风险管理程序

风险管理程序

《风险管理程序》由会员分享,可在线阅读,更多相关《风险管理程序(10页珍藏版)》请在装配图网上搜索。

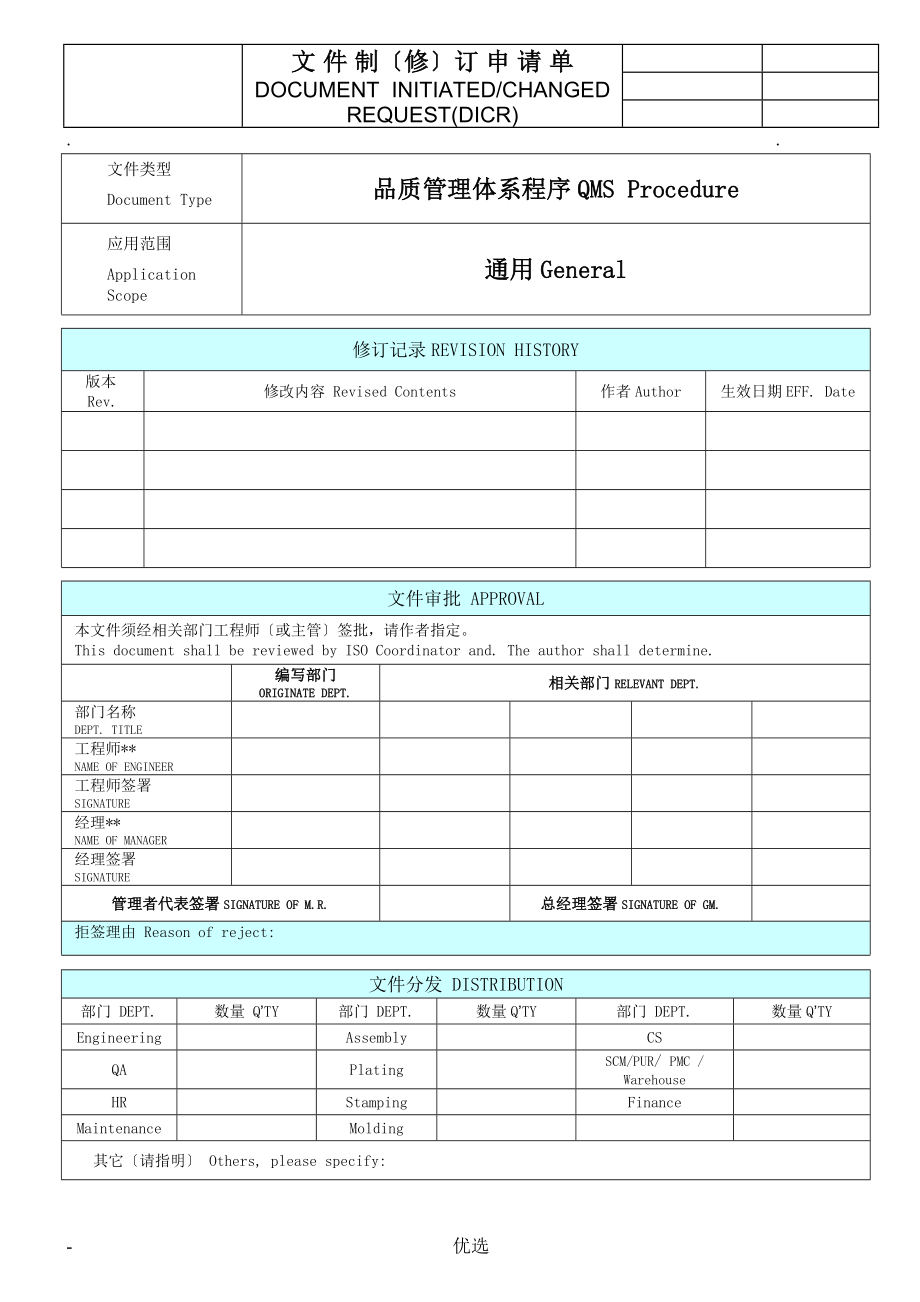

1、文 件 制修订 申 请 单DOCUMENT INITIATED/CHANGED REQUEST(DICR). .文件类型Document Type品质管理体系程序QMS Procedure应用范围Application Scope通用General修订记录REVISION HISTORY版本Rev.修改内容 Revised Contents作者Author生效日期EFF. Date文件审批 APPROVAL本文件须经相关部门工程师或主管签批,请作者指定。This document shall be reviewed by ISO Coordinator and. The author shal

2、l determine.编写部门ORIGINATE DEPT.相关部门RELEVANT DEPT.部门名称DEPT. TITLE工程师*NAME OF ENGINEER工程师签署SIGNATURE经理*NAME OF MANAGER经理签署SIGNATURE管理者代表签署SIGNATURE OF M.R.总经理签署SIGNATURE OF GM.拒签理由 Reason of reject:文件分发 DISTRIBUTION部门 DEPT.数量 QTY部门 DEPT.数量QTY部门 DEPT.数量QTYEngineeringAssemblyCSQAPlatingSCM/PUR/ PMC /War

3、ehouseHRStampingFinanceMaintenanceMolding其它请指明 Others, please specify:- 优选风险管理程序Risk management Procedure. .1 目的 Purpose: 通过医疗产品的风险管理,能够识别与医疗产品及其附件有关的危害,估计和评价风险,控制这些风险,对病人或使用者的风险降低到可承受水准.By risk management of medical devices, to identify the harm related tomedical devices and their accessories,estim

4、ate, evaluate risks and control the risks, to lower to acceptable level on patients and users risk.2 范围 Scope:适用于医疗产品寿命的所有阶段。To be applied for all stages of medical devices life. 3 定义 Definition: 3.1 损害harm对人体*的实际伤害或侵害,或是对财产或环境的侵害。Actual harm or invasion on human health or invasion on property or en

5、vironment.3.2 危害hazard)损害的潜在源 Potential source of harm 3.3 剩余风险residual risk采取预防措施后余下的风险。Residual risk after preventative actions3.4 风险risk损害的发生概率与损害严重程度的结合。The bination of probability and severity of harm3.5 风险管理risk management方针、程序及其实践的系统运用 System application of policy, procedure and its practice3

6、.6 医疗产品medical devices其制造商预期为以下目的用于人类的单独或者组合的仪器、设备、器具、材料或者其它物品,包括应用所需要的软体;其用于人体体表及体内的作用不是用药理学、免疫学或者代谢的手段但是可能有这些手段参与起一定的辅助作用;这些目的是:The manufacturers expected for the following purpose to apply for human devices, equipments, instruments, materials or other items either alone or in bination , including

7、 software needs, Which apply to the human body surface and the body was not the means of pharmacology, immunology or metabolism, but auxiliary function with the means, the purpose is :对疾病的预防、诊断、治疗、监护、缓解;- Prevent, diagnose, treatment, custody, relieve on disease 对损害或者残疾的诊断、治疗、监护、缓解、补偿;-Diagnose, tre

8、atment, custody, relieve, pensation on harm or disabled 对解剖或者生理过程的研究、替代、调节;- Study, replace, adjust on dissect or the physiological process3.7 多功能小组Cross functional team 适当时,多功能小组可包括管代、营业、工程、机加工、后加工、工模、品管、物料、加工商和客户方面的代表组成,具体成员视产品的情况而定。When appropriate, cross functional team caninclude management rep

9、resentative, sals, engineering, machining, after processing, tooling, QA, PMC, Supplier and the representatives from customers. The concrete members are based on the circumstance of product4 权责和权限 Responsibilities and Authority4.1多功能小组:cross functional team A) 负责风险分析;Responsible for risk analysis B)

10、 负责制定风险控制措施;Responsible for defining risk control actionsC) 生产后联络评审统筹;Liaison ,review after production 4.2工程部:Engineering负责工程文件的受控、归档和风险管理报告的撰写及文件归档。Responsible for the control, file of engineering documents, writing and file of risk management reports4.3管代:Management representative 负责多功能小组人员的风险管理知识

11、培训及畴划多功能小组的组织。Responsible for the trainingof risk management knowledge on cross functional team and organization establishment of cross functional team 5 程序及流程图 Procedure and flow chart 5.1风险管理方案 Risk management plan 5.1.1风险管理方案与报告不要求在同一时间内制定,可以在同一时间内撰写. Risk management plan is not required to estab

12、lish at the same time with risk management report, which can be written at the same time. 5.2 风险分析 Risk analysis 5.2.1产品预期用途以及与平安有关的特征的判定,可考虑以下特征:The intended use of products and determinant of characteristics related to safety, may consider the following characteristics:1. 预期用途是什么和如何使用 What is the

13、intended use and how to use 2. 医疗器械是否预期用于植入?If intended use of medical devices is for embedding 3.是否与预期要与患者或其它人接触?If intended use of medical devices is to contact with patients or other person 4. 在医疗器械中用到何种材料或部件或何种材料或部件与医疗器械共同使用,或与产品接触?What kind of materials or parts are applied into the medical dev

14、ices What kind of materials or parts are used together with the medical devices or contact with products 5. 是否有能量施加于患者和/或由患者身上获取? If there is energy applied to patients and /or attained from patients 6. 是否有物质进入患者体内和/或由患者身上抽取? If there is substance entering patients body and /or extracted from patien

15、ts 7. 是否有生物材料被处理后重新使用 If is there biological material reusing after treatment 8. 是否已消毒?或由用户消毒? If sterilized already Or to be sterilized by user 9. 是否预期由用户进展常规清洁和消毒 If the expected routine cleaning and sterilizing done by user 10. 是否改变患者周围的环境?如:温度/湿度/压力/大气/光线等 If change the surrounding environment o

16、f patients For example temperature/humidity/Pressure/air/lights etc. 11. 是否进展测量? If measurement conducted 12. 医疗器械是否进展处理分析? If processing analysis conducted on medical devices 13. 是否用以控制其它或药物与其相互作用? If controlled others or the reaction between medicinesand others 14. 有没有不希望产生的能量或物质输出? Is there non-e

17、xpected energy or substances outputted 15. 是否对环境变化比拟敏感? If sensitive on environment change 16. 是否影响环境? If impact on environment 17. 是否有根本消耗品或附件? Is there essential consumables or attachment 18. 是否需要维护和/或校准 If maintenance or calibration needed 19. 是否含有软件 If software involved 20. 是否有储存寿命限制 Is there sh

18、elf life restriction 21. 是否有延迟和或长期使用效应? Is there effect of delaying and (or) long-term using 22. 机械力?Mechanical force 23. 是什么决定的寿命What is life determined 24. 是否预期一次性使用? If expected disposable 25. 是否需要平安的退出运行或处置?If out of the operation or disposal safely needed 26. 安装或使用是否要求专门的培训? Special training ne

19、eded for installment or application 27. 平安使用信息如何提供? How to provide safe application message 28. 是否需要引入或建立新的生产过程?If productionprocess needed to introduced or built 29. 成功使用,是否决定性的取决于人为因素?If human factors are critical for the successful use 29.1用户接口的设计特征是否可能导致错误的使用? If wrong use is caused by design ch

20、aracteristics of user interface 29.2在产品使用中是否会因为分心而导致错误的使用? If wrong use is caused by distraction during application 29.3医疗器械是否有连接部件或附件?Do medical devices have connected ponents or accessories 29.4产品是否有控制接口? Do products have control interface 29.5产品是否显示信息? Do products display information 29.6产品是否有菜单控

21、制? Do products have menu control 29.7产品是否用于有特殊需要的人? Are products applied to special needs 29.8用户接口是否可能使用户开场行动? May Users interface make uses to start action 30. 产品是否使用警报系统? Do products use alarm system 31. 在何种情况下产品可能被有意误用? What kind of situation can products are wrongly used 32. 产品是否对患者护理非常重要的数据?Are

22、 products key data on nursing care of patients 33. 是否预期为移动式或便携式? If expected as mobile or portable 34. 产品的使用取决于其根本性能 Is products application depended on the fundamental performance5.2.2对可能产生危害的判定Determinant on possible harms 5.2.2.1 能量危害 Energy harms 电能、热能、机械力、电离辐射、非电离辐射、运动部件、非预期的运动、悬挂的质量、患者支持器械失效、声

23、压、振动、气压、磁场。 Electric energy, thermal energy, Mechanical force, Ionizing radiation, Non ionizing radiation, Moving partsUnintended movement, flying quality, the patient support apparatus failure, Sound pressure, vibration, air Pressure, the magnetic field5.2.2.2 生物学危害Biological harm生物污染、生物不兼容性、不正确的配方

24、化学成分、毒性、变态性反响、突变性、致畸性、致癌性、再感染和或穿插感染、热源、不能保持卫生平安性、降解。Biological pollution, Biological patibility, incorrect formula, poisonousness, Allergic reaction, mutation, Teratogenicity, Carcinogenicity, Reinfection and (or) cross infection, thermal source, Cant keep health Safety, Degradation.5.2.2.3 环境危害Envi

25、ronment harm电磁场、对电磁干扰的敏感性、电磁干扰的发射、不适当的能量供给、不适当的冷却剂供给、储存或行偏离预定的环境条件、和其它预期使用的医疗器械的不兼容性、意外的机械破坏、由于废物和或医疗器械处置的污染。Electromagnetic field, sensitive on electromagnetic interference, improper energy supply, improper coolant Supply, storage or deviate from expected environment condition, No patibility with e

26、xpected medical Devices, accidental mechanical damage, pollution from the disposition of waste materials and (or) medicalDevices.5.2.2.4 与医疗器械使用相关的危害 Harm related to the application of medical devices不适当的标识、不适当的操作说明、由不熟练未经培训的人员使用、合理可预见的误用、对副作用警告不充分、对一次性使用医疗器械很可能再次使用的危害警告不适当、对不正确的测量和其它计量方面的问题、与消耗品/附件

27、/其它医疗器械的不兼容性、锐边或锐角。Improper identification, improper operation instruction, use by unfamiliar or without training person, Reasonably foreseeable misuse, insufficient warning on side effect, improper warning to possible Once again Use harm for the use of disposable medical devices, No patibility, Sha

28、rp edge or an acute angle on Improper measurement and other measurement issues with Consumables / Accessories / other medical Devices.5.2.2.5 由于功能失效、维护和老化引起的危害Harm caused by function failure, maintenance and ageing错误的数据转换、维护标准缺少或不适当、对医疗器械寿命中止缺少适当的决定、电气/机械整合的缺失、不适当的包装、再次使用和/或不适当的再次使用、由重复使用造成的功能恶化。The

29、 wrong data conversion, lacking or improper of maintenance norm , lacking of proper decision on shelf life of medical devices, lacking of electrical / mechanical integration, improper packing , reuse and (or) improper reuse, function worsening caused by repeated use.5.3风险评价 Risk evaluation5.3.1产品平安性

30、特征的风险计算:Risk calculation of product safety features风险=严重等级*概率等级.Risk=Severe grades * Probability level5.3.2严重等级Severe grades严重程度Severe degree可能性的描述Describe the probability等级 Grade严重的Critical无预警的功能失效,直接影响检测数据错误判断,间接影响人员*或生命; No warning of the failure, directly impact on detection of data errors of ju

31、dgment, indirectly impact on health or life 4主要的Major有预警的功能失效,直接影响检测数据错误判断,间接影响人员*或生命;With warning of the failure, directly impact on detection of data errors of judgment, indirectly impact on health or life3轻微的Minor可消除或轻微的创伤Can eliminate or minor trauma2可忽略的Ignore不会造成创伤 No trauma15.3.3概率等级Probabili

32、ty grade发生程度Occurrence degree可能性的概率Probability等级 Grade经常: 几乎不可防止Often: Almost inevitable发生概率大于 1/100Occurrence probability more than 1/1004偶尔: 偶尔发生Occasionally: Occasionally occurs发生概率大于1/1000 Occurrence probability more than 1/10003很少: 相对较少发生Seldom: The relatively rare occurrence发生概率大于1/10000 Occur

33、rence probability more than 1/100002极少: 不太可能出现Little : Unlikely occurrence发生概率大于1/1000000 Occurrence probability more than 1/100000015.3.4风险可承受准那么 Risk acceptable rule风险严重等级概率等级Risk=Severe grades * Probability level风险大小The size of the risk可承受性缩写代号Acceptability (Code)14广泛可承受ACC56合理可行ALARP716不容许NACC5.

34、4风险控制 Risk control5.4.1降低风险 Reduce risk 对危害严重性和概率发生进展评价,如果判定为合理可行与不容许时,需要进一步采取措施降低风险,并重新对危害严重性和概率发生进展评价是否可承受。如果判定剩余风险仍是合理可行的,应评审其有关预期用途、预期目的的医疗受益是否超过剩余风险,如果其证据不支持医疗受益超过剩余风险的结论,那么剩余风险是不可承受的,那么不可以进展量产,直至采取措施降低剩余风险方可承受进展量产;如果受益超过剩余风险,可以判定为现实尽可能低的合理承受水准,那么可承受进展量产。Evaluate the harm severity and the proba

35、bility of the occurrence, if determinantas ALARP and NACC, need take further actions to reduce risk, and re-evaluate if the harm severity and the probability of the occurrence is acceptable. If the determinant of residual risk is still as ALARP, shall review the expected application, Does medical be

36、nefit of the expected purpose overtake residual risk If evidence does not support the conclusion of medical benefit overtaking residual risk, residual risk is not acceptable,which can not go to mass production till actions are taken to reduce residual risk. If benefit overtook residual risk, can det

37、ermine as realistic low ALARP, can go to mass production.如果判定剩余风险是不容许的,那么不可以量产,必须按上述方法采取措施降低剩余风险后评审是否可承受量产。If residual risk is determined as NACC, which can not go to mass production, shall refer to above method to take actions to reduce residual risk, then review if mass production can be accepted.

38、5.4.2降低风险采取措施产生的其它危害 Other harm caused by the actions taken to reduce risk 应对采取降低风险采取的措施进展评审是否导致新的危害产生。如果引入了新的危害,那么应按5.4.1评定相关的风险。 Review if the actions taken to reduce risk result in harm occurrence, if incurred new harm, which shall refer to 5.4.1 to assess the corresponding risk.6 制造过程风险分析与控制Risk

39、 analysis and control of Manufacturing process 6.1 依据D0B0014_F FMEA及FMECA程序,PE按制定的工艺流程表判定有关过程的特性。Refer to DOB0014_F FMEA and FMECA procedure, PE determine the process characteristics based on process flow 6.2 多功能小组进展 PFMEA 活动。Cross functional team conduct PFMEA activities6.3制造过程的风险评价:完成 PFMEA 风险分析后,

40、进展风险评价,计算相关的风险顺序值,决定其估计的一个或多个风险是否需要降低。 Risk evaluation of Manufacturing process: Conduct risk evaluation after plete the risk analysis, calculate the corresponding risk order value, determine the estimated one or more risk to be reduced.7 7风险管理报告 Risk management report 工程部将有关产品预期用途以及与平安有关的风险管理过程分析,评

41、价,控制/制造过程风险分析与控制的结果,包括对有关的剩余风险是否到达可承受水准的结论,撰写于风险管理报告中。NPD shall write risk management report based on the expected use of the product and risk management process analysis, evaluation, control /manufacture process risk analysis and control result including the conclusion of the concerned residual ris

42、k meeting acceptable level or not .8 生产和使用后的信息 The information of production and after use 8.1 各部门将收集到有关医疗产品或类似产品的信息,应传到达工程部。Each department shall collect information related to medical devices or similar products and relay to NPD . 8.2 工程部统筹相关部门对信息中可能与平安性有关的问题进展评价,特别是以下方面:NPD evaluate the security

43、related issues of information from the concerned departments, especially in the following aspects:8.2.1是否有事先未认知的危险出现; Is there non-cognitive risk occurrence ahead8.2.2是否有某项危害造成的原被承受或合理水准的一个或多个风险不再是可承受的; Does one or more acceptable risk caused by some harm bee no longer acceptable8.2.3初始评定是否失效。Does I

44、nitial assessment get failure8.3 如果出现上述的情况,工程部应联系多功能小组进展重新风险评价。 If above situations occurred, NPD shall contact cross functional team to conduct re-evaluation of risks 8.4生产后的联络评价结果应予以记录及归档。 Record and file the contact evaluation result after production. 9 相关文件References Document 9.1D0B0014_F FMEA及FMECA程序 9.2风险管理报告;Risk management report. .word.zl.

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 装配图网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。