.24347.48547.35147.25947.85245.228喷嘴速度系数0.970.970.970.970.970.970.970.970.97轮周效率(%)83.0687.9287.9887.5988.7188.5187.85391.1490.09喷嘴实际出口速度(m/s)393.59314.12324.75431

7、8.898304.503303.522305.985301.609295.69叶高损失(kJ/kg)4.973.083.3072.6152.1511.9391.7931.5821.348喷嘴损失(kJ/kg)4.8653.0993.3123.1942.9122.8932.9402.8572.746轮周有效焓降2(kJ/kg)68.71343.3449.00347.62845.33445.41245.46646.2743.88喷嘴流量系数0.970.970.970.970.970.970.970.970.97轮周功率(kW)4845.413014.093407.9273312.3023152.7

8、663158.192978.1623030.8262874.274喷嘴出口面积()88.6125.31141.34170.162208.063235.66267.591314.909370.0叶轮摩擦损失(kJ/kg)1.8630.89520.9140.6880.6140.5310.4710.4130.362喷嘴高度(m)23.7224.1027.4230.7435.3239.0842.1748.4053.68鼓风损失(kJ/kg)1.0180.07580.1520.1090.0110.0390.00460.0210.022喷嘴实际面积()91.45137.62168.66196.03216.

9、16248.16276.75324.16383.58斥气损失(kJ/kg)3.6370.3750.4310.4010.3490.3290.3470.3500.344原喷嘴数(个)384848484848484846部分进气损失(kJ/kg)4.6550.45080.5830.510.360.3680.35160.3710.366计算喷嘴数(个)374441424746474745隔板气封齿数(个)10101055555堵喷嘴数(个)147612111隔板漏气损失(kJ/kg)1.0011.230.8100.8480.7810.6960.8440.796节距(m)44.2564.5064.706

10、4.965.239.0942.1748.4053.68叶顶漏气损失(kJ/kg)1.1601.0891.3061.13581.1141.0440.6031.279喉部宽(m)10.0811.9612.8513.313.3313.2313.6613.9715.53总漏气损失(kJ/kg)2.1612.3192.1161.9831.8951.741.4472.075喷嘴出口角正弦0.22360.20080.20140.20200.20280.20450.20450.20580.2167级的有效焓降(kJ/kg)62.19539083345.18644.31442.37743.61842.90344

11、.03941.873喷嘴出汽角()13.1710.6911.6211.6511.7011.8011.8112.2012.95级效率(%)70.1175.4476.3977.2679.1681.5379.7683.8683.41喷嘴出口面积()88.5126.82144.5171.714221.283240.8270.740317.79375.143级的内功率(kW)4385.782770.23142.473143.3772947.123033.432810.2732884.6892742.81修正喷嘴出口汽流实际速度(m/s)394.416310.38313.327315.905286.311

12、288.56302.43298.88313.854级后压力(MPa)6.6855.64.773.853.342.872.251.841.54部分进汽度0.4740.960.8540.8880.9880.9590.9950.9790.978级的出口焓(kJ/kg)3401.37433863340.51330032573210.5314331443098动叶进口相对速度(m/s)229.357161.76164.046166.046136.770138.575151.339147.119162.0专业:班级: 姓名:学号:进汽角()22.6122.6622.6722.5525.12125.224.12123.91824.8动叶进口动能(kJ/kg)26.3013.08313.45213.7869.3539.611.45210.82613.122动叶理想焓降(kJ/kg)6.3874.194.8075.0855.7196.055.8375.9756.03 附录:调节级及前八级热力计算汇总表

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

最新文档

- 小学四年级下册综合实践活动纸杯娃娃的制作课件

- 建筑赏析5喀什教学课件

- 建筑赏析——教堂教学课件

- 小学四年级下册综合实践活动生活中的小窍门课件

- 建筑赏析:当代建筑的特点与实例课件

- 小学四年级下册综合实践活动玩石头课件

- 小学四年级下册综合实践活动好习惯伴我成长课件

- 小学四年级下册综合实践活动水是生命之源课件

- 小学四年级下册综合实践活动节约用水课件

- 小学四年级下册综合实践活动果蔬大变身课件

- 小学四年级下册综合实践活动月饼课件

- 建筑资料员培训基础部分-建筑识图详解课件

- 小学四年级下册综合实践活动最强大脑课件

- 小学四年级下册综合实践活动早餐的学问课件

- 小学四年级上册美术ppt课件第4课家乡的古塔报本塔浙美版