B4 Appendix 5 Rig Acceptance Checklist-Drilling Rig Services

B4 Appendix 5 Rig Acceptance Checklist-Drilling Rig Services

《B4 Appendix 5 Rig Acceptance Checklist-Drilling Rig Services》由会员分享,可在线阅读,更多相关《B4 Appendix 5 Rig Acceptance Checklist-Drilling Rig Services(6页珍藏版)》请在装配图网上搜索。

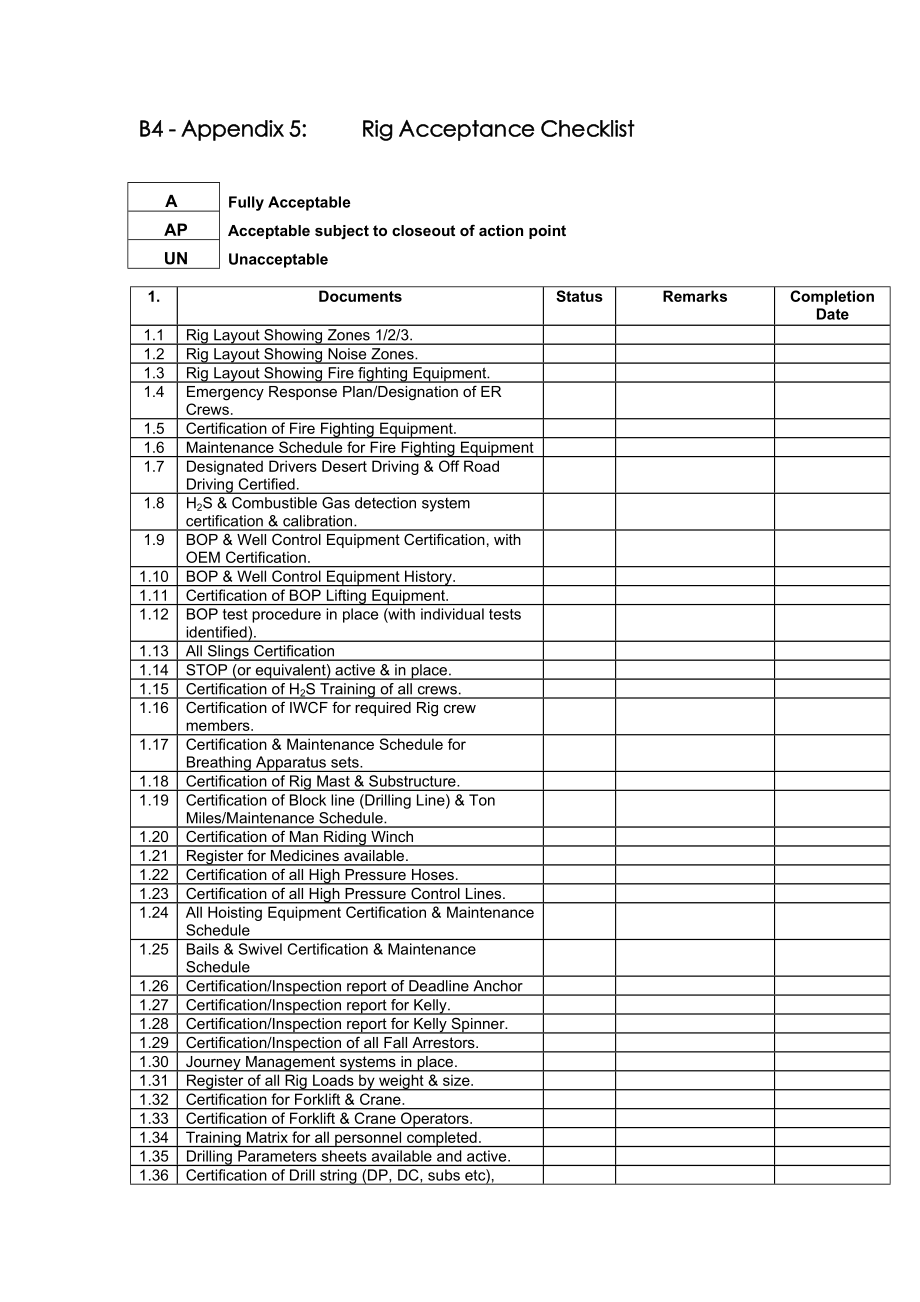

1、B4 - Appendix 5:Rig Acceptance Checklist AFully AcceptableAPAcceptable subject to closeout of action pointUNUnacceptable1.DocumentsStatusRemarksCompletion Date1.1Rig Layout Showing Zones 1/2/3.1.2Rig Layout Showing Noise Zones.1.3Rig Layout Showing Fire fighting Equipment.1.4Emergency Response Plan/

2、Designation of ER Crews.1.5Certification of Fire Fighting Equipment.1.6Maintenance Schedule for Fire Fighting Equipment1.7Designated Drivers Desert Driving & Off Road Driving Certified.1.8H2S & Combustible Gas detection system certification & calibration.1.9BOP & Well Control Equipment Certification

3、, with OEM Certification.1.10BOP & Well Control Equipment History.1.11Certification of BOP Lifting Equipment.1.12BOP test procedure in place (with individual tests identified).1.13All Slings Certification1.14STOP (or equivalent) active & in place.1.15Certification of H2S Training of all crews.1.16Ce

4、rtification of IWCF for required Rig crew members.1.17Certification & Maintenance Schedule for Breathing Apparatus sets.1.18Certification of Rig Mast & Substructure.1.19Certification of Block line (Drilling Line) & Ton Miles/Maintenance Schedule.1.20Certification of Man Riding Winch1.21Register for

5、Medicines available.1.22Certification of all High Pressure Hoses.1.23Certification of all High Pressure Control Lines.1.24All Hoisting Equipment Certification & Maintenance Schedule1.25Bails & Swivel Certification & Maintenance Schedule1.26Certification/Inspection report of Deadline Anchor1.27Certif

6、ication/Inspection report for Kelly.1.28Certification/Inspection report for Kelly Spinner.1.29Certification/Inspection of all Fall Arrestors.1.30Journey Management systems in place.1.31Register of all Rig Loads by weight & size.1.32Certification for Forklift & Crane.1.33Certification of Forklift & C

7、rane Operators.1.34Training Matrix for all personnel completed.1.35Drilling Parameters sheets available and active.1.36Certification of Drill string (DP, DC, subs etc), including hard banding certification.1.37Trip Sheets available & active1.38Welders Certified.1.39Schedule for all drills (Kick, H2S

8、, Strip, Fire Rig & Camp). 2.Rig Safety SystemStatusRemarksCompletion Date2.1Fire Fighting equipment in place.2.2Independent Fire Pump in place & tested.2.3Emergency Shut Down System installed & tested.2.4Operation of ESD clearly displayed.2.5Emergency Lighting installed & Tested.2.6Well Site/Rig co

9、mponents earthed.2.7Adequate & correct positioning of Safety signs.2.8Rig communications system functioning.2.9Well Site Alarms functioning.2.10Wind sock fitted & visible.3Personnel SafetyStatusRemarksCompletion Date.3.1All Crews have completed H2S Training.3.2Adequate Eye Wash Stations installed, F

10、ull & Functioning.3.3Adequate Shower Stations installed, Functioning.3.4Temperature Control for Eye wash & Shower Stations Functioning.3.5Personnel Protective Equipment for crew available in sufficient quantity.3.6Personnel Protective Equipment for crew of accepted standard, and fit for purpose.3.7B

11、A Sets charged, in good condition, and well stored.3.8Correct quantity of BA Sets available at critical locations & easily accessible.3.9Areas designated as high noise risk clearly marked, with protective equipment available.3.10Chemical Data Sheets available with correct PPE clearly stated.4Locatio

12、nsStatusRemarksCompletion Date.4.1Rig Floor4.1.1Floor/Set Back area in good condition4.1.2Samson Post inspected & Certified.4.1.3Railings Secured, straight & in place.4.1.4Barrier on V door.4.1.5Mud box available and in good condition.4.1.6Safe Working Loads visible on all Winches/Air Hoists.4.1.7Sa

13、fety hooks installed on all winches/air hoists.4.1.8Dedicated Man Riding Winch available.4.1.9Fail Safe on man riding winch.4.1.10Man Riding Winch clearly identified as “Man Rider”4.1.11All Winch Lines clear of derrick.4.1.12All Winch Lines in good conditions.4.1.13All Winch Lines fitted with guards

14、.4.1.14Mouse/Rat & rotary covers in place.4.1.15Drillers console instrumentation fully & correctly functioning.4.1.16All Gauges & Geolograph functioning & reading in correct units.4.1.17Block Weight Indicator (MD) correctly set-up for number of lines strung.4.1.18View from brake clear of obstruction

15、s.4.2Derrick/Mast4.2.1Raising System to derrick/mast top section fitted with fail safe.4.2.2Derrick level & Centred correctly4.2.3If required “Guy Lines” installed.4.2.4Derrick Lighting working and adequate4.2.5Crown Light Functioning4.2.6Jumper bars on crown sheaves.4.2.7All Lights secured with saf

16、ety lines.4.2.8Ladders & Safety Cage (if used) in good condition.4.2.9Monkey Board in good condition & tested4.2.10Stabbing Board in good condition & tested4.2.11Emergency Braking in good condition & tested4.2.12Mechanical locking device in good condition & tested4.2.13Safety harness available (atta

17、ched to derrick)4.2.14Sufficient number of safety belts available, and in good condition.4.2.15Air winch sheaves in good condition & safety lines installed.4.2.16Derrick man escape line installed & tested.4.2.17Tong counter weights secure and in good condition.4.2.18All Circulating Hoses snubbed4.2.

18、19Check list in place for raising/lowering derrick/mast.4.2.20Derrick sub base hydraulic jacks functioning & in good condition.4.3Mud Systems4.3.1Grating in good condition.4.3.2Ladders/steps in good condition.4.3.3Railing secured, straight and in place.4.3.4All moving equipment guarded.4.3.5Shakers

19、screens installed/available.4.3.6Fluid circulated around complete system, check for leaks.4.3.7Vacuum Degasser tested.4.3.8Poor Boy Degasser tested & Dimensions checked (inclusive of flare line).4.3.9Mixing equipment functioning.4.3.10High Volume annular fill up line installed & tested.4.3.11Mud dum

20、p line routed to waste pit.4.4Well Site4.4.1Location level & free of obstructions.4.4.2Parking area clearly marked.4.4.3Access to vehicles prevented within the location.4.4.4Waste collection system in place and segregated.4.4.5Muster points (minimum of 2) marked.4.4.6Smoke detectors in offices/accom

21、modations, and functioning.4.4.7Relevant safety signs in place.4.5Hot Work Area4.5.1Area Clearly Marked4.5.2Gas Bottles stored separately4.5.3Gas Bottles stored correctly in rack.4.5.4System in place to transport bottles in racks.4.5.5Flash Back Arrestors fitted to cutting torch.4.6Camp4.6.1Location

22、 level & free of obstructions.4.6.2Parking area clearly marked.4.6.3Access to Vehicles restricted within location.4.6.4Waste collection system in place and segregated.4.6.5Muster points (minimum of 2) marked.4.6.6Camp inspection completed.4.6.7Smoke detectors in offices/accommodations, and functioni

23、ng.4.6.8Medical Facility in place.4.6.9Medical Audit completed.5EquipmentStatusRemarksCompletion Date.5.1BOP5.1.1Koomey Capacity checked.5.1.2Koomey draw down test completed.5.1.3Full BOP Function/Pressure tested performed. As per contractors submitted testing procedure.5.1.4Handling/Lifting system

24、for BOPs functioning/ certified.5.1.5Choke manifold line up clearly marked.5.1.6Choke manifold checked for threaded connections.5.1.7Control panels labelled & all lights functioning.5.1.8A guard over blind/shear rams controls.5.1.9Relief valve installed on Koomey Unit.5.1.10Low level reservoir alarm

25、 installed on Koomey Unit.5.1.11Low pressure alarm installed on Koomey Unit.5.1.12Control hoses in good condition.5.1.13Control hoses tested to rated pressure.5.1.14Ram to Drill Floor dimension clearly displayed.5.1.15Shut in method displayed & explained.5.1.16Choke manifold flushed.5.1.17All Choke

26、manifold gauges in correct units & correct scale.5.1.18Gauges cross checked for accuracy5.1.19All Valves on Choke Manifold functioning5.1.20Flare line installed & staked.5.1.21Stripping tank correctly installed & functioning.5.2High Pressure Mud System & Cement Line.5.2.1Piston Chambers covered.5.2.

27、2Lifting equipment available for changing liners.5.2.3Discharge lines snubbed and staked.5.2.4Bleed off lines snubbed.5.2.5Setting of Pop Off Valves correct & tested.5.2.6Access to relief valves clear.5.2.7Relief lines drain down.5.2.8Pulsation dampeners at correct pressure, and charged with Nitroge

28、n.5.2.9All thread connection identified & secured.5.2.10Pressure Gauges functioning & correct units/range.5.2.11System Pressure tested to rated working pressures.5.2.12Chicksan package correct rating. Last Inspection report available.5.2.13Pump isolation switches clearly identified. 5.2.14Pump relie

29、f valves upstream of strainers.5.2.15Cement line and Manifold pressure tested.5.2.16Cement line chicsans last inspection report.5.2.17Cement line snubbed5.2.18Cement unit certification, including type of relief valve & last test record.5.3Tongs/Slips & Elevators5.3.1All tongs certified & inspected.5

30、.3.2Break out wire in good condition.5.3.3Make up wire in good condition.5.3.4Back up lines in good condition.5.3.5Inspection certificates available and current.5.3.6Tong hanging lines good condition.5.3.7Counter weights move freely.5.3.8Load cell working & calibrated.5.3.9Elevators in good conditio

31、n.5.3.10Latch spring ok.5.3.11Slips in good condition.5.3.12Dies secured in place.5.3.13Dog collar in good condition.5.3.14Inspection certificates available.5.4Draw works & Travelling Block.5.4.1Last inspection of brakes & links inspected & certified.5.4.2Elmagco Brake tested.5.4.3Brake cooling syst

32、em checked.5.4.4Air cooling system checked.5.4.5Air cooling starts automatically and intakes clear.5.4.6Crown-o-matic working & tested.5.4.7Minimum number of warps on drum.5.4.8Emergency stop installed.5.4.9All clutches and controls working.5.4.10All catheads clutch and controls working.5.4.11Check

33、block latch functions ok.5.4.12Inspection report for Block/Bails/ Swivel.5.5Drilling Line5.5.1Fast line free of derrick.5.5.2Deadline free of derrick.5.5.3Deadline clamp installed correctly.5.5.4Deadline anchor last inspected.5.5.5Deadline sensor working5.5.6Fast line spooler checked and installed.5

34、.5.7Fast line anchor inspected.5.5.8Deadline stabiliser installed.5.6Engines/Generators5.6.1Easy access to emergency switches.5.6.2Electrical cables run neatly & protected.5.6.3Provision for waste oil protected.5.6.4Lubricants stored correctly.5.6.5Drip trays in place5.6.6Fuel tanks locked off.5.7Ro

35、tary Systems5.7.1Check rotary table rotation (forward & reverse)5.7.2Rotary Locks (in both directions) functioning.5.7.3Gear Engagement functioning.5.7.4Air intake for Air cooling system from non-hazardous zone.5.7.5Air cooling system functioning automatically.5.7.6Kelly drive bushing checked visual

36、ly.5.7.7Master bushings checked visually.5.7.8Kelly Spinner function tested.6Miscellaneous/ OtherStatusRemarksCompletion Date.6.1Electrical Audit6.2Lifting equipment stored correctly.6.3Crane & Forklift inspection certificates available.6.4Safe working load of Crane properly marked.6.5Fall arrestors

37、 fitted to substructure.6.6Man Riding belts stored correctly in good condition.6.7Preventive Maintenance in place.6.8All pressure vessels inspected & certified.6.9Pre-spud meeting held.6.10Rig site drills performed Prior to Spud:Fire:H2S:Strip:Kick:6.11Camp Site Fire Drill performed.6.12Access control at Well Site, including:Guard:Muster Board:Spare Helmets/Safety Glass:6.13Emergency Radio available.

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。